One area in interior architecture and design is usually lost in translation. It relates to the difference between casework and millwork, which can be confusing due to commonalities. In essence, these two terms consist of two essential elements involved in the construction and interior design but provide quite different uses and require more skill in specific applications.

Knowing such points could better help freelancers as well as architectural companies on projects by specifying tasks more effectively, selecting the material to use, reducing efforts for implementing designs, and achieving the best cooperation ultimately.

This article digs deep into the distinctions between casework and millwork services , including their uses, design implications, costs, and best practices for integrating each into commercial and residential projects.

Table of contents

Table of contents

- Defining casework and millwork: essential differences

- When to use casework vs. millwork in design projects

- Materials and finishes: what is best?

- Cost comparison: what freelancers and firms should expect

- Installation techniques: tips for seamless execution

- Casework and millwork in new design trends

- Choosing between casework and millwork: practical advice for freelancers and firms

- Wrapping it up

- How Cad Crowd can help

RELATED: What casework shop drawings are and why architectural design services use them

Defining casework and millwork: essential differences

Casework and millwork are part of the construction and design vocabulary, especially in interior architectural services. However, they refer to two different approaches to built-in furniture and fittings:

Casework

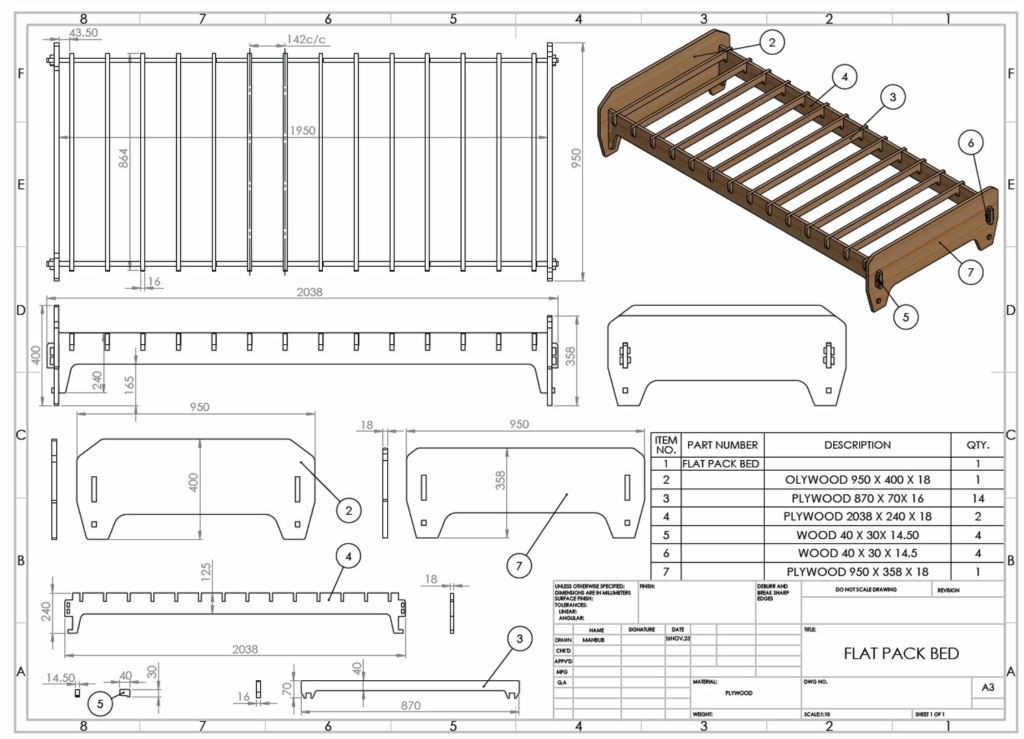

Casework is those modular, box-like elements that can be mass-produced and assembled on-site or prefabricated off-site. The term is also closely associated with cabinetry and other storage solutions.

Some of the key examples of casework include cabinets, bookcases, drawers, shelving units, and other types of storage. Most of the casework elements usually come in standard sizes, hence it is easy to produce them in large quantities and many different designs.

Casework is usually freestanding or semi-permanent, being removable or replaceable with no effect on the architecture of the space.

Millwork

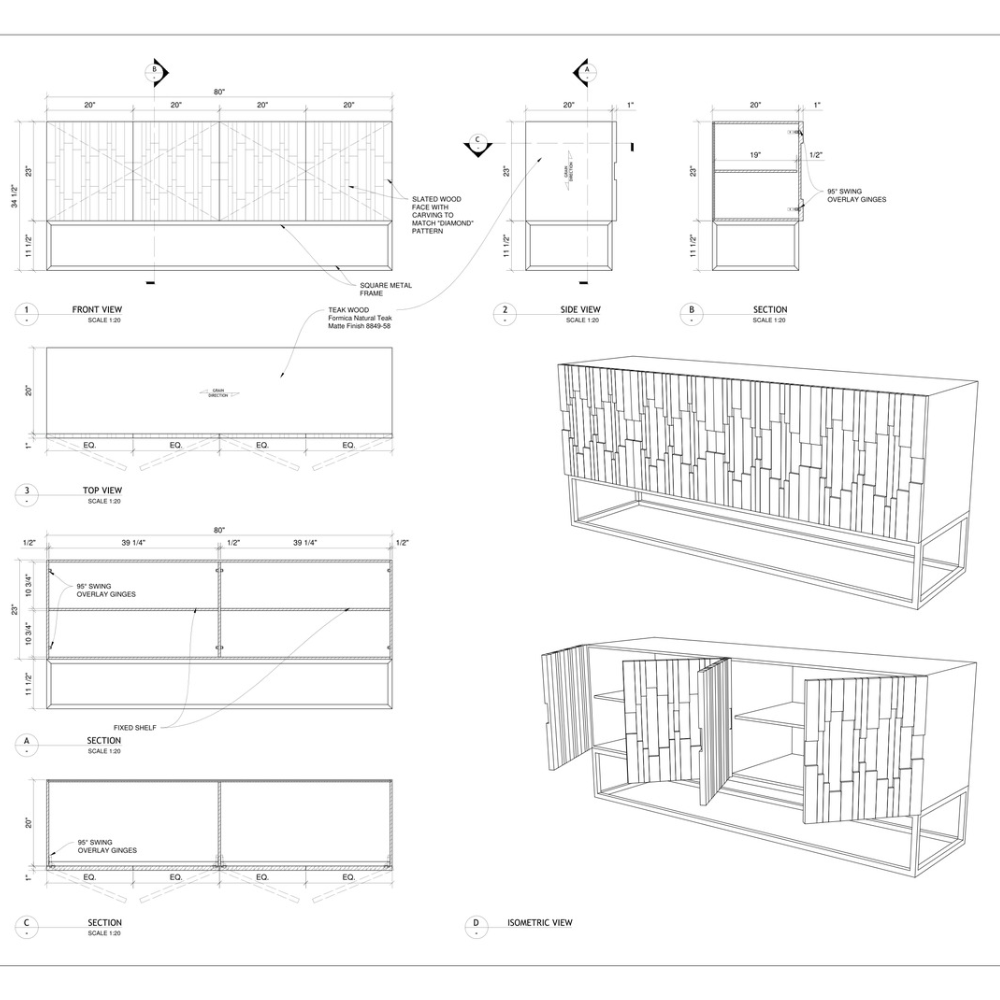

Millwork is custom, handcrafted pieces typically constructed in a mill and then installed permanently within a building. It includes woodwork and trim that gives buildings their aesthetic character, including moldings, baseboards, window casings, staircases, and paneling.

Unlike casework, the elements of millwork are mostly custom-designed for a given space and most have some intricate details that feature to define the overall architectural style.

Millwork is normally installed as part of a permanent feature of the interior structure, hence providing an integral role in defining the character and layout of the room.

RELATED: Millwork drawings for drafting and design: complete cost, rates, and fees for firms and companies

When to use casework vs. millwork in design projects

This is, of course, useful for both freelance designers and architectural firms to learn when to use casework versus millwork so an effective project management system results in a consistent design outcome and cost-effective means for execution. Consideration shall be made for:

Scale and scope of project

It is much more ideal and beneficial for projects wherein they need functional storage to take place which may be quickly built and installed in the site. For large-scale projects, it has found itself to be able to execute consistency for many rooms and locations by casework approach.

Millwork excels at designs that are defined by aesthetic detail and customization. Luxury residential projects or high-end commercial spaces frequently utilize millwork to introduce unique features such as unique moldings or custom wood paneling.

Customization requirements

Millwork is perfect for spaces that demand some distinct character or architectural cohesiveness because it is in its very nature custom. This creates alignment with most clients’ specific design preferences.

Casework is a cost-effective and feasible option in case customization is not such an issue. However, nowadays most manufacturing firms provide semi-custom casework that balances the degree of personalization with the requirements of keeping the costs within limits.

Time constraints

Casework is a prefabricated product and, hence, it can be manufactured and installed much faster than custom millwork, which is essentially about intricate craftsmanship and lengthy lead times.

In case of tight deadlines, the freelancers and firms look for casework to complete within the deadline. In case a project demands detailed design and if there is enough time in hand, millwork would provide a unique character with longevity.

Budget

Casework is always cheaper than millwork due to standardization in the production process. In the case of budget constraints, casework can offer a more realistic solution with functionality intact but without compromising the quality.

Millwork costs more as this is the work custom to each other, and usually with high-value woods or any other kind of design desired, making it pricey but for all luxury jobs and to acquire an atmosphere in those places or designs required; this one may pay some more amount for this to last a long time as the same.

RELATED: How architectural millwork design and drafting services can easily achieve company success

Materials and finishes: what is best?

Understanding which of the materials to use on casework and millwork best realizes your goals, whether durability and style or both, would be the most effective outcome.

Casework materials

Casework is typically constructed of very rugged yet cost-effective materials used most of the time such as MDF (medium-density fiberboard), particle board, and plywood, often topped off with laminate, veneer, or melamine.

Strength, low cost, and maintenance-friendliness mark these material types, being used in mostly high-traffic areas: kitchens, bathrooms, and offices.

Solid wood or high-end veneers may be used in high-end casework, but these are expensive and add much to the cost.

Millwork materials

Millwork is typically constructed of solid wood, though the most common woods used are oak, walnut, mahogany, and cherry. These woods provide a beautiful yet durable result.

Finishing millwork may include staining and varnishing, but more elaborate finishes can involve hand-carving or painting depending on the finish that will be used.

High-quality millwork also has treatments to accentuate the natural characteristics of wood. These are either glossy or matte finishes that play with the grain.

RELATED: Hiring freelance woodworking drafting and design services: All you need to know

Cost comparison: what freelancers and firms should expect

Casework and millwork are not the same regarding material, labor, customization, and installation.

Casework costs

Casework is generally cheaper, primarily in its modular manufacturing. Cost per unit will vary by materials, finish, and manufacturer.

The most basic types of casework average $100-$500 per unit for a prefabricated design. The cost of custom is higher than this but less expensive than millwork.

Millwork prices

Millwork is custom-made in nature, hence it requires more budgets. Labor is a very high-cost component because millwork involves skilled artisans to make complicated designs.

Millwork can be pretty expensive. Decorative molding services and custom cabinetry can run into thousands. However, millwork has long-term value in terms of its quality, durability, and timeless appeal.

Installation techniques: tips for seamless execution

Installation methods of casework and millwork show their differences in use and permanence in a design project.

Installing casework

The installation of casework is not that complex since the units are designed to standard measurements and can be installed on walls or floors without difficulty.

The modular system has the advantage of speedy installation, which is also the case in commercial establishments, where uniformity and saving time are of the essence.

Installing millwork

Millwork installation requires exactness as each part is built to fit into a room. It usually is undertaken by specialists like skilled woodworkers or millworkers; thus, each component finds its way perfectly within the design and architecture of the room well.

Because it does not readily come out, millwork must be very well contemplated during the design stage as a function of other architectural components that have to do with walls, ceilings, and flooring.

RELATED: Fabrication shop drawing services: all you need to know

Casework and millwork in new design trends

In the contemporary design landscape, casework and millwork share the spotlight:

Casework trends

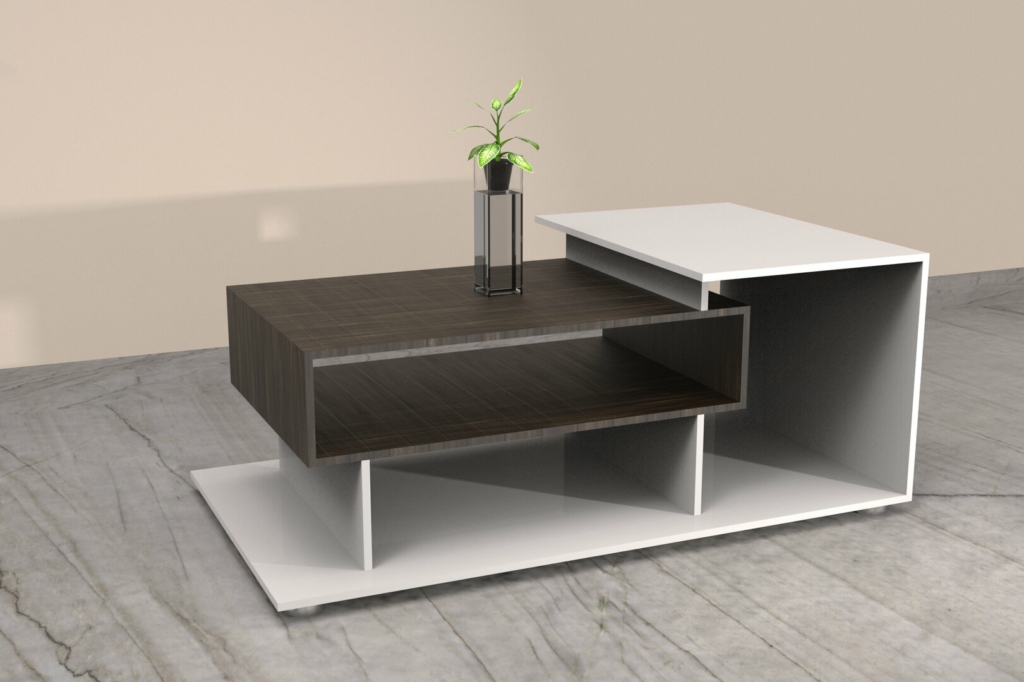

Current trends in casework tend toward lines that are smooth and sleek, with a focus on Scandinavian or modern-industrial aesthetic appeal, including clean lines, recessed handles, and matte or semi-matte finish.

Sustainable materials and finishes in casework design are increasingly being used to meet the trend for greener interior applications in both residential and commercial building projects.

Millwork trends

Millwork is gaining popularity in luxury design with a focus on craftsmanship and artisanal quality. Modern millwork blends traditional techniques with contemporary aesthetics to create statement pieces that elevate interiors.

Dark wood tones, intricate paneling, and accent moldings are popular in residential millwork, while commercial projects often incorporate custom staircases and built-in seating that blends functionality with visual appeal.

Choosing between casework and millwork: practical advice for freelancers and firms

For freelancers and architectural firms, the choice between casework and millwork would depend on the budget, scope of the project, and aesthetic. Here are some key tips to guide this decision:

Evaluate client needs

Determine whether the client values customization and aesthetic details, which would indicate millwork, or if they prioritize functionality and cost-efficiency, suggesting casework.

Consider project constraints

Sometimes, because of a tight timeline and budget, casework might be favored, but when the scope is more flexible, bespoke millwork elements add a personal, timeless feel.

Hybrid approach

Usually, a successful design is a hybrid of casework and millwork. For example, a storage module casework can be used, and custom millwork for a focal point like moldings, trim, or even a dramatic staircase.

RELATED: 4 Tips to improve cabinet shop drawings for manufacturing efficiency at companies

Wrapping it up

As such, it is essential for freelancers and architectural firms to achieve a balance between casework and millwork. A couple of them tend to have different benefits and cater to different design aspects functionalities and budgets. It is rather suitable for spaces with heavy flow because it is modular efficient and also budget-friendly. Millwork is that kind that requires custom elegance and durability; it usually becomes a hallmark of luxury interiors.

Yet knowing the strengths of each allows design professionals to gain from both casework and millwork when creating such functional yet visually beautiful spaces. Whether it was in crafting minute details of any custom millwork or an outfitting room with practical casework, rich possibilities now exist to transform interior spaces into lasting, powerful designs.

How Cad Crowd can help

Freelancers and architectural firms will eventually reach the point where they need to determine whether they need casework or millwork design. Good thing that Cad Crowd is here to help connect you with the best professionals in the field. Request a quote today.