Much of the budget for developing a new product for companies goes to the design phase. From the early stage of brainstorming to the final production-ready prototype, you can spend thousands of dollars to build and revise a design; and that’s for a relatively simple, non-electronic product, like a cookware or a backpack. Anything more complicated, such as Bluetooth radio or remote control, will cost you tenfold or more. Designing a product is not cheap, but it doesn’t always mean you can’t keep it to a minimum. The thing is, you have to keep it at near-perfect efficiency every step of the way. For a lot of small companies and startups, the most practical way to achieve that is by working with an engineering firm.

And to be even more specific, the engineering firm has to have at least one professional industrial designer on the team. According to the BLS (Bureau of Labor Statistics), an industrial designer devises an efficient system where workers, machines, materials, energy, and information may work together in harmony to make products or provide services. In other words, the work of an industrial designer focuses on coordinating all factors involved in production to achieve maximum efficiency – or reducing cost whenever possible – without sacrificing quality. Quite a mouthful indeed, but you get the idea nonetheless.

Mind you that most industrial designers typically have at least a bachelor’s degree in engineering, architecture, and fine arts. The vast majority of design programs include multiple courses in CADD (computer-aided design and drafting), 3D modeling, business, industrial processes, manufacturing methods, and drawing, among others. This is where you need to practice some due diligence; not every engineering firm has an industrial designer as part of its core team. An engineering firm that specializes in architectural design would prefer hiring a Bachelor of Architecture rather than a Bachelor of Engineering. And as you would expect, you want to work with a firm loaded with professionals of the latter category.

RELATED: Important benefits of industrial product design – using industrial product design services

Note: BLS’ list of occupations can be pretty confusing, but not necessarily inaccurate, at times. For example, the bureau makes a distinction between industrial designers and industrial engineers. They are all engineers, and share similar functions within an organization. Some firms hire both, because their roles are often interchangeable. Industrial designers focus on developing new products or improving the existing ones, whereas industrial engineers hone in on creating efficient manufacturing methods.

To give you an idea of why or how industrial designers can be the defining factor in your design decision, let’s take a look at their typical roles and responsibilities in an industrial engineering firm:

- Determine the requirements and parameters for product designs

- Conduct research into how a product might be used and who might use it

- Create product sketches (or CAD modeling) as visualization of design ideas

- Produce multiple photorealistic renderings of product designs

- Create physical prototypes

- Examine manufacturing requirements, including materials and workforce, to determine production cost

- Collaborate with other specialists, such as prototype makers, electrical engineers, and manufacturers to evaluate designs

- Determine whether the materials and manufacturing process can come at a reasonable cost

- Analyze product safety, function, aesthetics, ergonomics, and general user-friendliness

- Present product design ideas to stakeholders/clients for approval

An engineering firm doesn’t usually mention if it specializes in any specific product category, but the industrial designers in the firm usually do. It makes perfect sense for the firm to avoid making explicit reference to the matter because there might be multiple industrial designers, each with a different specialization, working in the organization. Some of them are perhaps put in charge of a medical equipment project or home appliances, while others develop ideas for sporting goods, housewares, furniture, jewelry, and so on.

RELATED: Why companies use product design sketches during new product development and design

Regardless of the product category, industrial designers work to minimize the use of resources (which may include energy, workforce, materials, etc.) to reduce production costs as much as possible while still aiming for the best results. Their main duty in an engineering firm is to circumvent design constraints by either mitigating risks of design failures (such as removing unnecessary elements) or using them as advantages to execute minimalist design approaches.

When developing a product, industrial designers take into account how consumers might use the product and test different designs to see how each iteration looks and works. They need to figure out an effective balance between good aesthetics, functionality, durability, and overall ease of use. However, the most important thing of them all is often the target consumers’ purchasing power. It makes little sense for companies to build the greatest product ever, if it ends up being too expensive for its intended buyers. For instance, a tech development company can probably release a high-performance laptop series any day of the week, but if the product is meant to fill the market for high school students with a purchasing power of $1,000 or less, well then there’s definitely something very wrong in the design and marketing aspects of the project.

Every product is intended to fill a market gap. You can also say that a product exists because there’s a demand for it. And the market is segmented by – once again – purchasing power. Each segment contains distinct demographics, priorities, and interests. Product design services are often determined by which segment you’re targeting. You come up with a product that fills specific needs for certain groups of people. This is the main reason companies offer different product tiers. Let’s just say “good” sits at the bottom, followed by “better” in the second place, but both are under the “best” tier. Now if we refer back to our laptop example above, the “student” variant is likely the good option, whereas the business model is a step above, before finally you arrive at the high-end version at the top.

You might think that an engineering firm only does engineering stuff, and you might be right, but not entirely accurate. Industrial designers do not develop a new product design from nothing. They work with other professionals in the firm, such as manufacturing experts, market analysts, and even other engineers. An engineering firm does primarily design a product based on your specifications, but it also provides a range of other services to ensure that the end-product is profitable for your company.

Besides offering the full range of industrial designer services as mentioned earlier, an engineering firm also performs thorough market research on your behalf. The firm typically uses various tools such as phone interviews, focus groups, questionnaires, and surveys to figure out potential buyers’ preferences and purchase history. Market research also helps determine the product’s appeal to the target demographics, existing competitors along with their price points, and trends. While it might not directly provide ideas as to how the product should be physically shaped, the data gathered from such a research give invaluable insights into the design decisions and where to position the product in the market. Some analysts also use data available from external sources, such as census and economic reports.

RELATED: How-to guide: new product design, engineering and prototyping your idea for mass manufacturing

This is how you gain a basic understanding of what products people want and at what price. Combine those insights with industrial designer’s expertise, and you get the right formula to plan for a design and aim for the desired profit margin.

Product design cost

Before you get to the final version of a product, you need to go through a lo t of different steps from ideation to evaluation, which may include safety certification, depending on the type of product. In the old days, prototyping was one of the most expensive design steps. When you work with a modern prototyping firm, almost every single design process is done on 3D CAD modeling software. Think of it as a “virtual prototyping” to test and analyze dozens or more design ideas on a computer screen.

While a physical prototype remains necessary, you won’t likely need it until you get to the final pre-production prototype iteration. Everything else before that is easily accessible and modifiable on the software. 3D modeling enables industrial designers to experiment with countless design iterations in a digital environment, where they can make use of all kinds of shapes, materials, mechanical components, colors, textures, and dimensions as needed. They can make adjustments with only a few clicks, and let the software do the rest. Whether you want to change the geometry, add/remove design elements, or reposition parts, the software can do everything for you almost in an instant. In case something doesn’t work, you can revert the changes or modify something else.

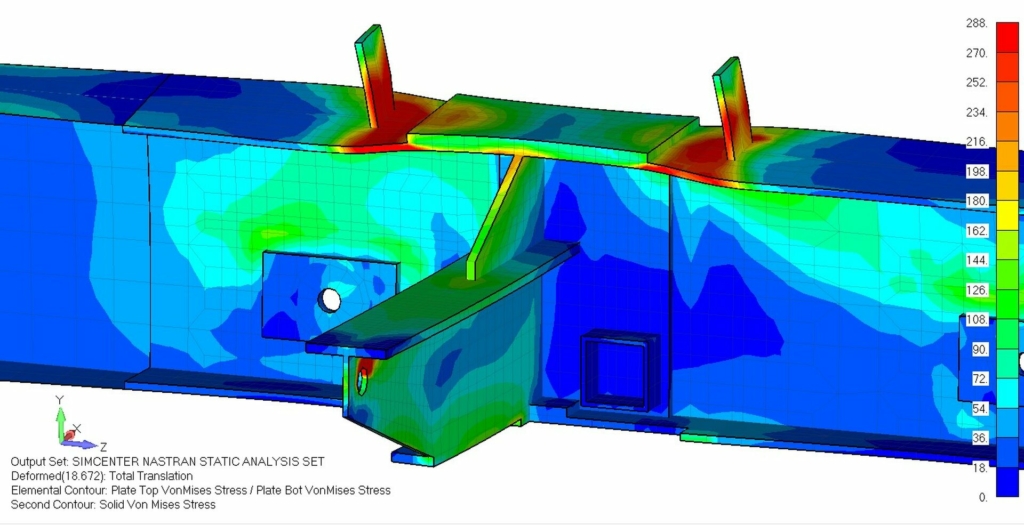

Let’s not forget that you see the design (on the screen) as a three-dimensional object. If your product is supposed to have some moving parts, or mechanical components if you like, the software can animate the model to help you see the product in action. Some programs even allow for full-fledged simulation for FEA, load cases, etc. In general, 3D CAD modeling and simulation software removes the need for physical prototype analysis. Another good thing about advanced CAD software is that you can configure it to calculate the cost of materials based on the model. It’s also easy to replace one material with another to see the difference in production cost. And because it’s automatic, the likelihood of inaccuracy is virtually zero.

RELATED: New product development and design: should your company work with a product design team?

How Cad Crowd can help

For more than 15 years, Cad Crowd has been working to connect companies, big and small, as well as startups and individual clients with some of the most reputable engineering firms in the country. Whether you plan to create an electronic product, furniture, home appliances, hi-tech drones and everything else in between, Cad Crowd has just the right engineering firms to optimize your design process efficiency.

Get a free quote to create the most engaging products today.