Imagine you’re about to wind up your first design task and you’re impatiently waiting to create a prototype to assess your success. But do you know there’s a very high probability of needing to repeat the design process, as many designers leave out many aspects of their first design.

To avoid such omissions, you need to have a definitive plan for anything you intend to design so that you avoid leaving out crucial features, and knowing these tips to create impactful prototype designs will help too. The plan will help you carry out all the activities required in an orderly manner. If you don’t create a good plan, the project is likely to fail.

I’m sure you agree with me that a well-designed prototype is a preliminary and essential step in strong product design and development services. It’s no surprise to find yourself coming up with many prototypes that act as early versions of newer prototypes you develop in the process of creating the perfect one. This is totally normal and should not worry you.

To help you create impactful design prototypes, we have prepared several tips that will make you an expert.

Tip 1. Evaluate Demand of your Product

The first thing you need to do is decide on the product you want to develop. Once you identify the product, assess whether the targeted customers really need the product so you don’t develop something with no demand. You will need to do deep research on the market and the products currently serving the same purpose as the one you want to develop.

It’s important to determine whether your idea is really viable. It’s not just about designing the prototype, but you also need to ask yourself if you can make the real product out of the prototype. If you can, then you’ll have passed a test of technical peril.

It’s also good to assess whether people will want to buy the product. This involves determining the demand for your product. You don’t want to experience losses with your product, so you should find out if customers are interested in the product you intend to introduce into the market.

Consider the cost of production and estimate the probable income over a certain time to see whether there will be a good profit in the new product. You pass the second test if your answer to these issues is positive.

Finally, think about the technological aspect of your product before making moves into prototype development. Is the approach you intend to use up to date? Does it introduce an improved version of an existing product? If yes, then go on.

Otherwise, leave it out, because people are always advancing in technological aspects. The only thing you should do is develop advanced tech products with a simplistic user approach. However, if the product is fully new in the market, use the prototype to showcase its features and functionalities to your potential customers.

Tip 2. Draw a Business Plan

You have found a niche, and the product has a high demand in the market. Don’t rush into the development of your prototype and throw yourself into the task at hand without considering all aspects. Instead, sit down and develop a good business plan to guide you in the process.

The following are the key things you need to consider when coming up with a viable business idea:

- The problem that your product solves

- The manner in which people tackle the challenge today

- The level of excellence of their solutions

- The gaps in the solutions

- The cost involved in developing them

- The uniqueness of your solution compared to existing ones

- Selling price of your solution so that you earn a profit

By answering the above issues, you will be in a position to come up with a product that the market needs. If you ignore these factors, you’re likely to develop a product that customers don’t want. I know you don’t want to lose everything you have saved and become broke. Drawing a good business plan, therefore, is a crucial step in developing a good prototype design.

Tip 3. Know What is Essential

Once you decide on the product to develop, the next step is to create a list of the most important points that should not be missing from your prototype.

Your product design has a lot of features. Some are basic while others are advanced. Therefore, write down all the crucial features and prioritize them.

I am sure you’re not planning to use your entire fortune in developing the prototype. Therefore, the cost is another factor you should consider while in the process of developing your prototype. Before you run out of funds, have the crucial elements done.

We would advise you to make a list of all elements that you want to be in the prototype and rank all of them from most important to the least. Now, assume you run out of time and funds. It will be easy to draw a line up to the point where you can cut out the less important.

Tip 4. Don’t Be Too Economical To Avoid Losses

Avoid being extremely economical when developing prototypes. When you realize there is a niche in the market and you want to develop and introduce a product, you should take the shortest time possible before you lose potential profit you could have earned when the product was in high demand.

RELATED: 101 Inventions That Changed the World in the Last 100 Years

Such a delay might be caused by some bad decisions such as not outsourcing services like 3D designers, and you wanting to spend a whole year learning and doing the design yourself. You will lose a lot compared to hiring a freelance CAD designer and saving the time. I’m sure you want to introduce the product before a competitor gets to it. Therefore, be flexible enough so you can market your product when demand is still high.

What is the point of holding back $2,000 you would have paid to a designer to make the prototype and risk losing $100,000 that your hot product would have fetched you in the market? Be flexible.

Tip 5. Choose Your Prototype Plan According to its Use

It is essential that you first understand the use of your prototype before you even get down to designing it. In case you want to make several prototypes, what is the purpose? Do you want to imply that a particular feature in one works better than the other? Are you trying to test the balance and compatibility of the prototype parts or are you looking to find out if the parts are working well and in good coordination?

Are you designing the prototype to showcase to an investor or manufacturer you wish to partner with? If so, then you could make the prototype simple yet visually appealing.

When you want to convince your boss at the workplace to adopt a new product you are developing for a certain task, you could concentrate on the functionality of the prototype to seek approval from the boss. Therefore, it all depends on the purpose of the prototype.

Make sure you respond to the above concerns before you make the prototype so that you know the approach to use in developing it. In this case, you are certain of what strategy to use as well.

Tip 6. Keep the Prototype Simple and Fast

To avoid losing the purpose of the prototype, develop it within the minimum time possible. Building a prototype should not take a significant portion of the time needed to create the actual product. Do not be obsessed with coming up with an ideal prototype within the first attempt as it will take a lot of your time. Do it in stages and embrace change whenever it arises.

I’m sure you don’t want people spending a whole day trying to understand your product image, and therefore, keep it in its simplest yet most comprehensive form for your potential customers.

Tip 7. Use Scaling

You now know the purpose of your prototype, and we are taking steps towards actualizing it. For you to save on money and space, it is advisable that you use scaling. This ensures you don’t need materials to make a whole thing, but just part of it as the prototype.

For instance, if you want to start making improved new glass tables, you could make just an eighth of the table using an eighth of the materials for the actual table. This saves you not only money but also the time required in making the table design.

Tip 8. Use Symmetry to Your Advantage

If your product is divisible into two equal parts, then you are lucky since you can use a single prototype to come up with two designs at once. All you need to do is be very skillful so as to visualize each half as a full product prototype. The line of symmetry, if well used, can save you money and time since a single prototype gives you two different designs.

Tip 9. Design the Prototype on Paper

Now that you have a list of all that will go in your prototype design, it’s time to design it.

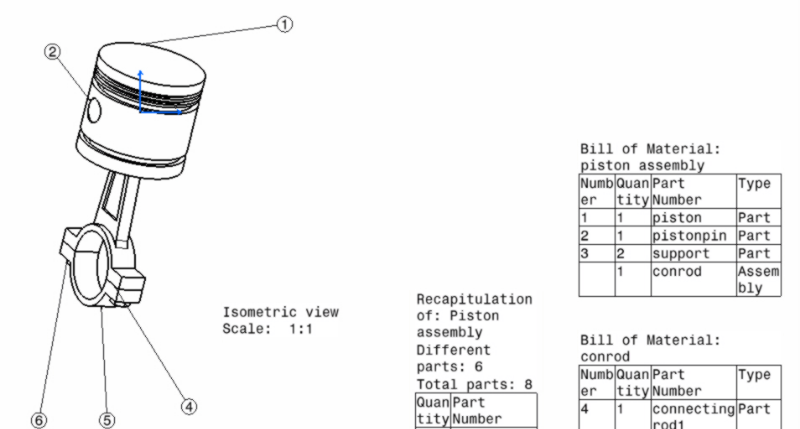

At this stage, we want to make a design of the product that we identified. The imaginative and creative power that you learned in your art classes sets in. You need to close your eyes and conjecture the picture of the product in your eyes, putting anything down on that drawing paper. Now that you have a clear picture in your mind, you need to sketch the product on a paper including everything in its right position. Ensure that you do not distort or omit anything on the design to avoid errors in the final prototype.

The 3D and CAD drawing programs are the best way to draw these designs, hence familiarity with the programs gives you an added advantage. However, you can still learn the way the two work and then try drawing the design. You can also get an expert to draw for you if you don’t have the time to learn.

The driving force here is that you must create a visual image of your design before developing the prototype.

Tip 10. Create a Mock Prototype

We advise you to begin by creating a prototype that does not work. At this stage, you can use a stone or wood and curve the exterior part of the product and see whether all the physical features of your product are well represented. If they are not well presented, simply go back to the designing stage and make some changes.

For instance, if you realize that your design looks bigger or smaller than what you intended to create, simply adjust the prototype or the design to your satisfaction. The purpose of creating a non-functional prototype design is to avoid transferring errors over to the real prototype.

It is advisable that you make several mock prototypes so that you will have a variety to test. Sometimes one prototype may not meet your expectations, and you have an advantage since you just turn to an alternative design.

Tip 11. Every Prototype is an Experiment

When you make your first prototype design and realize that it has some faults, you don’t stop there and hope to correct the mistake during manufacturing of the actual product. Make several others and discover something new in every prototype. The truth is that each prototype contains varying measurements and dimensions.

There are ideal measurements that will go into your final product. However, it is hard to get these dimensions in your first design and as a result, learn something new in each and every prototype you develop until you arrive at the best. It is better to make errors at the prototype development stage rather than doing so at the product development stage. You should, therefore, repeat the prototype design until you get the ideal dimensions rather than waiting for the untimely failure of your product. This way, your engineering design services won’t need to clean up the mess.

Let each prototype that you make be a source of learning for you. Show some people the prototype and ask for their opinions and recommendations that can help you improve the design. Therefore, make the best use of resources to avoid frustrations that come with the wrong product design.

Tip 12. Develop Prototypes for Specific Features

We saw that you should first identify all essential features that should go into your prototype. Therefore, after identifying them, you do not have to wait so that you have all the features to develop the whole thing.

You can start by first making prototypes for the already known features. This gives you a chance to spend quite a good time thinking and developing the feature. I bet by doing so, you will make an almost perfect prototype of selected features.

However, it does not mean that these features prototype cannot be edited further. It is very possible to make changes to match it with other features that come up in the process.

When making specific feature prototypes, you can consider making more than one version in case one does not work well. For example, if you are making a prototype of a tin that will be used to can meat, make a prototype of the lid first. You can have it in diameters of 10cm, 12cm, and 13cm. As you develop the other features, you will select the one that matches with the other features to be developed.

Tip 13. Convert the Mock Prototype into a Working One

You have done all the necessary corrections on your mock prototype, and you have a desirable design. The next step, therefore, is actualizing the prototype. Actualizing it requires you to put all the necessary parts in place so that you develop a real working thing. At this juncture, you can present the prototype to people to see.

This is also a great time to do some modifications to the product. The adjustments, which include identifying all the parts that are not necessary for the functionality of your product as well as adding those that are necessary, give you a chance to enhance or lower the cost of the product.

At this juncture, tune the product to your satisfaction until it resembles the end product that you want to introduce to the market.

Once you are done tuning it, you can now go to the final step of building the actual product. You could consider liaising with a manufacturer or get a bank loan to build your own plant for producing your new product. It all depends on what you want and the resources you have.

Parting Shot

Developing an impactful prototype design is not a single event but a process that should be taken very seriously as it can make or break your project. It starts with determining the right product, creating a plan, developing non-functional prototypes, and eventually making a good prototype or several prototypes.

During the process, it is good to observe simplicity, use scaling to avoid wastage of resources, get the best out of symmetry, and ensuring you take the least time possible. Remember that you are in business and you must minimize the cost of production by making sure you fully utilize all the materials you have at hand.

A good prototype leads to a good product which increases the prospects for that product in the market. If you want to become a pro in designing prototypes, just follow the tips above and you can’t go wrong.

At Cad Crowd, we can assist you with designing and creating your own prototype designs. We have the best CAD design freelancers in the world on our platform, and our services are backed by an accuracy guarantee.