The evolution of engineering drawing is a rich historical trend, from the ancient Egyptians who used corner rulers to ancient Greece where stylus and quills were the tools needed to make inscriptions. The invention of protractors, adjustable corner rulers, radiograph pencils, and the discovery of various projection objects in the late 18th century led to the revolutionizing of engineering drafting. Currently, the modeling of products and processes is undertaken mostly by means of computer-aided systems.

This trend started with the invention of programming languages that created reusable routines. These routines were saved and stored as libraries, and every newly written program was able to assign names according to their functions. The higher the number of routines in a library, the higher the functionality. Then there was the drive to make these libraries larger, by writing reusable programs.

With the growth of routine diversity in the libraries, programmers began to lose track of what was available, so a new way of reorganizing these routines and grouping them in purpose-oriented libraries was formulated. Then a new type of program was needed that would allow the use of as many of the library routines as possible with as little effort as possible.

These new program types were initially called applications (or application software). In all these historical trends of graphic representation, the goal remained: the establishment of a language that communicates information in technical and graphic terms from one individual to another.

Engineering modeling today is a result of all these trends, and with the emergence of the computer-aided design (CAD) software in two dimensions (2D) and three dimensions (3D), there has been a shift away from the traditional style of drafting. The main difference between 3D modeling design and 2D drafting is that mechanical equipment is modeled, rather than drawn. 3D modeling has indeed become the standard tool used in engineering designs, especially in the mechanical engineering field.

Engineering Model Presentation

3D modeling can depend on many different things, with the possibility of the representation even changing during the use of the model. There are two main types of model presentation in engineering: the internal and external representation. The internal representation deals with how a given design is presented within the software or computer.

It’s highly dependent on design implementation. The external representation, on the other hand, is a dynamic representation, which is highly dependent on the values of the data that are stored as libraries on the CAD software used for the modeling.

These representation styles are interrelated, in that from the internal representation we can distinguish between the data of the design and the available knowledge (model invariance) about the design. External representation is therefore highly dependent on internal representation.

The data of components for modeling is distinguishable properties. Model invariance, on the other hand, can be of two subtypes: metadata and programs. Metadata describes algorithms, operations on either a placeholder or real data. It is implemented using data structures on a 3D modeling computer software.

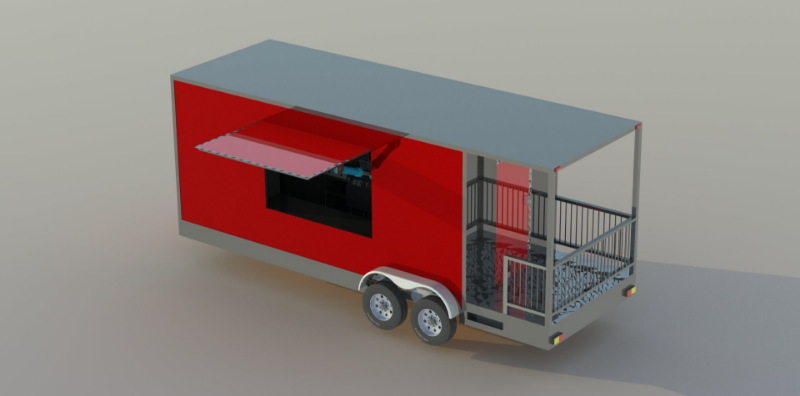

3D modeling is a mathematics, systematic, and graphic representation method used for producing a digital representation of an object, through CAD software. A model reflects the most important traits of whatever is being modeled. It supports the understanding of design in its simplified form and is mostly a finite representation of components and processes, so there is room for modifications.

One interesting advantage of 3D modeling in mechanical engineering is the certainty of properties and the behavior of components. Certainty is a result of the relevant data acquired and stored in the software, eliminating guesswork in design and implementation. For example, a bolt and a nut with the same diameter, pitch, and number of threads can easily be determined using the data available, and it becomes possible to predict with certainty that the bolt will fit into the nut.

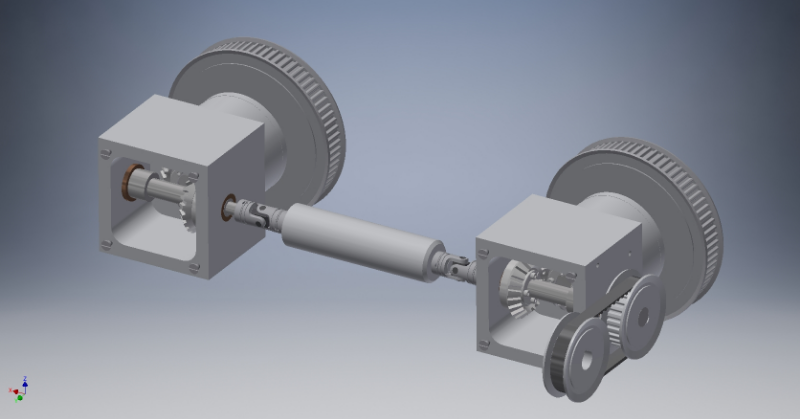

Another application of 3D modeling is in the process of problem-solving. Its uses in mechanical engineering can be found in product modeling, like the analysis of products, specifications, rendering, and application of materials, not forgetting prototyping. It also finds its place in mechanical machine designing, which includes part and assembly modeling and automotive and solid modeling. Maintenance and service routines done on mechanical products also use 3D modeling to identify the areas in need of repair.

Without models, it’s impossible to analyze, communicate, improve, or even solve problems. 3D modeling can optimize the control of these models, so it is crucial for efficient designs. 3D modeling has become indispensable in design situations where products or processes are developed for applications that have little or no practical data, such as spaceships and their trajectories.

Benefits of 3D Modeling in Mechanical Engineering

The benefits of computer-aided design software are limitless. Thinking on these advantages will probably make you wonder how the likes of Karl Benz and Nikolaus Otto were able to create technical drawings of their mechanical engines so successfully without the use of the computer software available today.

But if you have at least dealt with traditional engineering drawing, you’ll have an idea of how much work is put into it, especially if an inaccuracy can lead to an entire system failure. Some of the benefits attached to mechanical engineering services are as follows.

-

Design Communication

The primary aim of graphic representations in mechanical engineering is communication. 3D modeling enhances a greater communication of ideas, not just to engineers but to non-engineering personnel. Over the past several decades, there has been a gap in interdisciplinary communications in design. The engineer finds it difficult to explain geometric calculations to the marketer, and the marketer in turns finds it difficult explaining it to the consumer. With 3D modeling, the gap is bridged.

Visualization is also made possible and detailed internal designs are efficiently adhered to by everyone involved in the design process through 3D modeling. With a great deal of communication, the forecasting of data and a proper analysis of anticipated deficiencies can be tackled right in the design software.

The built-in user interface in 3D modeling software allows individuals with no mechanical engineering experience to understand product designs without the help of a specialist. Animation in 3D modeling also helps mechanical engineers and clients in observing the process of designs.

-

Easy Integration

A standard 3D modeling software gives the user the ability to export and import files for components, layouts, isometric drawings, and part assemblies. For designs that cut across fields of engineering like electrical engineering, the mechanical engineer can easily send the model to the electrical engineer, who can then load the design on his own 3D modeling software to finish it off.

The exact way in which the integration is done is a question of secondary importance. The purpose of integrating two or more models in 3D modeling software is for simultaneous design applications. This cannot be achieved in conventional modeling methods that pre-existed 3D modeling.

-

Flexibility

One of the ills of having to represent mechanical systems and components in the traditional form is the fact that they are subject to change. In the traditional drawing system, these changes can result in a complete overhaul of existing representations. With 3D modeling, changes can be incorporated easily into the CAD software, where values or variables can be changed. It’s also possible to replace components or change the way these components interact or function.

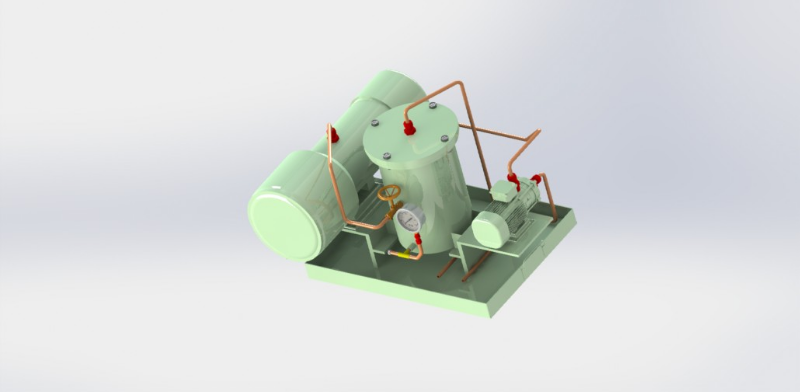

There exist multiple views on the design windows that enable users to either view a model at any angle or to magnify it. In designs like flow pumps and heating systems, virtual testing can be carried out, where minor faults and component incompatibilities can be easily detected.

Most faults in engineering designs are detected at the production or implementation stages, but with 3D modeling, this can be done in the design stage. In times past, a little change in a design would lead to an overhaul of existing drawings, but with 3D modeling, changes can be easily implemented with a few clicks of a mouse.

-

Modeling for Reuse

The ability for a design to be reused is an important characteristic of computer-aided design software. Most of the time, the benefits that arise from the reuse of a design are either unknown or simply taken for granted.

For example, in the ratio between the time expended in creating a design and the time expended for this same design to be brought to life, the lower the ratio, the better the economic efficiency of that design. The modeling of engineering designs should ideally be instantaneous, with its use unbounded by time. But in the real sense, the fastest way to model a design is to replicate another design. 3D modeling makes replication quick and effortless.

-

Incremental Development

Incremental development is the testing of extensions to designs, ensuring the extension works well in the process. With 3D modeling, minor abnormalities in extension and modification can be easily detected. For example, in mechatronics and automation, designs can be built in the form of blocks. With simulations, each new block added to the design can be tested for faults, deficiencies, and compliances to universal standards.

-

Better Actualizations

Actualization in engineering design is viewed as a time-dependent accuracy. In mechanical process control, for instance, if what is to be designed is changing with time, 3D modeling means the modeled design can be updated or actualized to fulfill its intended purpose as these changes occur. For dynamic environments where it is beneficial to work with the most recent information, good design actualization becomes important for better design outcomes.

In traditional methods, a design model can expire if there are changes to be made or if new information about it becomes available. New scientific discoveries can also render a model outdated without good actualization. 3D modeling provides the designer access to the actuality of the design for two purposes: to determine whether a given model needs to be updated or to determine which of two versions of the model is more recent.

-

Design Compatibility and Standard Compliance

With the existence of international codes and standards in all engineering fields, compliance with these standards in the design process is made easy with 3D modeling. The software is usually loaded with standards like BSI, ANSI, ISO, CSN, GB, DIN, etc. In traditional graphical representations, the engineer will have to model components and test them to know if they follow these standards.

3D models, because of these pre-loaded standards, are termed to be universal. A design can be created in a different country or in a different language than its intended market and it will still be universally acceptable.

-

Surface Geometry and Material Data

With material data, the reaction of components to effects like temperature, stress, torsional forces, and fluid flow can be easily determined. The materials and components have their specified surface features, which gives a live view of both the interior and exterior components. The factors to be considered when mating components are preloaded within 3D modeling software.

The designer doesn’t have to worry about clearance or flow process. 3D modeling systems also have indicators that inform the user of any component incompatibilities. For example, using a plastic valve where a metal valve is required. Material data like the temperature profile of the plastic valve may not allow this, resulting in an indication warning that the component being used is not compatible with the design.

-

Time-Saving

A traditional representation in mechanical engineering takes time. From proper line sizing to the calculations of projections, elevations, and representations of different views, a complex mechanical design will take days to complete in the traditional style. All of this can be done in a matter of hours using 3D modeling software.

When considering the time needed for a design project, it goes beyond drafting the graphical representation and extends to the presentation and explanation of the designs. In situations where a design is intended for mass production, a 3D model then reduces production time. The transportation of these designs is instantaneous with the help of the internet, also reducing the time needed for the delivery of traditional engineering drafts.

-

Cost Saving

Where there is time-saving potential in the design process, there is automatically cost savings associated with it. With standard built-in components, the guesswork is eliminated. This is beneficial to the engineer in terms of cost because there will be a relatively low amount of trial and error. Cost and efforts are the biggest resources that any mechanical engineer can save on by using 3D modeling. The provision of standard designs and templates helps the designer in saving time as they fast-track the whole process.

-

Higher Aspect Ratio

When a 3D object is viewed from different angles, some of the details observed can appear to be the same but most of these components will look different. In the production of a mechanical component or machine, there is a need to know all the dimensions, shape, and materials of the object. 3D modeling makes this easy for the designer, by letting her choose to work with a prominent quantity of dimension, leaving the software to automatically set other dimensions in place.

-

Easy Documentation

In 3D modeling software, there are preloaded documentations of standard parts of components like names, geometries, and dimensions, as well as a bill of engineering materials. Documentation is a very important part of any design process. In traditional drafting, the documentation is manually created.

But with 3D modeling, a detailed, foolproof documentation is created by the software. These documents can be shared, stored, and easily duplicated. The system automatically records each component or material used in a register, thereby automatically preparing a bill of engineering material without the aid of the designer.

-

Prototyping

Prototyping is an initial stage of design testing. Creating mechanical designs is one of the many steps in bringing ideas into reality. After the design stage, prototyping is done. In fluid mechanics, for example, different prototyping stages occur for testing pressure, fluid flow, torque, etc.

The traditional method requires that designs should be drawn up and a physical prototype made, but with 3D modeling, an accurate prototype can be formed and subjected to standard testing easily within the CAD software.

-

Material Rendering

With 3D modeling, the appearance of a design can be determined at the designing stages. This gives way for valuable input from production and potential buyers. For example, automotives designed by CAD services with proper material rendering can be accessed by the sales and marketing experts, who then make valuable suggestions regarding the choice of materials, the shape, and the color resins selected.

-

Design Precision and Quality

With almost a million standard templates of mechanical components, 3D modeling ensures precision and quality in designs. In a situation where a new component is to be made, it can be saved as a template for future use. A template can also be imported from external sources. This helps to save time and increases the quality of production.

-

Portability and Duplication

Portability is the ease of making a model usable on various platforms and is made available with 3D modeling. For duplication of designs, 3D modeling comes in handy as designs can be easily redrawn or duplicated by the CAD software suite.

-

3D Molding of Parts

The use of computerized numerical control (CNC) machines is integrated into 3D modeling, especially in producing prototypes of metallic parts. 3D models of these metallic parts are made in the form of molds and then the plastic injection is carried out to form these parts.

-

Facilitation of Design Process

In working with 3D modeling, parametric constraints can be applied to design components, with the actual data of these components stored in the algorithm of the software. The stored data prevents certain critical features of these components from being tampered with.

For example, in the spacing of pressure valves, if it’s standard that a certain model of valve is to be 4 inches apart with a specified angle, the model can be redesigned in terms of surface geometry, material rendering, and projections. While all these changes are being implemented, the predetermined constraints are maintained by the modeling software.

-

Knowledge-based Distributed Decision Making

3D modeling software doesn’t only rely on the use of knowledge and intelligence but recommends outsourcing them directly into where they are needed. The outsourcing of intelligence into the components of design software lets the engineering society at large increase the flexibility by activating the autonomy of models.

Indeed, intelligence is built upon knowledge. With 3D modeling, this knowledge is incorporated into models because knowledge is built upon information, and information is made into data. A designer with little or no experience can get information from knowledge-based data available in the software libraries.

If you’re in need of mechanical engineering design work, Cad Crowd can match you with an expert freelance CAD designer to help you complete your project. Send us some info about your design needs and we’ll provide you with a free quote for the cost of the design services. Whether you need help with a short-term or long-term project, we have the right designer for you.

If you’ve got an idea, but aren’t sure where to start, let us do all the heavy lifting for you. Host a design contest and watch as talented freelance designers from around the world submit design plans for your project. You pay only for the winning design but get to keep every submission.