Most businesses revolve around creating new products and finding people who are interested in selling them. Product design services are a part of almost every industry, which means creating prototypes to show company professionals and investors and creating the product itself. Once your business has a solid idea about what they want to be created, jumping from an idea to a physical object can be a difficult leap.

Table of contents

That’s why manufacturing services are so important. Manufacturing services involve taking an idea and turning it into that real product. Some firms hire entire in-house teams for parts of the process. Still, even if you have an in-house product designer or prototyper, creating your in-house manufacturing plant is not practical unless you’re a very large business.

Even then, many huge businesses still choose to outsource much of their work to manufacturers because it is more cost-effective to do so. Unfortunately, finding a good manufacturer or service such as rapid prototyping isn’t always easy, but with careful attention, you can find one that you can trust for your products for many years to come.

If you’re looking for manufacturing services, you may be wondering what sort of prices you can expect. This is complex to answer and depends on the scope of the project and materials as well as the price of an expert’s time. A quick answer is somewhere between $100 for a simple rapid prototype to $1,000+ for stainless steel machining.

To narrow down what the price for your particular project might be, you need to know what sort of manufacturing services you need. This article is designed to help with that.

Quick Pricing Snapshot

| Manufacturing Service | Hourly Rate | Per Project |

|---|---|---|

| Rapid Prototyping Services | $65 – $125 | $50 – $1,000 |

| 3D Printing | $40 – $125 | $300 – $1,000 + cost per item |

| Injection Molding | N/A | $1,000 + cost per item |

| CNC Machining | N/A | $1,000 + cost per item |

| Supportive Assistance | $28 – $60 hourly | N/A |

Types of Manufacturing Services

There are many types of manufacturing services out there. Not only is it separated between prototypes and runs of finished products, but also by what sort of process will be used for the service. A 3D printed product will require a different machine and have a different price compared to a product made by a direct metal laser sintering service.

There are over a dozen different types of manufacturing services and all of these have different costs involved. Let’s briefly look at some of the different services available and what they do.

Rapid Prototyping

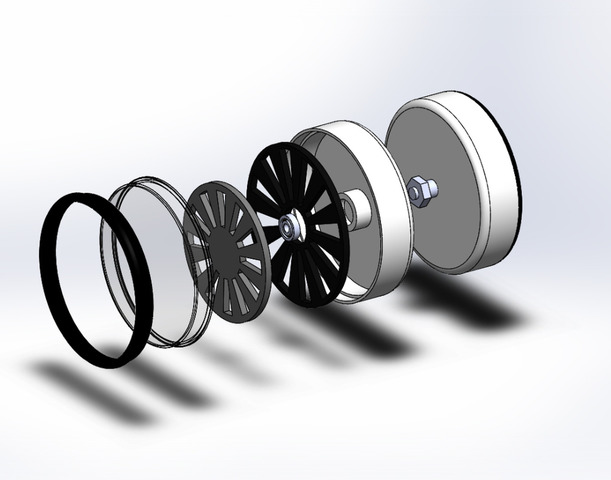

Freelance rapid prototyping involves the creation of a scale model or detailed 3D model of a potential product. The goal is to quickly transform an idea into a potential product that can be tested, experimented with, and changed into its final form.

There are several different forms of rapid prototyping itself, including different fidelity types and different stages, but the idea is still roughly the same—the first prototype for your product.

This is an essential step that should not be skipped. Even if you have a clear idea of your product and know what you want, a prototype is necessary to test for safety, show potential investors, advertise, and show manufacturers. A detailed model can help smooth the process, and help avoid embarrassing mistakes that will need to be redone.

3D Printing/Manufacturing

3D printing services involve creating your prototype and can even be used for a small run of finished products. 3D printers can create various products, but they excel at prototyping, individual parts, and figurines.

If you just need a small run of items, 3D printing is also a great option because it is much easier to adjust a 3D printer than it is to change an entire factory.

3D printing will vary in price as there are several ways to use the technology, including Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), Stereolithography (SLA), and Fused Deposition Modeling (FDM).

Which one you use will depend on whether you need metal parts or plastic and what finish you want the final product to have.

Injection Molding

Injection molding and casting services are a common manufacturing technique used when the same product needs to be replicated thousands to millions of times. It produces low scrap rates, and each product is likely to look very similar to the next one, which is ideal for branding.

It can be done in a variety of different material types but typically has higher costs due to the price of the tooling needed for the product, as well as the cost of making a digital prototype for the manufacturer to refer to.

Injection molding is an expensive starting point for the prototype due to the cost of creating a mold but can be very cost-effective if you need a lot of the product or plan to make dozens more runs of the same product over the years.

CNC Machining (Milling / Turning)

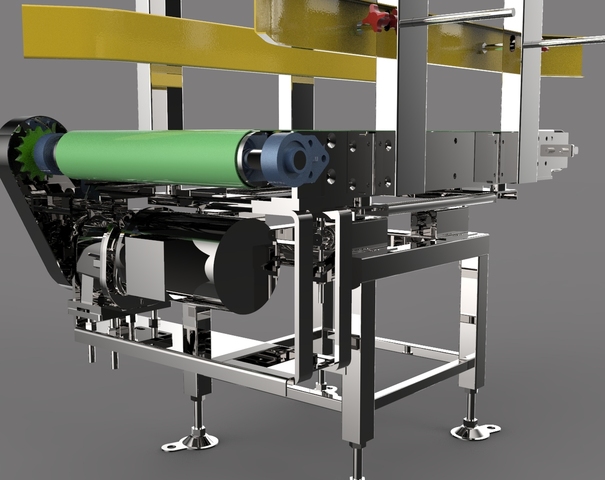

Sometimes, rather than adding metal or plastic to create a product, plastic or metal is instead removed to develop the product. CNC machining, both milling and turning, is one such method. CNC machining programming involves complex machinery that can cut different products, add holes for screws to go into, or cut glass into the desired shape.

CNC machining is useful when it’s easier to trim something down to size rather than build it up.

Other Manufacturing Services

Just as there are services to plan and make the project, there are also services to help make this process easier. Direct digital manufacturing services (DDM), for example, can reduce the expensive tooling process by using additive manufacturing in a whole new way.

There are also services to help connect you with the right manufacturer and help you pick out which type of manufacturing you need.

Services like this may save you time and money by helping you navigate the market and get what you want – a finished product. Now that we’ve taken a look at the different types of manufacturing—it’s time to look at the cost of the various technologies.

Prices for Manufacturing Services

If you’ve narrowed it down to which services you need, the next step is to get a rough idea of how much each service costs. Here’s a quick overview of general pricing for each type of manufacturing service.

| Manufacturing Service | Hourly Rate | Per Project |

|---|---|---|

| Rapid Prototyping Services | $65 – $125 | $50 – $1,000 |

| 3D Printing | $40 – $125 | $300 – $1,000 + cost per item |

| Injection Molding | N/A | $1,000 + cost per item |

| CNC Machining | N/A | $1,000 + cost per item |

| Supportive Assistance | $28 – $60 hourly | N/A |

You can use the above chart to help give you an idea of costs, but nailing it down the specific pricing will take a little math. Here’s how you can get a better idea of cost.

How Much Do Rapid Prototyping Services Cost?

Rapid prototyping ranges between $65 and $125 for an hourly rate. The cost per project will vary depending on how complex the project is, whether the prototype is a physical model or a 3D data file, and how many renderings are needed if it is digital.

A small project such as a figurine with no moving parts might only cost $50 to have a rendering done, whereas a product requiring many details or mechanical engineering services to prototype may run much more.

If you need physical prototypes, the number and what material you choose for them will play a role in how much it costs. In general, the more complex or expensive a product is, the more you can expect the project to cost to complete.

How Much Do 3D Printing Services Cost?

There is a broad range in pricing 3D printing services due to the sheer number of different types of 3D printing available. How much it will cost you depends on how big the item is you want printed and how many of them you want.

Often, the cost of 3D printing is decided by how much material will be used. $0.02 to $0.10 per cubic centimeter is a general rule of thumb. A plastic cardholder, for example, might cost $70 if made out of plastic, or $150 if made out of stainless steel.

Small parts might cost $12–$14 per piece if the part is made out of cheap plastic, but again, the price can climb if made from nicer materials.

Compared to injection molding and other techniques, this is very expensive. A few prototype samples can be sent to manufacturers for reference, testing, or for use at trade shows could run several hundred dollars. Still, injection molds play an important role in the manufacturing process.

3D printing is extremely fast and will allow you to run off just a few at a time—even one if you only need one. Even if the price of that single item is costly, it can still be more cost-effective than a run of 10,000 products when you only need one for testing.

How Much Do Injection Molding Services Cost?

Typically, manufacturers don’t charge an hourly rate but do charge for the mold needed for your product. Depending on the type of mold, these generally cost between $1,000 and $80,000. After this, they charge for each item created. Depending on the number of units, an item can cost less than a penny to make each, or several dollars, again depending on what it is.

As an example, if you needed a mold for a small 44m long part made out of ABS/PC plastic, and you wanted a run of 5,000 pieces, it might cost you $1,000 for the mold, and $0.45 for each piece. The total for this run would be $2,250.

RELATED: 7 Things to Keep in Mind When Thinking about Manufacturing Costs

The price of the same part in metal would be vastly more expensive. The cost would be lower per piece if you ordered 100,000 of them instead of 5,000.

If you need related services, such as preparing a CAD drawing for the manufacturer or how much it would cost to find a manufacturer for your product, see our “Supportive Assistance” Section.

How Much Does CNC Machining Cost?

Freelance CNC programming does not typically charge hourly but per piece. Each unit can cost anywhere between several hundred dollars to as little as a penny, depending on the build time, materials, and the part size.

There is also a tooling fee, which covers both the price of adjusting the machines for your project and the inevitability of tools breaking. The harder the material being cut, the more likely the tools are to break, and the higher the price will be.

Quantity is usually the biggest determiner of the price here, with larger orders getting better deals per piece. As an example, if you order 25 products of a very simple design, it might cost you $4 per part because you only ordered 25. However, a hundred units of the same product could be as little as $1 per unit, saving you a lot of money per piece.

How Much Does Supportive Assistance Cost?

Tracking down a manufacturer for your product, knowing which type of manufacturing is the right choice, or even who to choose for creating the prototype can eat up a lot of a project’s time. It is often quicker and easier to hire someone to find the right people for you.

Consultants and matchmakers exist in the field to do just that, and their prices are relatively low compared to other people in the industry. They are typically available for $28–$60 per hour.

There are a lot of different factors that go into the pricing of manufacturing services, and how much your project will be is likely to be as unique as the product itself. While this should give you a general idea of pricing, you’ll need to get quotes from manufacturers to have a better understanding the total price.

Finding Manufacturers to Help with Your Project

A ballpark price is excellent to help you get a general idea of pricing, but it can never be exact due to the unique nature of your product. Every product is different, and even one figurine might vary in price depending on the number of products produced and the quality of the materials.

The next step to nailing down your price is to find an industrial design service to work with you on the project and to get a quote from them. You can compare their pricing to your ballpark and gauge whether they are overcharging or suspiciously cheap using your ballpark as a reference.

If you’re not sure where to look to find freelancers, there are a range of websites out there to help you. Here are some of our top recommended websites and what they can do to help get you started.

Cad Crowd

Cad Crowd offers help in all of the services we just talked about, including CAD design services, finding manufacturers, and everything in between. They can not only help you with your prototype but make recommendations on material and manufacturing type and connect you with the right manufacturer.

This website is possibly the best place to start because they offer start-to-finish assistance with your product. They also provide more security and privacy than many other websites. Their 2D CAD drafting freelancers are already screened for quality, which can save money by reducing costly failed projects.

Cad Crowd is ideal for new businesses that don’t have a familiar manufacturer yet. They act as gatekeepers to sort out low-quality manufacturers from the good ones, but they’re not the only option.

Networking

Outside of websites like Cad Crowd, finding manufacturers takes some work. You can find rapid prototypers on places such as Freelancer.com, and they may have recommendations from there, but it’s not as simple as looking a manufacturer up on Google.

It’s also risky to choose a manufacturer sight unseen and send off your schematics without asking questions. An unethical manufacturer could steal your idea, or you could get back a misprinted, low-quality product that you can’t sell.

That’s why asking for recommendations is essential. Your network can help you by sharing their own experiences or recommending a manufacturer they have worked with on past projects.

Alibaba

Alibaba has manufacturers on the website. The manufacturers usually offer prices on a per unit basis, with a set number of pieces as the limit. Alibaba can help you get a clear idea of the cost of your project, and you’ll be able to find some manufacturers, but check carefully that they have the quality you are looking for.

Alibaba doesn’t screen firms for quality, and it can be challenging to discern the legitimacy of the businesses listed on the platform.

Important Questions to Ask

When choosing a manufacturer, it’s important to ask many questions before you submit your order. You need to ensure that they can do the work presented to them and that you won’t be left with poorly made products. A few questions you should ask include:

- What kind of materials do you use? Do you specialize in any particular kinds?

- Do you work with smaller companies or do small runs

- What sort of tooling can you use?

- Do you have any references?

Follow up with any references and ask them how they liked the product, what the quality was like, and how professional the manufacturers were. References are a great way to help determine whether a manufacturer will work well with your needs.

It’s also best to get quotes from a minimum of 3 companies before making a decision. By getting quotes from more than one company, you can verify that your ballpark is accurate, and also see what the average price is. If one company has much lower pricing than the others, or is more expensive, you’ll know that their pricing isn’t average.

RELATED: Engineering and Product Design Advice for Mass Manufacturing Services

Use extreme caution before using a very cheap manufacturer. There’s often good reason why they are inexpensive. There’s also no reason to use an extremely expensive manufacturer when a lower priced one can offer the same quality.

By asking a lot of questions and researching manufacturers as much as possible, you can avoid the expensive mistake of ordering hundreds of a product that you can’t use.

What to Have on Hand When Getting a Quote

The more information you have for the manufacturer, the more accurate a quote you will receive. You may want to have on hand a data file about how the product is to be made, a list of materials needed, and how many you will want at a very minimum. If you only want a few hundred or a thousand, expect the prices to be higher per item than a product run of many thousands.

Before handing any information about your product, or a reference prototype made by a prototype design service, ask for a non-disclosure agreement. This protects your idea from being stolen by larger companies looking to make a profit off of your ideas.

If a manufacturer doesn’t want to sign an NDA, be very cautious about handing your idea over to them. There’s little to nothing stopping them from taking your idea without such an agreement.

Conclusion

Getting the manufacturing services you need is a multi-step process, and it can be confusing if you’re not used to how the manufacturing world works. The costs associated with the process is also decided on an individual basis, and figuring out how much you need to set aside for the project can be equally difficult.

Fortunately, by determining how much of a product you need, your materials, and what sort of manufacturing process the product will be created with, you can narrow down the costs to get a good idea before you ask for a personalized quote.

Cad Crowd can connect you with manufacturing services, CAD services, and freelancers that are experts in all types of manufacturing. If you want to connect with us, get a free quote today.