2017 was quite an eventful year in the world, and the product design industry was no exception. There were many noticeable political and pop culture events as well as new product designs that hit the market. And with the changing landscape of the Internet, the new year is bound to be another eventful year with many new product design trends.

The Internet is always evolving. Companies are being forced to adapt to the digital era and new innovations are popping up to improve manufacturers workflow. While many product design companies are struggling to catch up with last years changes, an influx of innovations are just around the corner. With that said, here are some product design industry trends to look out for this year.

For companies, product data is priceless. Specific product specifications are often kept locked away in a single department, which doesn’t allow this information to be leveraged by the entire company. Considering that many products are always on and gathering data from users and those who interact with it, this data is even more valuable.

In 2018, watch out for the entire product development process to go completely digital. This will allow for complete transparency within an organization so that all information is accessible by everyone. Different departments will be able to leverage product design information as they see fit. For example, marketing and sales teams can benefit from these details.

Industries that are highly regulated will also benefit from digitalization. Organizations will be able to better meet regulations if the product design process is accessible and changes can be tracked as they are made. Every step in the design process will be digitalized, making the debugging process quite simple.

We are in the age of cloud-based product design, and it’s important for manufacturers to keep up. Traditionally, manufacturers would need to download a host of applications on their computers for their Product Life Management (PLM). However, cloud computing provides a cost-efficient and flexible alternative to that. With cloud computing, manufacturers will be able to use applications over the Internet, without the need to buy pricey applications.

This goes hand in hand with Software as a Service (SaaS). Rather than buying the license for an application or a suite of products, you could instead rent it for the duration necessary and run it through their servers. This cuts back on costs for the manufacturer as you don’t need to pay for maintenance or fork up an upfront investment.

Many manufacturers are making the shift to cloud-based PLM, which relieves them of the stress of maintaining the system with upgrades and updates and allows them to skip the hassle of hosting their own server.

No matter what products you’re producing, being able to measure how they’re performing in the real world is the key to improving future products. It directly affects a products profitability and the decisions a company makes when they are designing new iterations of said product.

A digital twin is the digital replica of your physical product that updates as its corresponding physical product changes over time. It utilizes software analytics, artificial intelligence, and machine learning to constantly update. It’s often used in machinery to keep track of productivity while allowing the manufacturer to keep an eye out for update opportunities and possible failures.

Digital twins are being used in many industries to optimize physical assets. Besides machinery, digital twins are also used in 3D modeling to create a digital counterpart of the model. It allows the designer to get an idea of how their model will function in the real world.

While 3D printers popped up and flourished over the last couple of years, 2018 is looking like a big year for manufacturers and product designers to adopt the printing technology to improve their work processes. 3D printers are becoming cheaper to purchase and operate, which was one of the major barriers of entry when they first hit the market. Smaller product design firms and independent designers will be able to not only get their hands on one, but use it to make a profit.

3D printers allow companies and entrepreneurs to create physical models of their designs that are increasingly cost-effective. With this capability, many iterations of prototypes are able to be created and the end-product is of a higher quality than it otherwise would have been.

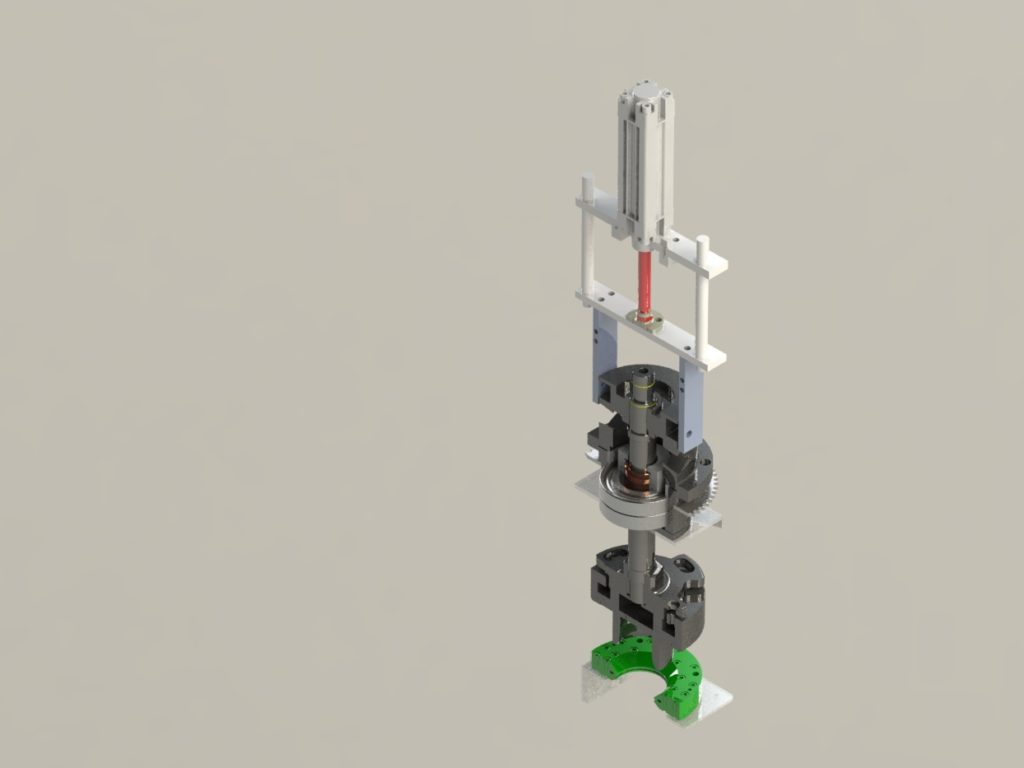

They are also useful to use alongside CAD models. While a CAD model can communicate the intricacies of a design and potential problems, it sometimes leaves some questions and issues may arise. A manufacturer can use a physical model to analyze the costs, determine further issues that may come up, and get a better grasp of the project as a whole.

Workplaces are becoming more and more global and remote. It is commonplace to find entire companies that have employees operating from different countries. While this may have created challenges in the past regarding workflow and communication, there are many tools available to facilitate global companies.

When it comes to product design, it can be especially hard to communicate the intricacies of a design remotely. Sometimes it takes having a face-to-face chat to completely grasp a product’s design. Getting teams to review designs, provide useful feedback, and ultimately improve the end product can be difficult.

Augmented reality is a groundbreaking technology that is improving the way teams work on designs. Using AR, an entire team can visualize a design better than they otherwise could. They can interact with designs, provide feedback they wouldn’t be able to unless they had a physical counterpart, and do it all from wherever they are in the world. Teams are able to look at 3D models from all perspectives and even walk inside of them, should the design call for it.

When a colleague gives you feedback on a certain part of the design, using AR, you can see exactly what point the feedback is referring to and address it without any air of confusion.

With rising costs of manufacturing and flooded marketplaces comes the need for a truly global economy. Product design companies need to design products that are not only used locally, but can be leveraged in multiple markets to make a profit. When your product efficiently reaches all marketplaces within reason, profit is abundant.

Consumers are pickier than ever and have high expectations for the quality of their products, balanced with their cost. To strike a good balance between quality, speed, and cost, manufacturing often needs to be outsourced globally. When done right, this can benefit everyone involved. A modern catchphrase that encapsulates the industry is “better-faster-cheaper.” Through global cooperation, manufacturers are better able to meet the expectations of consumers.

Long gone are the days of simple designs that aren’t interconnected. Modern designs are usually part electronic or software, like smart watches and thermostats. Previously mechanical designs are being integrated with software to improve their functionality and connect them to the Internet. What once was simply mechanical now involves sensors, processors, and other electronic parts.

These devices are usually more reliable and can do much more than their previous iterations. As companies adopt this trend, more and more products are becoming “smart” and designers are being forced to adapt to consumer expectations.

The term “Internet of Things (IoT)” was coined to reflect the influx of smart, interconnected products that all share information with each other. This is forcing product designers to learn new things, and manufacturers are being exposed to new opportunities and comparative threats if they don’t keep up with the trends.

We’ve all interacted with Siri, Alexa, and other iterations of the same digital assistant. These digital assistants only scratch the surface of what artificial intelligence can truly do. AI is capable of beating master chess players, and learning how to do so in only four hours. This is truly remarkable, and clearly, artificial intelligence is growing quickly and is going to change every industry, including the product design industry.

Artificial intelligence will find its way into product design, and the industry will change rapidly. Product and industry designers will be the ones to make AI accessible to the masses through their designs. Eventually, AI will find its way into the product design process and improve productivity.

With that said, artificial intelligence design is definitely a trend to keep your eye on in 2018 and for years to come. It’s being called the new industrial revolution by some and is bound to shake up many industries.

If you’re interested in working with a product designer, Cad Crowd can connect you with a top-ranked freelance CAD designer to get your project off the ground. Find out more about Cad Crowd and get a free quote today!

Designing a new product from scratch is no easy undertaking. It's a complex process that…

3D architectural renderings can definitely take an architect's presentations to a whole new level of…

The product development process allows the creation of services or goods for the market. This…

During the last few decades, monumental change has characterized the architectural design services industry. No…

Brand consistency happens when your company presents uniformed visuals, personality, and messaging across the entire…

Joining electronic components to a wiring circuit board by PCB assembly thus turns a bare…