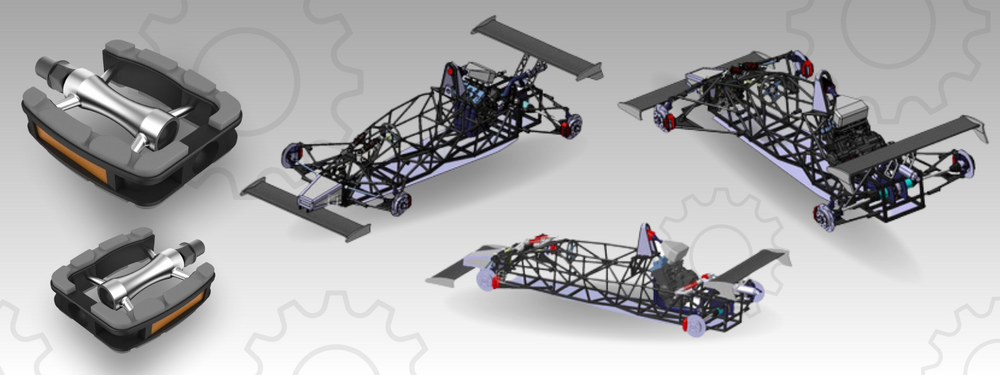

CAE, or computer-aided engineering, focuses on improving product design and solving engineering problems using computer software. It applies to various engineering processes, from design to manufacturing. CAE engineering utilizes digital simulation to perform design validation, ultimately leading to product optimization.

A massive advantage of CAE is that it doesn’t require a physical product to conduct the tests. The procedure continues with CAD and 3D modeling services, which model a product on a computer to see if the design meets the desired parameters. Simulation in a virtual environment saves considerable time and money, yet it still delivers accurate results.

Table of Contents

Table of Contents

Cost of CAE Engineering

In the United States, CAE engineers earn from $67,725 to $86,767 annually (or around $32 to $41 hourly); the median salary is $70,000 ($33 per hour). CAE may include many tests, including but not limited to thermal analysis, finite element analysis (FEA), and computational fluid dynamics (CFD).

An exact project quote depends on the scope of the work and the professional’s qualifications. A CAE engineer uses CAE tools and freelance 3D CAD drafting and design services during early development to aid decision-making regarding product materials, shape, and overall design.

| Cost of CAE Services | Range | Median | Additional Notes |

|---|---|---|---|

| Annual Salary | $67,725 – $86,767 | $70,000 | U.S. CAE Engineer’s Annual Salary |

| Hourly Rate | $32 – $41 | $33 | U.S. CAE Engineer’s Hourly Rate |

| Project Quote | Varies | N/A | Depends on scope, qualifications, and complexity |

Note: The cost of CAE services varies depending on the project’s complexity, the specific design aspect being analyzed, and the professional’s qualifications. The table provides a general overview of the cost and types of CAE analysis. An exact project quote is determined based on the project’s scope and requirements. CAE simulations, conducted by CAE analysis experts, use 3D models to eliminate the need for physical prototypes and depict real-life conditions for product testing.

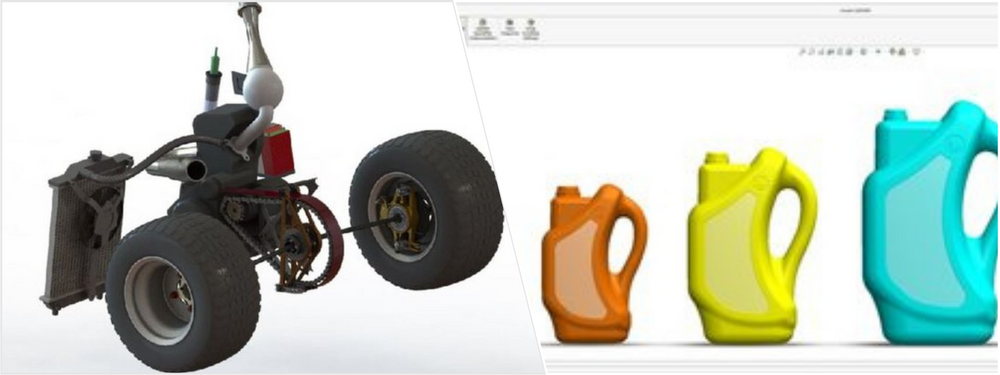

All the computer-based engineering techniques performed under the umbrella of CAD and CAM fall into the CAE category. Each CAE analysis focuses on a specific design aspect. However, some products require additional research to ensure safety, efficiency, and performance.

Relatively simple products such as sports equipment and bicycles may only need FEA simulation; complex electronics and piping infrastructures must undergo computational fluid dynamics (CFD) and thermal analysis to validate the designs before production. Otherwise, a small mistake in design can lead to an expensive revision.

| Types of CAE Analysis | Examples of Products | Purpose |

|---|---|---|

| Finite Element Analysis (FEA) | Sports equipment, bicycles | Validate design and analyze stress distribution |

| Computational Fluid Dynamics (CFD) | Electronics, piping infrastructures | Analyze fluid flow and thermal performance |

| Wind Tunnel Simulation | Road cars | Test aerodynamics and air traction |

| Stress Analysis | Buildings | Test structural stability under excessive load |

The simulation depicts real-life conditions or environments where the product is expected to be used. For example, to test the aerodynamics of a road car, CAE will turn to wind tunnel simulation to see how the air affects traction; to test how a building withstands excessive load, an engineer can run a stress analysis, often with the assistance of stress analysis experts.

RELATED: What are CAM engineering costs, company fees, & consulting service rates?

How it Works

There are three stages of CAE:

- Pre-processing: engineers build a 3D model of the system (or product to be tested) and design the required physical effects.

- Analysis (solving): engineers run the simulation, exposing the model to the physical effects in a digital environment.

- Post-processing: the result of the analysis is presented for review.

CAE software can generate digital objects to represent real-world forces such as heat, vibration, electromagnetic, snow, flood, and storms depending on the type of analysis. The accuracy of the analysis result entirely depends on how precisely the engineers model the system and the virtual environment.

Running a CAE simulation for complex geometries is hardware-demanding, and this means CAE requires an extensive amount of computational power, which is a big hurdle for small companies. The good thing is that sophisticated IT infrastructure like cloud computing makes it easier and more affordable for startups to access CAE without heavy financial investment. Engineering firms specializing in engineering design services and CAE analysis offer their expertise at competitive rates.

Advantages of CAE Engineering

The most significant advantage of CAE is that everything is done on screen. CAE is more efficient and requires fewer resources (i.e., time and money) than building and testing a physical prototype. Physical prototypes are necessary within the design process of any product, but the digital version reduces the urgency for a rapid prototype. Reducing the need for rapid prototypes can also lessen reliance on rapid prototyping companies, thus lowering production and development costs.

Early identification of design errors is crucial in product development. CAE helps detect flaws and refine the model before advancing. Simulations test multiple products, such as cars, using computer codes. Aerodynamics analysis experts analyze different designs in a wind tunnel simulation, while thermal analysis examines engine components in extreme temperatures.

Regardless of the analysis, CAE affects how a company designs a product. Designers and engineers use CAE to verify that the final product meets durability, performance, energy usage, and functionality requirements. The analysis demonstrates that a product, assembly, or components will fail to function. The company will then improve the design, often leveraging new product design services, to prevent the same failures from happening in a real-life scenario.

RELATED: The career path of CAD engineering, salary, rates, and more

Applications of CAE Engineering

CAE has been around for years and has undergone significant advances since it first emerged. Over the last decade, CAE has established a strong reputation as a reliable design verification tool in many industries, including automotive, infrastructure, consumer products, and electronics.

Despite the modernization and rapid development of computing hardware to increase accuracy, CAE still is not a complete replacement for physical prototype testing. The analysis results are, in essence, an educated guess at how a product performs under stress. A physical prototype, often developed through prototype design engineering services, is still necessary to define the actual boundary conditions and level of exposure to the elements.

CAE simulation is considered wasteful for sophisticated products like aircraft and smart systems (e.g., smart homes or smart cars). First, the products are composite materials, making it difficult to define the correct parameters for setting accurate boundary conditions.

Second, a complex product will require advanced analyses (including each system and component). With CAE, the cost and the computational power requirements are equally high. However, CAE is a dependable tool to explore how a product will perform before production begins.

Summary

Computer-aided engineering (CAE) is a transformative technology that enhances product design and addresses engineering challenges through digital simulation. By enabling virtual testing and design validation, CAE eliminates the need for physical prototypes, leading to significant time and cost savings.

CAE engineers in the United States earn a median salary of $70,000 annually and oversee various simulations, including thermal analysis, finite element analysis (FEA), and computational fluid dynamics (CFD). Project costs vary based on complexity and engineer qualifications.

The CAE process involves three stages: pre-processing, where a detailed 3D model is created; analysis, where the model undergoes virtual simulation; and post-processing, where the results are reviewed and interpreted.

With advancements in cloud computing, CAE has become increasingly accessible and affordable. Its benefits include early detection of design flaws and reduced production costs. Though not a replacement for physical testing, CAE provides valuable insights and is widely used across automotive design services, consumer products manufacturing, and electronics industries.

How Cad Crowd can help

Cad Crowd provides expert CAE services for businesses seeking design optimization and engineering solutions. Our experienced engineers utilize CAE to deliver high-quality results tailored to your project’s needs. To get started and receive a project quote, request a free quote for CAE services from Cad Crowd today!