When the home computer became a mainstream device during the late 1980s or early 1990s, the subsequent progress and widespread usage of digital technology were pivotal in developing and increasing electronics’ popularity. Compared to the early version of gadget designs introduced to the market, modern electronic devices are usually smaller, smarter, and equipped with more features. For example, TVs are now thinner, yet they produce much better picture quality; hard drives are much smaller but with much higher capacity and speed, and mobile phones can now do complex computation.

Every electronic device follows a similar development path to achieve the same purpose of becoming more sophisticated, economical, and accessible.To keep up with the increasing demand and fierce competition, companies have no choice but to speed up the production process without sacrificing quality and cost-efficiency. This gives rise to electronic manufacturing services (EMS), a range of design processes of electronic products handled under the roof of an outsourced entity.

EMS typically works on a contractual basis. Companies may hire them at any given point during the production process, meaning the collaborative work neither has to start at the beginning of a design process nor end at the final stage. EMS can provide something relatively simple like assembly and product testing or more complex solutions such as rapid prototyping services and component manufacturing.

Table of Contents

Table of Contents

Types of services

The term EMS covers various engineering design services works in the electronic product manufacturing process, including but not limited to design, prototype, assembly, distribution, supply chain management, aftermarket, and product analysis. The companies that provide such services are referred to as EMS. In more detail, the standard services are as follows.

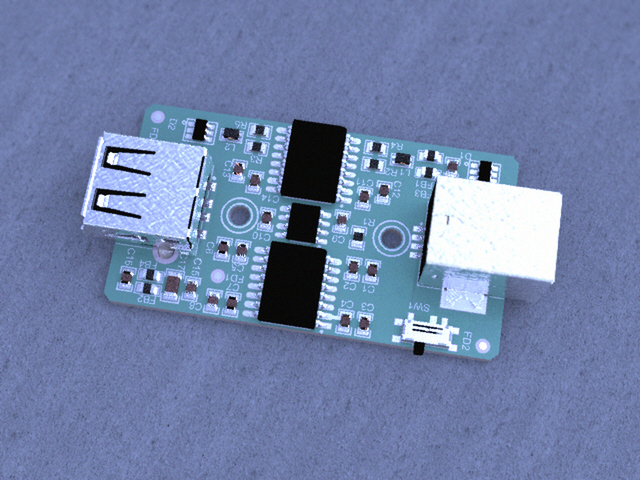

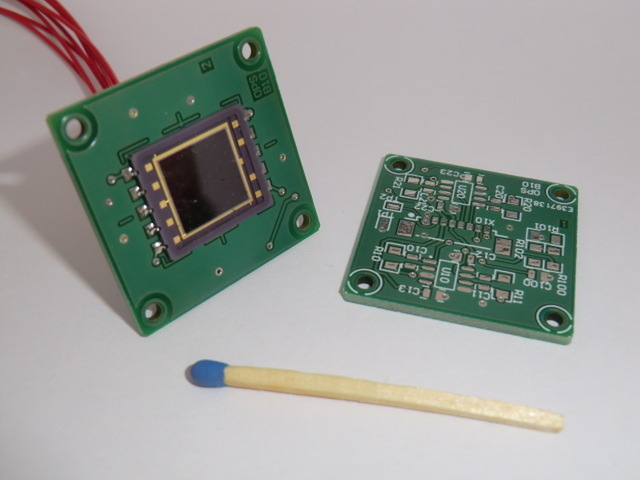

Printed circuit board assembly

The layout, design, and components of PCB are key factors to determine an electronic device’s functionality and how well it delivers those functions. EMS may use surface mount technology or soldering techniques to place transistors, resistors, and integrated circuits on the board.

A fully assembled PCB is the backbone of an electronic product (like a motherboard on a computer) to route power.

Cable assembly

For PCB and other product components to communicate with each other, they must be connected by electrical wires. Better quality wiring translates to higher efficiency. EMS helps optimize hardwiring by choosing the best possible conductor diameter, jacketing, insulation, and shielding materials appropriate to the company’s specification for the finished product. Testing the connection prior to high volume assembly is necessary.

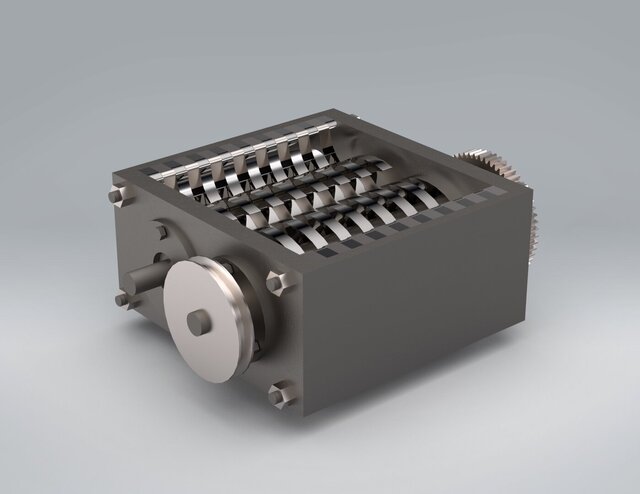

Box builds

Sometimes referred to as electromechanical assembly, box builds are the processes involved in manufacturing enclosures for PCB, point-to-point wiring, wire harnesses, and the box’s mechanical structure. It must be done with intrinsic safety in mind to protect workers from a variety of threats. Electronics design services work on them.

EMS can do this by simplifying circuitry, adjusting components to minimize shorts, and controlling internal temperatures. Enclosures can be made of plastic, metal, alloy, or a combination of multiple materials. Box building services may also include encapsulation and custom packaging.

Testing

Before a completely assembled PCB and the wiring and enclosure are ready to ship, the company wants to make sure everything works as intended. EMS is responsible for a series of testing to verify the product’s functionality and specifications. Inspection services range from simple visual checks to complete functional tests.

RELATED: How much do manufacturing services cost for your company prototypes, products & new parts?

EMS commissioned to conduct functional tests essentially perform turnkey operations because the inspection covers the visual aspect, safety, and performance. A product that passes all the tests is ready to use out of the box or very close to the final version. Extensive testing yields better quality electronics, thereby fewer defects, and fewer returns once the products are in buyers’ hands.

Prototyping

In the old days, EMS were mostly factory partners contracted to build PCB. Still, now they have expanded the range of products and services to an entire OEM system, including prototype design services making electronics. Just like all other products, prototyping offers invaluable benefits:

- Design check: A prototype, although looking like a fully functional product, is not for consumers but only for testing purposes. EMS can help identify any design flaw and recommend improvements to be implemented in the final version.

- Durability test: To see how durable a product will be in the hands of consumers, an effective method is to have the prototype exposed to abusive usage scenarios such as extreme temperatures, multiple drops, power surges, or plain and simple careless handling.

- Function confirmation: Having a prototype allows EMS to use a pre-production unit to confirm that all functions and features work as intended.

Releasing a flawed product to the market can be a costly mistake. Even big companies do it, such as Google with its Nexus Q and Samsung with the first version of its folding smartphone, among others. Prototyping helps a company stay on budget because all redesign and refinements are done before the final version hits the production line and reaches customers.

Contract design

Before the manufacturing process starts, an electronic company needs robust documentation, including a complete set of component specifications and bill of materials.

EMS can generate all those reports in accordance with a company’s objectives. If need be, EMS will also develop specific software or firmware to get the job done. The validation process is included in this step, so unplanned changes and updates are highly unlikely.

Inventory management

When the electronic device to be produced in high volume is reasonably sophisticated, the company may have to deal with a complex supply chain. The company can have EMS manage the logistics too.

An experienced manufacturing service with a respectable portfolio has the buying power to help drive down the cost of product components and their distribution. If the company demands, EMS will even handle the packing and shipping of consumer-ready products to warehouses.

Aftermarket services

As mentioned earlier, today’s electronic manufacturing services are not just factory partners that assemble and test PCBs, but full-blown turnkey services with the capacity to handle the entire production line of electronic devices on companies’ or clients’ behalf. The work continues after the production process with aftermarket services, including repairs, refurbishment, updates, and upgrades.

Product analysis

An inevitable part of the manufacturing lifecycle is component obsolescence when one or more components of an electronic product are nearing its end-of-life cycle. When the same problems are reported multiple times, which require the same repairs, EMS can propose a redesign that can save the company money in the long run. An electronic part becomes obsolete not only because of persistent issues, but sometimes the component is discontinued in favor of a better replacement.

Future of EMS

Of all the manufacturing industry changes, the advent of machine-to-machine communication is arguably the most critical step, leading to a range of innovations in the EMS field. The introduction of smart factories has allowed EMS to expand their business sectors and reach new kinds of electronics.

EMS with a strong inclination to embrace innovations are likely to stay at the forefront of the industry as they can take full advantage of many exciting technologies:

- Automation: Programmable robotic arms in the assembly line of electronic components and devices can only boost an EMS’s productivity, competitiveness, and profitability. The miniaturization of electrical components is unavoidable, and the presence of automatic assembly by robots increases accuracy and eliminates human errors.

- Internet of Things (IoT): The implementation of IoT may help an EMS create a more efficient autonomous assembly, better quality control, automatic error identification, robust safety measures for workers.

- Cloud computing: Utilization of cloud computing helps streamline communication between the company, EMS, and component suppliers. Every party involved can access the same central data.

- 3D printing: Mostly used for quick prototyping purposes. At this point of development, injection molding services remain the best method for mass production.

- Big data: Discovering patterns of error in the assembly line can anticipate potential mistakes in the future. The computation of large sets of data may also reveal room for improvement in every aspect of the business.

Another primary key in EMS practices is secure data infrastructure. EMS is responsible for protecting clients’ intellectual property even after the project has come to an end. Product design services need to be sure that their designs and innovations are kept safe in the right hands of a trusted partner. Implementing all those innovations will cost EMS a sizable investment amount, but the ROI certainly looks promising.

Growth of EMS

In 2019, EMS market size exceeded US 500 billion and is estimated to grow up to 5% between 2020 and 2026. It is a confident projection partly because EMS providers are keen to improve factory performance by adopting new technologies to support efficient operations.

RELATED: Engineering and product design advice for mass manufacturing services

There may be new global standards in the design for manufacturing industry thanks to upgraded EMS practices. Production capacity is expected to grow by a large extent, with the help of IoT and automation.

A significant portion of the projected growth is attributed to the increasing interest in smart home devices, especially in developed economies worldwide.

The United States will be the leading player in EMS development for the coming years. Many EMS providers have been expanding their capacity to produce microelectronic devices and wireless products and optoelectronics services, all for the smart home market.

Cad Crowd’s electronic manufacturing services are here for you

At Cad Crowd, we have the privilege of working with hundreds of the best manufacturing services in the world. If you need to be connected with one, let us know today. Find out how it works.

first picture: USB Isolatorhttps://www.cadcrowd.com/3d-models/usb-isolator

Third picture: Two-dimensional Optical Postion Sensorhttps://www.cadcrowd.com/3d-models/two-dimensional-optical-postion-sensor