In this post we’re discussing product testing and validation and the role of CAD design services for companies and firms. You’re responsible for your company’s new product development. But before it hits the market, you need to test it first, and this is where CAD simulation enters the picture. Continue reading below to learn the role of CAD simulation services for companies in product testing and validation.

Table of Contents

Table of Contents

What is CAD simulation?

CAD or computer-aided design uses computer software to create three-dimensional objects that can be tested. As far as CAD is concerned, simulations are like virtual experiments. The virtual prototypes let you test the physical components of the product with no need for the physical part or product. Reviewing virtual prototypes with the help of prototype designers makes CAD simulation services a valuable tool, as these help save money and time during product design.

To conduct a proper simulation, you must model the material properties and physical characteristics of any prototype, object, or product you’re working with to acquire accurate results. During CAD simulation, you can test different factors and properties, such as load direction, magnitude, and material properties. CAD simulations are run almost infinitely, making CAD simulations extremely powerful.

RELATED: Product simulation and analysis: why it’s worthwhile

What happens during simulation in CAD?

CAD software’s traditional use in systems developed was solely concerned with the shape and size of the object, whether it’s a small part of a machine, an aircraft, a giant ship, or even a building. However, CAD software users have started demanding the ability to test virtual objects (i.e., virtual product testing) within virtual environments. Thankfully, CAD software developers happily obliged. Testing products virtually under predetermined conditions replicating the real world requires more than just knowing an object’s dimensions; it entails considering various factors and parameters to ensure accurate simulations and realistic virtual experiences.

It’s also important to know and be familiar with its physical properties, and it’s also important to represent all these properties within the 3D CAD model. It would be best to see the influence of these physical properties on the performance of the object being tested. It is often done with equations or a mathematical model of the system’s behavior, and these equations go along with the system’s material properties, size, and shape.

For example, when a virtual aircraft is being tested, it’s critical to know how the air flows around the wings to produce lift. Mathematical equations for handling the airfoils’ physics can be incorporated into the system’s CAD representation to accurately replicate the real-world behavior of the aircraft’s wings for testing and analysis. Physical properties like the friction coefficient and other parameters that dictate the wing structure and strength should all be integrated into the model.

RELATED: What are CFD engineering rates, consulting services costs & company pricing?

One critical approach to CAD simulation is using FEM or finite element analysis & FEA engineering services. Physical phenomena are usually described by complicated equations that are impossible or impractical to solve for each point in the object. FEM modeling services solve this issue by subdividing complex equations into smaller, more digestible chunks.

Meshing is also possible with the help of CAD software and meshing experts, and it is the process of crafting a 3D grid in the object for defining the subdivisions. Once the meshing and mathematical model is in place, it’s possible to conduct model testing using different simulated experiments under various virtual scenarios. The design can also be changed, and simulations can be re-run, which can’t be practically done with an existing system.

Who uses CAD simulation services?

Simulation modeling is used in different engineering disciplines and a wide array of industries and academia. The following fields can use and benefit from CAD simulation services:

RELATED: The benefits of using design simulation at your company

Electrochemistry

The researchers in the next-generation technology of batteries use the simulation for designing new nano-scale and micro-scale materials to improve battery capacity, reduce charging time, improve battery safety, and increase the battery’s overall lifespan or its charge-and-discharge cycles.

Geology

Seismologists and geologists can use CAD simulation services to foresee the effects of different kinds of earthquakes on the surface shaking amount that would take place. This is made possible by understanding the mathematical relationships among other forms of underground structures, rocks, and soils.

Optics

CAD simulation services allow design engineering companies to simulate the materials’ optical properties. These materials include metamaterials known to have surface designs on a nano-scale that can change their properties. They can then use these to test and design new lenses and other types of optical instruments for various applications.

Telecommunications

5G telecom equipment designers use CAD simulation services for almost everything, from designing base station antennas for the optimum range to the identification of the placement of the base stations for the best coverage to discovering solutions for problems in offering serving in moving buses and trains. Designers can also test new protocols for communications by modeling algorithms, mobile devices, and base stations under different communication scenarios.

RELATED: How AEC companies can leverage VR and AR simulations in architectural design

Different types of CAD simulations

CAD simulation services, such as stress testing an object or product optimization, are used for various things. The different types of CAD simulations focus on unique situations that can generate qualitative or quantitative results, and CAD simulations provide numerous tools that help identify the best product design. The following CAD simulations are commonly encountered:

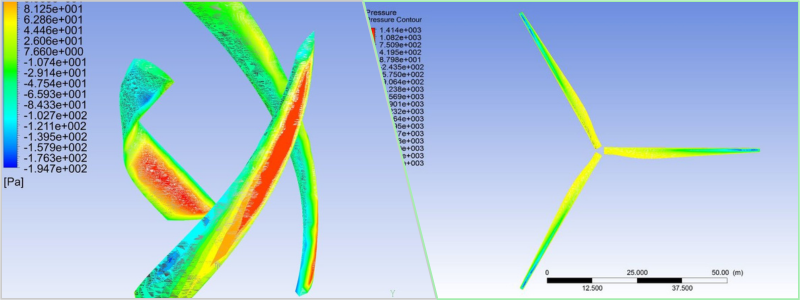

Flow simulation

CAD flow simulations are optimal for enhancing fluid elements in the design. For instance, you may have to test fluctuations in pressure or reconfigure elements for cooling.

Injection molding simulations

Injection molding simulations allow injection molding and casting specialists to test if the part geometry fills appropriately before cutting the mold. Optimizing part warpage, cooling line placement, and injection locations is also possible.

RELATED: How to design products for injection molding & prototyping firms

Stress analysis or structural simulation

Structural simulation reduces your product development cycle with the aid of stress analysis experts. This kind of CAD test will help ensure that your model will not fail and can function well under the loading conditions given.

Benefits of CAD simulation

CAD simulation modeling in business and engineering disciplines can benefit the organization. CAD simulation services have two significant advantages:

1. Test scenarios are getting more realistic than ever

Testing all the different operating conditions using traditional physical prototypes is almost impossible. But with CAD simulation, there is no such thing as a practical limit to the other operating scenarios that can be tested and modeled.

2. Shorter cycles for design and testing

The opportunity to re-test and modify a virtual design saves you from spending money or time to build and test several prototype iterations. It lets you settle on the specific design (i.e., product design) that meets all the requirements during the simulation before you develop an actual prototype.

CAD simulation modeling offers benefits over conventional approaches, including optimization, forecasting, and data analytics. These approaches are more theatrical, based on different assumptions about the behavior of an object. CAD simulation saves you from the need for various assumptions, and you only need a mathematical model to test scenarios and determine behaviors.

RELATED: How computer-aided design (CAD) services are used by engineering firms

3. Predict situations in the real world

The best and most crucial advantage of CAD simulation and CAD simulation services is that they offer real-world data. These simulations can provide insight into the physical product’s failure points and structural problems, allowing you to foresee any issues early on and be more reactive to changes.

As far as real-world data are concerned, simulations of projects are run according to requirements to deliver a wealth of information. Running CAD simulations also allows you to market much faster since you can test all the different checkpoints and components without developing a complete prototype. You can then evaluate theoretical situations and acquire as much data as necessary without challenging restrictions.

Are there challenges to CAD simulation?

Unfortunately, CAD simulations also have their challenges. If you haven’t learned about the limitations of your model, you might feel a false sense of security that the results of your simulation are 100% reliable. As expected, this can lead to damaging effects. Below are some frequently encountered problems associated with CAD simulation:

Garbage

The use of incorrect parameters will expectedly lead to wrong results. A physical parameter may not be a single number but more of a range of values with a specific distribution, and the model must adequately account for this variability.

RELATED: How the aerospace industry is using CAD design services: drafting, modeling, and prototyping

Tradeoffs

CAD designers usually must decide the tradeoff between computing power or time and accuracy for more complex systems, particularly those modeled with FEM. Highly detailed models may need more computing power and time for simulation than what is readily accessible. Cloud computing makes extra computing power available at a reasonable price for simulation tasks.

Mathematical model’s validity

Specific models have well-defined equations describing their behavior. CAD designers, in other instances, break new ground without a good primary research body with which the mathematical model is constructed. In cases like this, the equations might only be based on mere guesswork with limited empirical data amount instead of generalized physical relationships.

How Cad Crowd can help

Cad Crowd can help you find the best CAD simulation services to help you test and validate your company’s upcoming products.