When inventors, engineers, and entrepreneurs design a product, the main focus is usually on developing its features and deciding on its appearance. This way, they can satisfy the needs and preferences of their target market and make customers want to buy their product. Of course, that also means doing a fair bit of market research.

Now obviouly there’s nothing wrong with this! That’s what product design is all about. But we now have access to powerful tools that let us take the product design process up a notch, to ensure that we’re creating the best product we can. This is what product simulation and analysis is all about. By taking advantage of some of these CAD tools and the experts that know how to use them, you can put your product through rigorous testing in the virtual domain that you would probably not be able to put it to in the physical world. And

By taking advantage of some of these CAD tools and the experts that know how to use them, you can put your product through rigorous testing in the virtual domain that you would probably not be able to put it to in the physical world. And that means the potential to create better products that preform better and impress your customers. And it doesn’t have to break the bank.

The Importance of Simulation and Analysis Services

Many designers and engineers believe that simulating and analyzing products is overly expensive and maybe unnecessary. But isn’t really the case. While there is a temptation to think that sophisticated analysis tools are only of benefit to complex engineering or construction projects, the reality is that there are many advantages for all kinds of product designs. These include:

Evaluate Product Performance for Optimum User Experience

Your product might look great on paper, but are you sure it will function as designed in the real world? Are you 100 percent certain that it will fulfill your clients’ needs and solve their problems? Will it perform better and function longer than your competition? These are things that consumers really care about. If you can offer a more durable, sturdy, and functional product, well then you’re off to a great start.

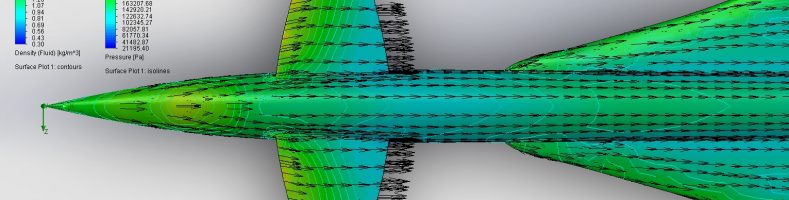

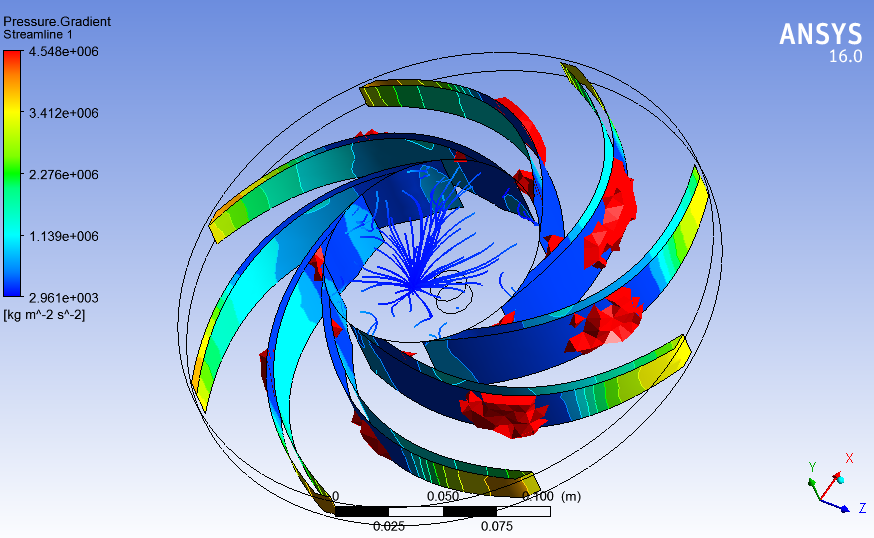

Simulation and analysis tools will help you answer the questions above and find out whether your product will perform at the level you need it to. This provides you with the opportunity to make improvements in the event that it does not. You can check how your product would hold up when exposed to gravity, vibration, heat, and other physical elements. You can also test how it would interact with real-world objects and predict how it would look and perform as it gets older and more worn. You can even “destroy” your product virtually (such as in digital car crash tests) to find out what would happen if your customers would drop, kick, or throw your product.

These are tests that are very difficult to perform in the real world. It can also be very expensive to create a bunch of nice beautiful things just to bang on them with a hammer. Tools like Finite Element Analysis, though, let you do all that in the safety of a virtual sandbox.

It’s rare to get things right the first time around but, if you do, you can confidently proceed to the manufacturing phase knowing that you have the best possible design. If your simulations and analyses suggest that your product is below par, you’ll have the opportunity to make the necessary changes and improve your design before you start producing it.

Narrow Down Design Options

Let’s say you have three ideas for your product but you don’t know which one of them works best and is the most cost-effective. How can you choose the design you’ll use for the final version of the product? Well, you could make a prototype of each design and see which one is best, but often the best and most cost-effective thing you can do is to run your ideas through simulation and analysis software first. This will help you see the performance of each design and find out which one provides you with the best possible results. Then you can focus on iterating prototypes of that design, thus cutting back on your development costs and time to market.

Identify Flaws and Potential Problems

Some design issues are clearly recognizable, so you take great pains to avoid incorporating them in your product. However, there are other problems that might not be noticeable on paper but can greatly affect the performance of your product in real life — especially in the long run. The key to avoiding these unforeseen problems is to use simulation and analysis software. Through these programs, experienced technicians can easily spot the flaws in your design and even predict exactly how they could affect the efficiency of your product. Armed with this information, you can take steps to remove these flaws and ensure they won’t affect your product’s performance and marketability.

Validate the Final Design

Simulation and analysis should start at the conceptualization phase, but they shouldn’t end there. These processes are also greatly important in the final stages of design. Running your final design through simulation and analysis software will help you isolate the last few kinks (if any) and give you the assurance that you’re on the right path. This will allow to manufacture your product with confidence, knowing that you’ve developed the best possible design.

Protect Your Business’s Reputation

Imagine that you’d push through with manufacturing without testing your design first. If it turns out to have several flaws, you’d end up producing faulty products that would disappoint your customers and draw widespread criticism and negative reviews. You can always go back to the drawing board and create a better product, but by then it might be too late. Your business would already be tarnished with the fact that you put out less-than-stellar products on the shelves, and your target audience would find it difficult to trust your brand.

“But I always test my products before manufacturing!” you might think indignantly. “Only a fool would put a product onto the assembly line without testing it first.” But are you sure you can trust the testing methods you use? There are certain things that you simply cannot reliably test without simulation.

Save Time and Money

The benefits listed above all boil down to one thing: product simulation and analysis can help you reduce your expenses and maximize the value of your product. Sure, you’ll need to spend money upfront when you hire freelance engineers who’ll assist you in testing, simulating, and analyzing your design. However, in the long run, you will experience lower overall costs and save more money.

This comes from the fact that you’ll avoid redesigning products in the middle of the manufacturing process — after you’ve bought raw materials, built molds and other tools, and paid the manufacturer. You also avoid the truly costly mistake of disappointing consumers.

Simulation and Analysis: Making it Mainstream

With the advantages mentioned above, it’s easy to see that product simulation and analysis are a vital part of manufacturing. Unfortunately, many designers and engineers never bother with these import processes. Many of them still don’t integrate simulation and analysis in the design process because they consider it 1) too difficult, 2) too expensive, or 3) completely unnecessary.

The key, then, is to show them that this is not the case. We have already tackled reasons 2 and 3 in the previous section, so let’s talk about reason number one.

Simulation and analysis can be daunting to those who don’t have experience with it, but it’s actually a lot easier now since many product and simulation and analysis software tools have been integrated into popular CAD programs. This makes them more convenient since users no longer have to toggle from one program to another just to simulate and analyze their designs. They’re also easier to use since they have adopted the CAD interface that many people are familiar with.

A lot of complicated steps in simulation and analysis — such as meshing and computational fluid dynamics — have also been automated. Because of this, designers and engineers can easily access these functions and apply them to their design without needing to have an in-depth knowledge the underlying algorithms and other factors.

Of course, it’s not just about investing in the right software. Companies also need to acknowledge the importance of product simulation and analysis and ensure that their employees realize it, too. One of the best ways to do this is to provide comprehensive training. This way, their staff will learn how create an accurate model of the product they’re testing using the right material properties and contact algorithms. They’ll also know how to interpret the results provided by the simulation and analysis software, analyze whether they’re getting accurate and quality results or not, and take the right steps toward creating the best possible configuration for their product.

What about individual inventors and small business owners? They can opt to invest in product simulation and analysis software if they’re familiar with CAD design and the relevant engineering skills. But, if they aren’t, and if they don’t have the time to learn, the best thing they can do is to hire professional freelancers who’ll take care of simulation and analysis for them.

This is where Cad Crowd comes in. We have a large network of freelance engineers who specialize in product simulation and analysis and have worked with numerous clients from different industries. Our freelancers have years of experience in the field, and they use only the latest and the best software to test designs, identify flaws and potential issues, and figure out how they can be made better. With their help, inventors and entrepreneurs can create the best possible product that won’t only impress their customers but will also make them stand out from the crowd.

Ready to begin? Contact us now to get a free quote and learn more about how Cad Crowd freelancers can help you.