The aviation, aerospace, and aircraft industries are soaring to greater heights, literally and figuratively. These fields have been seeing significant breakthroughs that have helped them grow bigger and better through the years. Today, 3D modeling services are the pillar of the success of companies in the aerospace sector.

3D modeling involves creating and developing three-dimensional representations of structures or objects. Many industries are currently using 3D modeling together with different software programs for large and small structures. Prototypes using 3D models allow businesses to plan manufacturing processes and test products. Continue reading below to learn how 3D modeling technology enhances aviation, aerospace, and aircraft design for companies.

Table of contents

Table of contents

- Construction of aircraft hangars

- Prototype creation and development

- Aircraft fuselage design

- Comprehensive reports

- Granular analysis

- Cost and price estimation

- Other benefits of 3D modeling technology

- How Cad Crowd Can Help

RELATED: How the aerospace industry is using CAD design services: drafting, modeling, and prototyping

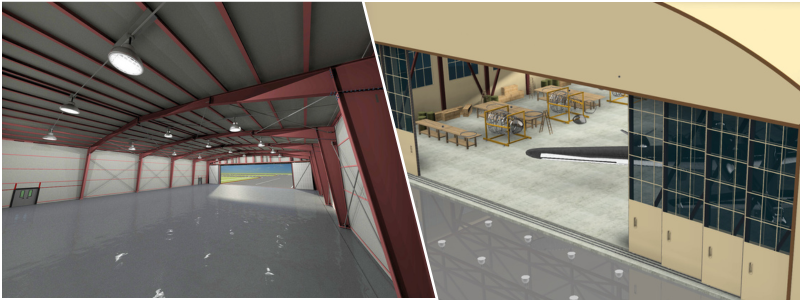

Construction of aircraft hangars

An aircraft hangar is a large metal building storing and maintaining airplanes. These structures often feature a few interior walls, open spaces, and a high ceiling. Hangars, however, are nothing like other facilities. Various intricate design processes are required to get aircraft hangars’ correct specifications and dimensions. Doing so will ensure they can perform their intended purpose and function correctly.

Leveraging 3D design services makes the construction of aircraft hangars more efficient. Engineers can better understand how to put a hangar together with the help of 3D models. They also see how the structure interacts and blends with its surrounding environment.

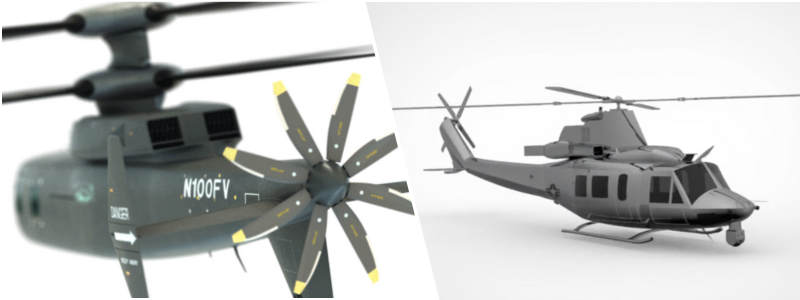

Prototype creation and development

Aerospace designers offer 3D modeling crucial for creating airplane components and prototypes. These models allow engineers to test if a module works well. They can also identify early on if there are potential flaws and errors in the design. Additionally, the use of 3D models makes it easier to envision the appearance of each fit and how well it fits with the other parts of the aircraft. Engineers can test different materials and designs without creating an actual prototype, thanks to 3D models.

For example, if engineers want to test the function of a new airplane seat, they have to develop a 3D model of that seat. Using this model, they can test various scenarios, including how well the seat will react during an emergency landing. Through these tests, engineers can ensure that the final seat design will be comfortable and highly safe for the passengers. They can also assess how aircraft makers arrange plane seats and how many of these seats will fit into a plane without the need to develop a full-scale prototype.

RELATED: Why do many businesses, firms, and engineers outsource 3D CAD modeling services

Aircraft fuselage design

An aircraft fuselage is the main body of an airplane, holding all the parts and elements together. Since it serves as the airplane’s frame, it should be solid and durable enough to endure immense pressure and stress. The fuselage should also be aerodynamic to reduce drag during flights.

Freelance prototype experts utilize 3D models to assess interactions between various designs, other aircraft components, and the ambient air. These 3D visualizations are crucial in devising prototypes to evaluate the impact of diverse materials on the fuselage’s durability and strength.

Comprehensive reports

3D models also help prepare complete and exhaustive reports about aerospace or aircraft projects. This is possible because 3D scanning stores all pertinent data about the project and its components and parts. An airplane engine’s 3D model, for example, can include details about the engine’s power output, emissions, and fuel efficiency. Manufacturers and engineers use this information to compare different machines and monitor an engine’s performance over time.

3D visualization services turn these 3D models into key tools for creating detailed renderings of aerospace or aircraft projects. Such visual depictions are crucial for reports and presentations, facilitating communication of the project’s advancements to stakeholders. Moreover, it enables the display of the completed project to potential investors or clients.

Granular analysis

Granular analysis refers to breaking down 3D models into components and parts. It helps engineers pinpoint potential issues with the design or better understand how a particular feature works. If the engineers want to check how the landing gear of an airplane works, for instance, a granular analysis will help them break down the 3D model of the landing gear into its different parts. They can then scrutinize every piece to see how it functions and discover potential flaws.

Engineers and designers typically use granular analysis with 3D printing technology when crafting 3D models of intricate objects. Since they can break an object into its components, creating a more realistic and accurate 3D model is more accessible. Such a detailed analysis is imperative when designing 3D models for printing, whether the objects are exceptionally small or large.

RELATED: 3D printing services, cost and rates for companies and firms

Cost and price estimation

Engineers also use 3D models for estimating the cost and price of aerospace or aircraft projects. The models may include details regarding the labor, materials, and other expenses related to the project. 3D models can also offer more detailed project specifications and plans. This allows manufacturers to develop the final project to the correct specifications and guarantee the availability of all required materials.

During project presentations to the investors, the 3D models can help explain the budget required for project completion. Engineers can also break down how they create the model, the other requirements of the project, and how the project will be completed. It allows potential investors to understand better how their precious money will be spent on the project.

Other benefits of 3D modeling technology

3D modeling has revolutionized the operations of many industries, including aviation, aerospace, and aircraft design. The following benefits of 3D modeling help improve and shape these industries for the better:

Extensive testing

Engineers leverage 3D design solutions for testing different aspects of aerospace, aircraft, and machine projects. Testing the aerodynamics of new aircraft designs or the strength of various materials, for example, is now easier and simpler thanks to 3D models.

Similarly, testing how an aircraft responds to different weather conditions or performs across various terrain types will be safer and more convenient since engineers only need to use 3D models to simulate these different settings and situations. Testing is critical because it ensures the safety and function of the final product. It also helps identify possible design flaws even before the project’s actual construction, which helps save money and time for all the stakeholders involved.

Stay ahead of the competition

The aviation, aerospace, and aircraft design industries experience cutthroat competition with tight margins. 3D modeling can save money and time, giving a company an edge over its competitors. Suppose you’re an aircraft manufacturer with high demands for a specific aircraft type, for example. In that case, you can use 3D models to quickly develop and test prototypes before your competition can do theirs.

RELATED: How much does 3D CAD modeling design cost & what are prices for freelance design service firms?

Better communication

Communication between the project team and stakeholders in aerospace or aircraft projects is simplified because 3D models offer project visualization. The virtual images help explain the project to the investors and the product’s end-users. 3D Designers can also use 3D models to develop virtual tours of a project. The tours allow pilots and other personnel to determine the capabilities of an aerospace or aircraft project.

Improved passenger comfort and safety

Precision is critical for aircraft, aerospace, and aviation companies. Every single part and element should be accurate and set to the proper standards to guarantee the comfort and safety of passengers. By utilizing 3D product modeling services, engineers can develop exact mockups of aerospace and aircraft products. This ensures the accuracy of designs and guarantees that the final product will meet all the project specifications and essential safety requirements.

When developing a seating space, for instance, 3D models allow visualization of the amount of space that every passenger gets. It includes legroom and other cabin amenities critical for passengers to stay comfortable even during long-haul flights. 3D models also let the team create a replication of an aircraft’s interior to understand better its layout and the measures they need to implement to ensure passenger comfort further.

Money and time savings

Finally, 3D modeling helps save money and time as it eliminates the need to develop actual physical prototypes. A designer can develop 3D models to test various materials and designs without building prototypes of the different iterations. For example, engineers who wish to test the function of a new airplane seat type can create 3D models of this seat and use computer simulations to try it. It eradicates the need to construct an actual seat, which can be time-consuming and costly.

RELATED: Freelance aerospace engineering services, cost, rates, and pricing for companies

How Cad Crowd Can Help

3D modeling technology is no doubt an integral tool that enhances aviation, aerospace, and aircraft design for companies. Cad Crowd can help you find the best designers who can help you visualize your final products even before the start of the actual manufacturing process. Get a quote now.