Having a product idea is one thing. Having a completed product that sells is another. Developing a product that customers love will determine whether your company can successfully satisfy its clients or not. That, in turn, will ultimately determine whether your business succeeds.

And let’s face it, entrepreneurs and businesses rarely have unlimited funds to work with. They may have only a single shot at developing a successful product that brings in sales.

If you’ve decided to contract an industrial design company to develop your idea into a completed product, understanding the process involved in it can help you be aware of what’s going on behind the scenes.

Yes, Product Development Follows a Process

To an inexperienced eye, it may appear that successful products just pop up out of nowhere. The reality is far from that. Design may be a creative process, but it involves a great deal of analysis as well.

In order to launch a successful product that sells, you need to follow a series of detailed, premeditated steps that ensure the product not only meets your expectations but also those of the consumers.

This product development guide describes the process of product design and development that’ll help you to better understand how an industrial design company develops your idea. I’ve divided it into four stages for easier reference: Ideation, Design, Engineering, and Validation and Launch. I’ve also included some product development tips that can help you understand what is going on and allow you to communicate that to your company in the best way possible.

Ideation

The ideation stage is the initial stage of our product development guide. It lays a strong and stable foundation for the rest of the product development process. Making critical errors in this phase may result in needing to make significant changes during the later stages.

Ideation begins with defining the idea of the final project and prepares the industrial design company for the product design process.

1. Project Briefing

The first thing that is needed to design and develop a product is understanding the problem and the client’s vision. The industrial design company will conduct a face-to-face or virtual meeting with you in which they will discuss your ideas and expectations.

During this stage, clear communication is paramount. You need to clearly articulate to the industrial design company what you envision your final product to be. Some questions that you may want to answer during this stage are:

- What is your product?

- Why is it needed?

- How did you come up with the idea?

- What customer problem is it going to solve?

- How will it be used?

- Who is this product for?

- How is this product unique?

- How does it differ from that of your competitors?

- How much do you expect your customers to pay for it?

Share as many details as possible. It will enable your designer to more accurately translate your vision into a completed final product. It may also be useful if you shared with them some rough sketches of your product.

2. Market Research and Analysis

Before proceeding with the product concept design, the industrial design company will investigate factors that may affect product design specifications.

First of all, it’s important to understand your future customers. The design team will do that by developing several customer persona profiles.

Saying that your product aims to help college students or stay-at-home moms isn’t enough to develop a quality product. Customer or buyer personas are fictional depictions of your ideal customers. They are detailed and specific and aim to pinpoint the exact pain points of your future buyers.

This will enable the industrial design company to focus on aspects like the color of the product or its shape. These may not be something that you have thought of, but they can leave a different psychological effect on your potential customers.

The color of your future product may determine the success of its sales. Each color represents and elicits a different emotion.

For instance, blue represents trust and loyalty while green symbolizes health and harmony. So, if your product is a vacuum cleaner, blue may help you sell it by communicating to buyers that it’s trustworthy and dependable. Meanwhile, choosing green may communicate that this vacuum cleaner is helping establish a green and eco-friendly household. Both will target different kinds of buyers and choosing a conflicting color can convey a completely different message.

Similarly, shape has a psychological effect on consumers too. Men will favor angular designs while women will prefer curved forms. So, you may want to have your product look a certain way so that you can better address the preferences of your future buyers.

There are only some of the factors that your industrial design company will take into consideration. It will also assess your competition and determine how your product can stand out. The rest will depend on each individual product.

Design

The design phase is the next one in our product development guide. It takes the idea from simple sketches to a fully developed virtual model of the final product.

This phase will determine what the finished product look and feel like to future buyers, how they will be able to interact with the product, and how it will psychologically affect them.

3. Product Concept Design

Product concept design is the stage when you will see your product idea starting to come to life. It can determine the outcome of the final product as a flawed concept design can result in a defected product design ultimately failing the entire project.

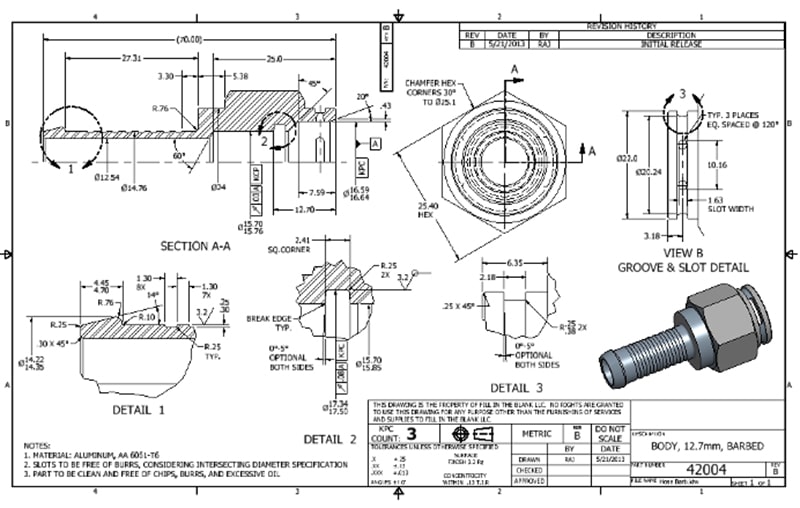

With the research data in mind, designers will start making conceptual designs of the product and make sketches of them. These won’t be pencil sketches that were done years ago but rather digital technical sketches. Think professional 2D CAD drafting services.

The designer team will brainstorm ideas and develop concept designs that will aim to meet your requirement and make the product attractive to future customers at the same time.

As a result, they will present you with a series of provisional product designs. Then, you’ll be able to choose the direction of the project and determine which of the designs will become your final product, as well as request any changes or modifications.

4. Product Design Visualization

Once you’re happy with the initial 2D CAD drafts of your product, the industrial design team will import these sketches into another program that is meant for 3D designs and proceed by making realistic 3D models of your product.

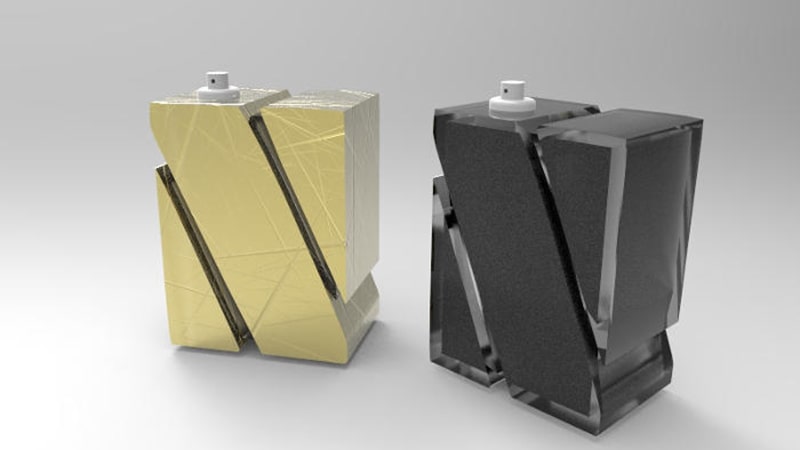

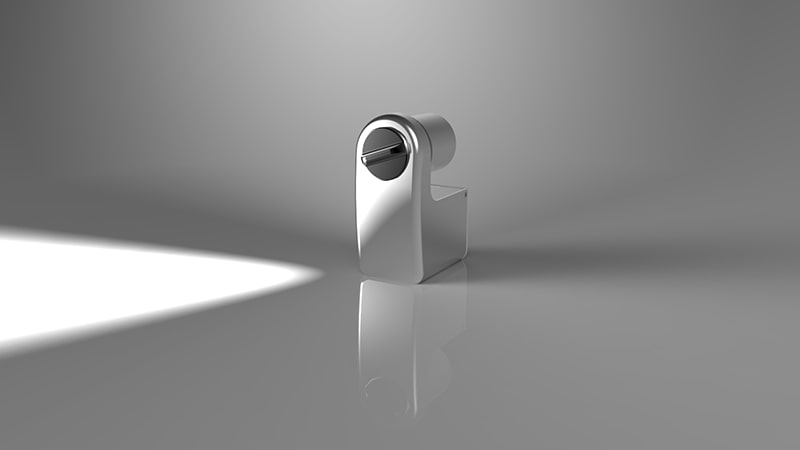

3D modeling design will enable you to see what your product will look like in real life as opposed to a 2D image. You will also be able to rotate the image and view your product from all angles. This will enable you to make any changes to it before the prototype is even created, saving you a great number of resources. It will also serve as a guideline in prototype creation for the design team.

Another benefit of three-dimensional depictions of your future product is the ability to use them in promotional materials. By using 3D rendering services, you can also acquire highly realistic graphic depictions of your product in a real-life setting. Designers will add texture and lighting to your product making it look hyper-realistic.

You can then display them on your website, brochures, and other marketing materials, or in presentations for your investors. This way, you’ll be able to kick-start your pre-marketing campaign and start creating buzz around your product long before its production has begun.

Some companies use this stage to test the potential market demand for their product. They present their customers with 3D images of their products and allow them to choose the designs that they most like. This can help them determine what models or variations of the product will or won’t sell and only offer the products that will certainly bring sales.

5. Packaging Design

An often overlooked aspect of the product development process, packaging design is an integral part of the product design process. You may view it simply as a means of enclosing your product to protect it from any outside elements and present it intact to the buyer.

In actuality, is the last aspect of your marketing campaign that can determine whether the buyer makes a purchase or chooses a competitor’s product instead. Successful packaging design most definitely has the potential to influence the level of trust your potential customers have for your brand as well as your sales. MRI scans show that attractive packaging creates more activity in the brain and affects emotions.

Case and point, product packaging matters and you should not ignore this piece of product development advice.

There are certain aspects that buyers are looking for even though they may not be consciously aware of it. Your product packaging needs to clearly identify your company as well as the product and state the most relevant details about it. If your product isn’t original and will need to face competition upon launch, unique packaging design can help it stand out and get noticed.

In addition to that, an increasing number of people are becoming more concerned about the environment. Therefore, packaging form sustainable, eco-friendly material can also boost your sales.

Luckily, product packaging design is another detail that your industrial design company can take care of.

Engineering

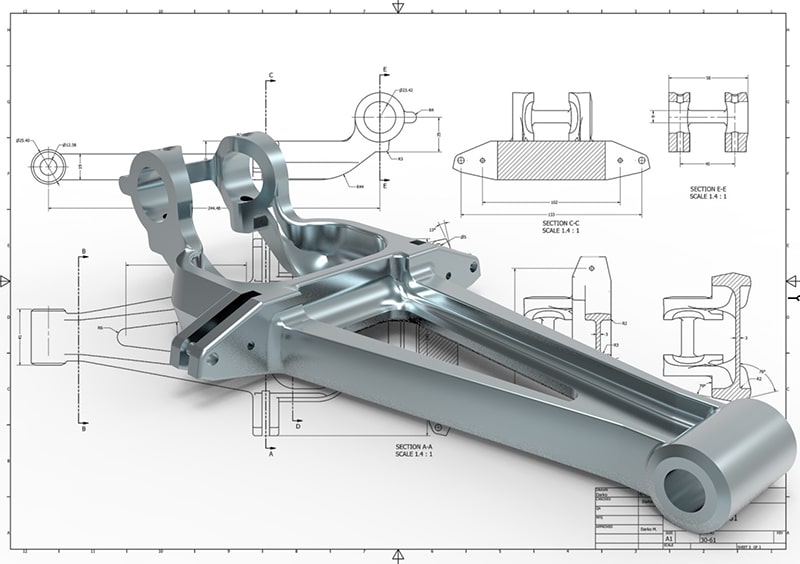

The engineering phase is when the industrial design company starts working on the functionality of the product. By the end of it, they have a fully functioning prototype.

The engineering stage usually is the most optimal time to reach out to investors. This is because you no longer work with an intangible idea. You not only have realistic designs of your future product, but you have a prototype that investors can try and experience.

6. Product Design Specification (PDS)

A Product Design Specification or PDS is a statement that outlines facts about the product, how a design is made, and how it meets the requirements of the client. It aims to focus not on the outcome, but rather on realistic constraints that may affect the final product. These will regard its performance, cost, environment, materials, patents, ergonomics, aesthetics, as well as market and company constraints.

The content of the PDS will depend on the specific nature of your particular product. However, a few questions that it may aim to answer are:

- How often is it going to be used?

- How long is its lifetime?

- Will it need to be resistant to factors such as temperature and humidity?

- How will it differ from similar competitor products?

- Does it require any specific materials?

- Is the product safe?

- Does it infringe any existing patents?

- Is the product easy to use?

- Will the product require software?

- Will target customers find the product attractive?

- Does the product properly represent the company’s image?

- Is the product subject to any political constraints?

- How is the product going to affect the environment?

These are factors that you may not necessarily think of. Yet, it’s the industrial design company’s job to ensure that they are taken into consideration.

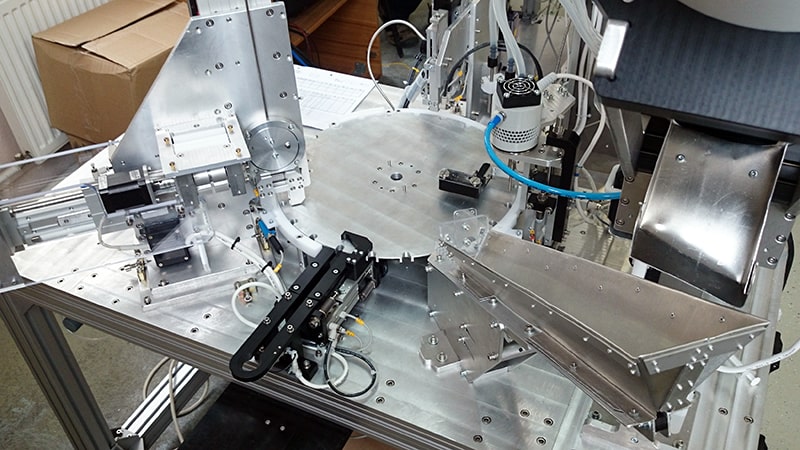

7. Prototype Development

You have seen your product in sketches, 3D models, and 3D rendering images. It may seem that it’s been enough for you to finally move on to the manufacturing stage. Nonetheless, you may need to prove that your idea works and the theoretical designs will be able to produce a working product.

This is especially true for novel product ideas that aren’t yet available on the market. Or, you may need a stronger presentation to secure funding from potential investors or to impress your future buyers.

Regardless of your specific situation, prototype design services can bring value and credibility to your product. Therefore, it’s not a good idea to skip it and move straight to the production stage even if it may seem like you would save time and resources by doing so.

There are different kinds of prototypes that you may need to develop. The nature of your product and its intended use will determine which ones will be the most suitable for you:

- Visual Prototype

A visual prototype serves as a demonstration of the aesthetics of the product. You will be able to get the feel of the shape and size of the final product and present it to investors and future customers. Thus, the design team will be able to identify and make any changes to the aesthetics of the product early on.

However, a visual prototype will not demonstrate the functionality of the product and usually won’t have any working parts.

This is, generally, the easiest and fastest kind of prototype. The industrial design company will not utilize materials that would be used when manufacturing the product. Instead, it will likely use much cheaper materials that would yield a similar general feel of the final product.

Materials may simply be left raw. However, they likely will be painted to mimic the aesthetics of the finished product.

- Proof-of-Concept Prototype

A proof-of-concept prototype will focus on presenting and testing the functionality of the finished product. Thus, it will contain working parts as opposed to the visual prototype.

However, it may not include all the working parts, but simply focus on testing whether the general idea or a specific aspect of the product works. The design team will be able to identify any problems and make adjustments necessary to ensure full functionality of the final product.

This prototype will also not necessarily look exactly like the final product. Or, it may lack design details. The industrial design company will assemble this kind of prototype from existing and much cheaper materials that will not be used to produce the final product.

- Scale Prototype

Imagine that your project is a car, a house, or something else that is considerable in size. Creating a life-size prototype may be problematic, impractical, or even a complete waste of resources. A smaller-sized representation of it can prove to be a lot more effective.

This kind of prototype can be extremely useful in presentations when 3D visuals of your product may not be enough to convey your idea.

The design company will produce a scale model from similar materials that it would use for a visual prototype. Depending on the type of the product, it is likely also lack full functionality.

- Functional Prototype

A functional prototype will focus on both its design and functionality. It’s the most complete out of all kinds of prototypes and will look and feel exactly like or very similar to the final product. Thus, it will serve as the closest thing to it.

A functional prototype will also include all the bespoke parts. However, where possible, it will consist of cheaper alternatives. It is important in the design process because it allows you to identify any issues with both the final design and its functionality.

In addition to the above, you’ll be able to more accurately estimate the costs needed for the manufacturing of the product, and, if necessary, adjust its price accordingly.

It is common for industrial design companies to create several prototypes or a series of them, especially if there are mistakes that need to be addressed.

Validation and Launch

The final phase of our product development guide aims to put everything together and prepare it for the product launch. It involves extensive product testing as well as ensuring that the product can be sustainably and continuously produced.

8. Product Testing

Once you have a fully functioning prototype, the industrial design company will first manufacture and release a limited number of units of the final product for testing purposes.

There may still be flaws in the design, some functionality errors, or software bugs that may have gone unnoticed when developing and testing the prototype. This will also be your first experience working with the manufacturer who will produce and assemble your product. So, there may be issues in, for instance, fitting the different parts of your product together. In addition to that, the product will also be produced using the actual materials which may affect its appearance or functionality.

All of these are absolutely normal and necessary to fully optimize the product for its launch. Doing this now will ensure that there is less possibility for any issues to occur later. So, you have a much lower chance of being faced with the need to rush improvements or recall the product when it’s already on the market.

Depending on your product and its nature, the industrial design company will determine the most suitable custom testing plan for it. It may conduct functionality tests, drop tests, temperature tests, cosmetic tests, functionality and durability tests, UX tests, as well as invite real users to try your product.

Sometimes, products require simple tweaks. For instance, if the glue that the manufacturing company uses degenerates quickly, it will be necessary to swap it for higher quality glue.

Nevertheless, if any significant changes need to be made, the team will work on an improved version of the product design and release another prototype that it will test again.

Once your product successfully passes all the tests, it’s ready for its official launch and mass production.

However, if you work with a reputable and experienced industrial design company, most of the critical errors and design flaws will have been flagged and corrected before you even get to this stage. This is why it is crucial for you to carefully choose the company that is going to develop your idea.

In some specific areas, such as medicine, sports, and similar, the industrial design company will need to conduct specific tests that will ensure that your product complies with the norms of the industry.

These tests may include reliability, durability, climate testing, electro-static discharge (ESD), electromagnetic compatibility (EMC), and more.

Your company will have determined which ones you need if you need any at all while putting together the PDS.

9. Product Manufacture and Kitting

Once the product has officially passed all tests, it’s ready to be manufactured and prepared for shipping. During this stage, you will not only need to manufacture the product itself, but also its accessories, such as cables and chargers, the packaging, as well as instruction manuals and other necessary documentation. Therefore, one of my final product development tips is to factor that into your expenses beforehand.

When working with manufacturing companies, larger batches usually signify cheaper production costs while smaller ones result in more expenses. Thus, more sales equate to lower overall production costs.

10. Product Launch

Once your product has been developed, manufactured, and prepared for shipping, you can fully delve into your marketing efforts in order to secure more sales for your product.

Once your product is out on the market, it’s important to keep listening to and collecting customer feedback as well as monitoring your competition. While there may be nothing wrong with your product, there will always be something that you may be able to improve over time in order to best meet your customers’ needs and beat your competition.

If this product development guide has inspired you to act upon your product idea, Cad Crowd can help. We have a vast database of experienced professionals in a variety of fields who can make any of your product dreams a reality. Check out how it works or request a quote if you are ready to get started.