In today’s modern world of business, there is a multitude of different processes and systems that design and contract drafting services can utilize. Technology has changed rapidly over the last 10–20 years, particularly with CAD and CAM systems. Inevitably, due to this huge development in technology, there are many businesses using legacy processes that often prove inefficient.

This is where CAD-CAM migration is beneficial. In this article, we look at exactly what CAD and CAM migration are, the common steps involved, and how it can improve your business.

What is CAD and CAM Migration?

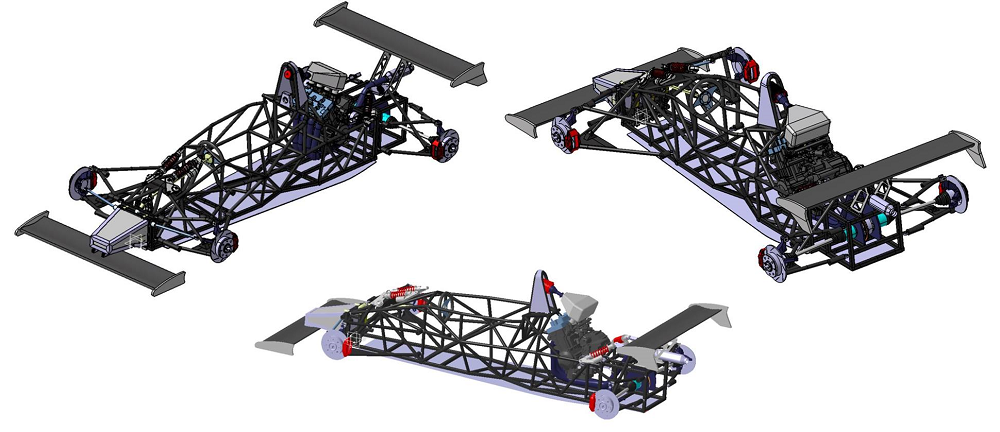

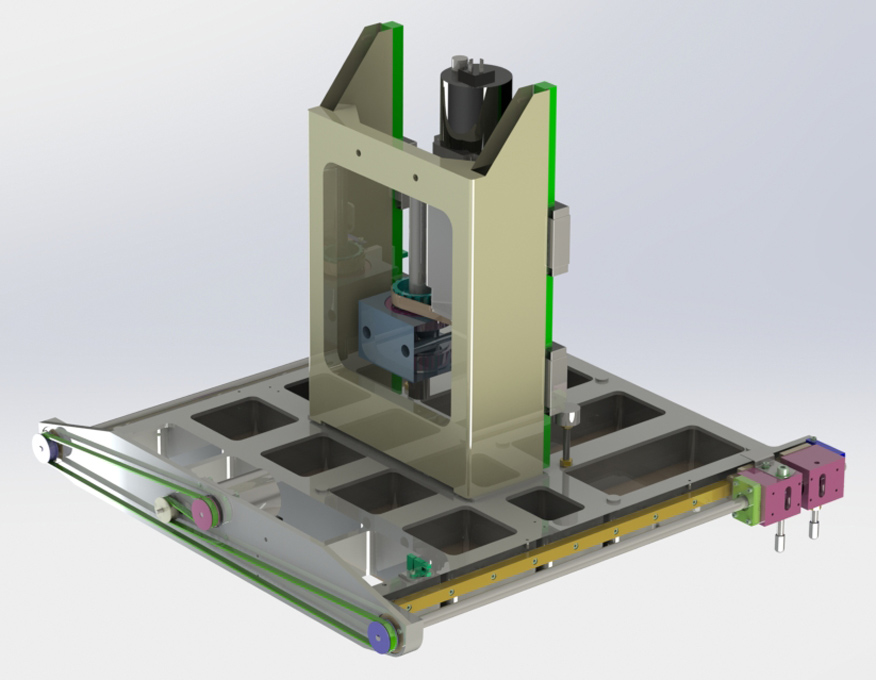

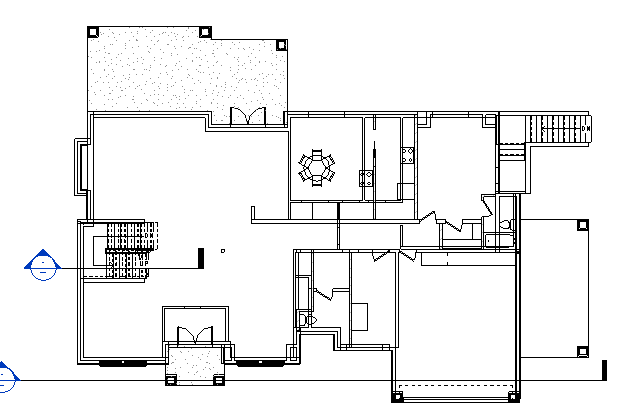

This is the process of transferring and converting existing information into usable CAD and CAM files. The most common example is a manufacturing company that currently uses paper drawings and blueprints. A migration process would involve scanning and converting these paper documents into digital CAD files that can then be processed and edited using CAD software.

That is one type of CAD migration service. The other main type is converting a myriad of different file types and documents into one single file type, for use on one platform. Let’s say, for example, that a business is currently using a myriad of different software programs such as CATIA and SolidWorks. They have an unorganized, fractured operation that is inefficient.

A migration process would involve converting the CATIA and SolidWorks files so that they can be used on a single program, such as Autodesk. Instead of having a fractured process with multiple different programs, you streamline your business and use a single program for all workflow aspects.

Why Is Migration Necessary in This Industry?

First, let’s look at why a full migration may be necessary. This is not something that would be undertaken lightly—migration can be a lengthy process that requires planning and forethought. Within the CAD and CAM industries, however, migration is common—technologies are continually improving, and businesses often use legacy systems that are inefficient. We have listed some of the main reasons for migration below:

Transfer from Archaic Systems

Some businesses still use paper-based systems for their design and production processes. Initial product drawings, for example, maybe hand-drawn. They may rely on drawn blueprints and a paper-based filing system for data. In today’s modern world, this is quite inefficient. Digital CAD drawings are proven to improve efficiency. Moreover, cost savings are made due to reduced labor and equipment expenditure.

Utilizing a Technologically Advanced Program

Even businesses using CAD systems may not have the latest technology or be using a system that is the most effective for their business needs. Some archaic CAD software is still usable today—a business may have used this software for years when in reality, there could be a new program available that offers more features and functionality. In this instance, migration from the archaic program to a different platform could be a great long-term business choice.

Streamlining of Business Processes

It is not uncommon for a business to have several different departments that all use different software and systems. In the grand scheme of things, operating in such a way causes fragmentation and a slower overall process.

Different departments may not be able to easily share designs and information, for example. In this instance, the migration of one department like an AutoCAD drafting and design service could be hugely beneficial. Bringing each department together onto the same platforms could improve efficiency and communication.

Accessibility of Data

CAD and CAM systems provide businesses with excellent data management functionality. You can do so much with a simple CAD file and incorporate a myriad of important information. Moreover, the data can easily be accessed, edited, and redistributed. Migrating to CAD and CAM systems can improve your ability to access data.

What Are the Common Steps Involved with CAD-CAD Migration?

The migration process is complex—it’s not a simple case of exporting a selection of files into a different software program. To successfully migrate to a new CAD or CAM system requires detailed planning and analysis of the files and assets used. Furthermore, a company must have the appropriate training and facilities available, so that their employees can use the new systems once data has been migrated.

Due to the complexity of the migration process, using a third-party CAD design service is advisable. There are a plethora of organizations that specialize in this process. They can work with your business to ensure a smooth transition, and that the process is executed effectively. We have outlined some of the basic steps involved with CAD migration and CAM migration below. Please note that the intricacies may vary depending on the software and systems involved.

1. Dissecting the Current Files And/Or Process to Ascertain the Best Process

Migration is an involved process that must be planned and analyzed. The first part of this process involves looking at your current operation. Those responsible for the migration must look at the procedures currently in place. This would involve a physical assessment and documentation.

For example, if a business used blueprints and drawings, the CAD digitalization service would look at examples of these drawings and how they could be transferred into working 3D CAD files. Moreover, they would look at other processes surrounding the drawings such as how they are shared with other departments, and how the information is stored.

In addition to this, they would look at the business requirements to understand how the drawings and data are used and for what purposes. Essentially, they would analyze every aspect of the business so that they have a clear picture of what is used, and what would be the best course of action regarding migration.

2. Analyzing Potential Issues and Safeguarding Files

Aside from looking at the current processes involved, you must be aware of the potential issues and formulate safety precautions. There is the chance (albeit a small one) that errors can occur during migration. For example, files could become corrupt, or some data may not be able to be migrated. Before starting the migration process, it is important to look at potential issues such as this to minimize the chance of their occurrence.

RELATED: How 3D CAD & CAM Have Changed New Product Design

The migration team would look at how data is currently used and stored. Once this has been determined, they would then look at the potential issues that could arise together with solutions of how to overcome the problems. In addition to this, a safeguarding plan would be put into place. This would ensure that the migration process creates backups of files, and has a contingency plan so that there is no loss of data or security.

Protecting the integrity of information, and preserving company information is a vital part of the migration process.

3. Preparing the Files/Documents to Ensure They Can Easily Be Migrated

Once extensive planning and analysis have been performed, a plan should be formulated of the migration process. After this stage, preparation can be made to ensure the files and/or paper documents are ready to be migrated. This can involve a myriad of different things such as security checks, organization, and identification of document locations and folder structures, and ensuring correct naming schemes.

For example, if a business was migrating paper documents into CAD systems, they would first have to identify the physical location of documents, and how they are stored. Moreover, simple things such as paper size, and important information could be recorded too. They may even have to hire a paper-to-CAD conversion service.

In addition to this, the business would decide upon file naming formats once the paper documents have been converted into CAD files. Furthermore, they would decide upon folder hierarchies and folder naming conventions.

All of this helps to ensure a smooth migration process. It also ensures that the documents can easily be found in the new system and are logically organized.

If a company was migrating to a new CAD system, most of this process should already be complete. The folder hierarchy, for example, would already be in place, as would a naming process for the individual CAD files.

4. Extraction of Data from the Legacy Platform

Up until now, nothing has actually been done with any of the existing data. It has merely been analyzed to ensure it is ready for this next step. Now the information data can be extracted from the legacy platform. Steps 4 and 5 are sometimes completed together in one process, but this depends on the data involved.

With paper-based documents, the information would first have to be scanned to create a digital format. This is usually via a photocopier with a scanner function, and the resulting scan would create a PDF document that can then be manipulated and transformed into a CAD file that can be edited. This would have to be repeated for each file.

If a company is simply migrating from one platform to another, extraction is generally not required. The files simply have to be converted to a different format so that they can be opened on the CAD software.

5. Conversion of CAD/CAM Data Into a New CAD/CAM Platform

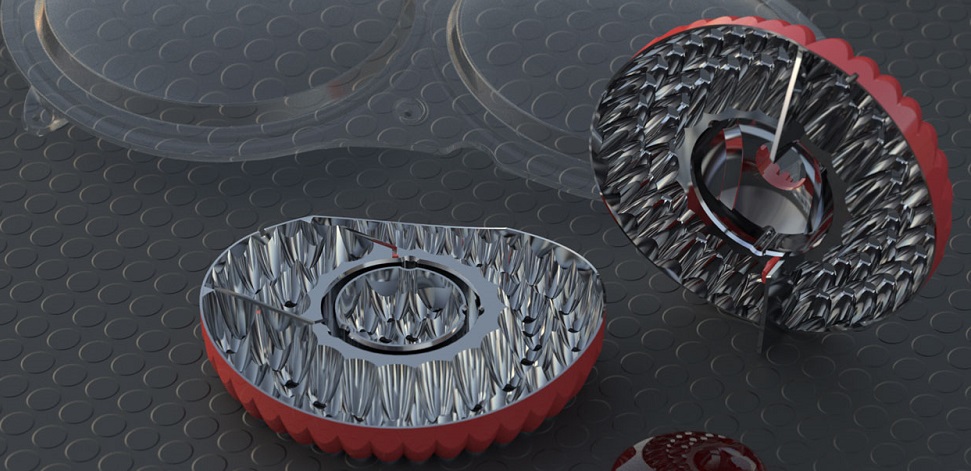

Finally, once the data is digitally available, and in a format that can be converted, the information can be transferred into the new CAD platform. There is a myriad of conversion tools available that businesses use to process CAD files. Depending on the business needs, data could be converted into vendor-neutral file formats, or proprietary formats specifically used with the new software through a CAD redrafting and conversion service.

It is preferable to use vendor-neutral file formats—these are file types that are not tied to one specific program. IGES and STEP are two well-known examples of non-proprietary CAD file formats that can be used on a wide variety of different programs.

This step is the last in which the data is processed—after this, barring any errors, the migration process should be complete. After the initial migration, there could be a troubleshooting period in which any errors are sorted and the system and platform are checked to ensure that all data is present and correct.

6. Training of Employees for the Usage of the New Platform

If your business is migrating to a new CAD program, training is vital. In all likelihood, this step would take place earlier in the migration process or even before. Ideally, your employees must be fully trained on the new software by CAD drafting services ready to use it as soon as the migration is completed.

Training could be extensive and include a myriad of different elements—this depends on the experience of your staff, and what technology they worked with beforehand. For example, if your staff previously created designs using paper and blueprints, their computer knowledge may be limited. They may have to have extensive training therefore not only CAD software but also the basics of computing too.

Alternatively, if you are migrating to a different CAD system, the learning curve would be easier – your employees would already have a fundamental grasp of CAD software and how it works together with basic computing knowledge.

Additional training may also be needed regarding data protection, data security, and the management of CAD and CAM files on your new system.

What Are the Benefits of CAD Migration and CAM Migration?

Now that you understand more about CAD migration, it is important to know why it’s beneficial. What actual need could your business have to use a different CAD platform, or transfer your information into a modern digital format? There are several compelling reasons including efficiency, cost savings, and standardization, which we have discussed in detail below:

1. Standardization of Data Formats and Information

For a business to work effectively, data must be standardized and accessible to every department. The processing and transferal of information should be streamlined. Department A should easily be able to send information to department B, who should then be able to edit it as required and view it instantly.

Over time, a business may have adopted various different systems and processes. For example, the design department may use manufacturing drawing design services. To transfer these documents to other departments for approval, they would have to scan them in or deliver them by hand.

This is obviously time consuming and inefficient. Moreover, to make changes, the drawings would have to be returned to the design team who would then have to create new versions from scratch.

Migration in this instance would allow both departments to utilize CAD software to create and approve designs. The design team could create drafts using CAD software – they could then simply email these designs to other departments, or even store them on a commonly accessible server.

2. Take Advantage of the Latest Industry Technologies

Using archaic processes limits a business’s productivity. For example, if you are using blueprints and paper drawings, there is a limited scope of how you can use these items. Making any changes is an arduous process. Moreover, the documents can’t easily be shared. Migrating to a 3D CAD system allows a business to take advantage of new technology.

CAD software is extremely advanced – drawings and designs can be packed with important information. Moreover, changes can be made quickly, and everything is non-destructible. By migrating to a new, advanced system, your business can take advantage of the features it provides. This can help improve your design process, but also helps your business produce new and improved industrial designs, for example.

Furthermore, as CAD software develops, your business can simply update the software and be privy to any future developments – you become future proof.

3. Efficient Business Management

Efficiency is key in modern business. You must have an efficient process that allows you to react to customer requirements. We have already touched on this above, but using archaic design processes are extremely inefficient. The process involved in utilizing drawings and blueprints is hugely time-consuming.

First, the drawings have to be created – this in itself is a lengthy process, even for experienced 3D modeling designers. Secondly, the drawings then have to be somehow translated and shared with other departments. This again is time-consuming – they may have to be scanned, or physically moved from one office to the next. In the design and production industries, using techniques such as this simply isn’t viable.

In contrast, a CAD and CAM system is streamlined and effective. This effectiveness is amplified when each department has access to the same system. Migrating paper-based design systems can, therefore, help immensely.

4. Reduction of Costs

As with any business improvement, a cost-saving is desirable. This is one of the main benefits of migrating to CAD and/or CAM systems. Compared to traditional methods such as paper-based design, there is no comparison. Using paper-based processes has an increased cost of labor as more time is involved to hand-draw designs. Moreover, administration costs and equipment costs are higher.

RELATED: 12 Benefits of Outsourcing Your Company’s CAD Services

In contrast, CAD and CAM processes are proven to be cost-effective. Yes, there is an initial cost for the migration, software, and training, but this initial outlay will be paid for tenfold in the long-term. Processes will be improved, and more importantly, costs will be reduced.

5. Improved CAD Production Processes

Finally, the actual design and production process will be greatly improved. We have made various references and examples of this above. There is no comparison between the time and effort involved to create a design by hand, or creating a design using CAD software. Moreover, the production process will benefit from the improved communication between departments, and the standardization of data transfer.

These improvements will help the design and production process. Ultimately, you can improve your business and provide a more efficient, and cost-effective service to the end customer – which is the main point. This, in turn, can potentially increase sales, revenue, and profit.

Consider CAD Migration for Business Longevity

We hope you have found these tips and information beneficial. As a business, it is important to look at procedures such as CAD migration. If you use CAD and CAM as an integral part of your business, it is recommended to stay up to date with the latest technologies – this will ensure that you can remain reactive and run an efficient operation. Moreover, it will allow you to provide the best service and/or products to your customers.

Remember that Cad Crowd can facilitate migration services – we bring together professional businesses that provide CAD services such as migration, together with companies that require their expertise. Our platform is easy to use, and we work with thousands of talented business that have years of experience in the CAD and CAM industries. Find out how it works.

Nice article give good idea.

Can you give more about CAD to CAD migration let us say migration from NX to CATIA .