Product innovation is far from being easy and straightforward. However, it can work wonders in getting your name out there in the business world and open the doors to endless opportunities. The first and most important step to turn your envisioned idea into an actual product is to share it with the rest of the world. For instance, can you believe that only a handful of people were willing to buy into the concept of electricity when it was first theorized?

During the late 1800s, even Thomas Edison was criticized by most of the leading scientists of his time. The same scientists claimed that electricity was nothing but a concept from a fairy tale and that harnessing it on a wide scale is far from possible. Of course, everyone now knows these claims were rubbish as people enjoy a well-lit world.

Table of contents

Table of contents

- What is a physical prototype?

- Different types of physical prototypes

- Popular methods of physical prototyping

- Why do you need a physical prototype?

- How to use physical prototype design services to create physical prototypes

- Other essential things to remember as you work on the refinement process of your physical prototype:

- How Cad Crowd can help

RELATED: Different kinds of prototypes and how to use them for your design project

Imagine if Edison hadn’t come up with the idea, pursued his dream, and persevered to turn it into reality. And imagine how easier things would have been if Edison had a physical prototype of his idea back then. Whether you’re a budding entrepreneur or you’ve been in the business for years, here’s a quick inventors’ guide to using physical prototype design services for product innovation.

What is a physical prototype?

A physical prototype is the first or test version of a product. You’ve likely already seen a prototype in the past. The material used or how the prototype is made depends on the specific things you would like to test. For example, if you plan to test the dimensions, you only need to test the physical space to ensure that every part isn’t too small or too big. This kind of prototype will not be functional and will just be hollow instead.

RELATED: 21 Companies looking for your invention ideas to license new products

Different types of physical prototypes

Most prototypes are broken down into two major categories. Prototypes are used to test aesthetics or test functionality.

Aesthetic prototype

An aesthetic prototype is precisely as its name suggests. This type of prototype tests the looks or aesthetics of the product. This includes the visual design, dimensions, and ergonomics. These prototypes come in handy for photos or presentations because they are meant to look “pretty.”

Functionality prototype

A functionality prototype tests mechanisms, material strength, reliability, and durability. These often look rougher and just like how you envision a prototype. It’s because these are only used to test functionality, which means that appearance is out of the question.

RELATED: Elevating your company using CAD product design services during product development

Popular methods of physical prototyping

The following are the most popular processes and methods of creating prototypes:

3D printing

The past 20 years have seen significant breakthroughs and advancements in technology, including hiring professional 3D printing design firms. One of the most amazing inventions that the world has seen is the development of 3D printers. These machines can print full models or parts of a model with various materials. The most commonly used materials are PLA plastics, nylons, silicones, and others. It’s possible to print a prototype in just one go or print it into several parts and assemble it afterward, depending on its size.

CNC machining

CNC (computer numerical control) machine is a maneuverable motorized tool that usually sits on a motorized platform with a computer controlling it. CNC machine is the umbrella term used to refer to different machines. These operate on various materials, such as metals or wood. CNC programming services have clear advantages over the standard NC operation, particularly when it comes to matters of parts precision.

RELATED: CNC programming c& CNC machining service rates for companies

Why do you need a physical prototype?

It doesn’t matter if you belong to a global conglomerate or you’re a start-up owner; it’s always a good idea to include a physical prototype design in your business plan for the following reasons:

Physical prototypes can spark ideas for other inventions

For example, you’re trying to make a prototype for a new remote control car, and during the testing process, you discover that a mobile app is required to control the car. Suddenly, you’re onboarding coders into your team. But what matters more here is that you’ve pinpointed another new product that needs and deserves to exist.

Physical prototypes facilitate market research

Every time you place a physical prototype in the hands of your potential consumer or present a visual prototype to them, their reactions can serve as your basis for gleaning more data about your target audience.

RELATED: Key differences between prototyping and prototype engineering for companies & firms

Physical prototypes enhance your final design

Take note that the purpose of your physical prototype is to serve as a passing stage in the production process. To get to the next level of success, it’s important to identify errors in the prototypes and work hard to fix these flaws. A new product design and product development firm can help.

Physical prototypes allow you to understand user experience

By having a physical product available, you can better understand the design of the prototype in such a way that would otherwise be impossible if it’s only a written theoretical idea in your inventor’s journal.

How to use physical prototype design services to create physical prototypes

Whether you’re a veteran inventor or a complete newbie in the product manufacturing industry, here’s how you can take advantage of physical prototype design services to help you with your new product innovation:

RELATED: 6 Ways you can use 3D printing services to create a new prototype design

1. Craft your ideas first

One of the trickiest parts of product design is coming up with a product idea in the first place. As an inventor, your first question should be about your product’s ideal design, appearance, and how it feels. Working alongside a new invention design firm can proof to be invaluable.The answer to this question will depend on factors such as the market’s top design trends, the needs of your target customers, cost, usability, your current market position, and the scenario of your competitors. First, you can do thorough research, brainstorm with your team, and understand that your new product should solve your customers’ problems.

2. Come up with a rough representation of your invention idea

After you’re done with extensive research and finalizing an idea, creating its simple representation is the next step. Since it won’t do any good to have the representation of your product in mind, you need to manifest it either virtually using a computer program or traditionally with a pen and paper. Today, software programs such as CAD let you come up with virtual 3D replicas of products.

RELATED: Advantages of using rapid prototyping services for your business

Aside from giving you a clear idea of the dimensions and size of your product, it will also let you observe the performance of your product in a virtual simulation. Using an early mockup also enables you to improve your product’s reputation. This is an excellent way of showing your seriousness about the design of your product and your willingness to go out of your way. After making a rough mockup of your new product idea, the most important and exciting part follows.

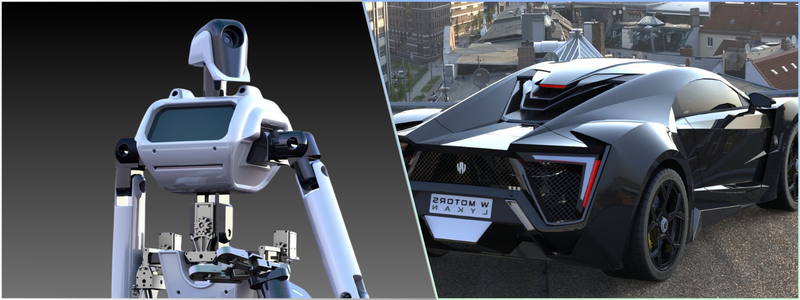

3. Develop a physical prototype

This is the stage where physical prototype design services enter the picture. It’s the stage when you will finally start to develop your prototype. Take note that your physical representation must be 3D rendered correctly by an experienced 3D product rendering professional. This should be made in a way that will best represent the final product. Physical prototype design services often use two approaches to create physical product prototypes: CNC prototyping and 3D printing.

RELATED: Why is industrial design important for new product and prototype development?

4. Polish the prototype to perfection

The last stage is the most time-consuming and painful of them all. It’s because this is the stage when your product needs to undergo a series of redesigns and tweaking to meet your expectations. Ensure you invest in rapid prototyping design services to assist you every step of the way. Below are some of the most common reasons why you might need to redesign your product:

- The market’s product trends are changing.

- There are ergonomic problems with the product.

- You want to expand your product’s functionality.

- Early prototypes showed functional and structural problems.

Other essential things to remember as you work on the refinement process of your physical prototype:

- Always be ready for changes. Understand and remember that your product needs to go through several changes so that you can effectively launch it in the market.

- Ensure you stay updated with the latest product design trends to maximize your profitability and appeal to your target audience better.

- Don’t stop updating and upgrading—the industry of product manufacturing changes day by day, which means that your product should, too. Continue to experiment with new ways and methods to enhance your product.

- Please note that your product will always have room for improvement, no matter how perfect you think it is.

RELATED: Top tips to create impactful prototype designs for company products

One more tip to remember is to ensure that your product is patented within a year before you disclose your product to ensure that your idea won’t be duplicated or plagiarized. Working with a patent lawyer is also recommended to protect your ideas better.

How Cad Crowd can help

Physical prototype design services are essential in the different stages of your product development process. Cad Crowd can help you achieve great success with your physical prototypes by helping you find the best services that will bring your new ideas to life. Contact us for a free quote.