When you have your inspired idea for a new product, you’re thinking about all the problems it will solve and the features in design magazines it’s going to get. What probably doesn’t cross your mind is how much getting to that point is going to cost. Whether you’re an old hand at bringing products to market, or this is your first time looking into the process, knowing how deep your pockets will need to be is vital. If you don’t get your cost estimations right, there will be some severe effects on the overall budget.

A big chunk of your investment into your product will come at the designing and prototyping stage. This is where a lot of money will get spent while no cash is rolling in and knowing the price of things ahead of time isn’t always easy. That’s why doing a price cost estimate (PCE) is essential. Get your cost estimate too high, and you risk affecting your positive relationships with your suppliers. A cost estimate that is too low will quickly eat into your profit margins and even wind up with you making a loss per unit.

Here, we’re going to explore:

- The different theoretical approaches to cost estimation

- Why understanding these theories will make your PCE more accurate

- Different factors that affect your costs

- The processes you need to follow that will cost you money

- Things you need to consider when estimating the costs of your product

Ultimately, you need to know how much your product costs to make so that you’ll know how much to sell it for. Get the right price, and you’re on the way to turning a profit, so read on to make sure you know how to estimate your design and rapid prototyping costs.

Table of Contents

Table of Contents

Theories about price cost estimation

With so much money going into designing and manufacturing products, it’s no surprise that there has been plenty of academic research in the field. There are plenty of people who make a career out of estimating costs, and the Bureau of Labor Statistics has the role growing at 9% from 2018 through 2028, which is faster than average. There are two basic ways to estimate costs, and there are have been plenty of models and theories posited around them.

The quantitative approach to PCE

When a cost estimator uses a quantitative approach to their job, they look at:

- The design

- The features that the product will have

- The processes that will go into production

And they will use this information to analyze variables and resources that will be needed to provide a cost estimate.

Getting a quantitative cost estimate for design and prototyping isn’t going to be easy. This process is best suited to having a detailed product design in place. There needs to be a lot of information on hand to be accurate, although it will normally give you a very detailed picture of what you can expect your costs to be.

RELATED: How to hire a freelance 3D rendering service professional or remote firm

Although not well-suited to the initial stages of product development, it’s worth knowing about the process. Further down the line of your path to market, you can commission this type of estimate to make sure that you’re on track.

Taking the Qualitative Approach to PCE

Rather than just looking at the raw data about the project like in the quantitative approach, this method takes a look at previous projects and their costs to give an idea of what your project will cost. A cost estimator will have a database of projects and will look for similar ones in terms of:

- Materials

- Processes

- Design specs

And give an estimate based on past experience.

The data that you get is only going to be rough because it’s not based exactly on the product that you want to make. Particularly if you’re making something innovative or with lots of customized pieces, there might not be any reliable historical data to work with.

If you’re looking to make something that can use a lot of existing components and isn’t completely off-the-wall, yet haven’t gone much further than the idea and pencil drawing stage, a qualitative PCE can produce pretty reliable numbers.

Which One Will Work for My Project?

It’s going to come down to which stage in the design and prototype process you’re in as to which cost estimate method you choose to go for. It’s best to look at your costs early on before putting too much money into what you’re doing. Get too deep money-wise, and you might feel you’re committed without having an idea of how deep your pockets need to be.

Coming to the cost estimation party a little late? Once you’re into the product design service process and have a fair idea of what you’re doing and what you’re going to need, a quantitative approach is probably going to work well. Remember to look back at the money you’ve already put into the project at this point, too.

Being more prepared and thinking about costs early is going to send you down the path of a qualitative cost estimate. This is going to need plenty of research about past projects and also what’s already available on the market in terms of:

- Components

- Tools

- Materials

- Skills

Whichever method you go for, you can do the number-crunching yourself, or bring in a professional cost estimator, who will have access to industry databases.

How to do a price cost estimate

Getting a grip of your costs might sound rather academic and like a whole load of number crunching – and you can choose to go down that route – but you can do some initial research by finding out the costs of other projects. A valuable source of information about past projects similar to yours is to investigate design firms and freelancer sites. Looking at how much a freelance designer or prototype engineer will charge for their services is an excellent way to see what’s involved in getting your project rolling.

It’s going to be an ongoing process rather than a one-time thing. Think about the process of buying a first home. First, you get an idea of how much money you can afford to spend each month; then you find out how much you can borrow, look at what that can buy you, then find out all the extra expenses like fees and taxes. All along the way, you’re revising what your costs will be. Doing a PCE for your product idea is similarly not a one-off activity but something you should be returning to at every stage to plug in the extra information that you garner.

Estimating costs at the design stage

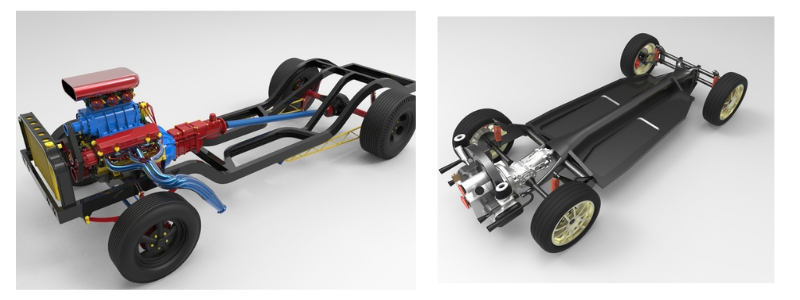

Your decisions early on in your design and prototyping will affect costs massively. At this stage, crucial decisions are being made that will dictate everything else moving forward. You’ll need to choose priorities such as product quality vs. product cost at this stage. Things to take into consideration while estimating the cost of your design are:

- Design module availability – This means whether the pieces that you need to realise your design are on the market and how easy they are going to be to procure

- Manufacturability – Are there tools, robots, and factories out there that can make your product?

- Extent of customisation – You probably don’t want to be using all off-the-shelf components for your product, so you need to understand how many things will be custom-made for you and how complicated those pieces are

- Design complexity – The more moving parts, joints, circuit boards, pieces of software, etc. that you need, the higher your design and prototype costs are going to be

These should be tackled when putting together your preliminary design. A good designer can conceptualize your product while keeping an eye on costs, although it’s up to you to set parameters and priorities. By drawing on the skills and knowledge of your designer, you’re using the qualitative approach to estimating your costs.

Costs with your preliminary design

Your preliminary design will be a test of the feasibility of your idea; the first time you check that things might be able to work together. You will find out a lot of information at this stage that will start to bulk out the cost estimate for your prototype and your product.

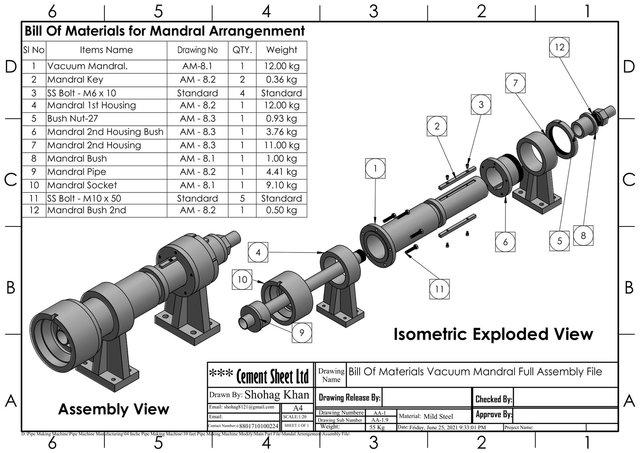

Once you’ve got your preliminary design, you should have an idea of:

- The components that you’re going to need

- How complex your product will be to produce

- The materials that you can use with your product

And this will go into your Bill of Materials (BoM). We’ll go into more details about this a little later.

Schematic design or 3D model stages

Depending on what you’re making, you’ll need to get a more detailed design in the form of a schematic for electricals, or a 3D model for something like a toy. This is when you start to get more details and can maybe start moving towards a quantitative cost estimate – you’ll have more specific information about what you will need rather than generalizing. Here’s where the details about materials will get drilled down, and you will understand more about the processes you will need to employ. It’s also when you will have the specifications for your prototype laid out, so the cost of producing it should start to crystallize at this point.

What you’ll have at this point

Once you’ve gotten through the design stage, you will have begun racking up a fair amount of costs. If your early price cost estimates include sufficient detail, you shouldn’t be surprised at your investment up to this point. Along with a pile of invoices and expenses, you will also have a Bill of Materials (BOM). The BOM is a list (often a spreadsheet) of everything you’re going to need to produce a single unit of your product. If the BOM is accurate, then the document will have started with some general ideas and morphed into a list of every screw, every amount of clue, each transistor needed.

To get a cost estimate for your prototype, you can start by adding together the price of one of everything on this list. Add to that the cost of your prototype engineer and you’ve got a reasonable idea of how much you need to spend on your prototype. Just remember, everything you’ve spent up to this point also goes into the final costs, too. You should also be looking at Minimum Order Quantities, even before your prototype. You may only need two LEDs for your toy, but the specs you need might mean you must buy at least 10 units from the manufacturer. Look at your purchasing needs early.

Challenges of cost estimation

According to a study out of Aberdeen University, the three biggest challenges when managing costs on a project that is producing a product are:

- A lack of overall perspective, meaning that the big picture is looked at early on so that costs just roll in without having an understanding of where they belong in the process. This is why you need to be assessing your costs at every stage, plugging in your new data into your current estimates, and moving from qualitative to quantitative estimation as you know more details

- Taking too long to understand costs means that decisions can get held up. For example, if your designer needs to know whether to use aluminum or magnesium alloy to finalize the 3D model but you’re having to do a load of calculations in a spreadsheet, things can get held up. Planning and understanding your cost variable early on will make things quicker

- Raw material cost fluctuations aren’t really something you can have much of an effect on for some products. However, you can think smart when you’re conceptualizing and designing and choose materials that have less volatile market prices

Knowing these challenges before getting started in estimating the costs of design and prototyping will help you choose the best methods of calculation for you.

Summing up

The costs of getting your idea through the design and prototype design engineering stage and heading towards production cover three main areas:

- The materials that will be used

- The costs of hiring the people to design and engineer your product

- Fixed costs for running the business

It’s not always easy to get an accurate estimate of these costs, and that’s why there are plenty of people who make a lucrative career out of being a cost estimator. The complexity of the item you want to produce will decide whether you need to bring in a professional or do it yourself.

A cost estimation at the stage of design and prototyping is vital. Whether the product is getting funded from your life savings, through loans or finance, or with money from investors, knowing what you’re going to be spending on is vital. It’s easy to spend money, but it’s not as easy to tell if you’re spending it on the right things, so it’s worth reflecting on your costs early on.

In the end, the things that will influence the costs of your design and prototype are:

- The complexity of what you want to make

- What you will make it out of

- Who you will use to move you through the process

- The level of custom and standard parts used

- How innovative your product is

The degree of future software innovation and manufacturing technology is the most significant factor in determining prototype costs. After all, if nothing has ever been made like what you want to make, how can anyone know what it’s going to take to get a working model made?