The design and manufacturing of a product and processes are intrinsically linked. This means that the processes of computer-aided design (CAD) and computer-aided manufacturing (CAM) are also very closely aligned, so much so that they have become nearly synonymous with each other.

There are some significant differences in the processes, although, over the last 60-something years, the use of CAD and CAM has increasingly pulled the design and manufacture process much closer together. In this article, we’ll explore:

- The differences between CAD and CAM

- What the most common systems in CAD and CAM are

- How the processes used in both have developed over time

- The integration of design and manufacturing systems

We hope this will make the process your company will need to undertake clearer and give you a better understanding of design and manufacturing services as you make your way through the process to bring your idea to life.

CAD vs. CAM: What You Need to Know

Although they are very much linked together in the process of product manufacturing, CAD and CAM are very different beasts. There are various pieces of software needed to work in each field, as well as very different skillsets.

The Basics of CAD

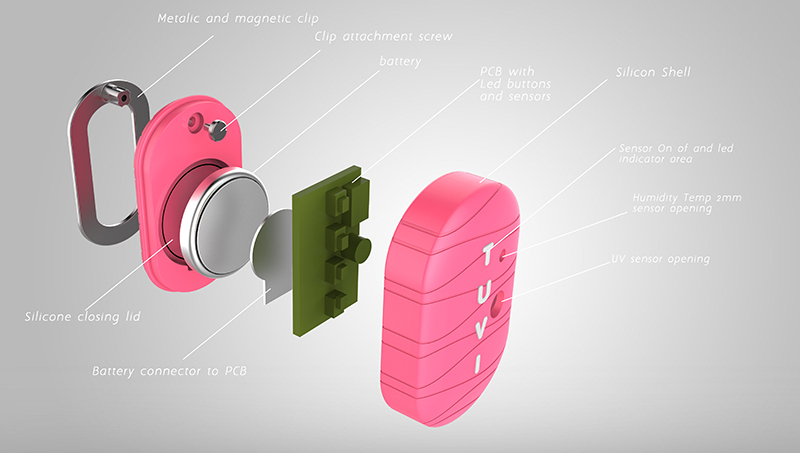

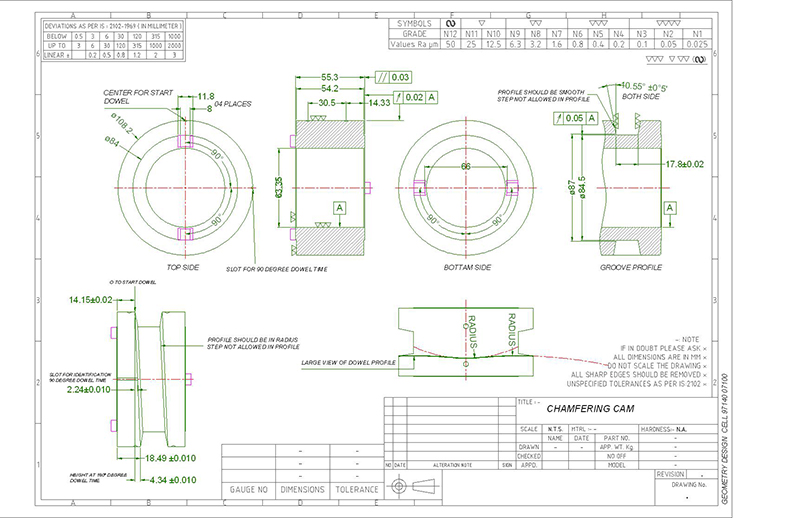

Computer-aided design is the process of using a computer to make a geometrical, mathematical model of an item. During the process of designing using CAD, the technology and language for the design will be set.

The purpose of CAD is to conceptualize a design; to give it shape, form, and detail. It is a process that has all but replaced the role of a traditional draftsman. That’s a person whose job it was to draw by hand, using pencil and paper, the item that is being considered to be manufactured.

Every part of the item being designed can be individually drafted on a computer and then checked to see that they fit together properly. A computer can do this with a lot of accuracies, and it’s a lot easier to tweak a problem of a couple of millimeters in a design program rather than having to redraft a whole design on paper.

The Basics of CAM

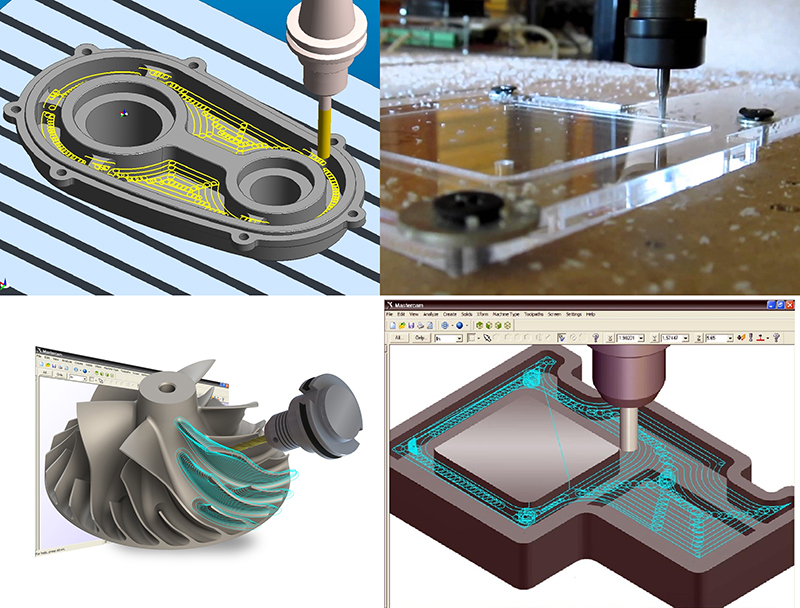

After an item has been designed and all of the details specified, it’s then time to move on to getting it made. Computer-aided manufacturing means using computers to create computer numerical controls (CNCs) so that machines can follow instructions to make something.

CAM can control a whole range of processes, including:

- Milling

- Lathing

- Routing

- Cutting

- Metal stamping

- Grinding

- Laser cutting

- Robotic actions

And pretty much any other manufacturing process that you care to think of.

CAM requires a knowledge of all of the materials and processes that go into making an item. The systems created in CAM are there to control physical processes, equipment, materials, and labor to make the process of manufacturing as easy and cost-effective as possible.

As well as working to make the components of an item, CAM can be used to create assembly processes for each part, allow for inspection and testing, and also have the item appropriately packaged. It allows for greater automation of nearly every part of the process.

Processes In Harmony

As different as the two ideas may be, neither a CAD service nor a CAM engineer works in a silo. A good designer will know the manufacturing process so they can select the right materials. For example, an engineer will need to know something about design so they can create the right systems to make the product.

By its very nature, once something has been designed using CAD software, it will then be used as the basis for CAM. The files for the design will need to be passed over to the freelance engineer designing the factory machines to bring the design to life.

Using both CAD and CAM together means a production line will:

- Be more cost-effective: Since the amount of labor used is reduced, both in terms of draftsmen and machine workers on a production line.

- Less prone to error: Because when a computer is in control of a laser cutter, for example, it will repeat the same process exactly, each time, without getting tired.

- Consistent quality: There’s no deviation from the designed product when there is computer numerical control in the process.

- Less wasteful: A well-designed product can take into account the size of raw materials and find the best fit easily, e.g. when designing a clothing pattern, it’s easier to understand how to fit multiple pieces from a roll a fabric using a computer.

Over the years, the technology and training in the two systems have been able to increase understanding of the conceptual overlap and make designers and engineers be able to work together much better.

Different Technologies

Since the demands of CAD and CAM are very different, the technology used to produce the work is different too. Of course, a CAD model needs to be able to be interpreted by the person designing the CAM processes and systems.

Some of the most common CAD systems in use are:

- AutoCAD

- Autodesk Inventor

- CATIA

- Solid Works

And the commonly used CAM programs include:

- Work NC

- Siemens NX

- Power MILL

- SolidCAM

We have articles that cover these programs, their capabilities, and how they might help your project in our blog. Suffice to say, depending on the CAD software that is used, there may come limitations to the CAM software that can be used, so make sure that you understand your needs from both ends of your project.

How Times Have Changed

The beginnings and subsequent development of both CAM and CAD design services are intrinsically linked to the advances in computer technology over the last sixty or so years. The way the two technologies have integrated and made higher demands of each other spurred them to become the systems relied upon so heavily nowadays.

Where Did CAM Come From?

At its most basic, CAM is using numbers and math to tell a machine to complete a repetitive process. The first machine that did this was invented in the 1950s, in which the designer made punch cards to feed the machine a set of instructions.

In the same decade, an MIT lab invented the first coding language, G-code. With this, programmers could create co-ordinates that were able to lead a machine over a piece of raw material, whether it was a piece of wood getting routed or a sheet of aluminum getting cut to size. The new language of computers meant an engineer could now feed into a machine:

- It’s location relevant to the materials

- How fast to work at and motor speeds

- The correct path the follow

As PCs became ubiquitous in the 1990s, it led to more integrated work with CAD systems. The machines that are now used in CAM are far more advanced and include actions like:

- Laser cutting

- Plasma cutting

- Water cutting

- Milling

CAM has made both industrial and small-scale production much more efficient, and more accessible. From early commercial uses in the automotive and aerospace industries, using computers to guide machines in manufacturing processes is now pretty much the norm.

The History of CAD

The history of CAD has had a similar path, with CAD finding more and more applications as computing power improved. General Motors was one of the early pioneers of CAD, using internally created systems to design cars in the 1960s.

The aerospace industry was pioneering CAD use in the 1970s. CAD was also adapted to be used in the semiconductor market, where computers were able to predict the current flow. As computers became more powerful with the invention and refinement of the silicon chip, more applications were found for CAD.

Consumer electronics was the next big market for CAD in the 70s, and there were many competing systems for designers to use. In the 90s, the programs being used became more harmonized and market leaders began to emerge.

As CAD systems became more powerful, CAM processes became better and there were higher demands placed on designs than when they had been done manually. CAD software became able to specify such things as:

- Feed rates

- Accurate angles

- Tool speeds

- Clamp positioning

This, in turn, made the manufacturing process more comfortable and meant designers needed to become more aware of what would happen down the line from their work.

From simply creating a model image on a computer rather than on paper, CAD has developed to be able to do physical and thermal stress testing of materials as well. With 3D modeling advances, a well-produced design can even work as a dynamic prototype—predicting design and material failure without the need to produce an expensive physical product.

The Marriage of CAD and CAM

The progress of computer-aided design and manufacturing has been tied up together. As machines could be better programmed to carry out actions, designs needed to adapt to show the machines what to make.

At the same time, as designs were able to get more accurate and provide more details, engineers needed to do less work creating production lines but then had to plan processes with more precision. Everything has got more accurate.

The advent of 3D printing services is the culmination of the two processes. A designer is now able to create their model with multiple moving parts for it to be sent to a 3D printer to create. This process is different to tradition computer numerical control, in that the material is being fed into the machine rather than being worked on.

Even when looking at processes outside of 3D printing, which is still in the early stages of development, CAD and CAM have been getting closer together as skills to be mastered. Another example of the joining of the two fields is the testing of electronic component specifications. As electronics get smaller and more intricate, very accurate design and checking of current flow are needed to ensure a perfect manufacturing process.

To Conclude

Using computers to be able to design and manufacture products has changed the world around us. There is a level of accuracy that couldn’t be achieved by manual drafting and drawing of designs and engineering processes to be able to create them.

There has always been a direct link between design and manufacturing—designers have always needed to understand materials and machine limitations while engineers have had to be able to look at a design and understand what is trying to be achieved.

Computers have taken a lot of the strain in this process and CAD technology is now able to integrate into CAM and directly provide details for computer numerical control or instructions for 3D printers. The benefits to the industry of bringing the two disciplines closer together have been greater efficiencies, less long-term effort, and a more effective use of materials.

Cad Crowd’s Freelance CAD Designers and CAM Engineers Are Here to Help

At Cad Crowd, we’ve amassed a vast database of nearly 25,000 freelancers from around the globe. They are qualified, experienced, and ready to tackle a CAD and CAM project of any scale.

If you’d like to start working on your project right away, first, take a look at how it works. We also organize design contests that allow you to receive several design concept ideas which you can then choose from, take a look at how you can launch a design contest, and see what our freelancers can offer.