The idea behind FEA (finite element analysis) is to predict how a design or structure responds to various types of physical forces and study the possibility of failure without using a physical prototype. Everything is done on a computer screen by combining 3D CAD technology and mathematical-based geometry analysis. It is a virtual simulation to visualize the effects of the usage environment on design parts, components, and assemblies made of any known material. Physical forces may include air pressures, water pressures, weights, vibrations, repeated impacts, dynamic loads, static loads, and temperature changes, to name a few.

Table of contents

Table of contents

- The purpose of FEA (finite element analysis)

- Push-button solution

- Common mistakes when hiring FEA engineering services

- Discover FEA with Cad Crowd

The purpose of FEA (finite element analysis)

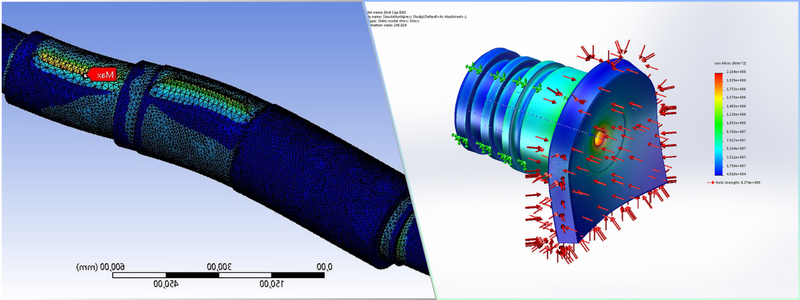

FEA services are meant to replicate both common/likely and worst-case real-life scenarios in the simulation. Under each scenario, the simulation offers comprehensive imagery depicting how a design responds and withstands physical forces until it deforms and breaks. The data is the foundation for discovering the solution that meets pre-defined design requirements like safety, durability, performance, and repairability.

RELATED: Product simulation and analysis: why it’s worthwhile

Since all physical products of any industry are affected by the conditions in which they are stored and used, they can be subjected to FEA tests. From the simplest small wooden carvings and complex crude oil pipelines to intricate blood transfusion devices and sophisticated microchips, FEA simulation engineering designers can determine the amount of stress loading under which their building blocks will fail. Manufacturers then use analysis results to improve their products.

Push-button solution

Several popular 3D CAD software packages come equipped with powerful FEA features. Many vendors still offer stand-alone software tools for each functionality, but integrating both technologies simplifies the analysis procedures. FEA simulation can only happen when the engineering design experts subdivide the CAD model into more minor elements in the form of a geometric mesh that represents the building blocks of the design. The “meshing” procedure is an automated process requiring manual inputs for refinements in specific design areas such as joints, connections, and edges.

RELATED: Finite element analysis costs, consulting company rates & engineering services pricing

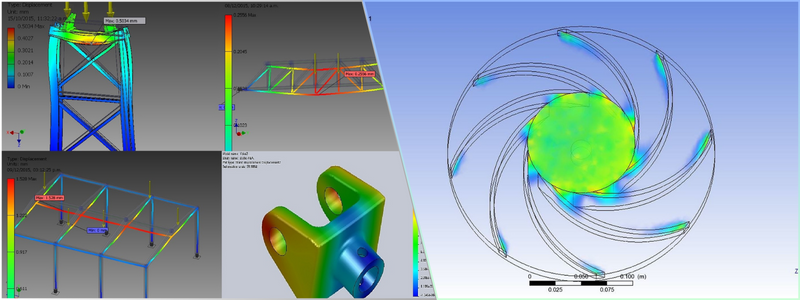

The simulation also implements a semi-automation principle where users determine design characteristics, including material properties and assembly features, before running the analysis. The mostly automated computational procedure should allow users to perform an FEA simulation. Users can create (or have access to) the CAD model and the appropriate software to activate the simulation program. Thoughtful analysts argue that the idea of a push-button solution can be dangerous, and they almost certainly have a point. Every design is unique.

Two comparably shaped products of different materials should display dissimilar behaviors even when exposed to the same physical force; two distinctive products built from identical materials will also exhibit unalike responses to matching environmental factors. The inclination to run an FEA simulation is irresistible, especially in a hi-tech world where the solution to the problem is just one click away. Any suggestion to imply that automation makes every analyst equal is nonsensical. There will always be design issues to discover and, thereby, engineering problems.

Considering the level of complexity in design intent, materials science, and the physics of structural deformation, FEA is by no means a trivial matter. Just because users can run the analysis does not necessarily mean they should. No degree of automation can make FEA analysis easy, let alone accurate. More importantly, the results of the FEA simulation are approximate at best. They are only as accurate as the engineers determining the design constraints, materials’ parameters, and load thresholds. Take a stress analysis as an example.

RELATED: Product testing and validation: the role of CAD simulation services for companies

Among the first things to define are the types, strength, and direction of strains exerted on the entire model during a typical usage scenario; specific criteria, such as the forces acted upon welded or glued connection as well as the cumulative effect of dynamic and constant loads, are determined next. To come up with realistic approximations, users must input multiple assumptions into the software:

- Specific loads are considered likely usage conditions, while others are worst-case scenarios. All have varying degrees of intensity. Some loads only occur during the product assembly process.

- Every material acts differently when exposed to external forces. Part properties, including thickness and length, will affect the material’s tensile strength.

- Points of connection in the assembly, such as glued edges or welded parts, have different boundary conditions from solid blocks.

RELATED: What are CAE engineering costs, company consulting rates & services pricing?

Users must have access to an accurate database defining materials’ known characteristics and behaviors under stress, loads, heat, and pressure. In any case, a successful FEA simulation relies on at least the following complex steps:

- Assessment: make the correct assumptions and ask the right questions to the software

- Validation: ensure the software is mathematically precise enough to generate a workable solution

- Interpretation: understand the results and translate the information into product performance data

Software developers and vendors keep on improving accuracy and interface to make the tools more reliable and easier to use. Users still need professional credentials to effectively and accurately utilize the analysis.

Common mistakes when hiring FEA engineering services

FEA is a powerful computational tool to simulate the almost limitless possible deformations in structures as it is exposed to physical forces. It was once considered a domain exclusive to expert engineers and supercomputers. Still, thanks to technological advances and market competition that drive computer prices down, FEA is easily accessible by 3D artists and CAD users anywhere.

RELATED: What are CFD engineering rates, consulting services costs & company pricing?

In any case, freelance finite element analysis & FEA engineering services exist mainly because only some people are qualified to run the analysis and interpret the results. The much-debated concerns over the democratization of FEA are not entirely baseless. Companies currently looking to outsource product analysis to external FEA consultant services should not fall into the trap of such democratization, leading to the following mistakes:

Incorrect Credentials

For most people, FEA and all its capabilities to predict the structural behaviors of products or materials are almost magic. It was once a black art practiced only by the most educated engineers. Since the rapid development and adoption of CAD technology, FEA has gradually made its way into the computers of typical 3D artists and casual users. Both the pre-processing and post-processing steps are mostly automated within the CAD interface. Familiar menus make operation as easy as it can be.

One of the most significant issues with democratization is that entry-level engineers and 3D product modeling services feel qualified to offer FEA services. Widespread adoption might be a good thing in other technologies, but there is a real danger in hiring a person with incorrect credentials to perform FEA. While most modelers and junior engineers probably have access to the FEA simulation program from their CAD software, they are not supposed to practice the analysis at a professional level.

RELATED: CAD vs. CAE: what stage of product development is your business in

They can run the simulation and come up with approximations. Still, at the moment, CAD software vendors need to offer a reliable mechanism to warn users that the generated results might be wrong. Even if some software packages do provide warnings, there are no easy-to-follow procedures to discover the underlying issues and fix the problems. The most effective workaround is to consult time-tested engineering experience and knowledge.

Wrong tools for the job

Nearly all major CAD software packages come with structural analysis features ready to deploy. 3D Modeling design firms specializing in 3D design and modeling may think that expanding the business into FEA territory is a good idea because the software has built-in features. The specializations do not fall under the FEA category. Companies or individuals looking to hire FEA services must avoid the firms at all costs.

RELATED: How computer-aided design (CAD) services are used by engineering firms

Integration between modeling and analysis is good, but only when the users are qualified to operate both. Many of the built-in features are stripped-down capabilities of the full-fledged FEA software. The features are not necessarily destructive but tend to omit many customization options in favor of automation. In other words, the analysis generates results by removing actual engineering inputs from the equation.

No modeling option

Firms or freelancers may rely entirely on the included features (in the CAD software) and automated functions. They have a model from the client, run the FEA simulation, and deliver analysis results within an hour. Every client needs to understand that a slight deviation in dimensions, load points, and angles can change the results to a great extent. Depending on how they were built in the first place, some models might be sensitive to minor variable alterations.

A typical stress analysis on a model may take 10 minutes or so using powerful computers. However, a true FEA professional will build dozens (if not more) of model variations to determine the proper constraints and structural behaviors based on in-depth engineering knowledge of material properties. Until the model is rebuilt multiple times with perturbations, it isn’t easy to accurately predict its structural behaviors. Repeated simulations with varying engineering parameters and boundary levels are indispensable for accuracy.

RELATED: Freelance aerospace engineering services, cost, rates, and pricing for companies

Lack of documentation

FEA documentation must provide enough details to allow clients to reproduce the results. Every project has documentation requirements but should contain at least model identification, source geometry, model assumptions, simulation parameters, and validation. Although the focus is on the results, proper documentation ensures the model and design remain traceable from the client’s standpoint. FEA aims to visualize the structural behavior of a model, and the client must be able to gain clear insights from the analysis at the end of the process.

Assigning the task of FEA simulation to an unqualified person (whether as a cost-saving measure or due to an uninformed hiring decision) can be hazardous instead of advantageous. A qualified consultant has real-world engineering experience, specifically in the field related to your models or products. FEA enables companies to solve complex structural design problems, but only if the consultant performing the analysis has a working knowledge of engineering practices.

RELATED: Top 101 engineering and mechanical design firms in the United States

Discover FEA with Cad Crowd

Avoid common mistakes and achieve optimal results for your projects. Equip yourself with knowledge, sidestep potential missteps, and contact us for guidance. Contact us today to hire the best FEA expert for your company.