Innovation – the key to all great, disruptive creations, strikes like a bolt of lightning. When it hits you, you must take advantage of it.

Many great products have come from seemingly thin air, and many have come from hours of toil and hard work trying to manufacture innovation from nothing. Either avenue will get you an idea, but turning it into a reality is much more difficult. You may wish to hire a CAD service to speed up the process.

Have you ever seen a product and kicked yourself because it was so simple and obvious of a creation? Or, worse still, have you seen a product on the marketplace and said to yourself, “I had that idea ten years ago?”

Having an idea and knowing that you could do something is one thing, but it’s an entirely different beast to actually make it happen.

How many people must have yelled in anguish when the Pet Rock was introduced? Or, more recently, who wouldn’t have loved to have ownership over the creation of Silly Bandz, the animal-shaped rubber bands?

There is one thing that separates the wheat from the chaff in all these instances – and that’s execution.

If you can take an idea and make it a reality, or you can see a problem and make a physical solution, then you have a leg up on almost everyone else, and you could see yourself become the next inventor of something frustratingly brilliant and simple.

Saying that execution is the only delineating factor between inception and creation is a bit misleading, though. There is a lot more involved with solving a problem and putting it out on the marketplace.

How do you know what to do to get your product idea out there, and how do you know it’s going to work?

10 Steps to Design, Manufacture, and Sell a Product or Prototype

1. Idea Generation

The first step to any creation is its initial inception. In many cases, you may already have completed this step. If you already have an idea in your head for a product, then you have completed the ideation step.

In other cases, however, this is a time-consuming process. For the casual inventor, typically, an idea is already ingrained into their mind – the difficult task is making it a reality. For a company or organization that is presented only with a challenge or problem, they first need to come up with the actual idea to solve the problem before they can make a product.

How do you come up with an idea? There are several avenues that you can pursue to begin product ideation and help jump-start your thought process.

Does it solve a real-world problem? Think of an issue that you have faced or are frustrated by, such as never being able to find an outlet at the airport. By starting with a problem, you know that if you can find a solution to it, you will already have customers because there

Simplify

Simplifying and refining products is a great need for today’s consumer. If you can create something that will make two products into one or will do the job of something else in half the time, then you will have created something with instant demand. For instance, the new TV remote that you can speak into when you want to search for a channel.

Redesign

Sometimes a new product idea is as simple as a new design on an old product. Apple has made billions of dollars reintroducing the iPhone with slightly adjusted features and a new look every couple of years.

You don’t need to disrupt an industry to put out a marketable product; in many cases, you just need something that performs the same function but is a bit more aesthetically pleasing.

Repurpose

In most cases, nothing new needs to be truly created, such as materials or technology. They simply need to be put to the proper use. Air mattresses for camping are used because they are lightweight and relatively comfortable, but you could design one with memory foam or some other cushion instead, and, without creating any new materials, would have designed an entirely new product.

2. Research

Coming up with the idea was the fun part. You can brainstorm, call meetings, and talk with coffee in your hand for hours on end, but eventually, you need traction. The first step after you have come up with an idea is research, and there are many different paths that need to be appropriately investigated.

First, you need to understand what you are trying to create. Are you going to be using new materials?

Let’s look at the camping mattress; for instance, you are going to create a mattress that doesn’t leak air and is just as lightweight and comfortable. First, you’ll need to investigate what materials fit your criteria.

Memory foam is too dense, but is there something else that may work? This is probably the most open-ended and time-consuming part of the process, and it’s crucial to investigate multiple possible solutions, in case one of them doesn’t work out.

Once you have researched the solutions to your problem, including materials, technology, etc., you’ll need to examine the marketplace. It is no use to you if you create an excellent product that solves a problem no one cares about. Regardless of how cool it is, I would never buy a device that ties dress shirts in knots because it doesn’t solve a problem I have.

Create some surveys, generate discussion about the product, and see if it appropriately solves peoples’ problems and if they’d be willing to buy it.

In the end, money is master, and if no one is willing to pay you for it, it isn’t worth creating, so you need to gather a voice of the customer first.

Finally, you need to do a competitive analysis. Find out if there is a similar product out on the market. This can be useful in several ways.

First, it can give you a starting point, as well as validation. If there is a similar product, you know it can be done, and it will provide you with some ideas as to how it is done. Unfortunately, since there is, you need to create something different.

Company X developed a camping mattress using a sturdy mesh filled with

By knowing the competitive products, you first ensure that you don’t violate any copyrights or intellectual property, and second, you give yourself the opportunity to create a better product than your competitor.

3. Planning

Planning is a necessary yet tedious task when creating a product. Once you’ve gained the momentum after creating an idea, and subsequently gotten customer feedback, figured out what potential solutions you are going to use, and how you can do it without stepping on anyone’s toes legally, you have to stop and take a step back.

Up until this point, everything has been hypothetical, and somewhat fanciful because you’re just dreaming and brainstorming. Now, you are putting ideas into action.

To properly plan, you need to know your product and its different versions, because there will likely be several different iterations.

What are the various features you are going to include?

- Will your mattress have a removable cover?

- How heavy will it be and how much space do you want it to take up?

- What is your time frame for getting it to the marketplace?

- How much money do you plan to make from it?

These are the questions you need to start answering in the planning phase. You won’t be sketching the design yet, and you don’t need to have hard and fast answers to everything, but you should have a financial structure and a timeline in place.

The other questions, such as space and features, will change depending on the product and purpose but are still essential to begin thinking about. You will get nowhere if you plan to create a camping mattress that is too big to carry around with you, or if you are designing a shoe that is made of non-durable or non-breathable materials.

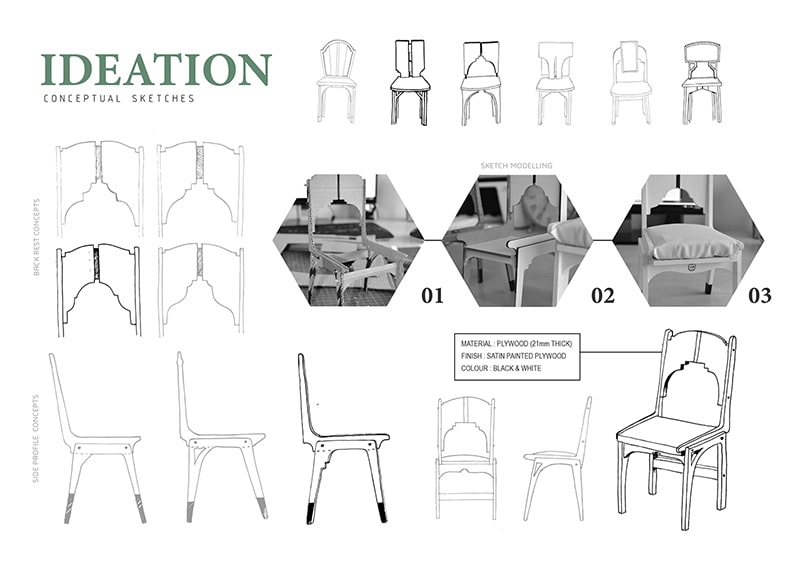

4. Draft a Design

The initial draft need not be on a CAD program or require any technological knowledge. In many cases, the first draft has been done in some shape or form in the ideation or planning phase.

Before you make an elaborate plan or hire someone to do AutoCAD drafting and design or SolidWorks design services, though, you’ll want to do a sketch yourself. This initial sketch will help you get a general idea for what the product will look like, what features you may want to add, and what overall dimensions you want in the design.

This initial drawing will likely be a brainstormed, thinktank version, where everyone involved in the process will give a bit of input. You can sit everyone together in a conference room and sketch something up on a whiteboard to get a general idea.

Whoever is in charge of marketing may tell you that the customers prefer it to be red, and they’ll need handles on the side, and an engineer may indicate that you shouldn’t make it more than 4 inches thick. The critical part of this process is to get the information onto a diagram so that it can be designed and refined from there.

This does not need to be perfect. In fact, it should include way too much information, including conflicting information. In many cases, people in the creative process will have different opinions over what would look better and what would work better.

Be sure to include all of this information, and you can design and prototype that out later to test what actually is the most realistic solution. Once you aggregate all of this information, you’ll have something to develop on, and it will create your different product iterations and designs.

Something to remember here is that more information is better on the initial sketch. Aesthetics are an important consideration – try to include details about colors, shapes, textures, etc. Anything that would be pertinent to the design should be thrown in here. You can take it out later, and you just need the information to start with.

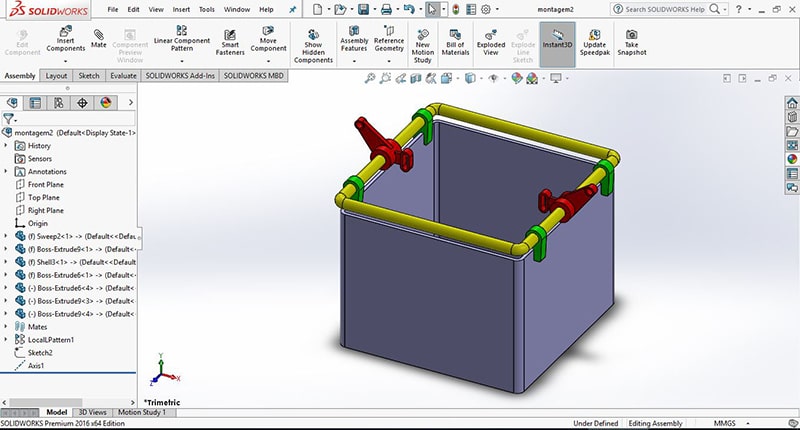

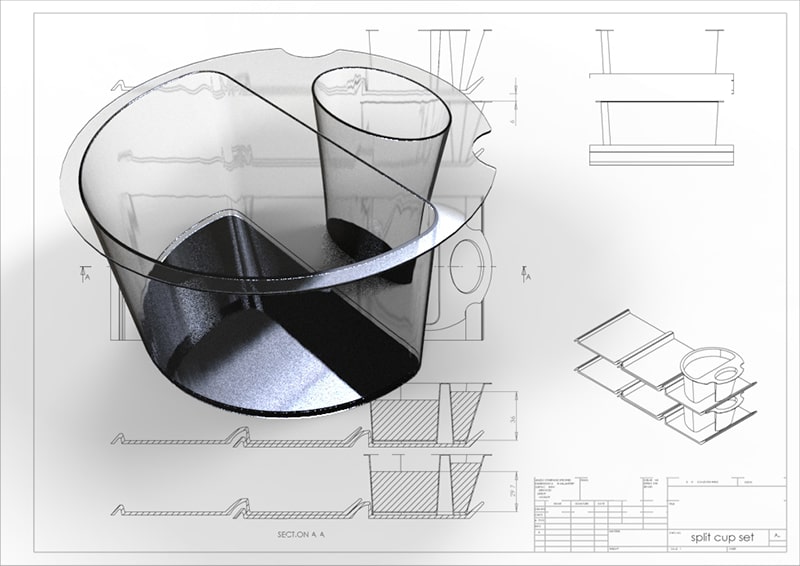

5. Create a Computer Mock Up

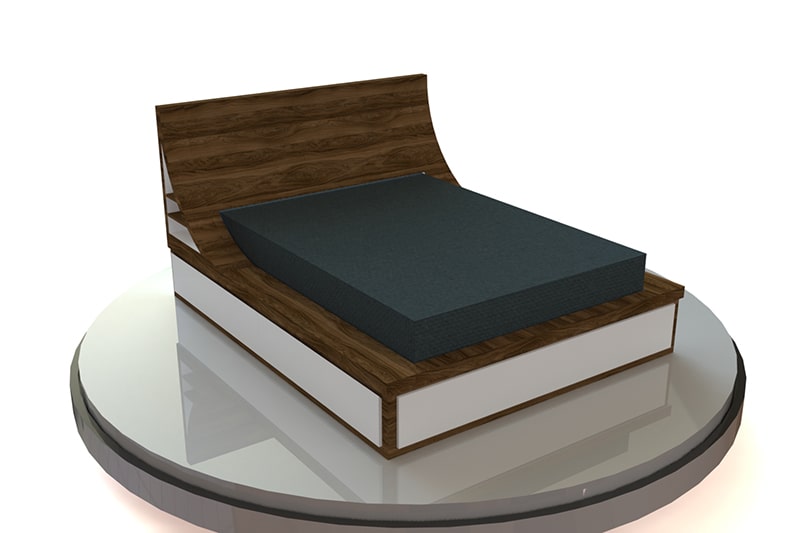

The first “official” design will be a huge milestone for you and your product. You can hire an industrial engineer or CAD designer to model up the first iteration of your product for you, and you’ll be able to truly visualize what it looks like.

Remember, this is an early design, not promotional marketing material or anything like that.

This is also where the rubber hits the road. When the first computer sketch is designed, you will start to weed out the unusable features and solutions, as well as rapidly examine different choices to see what is the best option. Remember to be flexible here and let the design lead you. If something seems unfeasible, let it go, or design around it.

You will take this model and begin basing everything else off of it, including iterations, cost structure, and manufacturers, so you want to include pertinent details.

Numbers are just as important to design as shapes and colors are. The suppliers and manufacturers will want to know the width of the mattress or diameter of a screw in the machine, for example, and they’ll need to know how thick the material needs to be and what it needs to perform.

A well-designed computer sketch can give an approximation of what load you want your mattress to hold or how tightly it can be rolled up, or how much weight your brand new pneumatic lift design can support, so it’s vital to spend time on this step.

Using a trusted and adequate product design service, you can have them draw up an accurate design that tells everyone exactly what is needed of them. You will need to work closely with them during this time because they will have to coordinate what your team has sketched up on the back of a napkin or a whiteboard somewhere and turn it into a scaled, accurate study that can move and pivot and be measured. Get this right, and the next steps will fall all the more readily in line.

6. Create a Prototype

The first prototype is a huge milestone when you are creating a product. In today’s modern age, we have the benefit of things like 3D printers, and companies dedicated to small-batch manufacturing and rapid prototyping. So, as soon as you have a design, you can get a prototype made up as quickly as possible.

Take a minute to enjoy the fact that you have a physical product in your hands to look at, measure, test, and tear apart – because you probably will tear it apart. Proof of concept means that your product is valid, and you will be able to market it as such.

This prototype means much more than just a fun product that you created by yourself, and it is going to be the basis for your testing and examination for the foreseeable future.

You will take this prototype and subject it to tests. There is going to be rigorous physical testing and proving out of your design to make sure that it stands the test, and it will probably fail many of them.

That’s why this is the first iteration because it is not complete. It’s exciting to have a prototype made, but prototypes don’t typically make it to the consumer, because they have to be broken down, reconstructed, and improved upon until they are viable for the market.

This model, your first iteration, will be subjected to numerous tests so that you can redesign it because your final product will probably be nothing like the prototype that you now have sitting in front of you.

This is one of the most difficult steps because it involves leaving some things behind. As you test and trial your product, you will learn where your initial assumptions were wrong, and where your ideas need to change.

Be willing to adapt in this stage, so that you can create what’s best for the consumer. Ultimately, they will be the ones paying for it, and you want them to like it as much as you do, if not more.

7. Redesign

Here we begin the endless cycle. Prototype, test, redesign, start over. You may go through steps 4 through 7 twenty times over three years to get a working finished product.

If you’re lucky, you’ll only have to start over once or twice and can get the product manufactured after that, but many times you’ll have to rework the product for a long time to make it work properly.

It’s essential to have a flexible and willing crew of engineers and designers to work with you through this because you will be relying on them for quite a bit.

Luckily, you have already done these steps once, so if you have done them correctly, you will only need to tweak the designs. What was one of the most important things for your model to include earlier?

Numbers.

These are going to be fluid components of your design. Either it was too long, too thin, didn’t support enough weight, or had too few screws. Something numeric will be changing after your testing because you have now generated quantitative feedback.

If your design is well made initially, and the dimensions and relationships are well defined, these tests will simply mean you have to plug in the new numbers, and it will automatically be adjusted to your accurate product. That’s why it’s necessary to do it right the first time so that it will be more comfortable in the long run.

Another important consideration is that redesigning, prototyping, and testing your product will cost time and money. Obviously, you want to do it as well as possible the first time, so you don’t need to spend that extra time and money to redesign it multiple times, but there is going to be a cutoff point you must consider.

At some point, you may be called upon to present the best available product, as opposed to the perfect product. This is especially true if you are working for a large company that cares about deadlines and only needs it to be better than a competitor’s idea.

You will need to calculate how much you may be spending with each iteration and find the sweet spot where you will maximize your return on investment and minimize the rework that is necessary.

8. Get Samples

Let’s skip ahead to the final stages because you could be stuck in the loop of

Assuming you have completed your testing, finished the iterations, and finally have a completed, tried and tested product, you need to start getting it manufactured.

Fortunately for you, you have a well-crafted, accurately dimensioned drawing that gives a manufacturer all the information they could ever ask for, thanks to your rigorous steps of drawing, designing, prototyping, and redrawing.

Before you get samples, you’ll want to look around and shop for different manufacturers that can make your product. Once you send them your design, they can give you price estimates and lead times. In some cases, there will be fixed, upfront costs that need to be considered, so budget in some extra funding if your design may need that.

For instance, machine-made parts and products will require fixturing, and fabric components will need to have their machines calibrated and gauged to accommodate what you are manufacturing correctly.

Choose several of the best options, either based on finances, lead time, or whatever criteria are vital to your process, and have them send you samples. It is crucial that you get samples made before committing to a manufacturer.

These will be your litmus test for who you should choose, and they will be subjected to the same rigorous tests that all of your designs underwent. Essentially, you need to make sure that this actual, finished manufactured product meets the same standards and checks out the same as your final product prototype did.

If it doesn’t, then it won’t work for your design. In most cases, however, all of the samples will be close to your original standards, and you’ll have to choose between them. Is the highest tension tolerance the most important thing for you?

Choose the sturdiest part. If you’re looking for the cheapest part that fits your tolerances, choose that one. It’s as simple as that.

9. Begin Manufacturing Your Product

You have finally made it. This step doesn’t take into account all the necessary evils of finding distribution for your product, developing sales channels, and all the fun business aspects of it, but we don’t really want to talk about that right now. You just made a product!

And hopefully, like Silly Bandz, once it’s on the shelves, it will fly off them and you’ll make millions of dollars.

Something to consider when you have finally chosen a manufacturer and begun producing your widget is that the marketplace is ever-changing. You may want to retain the designer who created the multiple drafts of your product, because, in 12 months, customers may ask for an even better product

In many cases, you’ll likely want to stay ahead of the curve and continue innovating on it, either to introduce better features or to engineer out costs. Whatever the case, however, the design phase never really ends.

The essential part of creating something is making money from something, right? You have sketches, designs, and samples of your product.

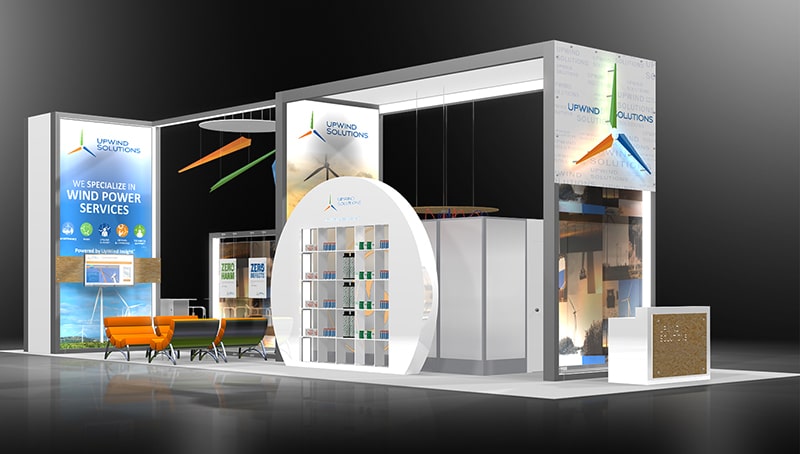

Put it out there everywhere a customer could see it, at trade shows or in grocery stores (depending on your product. I don’t necessarily want to buy a new, streamlined Diesel engine from my local Kroger grocery store).

You can use CAD design to create interactive displays where customers can test them out and model various scenarios to see how they fit their needs. You can show them how the product could be customized or tailored to them individually.

As much as CAD software is an engineering and design tool, it is a uniquely capable marketing tool as well. With an engineer on hand to adjust designs or create dynamic displays, you can demonstrate your product in ways that really wow a customer and make them want to be on board with your company.

You can use it as a tool to reach your audience and demonstrate that possibilities that your product can offer them, without even having to manufacture new pieces. As long as they can see the benefit of it, and hold a prototype that you’ve proven capable through testing, you can convince them to buy it or tailor it to them.

Not only is this an upbeat and ever-changing marketplace, but it’s also one where you can enter quickly if you have the right tools. Being able to capably and accurately design a product will improve your ability to invent, redesign, and manufacture something for sale.

Cad Crowd Will Connect You with CAD Design Professionals

There is a lot that goes into the creative process, especially for intricately engineering products, but using design tools, you can take an idea and begin selling and turning a profit as quickly as you want.

Working with a qualified and professional designer will help you to utilize these tools effectively and allow you to make your product idea into

Cad Crowd will connect you with qualified professionals and protect your intellectual property so that you can work with Industrial Engineers, CAD Designers, and Drafters to get your product to the marketplace as quickly as possible.

Next time you see a product on the market and think, I could have made that, make sure that you are the one who did make it.

See how it works or get a quote.

This blog is amazing and this information is very useful for Design and Manufacture a New Product thanks for sharing us…