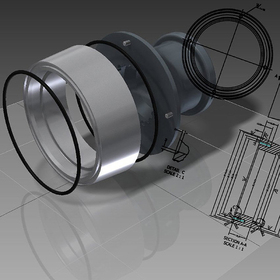

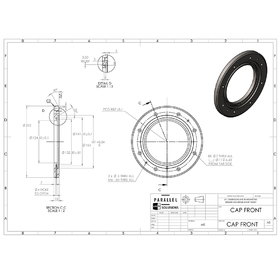

Computer-aided design (CAD) isn’t just for creating completely new designs. It can also be used to recreate existing parts. One of the best ways to save time and money when creating a new design is by using existing parts. But if you want to integrate an existing element into a new CAD design, then you need to recreate that part within CAD.

When digitizing a part, accuracy is essential. If your dimensions are off, then you can end up with a mismatch that could derail your entire project. This is why you need to hire an experienced CAD professional to translate the part into CAD format properly.

There are many different reasons why you might want a CAD model of an existing part. You might want to create a part you can’t buy, build a model to use in a larger design, or create a model you can use as a starting point for a new design. Let’s take a moment to look at each reason in greater depth.

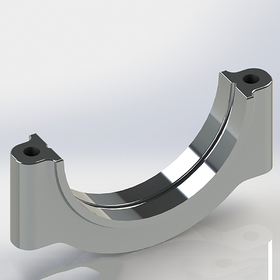

Few things are more frustrating than having trouble finding the part that you desperately need. If you work with older machines, you’ve probably run into a situation where the part you need is no longer in circulation. By using part-to-CAD conversion, you can create duplicates of parts that are no longer being sold by their original manufacturer. It’s important that you don’t just create a model that looks just like the original part, you also need a design that you can create physically.

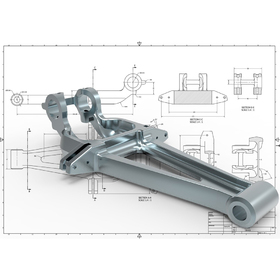

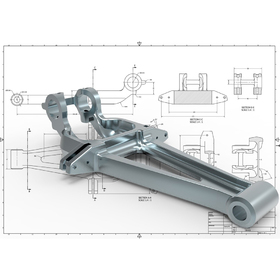

When car designers start drafting their next vehicular design, they don’t reinvent the wheel. They can save time and money by designing around pre-existing wheel standards. Most complicated pieces of machinery are built using a wide variety of preexisting parts. Utilizing existing components is an excellent way to cut down on costs, but you might not have access to the original CAD designs for the component. To integrate a part into your design seamlessly you need an accurate CAD model of the piece.

Every inventor builds on those that came before them. Most inventions aren’t entirely original creations but variations on existing designs. You might find that you have a goal in mind but while some parts come close to your vision none completely match your goals. Solve your problems by modeling the part in CAD software and then altering it to serve your purposes. CAD is great for reverse engineering designs so that you can rework them as you see fit.

The best thing is that no matter why you have the CAD file created you can go on to use it for different purposes later down the road. You might think that all you need is a replacement, but after you’ve replaced the original part, you could come up with an idea to improve on the part. In that case, you’d already have the CAD file to use as a basis for your new design.

CAD designers can use different methods to turn physical parts into CAD models. Each option has pros and cons. The method that gets chosen will depend on whether or not the part is available to the professional tasked with the conversion. Some parts are easier to acquire than others.

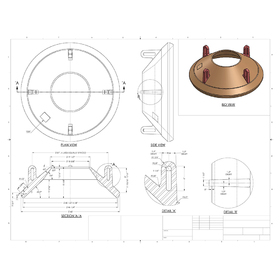

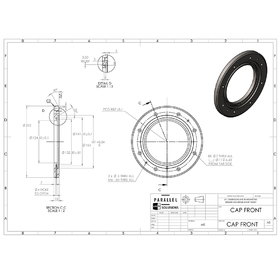

If you can send the part to a CAD designer for conversion, then they can perform a 3D scan. A 3D scanner uses lasers to scan any physical object that you place inside of it. As the laser scans the object, it automatically creates a digital model the same way a traditional scanner would create a 2D image. 3D scanning offers an incredibly high degree of accuracy, but it isn’t always easy for people to get their objects adequately scanned.

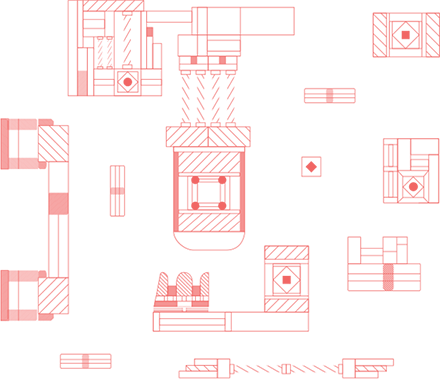

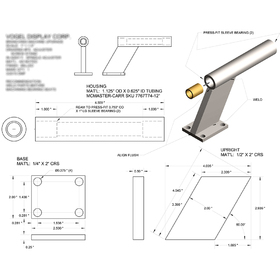

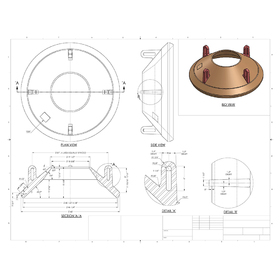

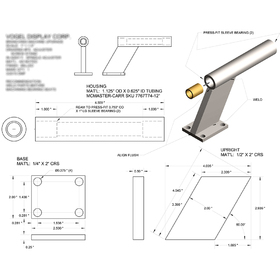

If there’s no way that you can send the part to a designer, then the options will be a little more limited. To make up for the lack of physical access to the part, you’ll need to try and provide as much information on the part as possible. Taking photos of the part from every angle and carefully measuring it will help create the most accurate CAD drawing possible. This method works well for simple parts that would be expensive to send in for 3D scanning.

The quickest and most accurate way to transform a physical object into a digital model is through the use of a 3D scanner.

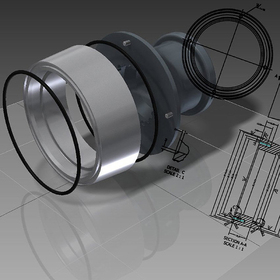

3D scanners work by pointing lasers at an object and recording the locations of every point on the surface of the object. This process can gather millions of points of data in a matter of seconds. After recording countless points, the scanner creates a point cloud which reveals a digital recreation of the original object. Because modern 3D scanners can collect an incredible number of points in a short period, it’s possible to create incredibly accurate 3D models. The resulting model can include minor variations that would be too small for the naked eye to see.

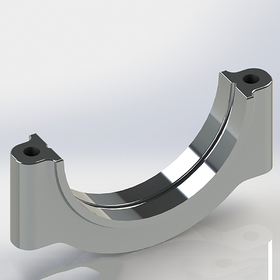

While having a 3D model made up of millions of points might be helpful in some scenarios it’s usually better to have a cleaner, sleeker model that will be more useful in CAD. This is why experts in part-to-CAD conversion carefully clean up the 3D scanner data to produce a model that is both accurate and useful. That model is then brought into the CAD program of your choice and converted into the final CAD model.

While 3D scanners have significantly improved the process of digitizing physical parts they still need to be operated by experts if you want to see the best results possible.

In an ideal world, everyone would have easy and affordable access to a 3D scanner. But the truth is that some people don’t have access to the technology and can’t send the part they need scanning off to someone who can get the job done. If this is the situation that you find yourself in then don’t give up, a skilled professional can still produce a CAD document through more creative methods.

More information is always better when it comes to recreating parts. To create a detailed 3D model from 2D photographs, it’s helpful to have photos taken from every angle. It’s also important to have measurements of each piece of the part so that the proportions and scale of the model will be correct. Of course, it’s not just about quantity. Quality of information is also essential. Pixelated photos or inaccurate measurements can derail a project.

Finally, think about whether or not the part has interior components that can’t be captured by a photograph. If a part is hollow, this will need to be noted if you want to recreate it accurately. In these scenarios, you might have to try and bisect or otherwise disassemble the part so that the designer can capture it, inside and out.

It’s important to realize that you should treat this method as a backup plan, a step you take if your attempts at getting your part scanned fall through. A skilled designer working with high-quality photographs can do a remarkable job of modeling the part, it just won’t be as accurate as the result of a 3D scan. While you should know that this option is available you should still do what you can to get your part scanned before deciding to go this route.

If you aren’t accustomed to working with CAD software, it’s important to remember that there are a wide variety of CAD programs that are available. Each program has pros and cons, with different industries and regions favoring different software.

Some options include:

This is a short list of options available. If you are working with a designer, they will likely recommend which software to use for your project, but if you have a preference they will likely be able to accommodate it. You can also request a CAD file that is designed to be compatible with as many different applications as possible.

Many companies will create a 3D model from your part, but that doesn’t mean they’ll provide you with the sort of CAD file you need. A 3D model might look good when it’s rendered, but that doesn’t mean that it was structured appropriately. It takes a skilled AutoCAD design service to properly structure a CAD model so that it can be built and upgraded effectively.

Creating a practical CAD design also requires the sort of critical thinking that computer programs can’t offer. While a program might mindlessly copy everything it detects when scanning a part, an experienced designer knows that things aren’t so simple. Imperfections and defects can appear in parts due to use or errors in manufacturing. A thoughtful designer will work with you to create a CAD model that goes beyond the surface level.

If you’ve ever found yourself looking to buy a new part for an old machine you understand how frustrating it can be. A project can easily derail simply because the people behind a particular part stopped producing them. Today you don’t have to call it quits just because a component is missing. With the help of our CAD freelancers, you can duplicate an existing part with complete accuracy.

Cad Crowd freelancers are a cut above the rest because we pre-vet everyone we recommend. We will help you digitize your part with complete accuracy.

Whether you’re looking to replace a part that you can’t buy anymore or integrate existing parts into a design that you are working on, part-to-CAD modeling is the solution to your problems. At Cad Crowd we will help you find an experienced CAD professional who can help transform your physical parts into digital models.

Contact Cad Crowd today if you have a part that you want to convert into a CAD file. We’ll give you a free quote, so you know exactly what you need to make your dreams come true. Don’t leave things up to chance, trust the conversion process with our experienced CAD freelancers.

Cad Crowd provides the world with excellent freelance 3D modelers and CAD services for all sorts of projects. Whether you're an independent entrepreneur or a company looking for flexible 3D design services, we can connect you with the best of the best. All of our clients get accurate and guaranteed service from experienced designers and engineers.

You can host a crowdsourcing design competition, where you leverage our entire community and they submit proposals for your project. You choose only the best design and pay once.

Regardless of what type of work you need to get done, our 3D modeling services are here for you. Contact us now for a free quote to get started today.