This post covers how companies use 3D models and prototypes for toy development. Those colorful and engaging toys you see on physical store shelves and online catalogs weren’t created in a single day. Like other products, they have undergone a rigorous process of refinements and modifications before becoming cherished items loved by children and adults alike. In an ideal world, a toy’s initial design would require no adjustments, and production could commence immediately after the design’s completion.

Like all other sectors, the toy industry has been influenced by technological advancements. In the past, modifying molds and creating prototypes were time-consuming and costly. However, the advent of 3D technology brought about transformative changes. 3D modeling, a cutting-edge technology, has significantly impacted the toy industry, revolutionizing how toys are designed and developed. Thanks to this innovation, companies can now swiftly generate cost-effective 3D models and prototypes, facilitating the testing of realistic toys and preparing them for the market.

RELATED: New product design: how to design kid-friendly toys

As a result, manufacturing 3D printing services have become an invaluable tool in the toy industry, providing enhanced efficiency and creative freedom in toy development. 3D models play a pivotal role in contemporary toy projects because they streamline workflows and enhance efficiency. In today’s fast-paced world, where trends can shift in the blink of an eye, the ability to bring your toy to store shelves swiftly has become increasingly important.

Beyond accelerating development, 3D modeling offers several additional advantages, including improving the precision of equipment operation, fostering the conception of innovative toys, and reducing overall production costs.Continue reading to discover how companies utilize 3D models and prototypes in the various stages of toy concept development and the creation of 3D toy prototypes.

Table of Contents

Table of Contents

- 3D Modeling at a glance

- Role of 3D modeling and 3D printing in the toy industry

- How companies utilize 3D models and prototypes in toy development

- 1. Build better relationships with customers

- 2. Economies of scale and cost-effectiveness

- 3. Better communication across external and internal teams

- 4. Mass customization

- 5. More efficient data management

- 6. Development of new toys

- 7. 3D Toy prototyping made easy

- 8. Strike the perfect balance between safety and functionality

- Final Thoughts

- How Cad Crowd can help

RELATED: 10 Simple products that made millions for inventors

3D Modeling at a glance

The captivating 3D art you see today is the culmination of various stages of art creation, one of which is 3D modeling. In this phase, artists utilize specialized software to craft distinct three-dimensional objects. 3D modeling refers to the technique of developing a three-dimensional representation of an object using dedicated software. These 3D models effectively convey the depicted object’s texture, shape, and size.

Artists can create 3D models for existing products and conceptual designs that have yet to be brought to life in the physical world. To construct 3D models, 3D modeler experts plot points on a Cartesian plane to represent depth, forming a digital framework. Within this framework, the artist manipulates and adjusts polygons to achieve the desired appearance and form of the object.

RELATED: Rapid prototyping & design for new toys

Role of 3D modeling and 3D printing in the toy industry

The toy industry’s potential for 3D printing may not be the first thing that comes to mind when considering technological advancements. However, in today’s consumer-driven world, where toy makers strive to achieve and maintain a competitive edge, 3D models and prototypes provide numerous advantages. These benefits include enhanced design customization, accelerated time to market, and the opportunity to establish innovative business models.

As a result, 3D printing companies have become essential partenrs for modern toy manufacturers seeking to stay ahead of industry trends and meet consumer demands. 3D modeling fosters creativity in design—a highly valued asset in the toy industry—and streamlines and accelerates the manufacturing process for toy development, ultimately leading to reduced costs. The advent of the digital age has further propelled the growing interest in 3D technology, adding to the momentum in this field.

RELATED: 88 New inventions and ideas that made millions of dollars for inventors

In this era, toy designs are created and refined within the digital realm, offering unparalleled flexibility and the ability to manipulate designs without constraints. The combination of creativity and efficiency made possible by 3D modeling transforms how toys are conceptualized, designed, and brought to market. Here are the different ways that 3D models and prototypes help in the toy development process:

How companies utilize 3D models and prototypes in toy development

1. Build better relationships with customers

3D modeling creates opportunities for toy developers to engage with their customers and foster stronger relationships within their customer community. Toy companies can invite aspiring 3D product and concept design firms to submit their 3D designs, and the most exceptional creations can be selected for 3D printing as limited edition products. Through this collaborative approach, companies not only tap into the creativity of their customer base but also cultivate a sense of inclusion and empowerment among the community of toy enthusiasts.

RELATED: What are 3D product animation costs, design service rates & pricing for companies?

2. Economies of scale and cost-effectiveness

From the perspective of manufacturers, 3D modeling has the potential to significantly reduce prototyping time and decrease the costs associated with creating molds for multiple iterations of designs. By utilizing 3D prototyped toys, manufacturers can readily assess the costs associated with the processes and materials required for toy development. Valuable data gathered through multiple tests can be leveraged to improve the product’s design substantially. Additionally, 3D modeling enables manufacturers to enhance cost-effectiveness during mass production, ensuring the final product’s efficiency and precision.

3. Better communication across external and internal teams

Switching from a 2D image to a 3D model makes evaluations of internal designs faster and more effective. 3D modeling facilitates improved communication among internal teams, suppliers, and consumers, ultimately reducing market time. Moreover, 3D models allow for interactive exploration and modification, enabling designers to make informed decisions and iterate on designs with greater precision and confidence.

RELATED: 3D modeling: an overview of history & industry applications

With the aid of a functioning 3D model, both internal personnel and clients can more easily visualize the individual components as well as the overall design of the final product. Additionally, 3D animation services can generate interactive models that provide a dynamic view of how the product will operate and function in real life. This level of interactive comprehension and visualization is not achievable with traditional 2D modeling, making 3D modeling an invaluable tool for conveying design concepts and functionality.

4. Mass customization

As a result of the high amount of time necessary for building a mold and the involved high tooling costs, producing more personalized toys using traditional manufacturing methods like casting or injection is fundamentally unpractical. The time and price required to develop customized toys in this particular scenario are never justified by the typically low costs of manufacturing encountered. 3D modeling can also be used for relieving the disadvantages of tooling fabrication. Toy developers can also generate more personalized and intricate mold designs and develop them at a lower cost faster using 3D printing molds.

RELATED: 5 Tips for successful product design

5. More efficient data management

3D modeling experts and manufacturers often face challenges in data management, especially when dealing with multiple product evolutions and revisions. Transitioning from 2D modeling to 3D modeling can significantly improve productivity by streamlining the process of managing design data. With 3D modeling, tracking design information becomes more efficient, and updates to components can be made automatically using 3D modeling software.

3D modeling software eliminates the need for manual updates to each component in the design. Additionally, 3D modeling helps standardize drafting procedures and ensures all team members are aligned and working with consistent, up-to-date information. As a result, 3D modeling enhances collaboration and reduces the risk of errors and miscommunication within the design process.

RELATED: Accessible design: better products for everyone

6. Development of new toys

As the toy industry welcomes the emergence of innovative toys, 3D modeling is proving to be a valuable asset in this domain. Educational toys—often called pedagogical toys—are designed to help children develop and strengthen their skills in fundamental areas such as science, technology, engineering, and mathematics. One notable example is the introduction of child-friendly 3D printers that empower children to design, print, and create toys.

This hands-on experience provides a dynamic way for children to engage with technology and engineering concepts while fostering creativity and problem-solving skills. For toy makers, integrating 3D modeling and printing technologies presents an opportunity to expand their product offerings and contribute to the educational development of the next generation.

RELATED: Top 101 new product design and development firms for services in the US

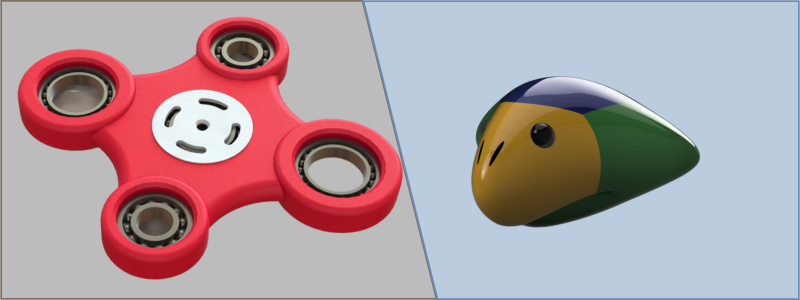

7. 3D Toy prototyping made easy

Transforming an idea or concept into a final physical product involves several stages before introducing a new product. 3D toy prototyping plays a crucial role in this process, enabling designers to assess a toy’s appearance and functionality. 3D printing is widely recognized as one of the best technologies for prototyping, as it offers a cost-effective and expedient means of producing visual and functional prototypes to achieve this goal. With the assistance of 3D printing, toy manufacturers can create practical models for evaluation and testing with potential distributors and end-users.

This evaluation process helps determine the specifications and requirements of the final product. 3D modeling and rapid prototyping services allow designers to rapidly produce multiple prototypes, facilitating comprehensive feedback that can be incorporated into the final design. Moreover, the iterative capability of 3D printing fosters further experimentation, paving the way for enhanced product innovation and the development of improved toys for children.

RELATED: Sustainable product design tips for a healthy world

8. Strike the perfect balance between safety and functionality

While pursuing new creative and immersive play experiences is important, physical safety attributes must be not overlooked, as neglecting safety can threaten the product development process and, ultimately, the end users. To mitigate this risk, toy manufacturers must adhere to established consumer safety specifications for toy safety. These specifications encompass a comprehensive set of technical standards that outline design considerations and material requirements to ensure the safe development of toys.

The overarching goal is to have a unified standard and testing protocol that facilitates the creation of safer toys globally, thereby prioritizing the well-being of children who engage with these products. Adopting safety standards can be highly cumbersome when relying on traditional prototyping methods. However, 3D prototype design engineers offer a more efficient approach, as they can be readily tested for safety and functionality, with design modifications easily and quickly incorporated as needed.

RELATED: 11 Tips for good ergonomic product design and development

Additionally, 3D-printed toys can be observed in controlled test environments with children to evaluate various factors such as age-appropriateness, durability, safety, and functionality. Using 3D models and prototypes also facilitates the presentation of toy samples to prospective distributors and buyers, providing valuable opportunities to gather feedback. Insights gained from these sample prototypes and tests can be considered when developing subsequent iterations, ensuring that the final product meets safety standards and consumer expectations.

With the capabilities of 3D printing, toy manufacturers have the flexibility to create multiple versions of a single design, each with enhanced features, materials, and ergonomics, as the revision process becomes more streamlined. Similar to practices in other industries, toy makers can implement the Continuous Improvement Process (CIP) to optimize their toys and achieve success in the market.

RELATED: How companies have simplified product design: 3D printing and prototyping

The use of 3D models and prototypes in the toy development process empowers manufacturing companies and designers to craft toys that reflect their creative vision, all while operating with a higher level of confidence in the quality and safety of the final product. Through 3D technology, the potential for innovation and excellence in toy design is further realized.

Final Thoughts

The toy industry has been transformed by 3D modeling and prototyping, allowing for enhanced efficiency, creativity, and safety in toy development. With 3D technology, toy designers and manufacturers can swiftly create cost-effective and realistic prototypes, facilitating the testing and refinement of new toy concepts. The use of 3D models fosters improved communication, efficient data management, and streamlined revisions to designs.

RELATED: How to render a product design with freelance experts

The technology empowers toy makers to engage with their customer community and produce innovative educational toys, including child-friendly 3D printers that introduce children to technology and engineering. Adherence to consumer safety specifications is made more efficient with 3D prototyping, ensuring the well-being of children while balancing functionality and creativity. By implementing a Continuous Improvement Process (CIP) and leveraging the capabilities of 3D modeling, the toy industry is unlocking new possibilities for innovation and success, all while ensuring the highest standards of quality and safety.

RELATED: Custom Miniature Design for Manufacturing, Cost, Rates, and Pricing for Companies

How Cad Crowd can help

Are you ready to bring your innovative toy concepts to life? At CAD Crowd, we’re here to help you every step of the way with our new toys and games design services with CAD product designers on demand. Our skilled designers ensure your creative vision is expertly realized, transforming your ideas into functional and captivating 3D models and prototypes. Whether you’re looking to develop educational toys, interactive games, or the next big hit in the toy industry, our experienced CAD product designers have the expertise you need. Don’t wait—collaborate with CAD Crowd today and experience the future of toy design. You can get started with a free quote to see how our services fit your budget.