In the last decade, 3D printing has moved out of R&D labs and manufacturing settings to find more widespread use with the general public. Prices for 3D printers have plummeted, with some models now selling for less than the cost of ink-jet printers when that technology was considered to be cutting edge.

Consumers are increasingly utilizing 3D printers in the home and by small businesses across the country. 3D printers are even showing up at an expanding list of public libraries. These libraries often hold classes on 3D printing technology, and most provide 3D printing services to the public, either at no cost or for a very nominal charge (usually just the cost of materials consumed by the printer). To get a model designed, many people are using 3D printing services.

3D printing has also been making its way into the classroom, and for a good reason. As we’ll discuss in more detail below, 3D printed objects in and of themselves are a valuable teaching tool. But more importantly, by mastering the skills associated with the technologies and techniques behind 3D printing, students will become better prepared to meet the challenges they’ll face in the workforce.

3D Printing and Education

If you’re new to 3D printing, you’re not alone. Since the cost of 3D printing equipment was for many years astronomical, few people outside of large R&D or industrial settings had the opportunity to be exposed to it. In a nutshell, a 3D printer is a device that operates by building up material, usually just a little bit at a time and usually in layers, to produce a three-dimensional object. A handy way to grasp this concept is to compare a 3D printer to a device you’re already familiar with – an ink-jet printer.

- An ink-jet printer uses a material (the ink), a little at a time (fractions of a fluid ounce), in layers (one line at a time), on a two-dimensional sheet of paper.

- A 3D printer uses a material (plastic or metal), a little at a time (often just fractions of an ounce), in layers (often only 1/250th of an inch tall), to construct an actual three-dimensional object.

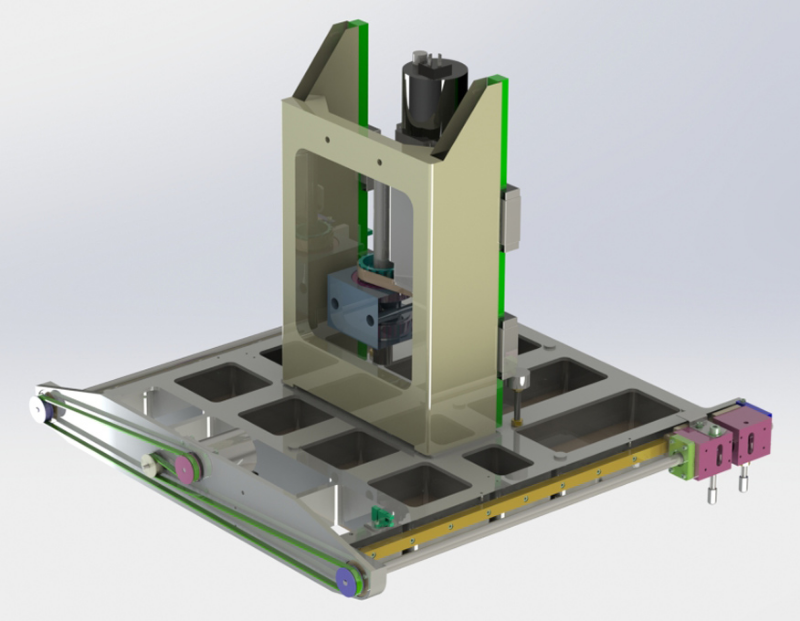

3D printers come in many sizes and styles, and as you can imagine, a wide range of prices. From a cost and ease-of-use standpoint, the type of printer used most often in an educational setting is known as an FDM printer. FDM stands for Fused (or Filament) Deposition Modeling. These printers construct an object by laying down (depositing) layers of melted plastic that adhere (fuse) to other layers of the object (which is based on a 3D computer drawing, or model).

There is also a wide variety of plastic types available to print with, but the one most commonly used is called polylactic acid (PLA), a biodegradable plastic made from renewable plant resources. (The plastic is purchased in reels that look remarkably similar to the spools of plastic filament that you load into your garden string trimmer.)

There are other types of 3D printers available, but for the remainder of this article, we’ll stay focused on these deposition-type printers. For a more in-depth review of 3D printers, you can check out our article on the history of 3D printing. In the meantime, let’s move on to the advantages of using 3D printers and 3D printing technology in education.

3D Printed Objects Themselves Can Be of Tremendous Value in the Classroom

3D printed objects themselves can be an invaluable teaching aid. Studies have shown that providing visually oriented instructional materials to students improves their overall ability to learn. An obvious example involves art: Most students can develop a much greater appreciation of a famous work of art by viewing the work directly.

School systems rarely have the financial resources to fly children to major museums around the world, however. So until recently, teachers have been limited to using photographic reproductions. But now, 3D scans of thousands of the world’s most famous sculptures and statues are available online for printing on 3D printers.

Students can now visually and physically examine replicas of the world’s greatest masterpieces in detail. (This has the potential to be even more of an awe-inspiring activity when you consider that visitors to a museum are usually prohibited from touching any works of art.) It is also possible to make three-dimensional, fully textured replicas of celebrated paintings using 3D scanning and printing technology. These replicas accurately reproduce the finest details of the paintings, down to the very brushstrokes themselves.

In addition to their visual impact, 3D printed objects can have a positive effect on an approach to instruction known as active learning.

There are probably as many definitions of active learning as there are proponents. Most would agree that active learning is a process by which students master a subject by developing skills associated with that subject (as opposed to passive learning, where students simply absorb information by listening to lectures and reading textbooks.)

To the point: An example of passive learning is you reading this article about 3D printing in the classroom; an example of active learning is students in the classroom actually designing and printing 3D objects (and collaborating with others to troubleshoot any problems they encounter along the way). Active learning has been shown to improve students’ critical thinking skills and increase their attention during class.

But there are other educational benefits to 3D printed objects.

It Isn’t Only about 3D Printed Objects

Getting involved with 3D printing technology involves much more than just turning on and running the printer. Students need to know how to prepare a 3D computer-aided design (CAD) model for printing, they need to understand the mechanics of 3D printing itself, and they need to know what actions to take when things go wrong anywhere along the process.

But even before all that, students need to have 3D models to print. Obtaining or designing these models is an activity that students of all ages can participate in, regardless of their level of educational ability.

3D printing starts with a 3D model of the object to be printed – a three-dimensional digital representation that accurately depicts the size and shape of the desired finished product. Younger students, and those with lower skill levels, can select from an almost limitless number of pre-existing designs. Older students, and those with higher skill levels, can be encouraged to use their imaginations to design models of their own.

There are many software programs for 3D modeling in use today, some quite sophisticated, many available at no cost. Tinkercad, SketchUp, Fusion 360, and Blender (sometimes spelled Blendr, but far and away the most popular program out there) are examples of free software programs that run on a variety of operating systems, either as stand-alone programs or in the cloud through a web browser.

Teaching students the fundamentals of design challenges them to use their imaginations, helps them develop critical-thinking abilities, and provides them with skills that can be applied in many other areas of life. Which is important, because:

Learning about 3D Printing Prepares Students for the Jobs of Tomorrow

In recent years, 3D printing has increasingly been moving out of development labs and into actual use manufacturing products out on factory floors. This trend is expected to continue for the foreseeable future. As the cost of shipping, labor, and of producing parts in general increases abroad, industry experts expect more companies to bring the manufacturing of goods, and the jobs that go along with that, back to the United States.

3D printing technology will prove to be the cornerstone of this economic transformation. And job seekers having hands-on experience with this technology will have a competitive advantage when trying to land these new openings.

For many years, one of the significant uses of 3D printing has been for a process known as rapid prototyping. In rapid prototyping companies, engineers and designers can create an actual full-scale model of a product, based on the engineering drawings, in a matter of hours using a 3D printer. For that matter, actual finished products could be produced in this manner.

But while creating a prototype with a 3D printer can be considered a rapid process (and it is, compared to machining and assembling individual parts by hand), until recently, the same process has been considered too slow for manufacturing purposes. It turns out this is not necessarily a bad thing when it comes to manufacturing customized items, or for products that would be difficult, if not impossible, to manufacture using other methods. But historically, 3D printing hasn’t been used much for the mass manufacturing of products, especially compared to faster methods such as computer numeric control (CNC) machining.

But no longer. Industry insiders are now claiming that 3D printing speeds have been doubling every two years and will continue to do so. And while this increases the possibility of using 3D printers for high-speed production lines, the jobs that will be created will be mostly higher-skilled positions. Learning the ins and outs of 3D printing technologies in school will help students be better prepared for these future opportunities in the workplace.

But even considering the mass production of products, as we mentioned above, when it comes to the benefits of 3D printing:

Students Will Learn CAD along the Way

One of the steps in fabricating an object using 3D printing is preparing the 3D CAD model for the printer. While the model itself contains all the information needed to uniquely identify its size and shape as a whole, the printer will be printing the object in individual layers. So, slicer (or slicing) software must be used to divide the digital model into numerous thin slices and then convert this information into a format readable by the printer. (Cura is an example of one of the more popular open-source programs available for this purpose.)

In just a matter of seconds, the slicer software breaks down a CAD model into an instruction set known as g-code. G-code contains all the commands that control the speed and direction of the print head as it deposits layer after layer of extruded plastic to form the 3D printed object.

For some students, g-code may be their first exposure to programming. Since an instruction set can be many thousands of lines long, students won’t necessarily be coding the commands directly. Fortunately, the slicing software handles this task automatically. But if there are problems with the object during printing, it is often helpful to be able to examine the code to look for obvious problems.

Even though slicer software handles g-code creation automatically, this exposure to coding is an excellent introduction to full-fledged computer programming. Slicer software handles much more than

There Are a Ton of Resources Available on the Subject for Teachers

Most of the discussion so far has been focused on how learning about 3D printing benefits students. But there are benefits for teachers as well. MakerBot, a 3D printer manufacturer in New York, offers a guide to 3D printing called the MakerBot Educators Guidebook that they make available for download at no cost. And Leapfrog, another maker of 3D printers, offers free instructional courses on their website. A quick search would turn up much more.

We may not have to wait much longer for 3D printing technology to progress to the point that it enables schools to provide students with badly needed classroom supplies like 3D-printed pencils, scissors, and crayons. But as we’ve noted before, when it comes to the benefits of this technology:

Students Will Learn Invaluable Skills

While the most rewarding part of the whole 3D printing process, at least in the minds of students, may be the moment when they can finally hold their completed projects in their hands, the most rewarding educational experience will be the knowledge they acquire by learning the mechanics of printing those projects.

As we discussed earlier, to print a 3D object, the CAD model must be cut into layers by slicer software. This software is often designed to also allow users to adjust many of the parameters associated with how they want the object to print. Many slicing programs have settings that will enable users to adjust, for example, the height of each layer, or the thickness of the object’s walls, or even the object’s size and orientation while it’s being printed.

Students will also learn how to set up and adjust the printer itself, from simple decisions like choosing the color of plastic filament to load, to more complex chores like leveling the print bed (the platform the object is printed on). Special tools and skills are usually not needed when getting a 3D printer ready to print, but close adult supervision will be necessary for younger students.

Handling the preparations and final adjustments necessary before an object can be printed will help students develop hand-eye coordination as well as creative- and critical-thinking skills. Students will also build confidence in working with tools and with the printer itself, which will be helpful when working with industrial, office, computer, and lab equipment later in life.

As such, learning to work with intricate software and precision machinery will also provide students with another lasting benefit.

Becoming Proficient with 3D Printing Technology Teaches Students Troubleshooting Skills

Even though 3D printing has been around for several decades, in some ways, it’s still an evolving technology. To illustrate this, let’s consider our ink-jet printer analogy from earlier. To use an ink-jet printer to print a document or photo, you simply turn the printer on, queue up your document, and click the [PRINT] button. That’s it. Problems occur relatively infrequently, and when they do, the fix is usually fairly straightforward.

The same can’t be said for 3D printers. While the technology is impressive, 3D printing is still a very complicated process. Even high-end machines that usually crank out print jobs consistently and reliably will experience problems from time to time (or at the very least, will need maintenance performed at specified intervals).

Which means when you’re printing an object on a 3D printer, things are inevitably going to go wrong, either on the software side or with the hardware. And that’s actually a good thing because it’s in the solving of problems that the opportunity for real learning happens.

3D Printing Is Changing the World

It has been said that 3D printing is going to change the world in ways that haven’t even been imagined yet. There is no doubt that it’s having an impact even now, in fields as diverse as aerospace, fashion, and medicine. But whether or not students will eventually utilize 3D printers when they enter the labor force, the skills they will acquire today by learning about and working with 3D printing technology will serve them well, regardless of their chosen careers.

If you have an idea for a product you’d like to get 3D printed, let us know. Connect with Cad Crowd to have a 3D model designed that is ready to be 3D printed. Find out how it works!