So, you have a market-ready idea for a new toy? The process from getting your idea out of your head to putting it on the shop shelves can be somewhat opaque. Here, we’ve put together a guide on how to navigate your way through the steps.

Designing toys should be as fun as playing with them. If you know what to do to get your idea onto the market, it can be an enjoyable and creative process. Once you know what to do, it will just be a matter of moving along the process, albeit sometimes slowly and carefully.

What to Do with Your Idea?

Wherever your inspiration comes from, the journey from mind to market is generally the same. This includes:

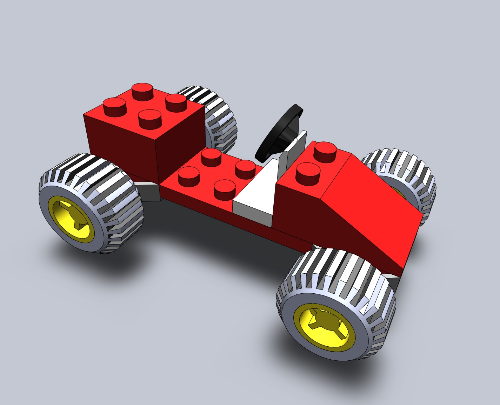

✔ CAD Design & 3D Modeling Services

✔ Prototyping

✔ Patenting (if needed)

✔ Pitching your toy

✔ Market research

✔ Manufacturing DFM (Design for Manufacturability)

✔ Children’s safety testing

There can be many pitfalls along the way and things that can be easily missed. A lot of these stages also have costs involved, although Cad Crowd’s CAD services and freelance design engineers can help you keep a lid on some of the money you’re going to spend.

Forewarned is forearmed, so in this guide, we will be covering some of the significant pitfalls as we talk you through the process.

Thinking About Your Design

Designing a toy well is going to be the key to all of the other steps working out. Once you’ve had your idea, you need to refine it by asking yourself some of the following questions:

- Who is in your toy’s target market? Whether you aim your toy at two-year-olds or ten-year-olds is going to have a massive effect on what the end-product will be. Sharp edges and small pieces are a big no-no when designing toys for toddlers. A toy with lots of moving parts is going to engage an older child.

- What is the point of your toy? A toy to help young children develop motor skills is going to look very different to a pre-teen team-building toy. If you’re going for something educational, you need to ensure that it matches the expectations for the age you’re targeting.

- Is sustainability a factor for you? The materials you use, the packaging your toy goes in, and how long it’s going to be used by the child are all things you’re going to need to think about. Working to reduce the environmental impact of the toy you design (learn about sustainable product development) could help give you an edge over competitors during the marketing process too.

What’s your price point? Spend some time in independent retailers, large chain stores, and online to see what’s available at different prices. The size of your toy and the materials you use are going to affect how much you can sell it for. The margins in toy retailing are generally smaller than the x3 – x5 seen in most other sectors.

Once you have the idea developed in your mind, the next step is to get it down on paper. Unless you’re a great artist with training in using design software, you are best contracting this part to a professional.

Find a Professional Toy Designer

The first real step to making your toy design a reality is to have someone design it. Having a model drawn up by a toy design freelancer will show you what your possibilities are. At this point, you can finesse your ideas and play with them too.

Be as clear as possible with the designer you commission. They’re responsible for bringing your idea to life but also need guidance to produce what you want from them. When searching for a toy designer, make sure you ask for samples of previous work so that you know their style.

Things such as materials, colors, and a general idea of how it will fit together will be considered during the toy design process too. You can start to understand the components, whether it’s how many panels of fabric your teddy bear is going to need or how many ball hinges for robot arms are going to be required. Getting this information into the design is going to make prototyping easier and is a necessity for a patent, which we’ll go through next.

This is probably the point where you’ll first spend a chunk of money. It’s worth doing your research to get a good toy designer. Being tight on cash at this point isn’t going to make your journey through to prototyping and manufacturing any easier – it’ll likely make it more robust.

Protect Your Intellectual Property

Once you have your idea down on paper – and stored on your computer, hard drive, and cloud service – it’s the ideal time to look at patenting your idea. By patenting your toy design, it means no one else is going to be able to copy your idea.

You can be sure that your design is safe during the design process with Cad Crowd. All of our freelancers are bound by a non-disclosure agreement. However, the more people you share your idea with, the more risk that someone will try and take your idea.

A lot of big toy companies won’t even meet with you if you’ve not sought a patent. This is for their and your protection – no one wants to be worried about ideas being stolen. Cad Crowd has a patenting service available, making the process much smoother and more straightforward.

Patenting your idea is another investment into your idea. You could choose not to do it, but if your toy design is going to make you money, you need to make sure only you can profit from it.

Commissioning someone to do this work for you isn’t the only option, but it will make things easier. There are strict requirements that need to be met, and your detailed design will need to be submitted.

The general guideline with your design is that a skilled craftsperson should be able to make it without looking at anything else – this is the standard you need to look for from your designer.

Time to See What It Looks and Feels Like

Making a prototype of your toy is when it will come to life. This is the point when you will see how your chosen materials look and feel and if your moving parts work in the way you expect.

Another interesting thing about a prototype is that you can put it into the hands of children. You can see how they respond, how long they play with it, and whether it’s engaging for them.

Taking time to allow children to play with your toy is going to be invaluable. It will let you know if things need to be improved or altered. You will see how intuitive it is to be played with and maybe even spot ways to make it more engaging. The feedback you get direct from children will be of massive benefit, and a prototype is a great chance to be able to have this conversation with them.

A well thought through idea that’s coupled with a great design should make the toy prototyping stage much more accessible. It’s ok to go through two or three different prototypes – this is the stage where your toy design can evolve, and unforeseen issues can be resolved.

If you’ve decided to patent before having the prototype made, you’ll need to be careful not to stray too far from your original design when making any adjustments. By suddenly deciding you want your alien toy to have six arms rather than eight, for example, you will be making something very different from your patent application.

Get Your Toy into the Shops

In the days before the internet, getting the toy your designed and into the shops would be a challenge. Now, things aren’t quite so difficult since you can market your product directly to consumers in various ways.

Having your toy manufactured can be costly, so it can help to have orders in place. Some of the ways you can fund the manufacturing process include:

- Pitching your toy, with your prototype and feedback, to toy companies and retailers. If they place an order, you can use this to get credit from a bank to fund the manufacturing process.

- Crowdfunding websites, such as Kickstarter, can be a great way to directly engage with your buyers. They can place orders for the product and showing them the prototype being used by your target age group can be a great seller. Once you have enough orders, you can use the money to start manufacturing.

- Make to order using sites such as Etsy. Depending on what your toy is, you can market your toy using the prototype so your potential buyers can see what exactly you’re selling. Once you have an order you can get it made; this works well if your product can be 3D printed, for example.

- Self-funding the manufacturing process is possible, but risky. You can inject your capital or take out a loan to have a batch of your toys made and then start selling them, either online or by taking them into independent retailers to see if they will buy some stock off you.

Whichever way you decide to go, you should research the manufacturing process needed for your toy so that you’re ready to go. Cad Crowd has a range of consumer product designers available to help, for example, if you need a mold or die designed and cut for your product.

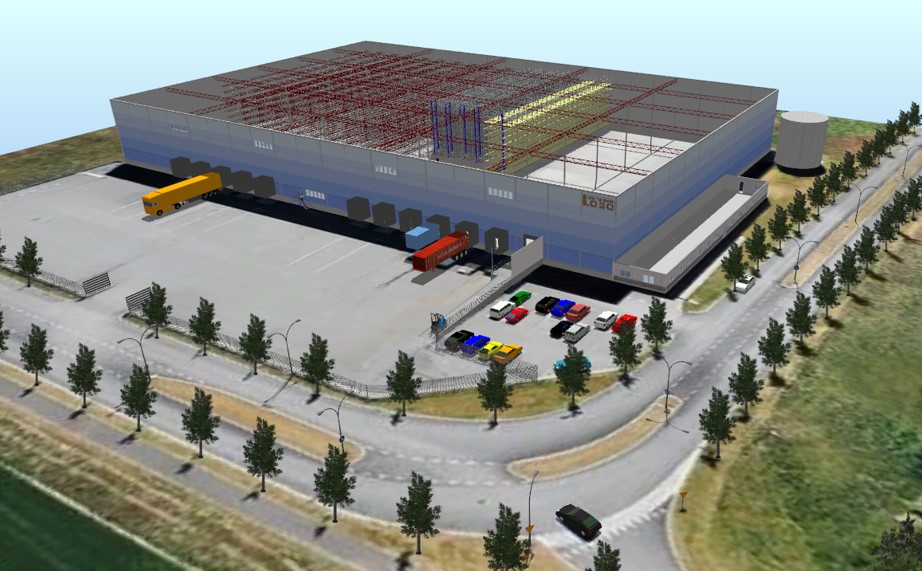

Find a Factory

You can seek out mass toy manufacturers from the USA trade association for the toy industry, The Toy Association. Cost per unit will be lower the more you order; it will be worth investigating the point at which your prices will go down, so you know what type of order size to aim for when pitching to retailers or setting your Kickstarter targets.

Factories all over the world should be able to help you get your toy into production. Choosing to manufacture in the USA could be a great marketing tool, but your costs are going to be much higher so you might make less profit.

China is a popular place to have things such as toys manufactured. You do need to be careful in choosing a toy factory so that you have reasonable quality control and someone who knows the industry. Any factory you select as your manufacturer should have a good knowledge base of your industry.

They should be able to answer your questions with ease, already have the standard tools you’ll need, be willing to offer help in supplying the raw materials you require and have up to date safety and audit certificates.

Be aware of any critical issues you could face; this is something else your factory may be familiar with or can at least point you in the right direction to get help understanding the rules you need to abide by. For more detail on how to get the manufacturing process started, Cad Crowd has a product manufacturing guide ready for you.

Does Your Toy Design Meet Product Safety Standards?

To sell toys aimed at children 12-years old and younger, you must have it tested for safety. The testing must be done on a finished product rather than your prototype. Fortunately, there are lots of approved labs all over the world that you can commission to undertake the necessary safety steps.

The United States Consumer Protection Safety Commission collates all of the standards that need to be passed. It’s worth noting that the standards for testing toys can and do change reasonably often. Make sure that you check the most up to date information. The time lapsed between your initial research and getting your toy manufactured can be up to two years – plenty of time for new rules to be published.

Different types of toys will need to meet different standards, factors that can affect the testing required include:

- Target age range

- If there are projectiles

- Materials used

- Use of electronic components

According to the CPSC, there may be a range of tests that need to be done on your toy to make sure it gets all of the necessary safety certificates. You must use an independent laboratory to complete the testing on the first batch that you have manufactured.

Once your toy has passed the tests and been awarded all the necessary certificates, you shouldn’t need to test again if you are doing short production runs. If your toy ends up in continuous production there will need to be periodic testing, as outlined in a guide from the CPSC.

The CPSC also has a list of over 400 labs around the world that can do the testing, and they recommend that you find one that can do all of the tests in one go. This should make things much more cost-effective and speed up the whole process.

Putting Your Toy on the Shelf

Along with designing the actual toy and everything that goes into the process, you’ll need to figure out what the packaging will look like. There is a swing towards the demand for sustainable packaging and using recyclable materials to package consumer items now. As long as it won’t directly damage or compromise the toy, consider avoiding plastics in the packaging stage.

By the time you’re looking at packaging design, you’ve probably invested a great deal of time and effort into your toy. Compromising on the packaging could put all of your efforts to waste. You can hire a freelance toy packaging designer who can help you in the process.

Working out how you want your toy to look on a shelf or as it lands on the doorstep after being ordered online is a massive part of the sales process. As well as sustainability, you need to consider factors such as portability, being appealing to children and parents, and costs. A shop isn’t going to put something on the shelf that looks drab and dull; a child isn’t likely to run and tell their friends about the toy that was delivered in the dull brown box.

Sell, Sell, Sell

Throughout your journey to design, prototype, and manufacture your toy, you will have been learning about your market. From the ideas stage when you’re choosing the target age, all the way through to figuring out how to get people to click your link or pick up your box, this has all been part of your market research.

At the design and prototype stage, it’s vital to get feedback from people about your toy. Friends, family, and colleagues can be useful, but there may be more kindness than honesty in their answers. Getting your toy into the hands of children and parents that are objective is the best way to know if you’re idea is really making its mark.

A business plan that involves bulk orders at major retailers is going to require some potential sales numbers. Doing research such as focus groups, online surveys, and vox pops will give you something solid to present to the people looking to stock your toy.

Using a crowdfunding website can offer excellent market insight, which can help you expand your sales too. Information about who is buying your toy online will be invaluable when looking at which retailers to approach.

Some Common Pitfalls

The whole process to reach the stage of having a batch of completed toys shipped to their buyers is long and arduous. Along the way, there are many things that can go wrong. You don’t have control over all of them, but you can try and mitigate for some of the common problems, such as:

- Patent issues – Your design might not be detailed enough; your idea might not be original enough; you might have had the same idea as someone else many years ago without even knowing it. Redesigning your idea can be the solution at this stage – don’t give up.

- Prototyping issues – An idea might look great on paper, but once it’s made real, it might be disappointing. What if your projectile doesn’t get enough power to fire more than a couple of inches, or your robot overbalances with all the tech you’ve packed into it? Sometimes prototyping can be tough to get right, but it will be worth it when you have a working model of your idea to show buyers, children, and manufacturers.

- Manufacturing issues – Whether producing in the USA or overseas, there is a lot of potential for misfortune as your toy gets manufactured. Keep an eye on quality control, maintain communication with your factory, pay a site visit if at all possible. Remember, at this point, you are a paying customer, so it’s okay to be demanding.

- Safety issues – Sadly, some toys do fail safety tests. It’s a tough point to have a problem since it is so close to the end of the journey. However, you can mitigate the chances of issues at this point with a detailed and well-thought-through design and prototype and lots of research to understand requirements.

Conclusion

Taking an idea for a toy and making it a reality is a great journey, full of creativity and the ability to work with talented designers, engineers, and business people. Designing, prototyping, and manufacturing a toy will take time and effort and you will learn a lot of lessons along the way.

Maybe you never knew how to go about getting a patent. It probably never crossed your mind what import rules there are on toys coming into the United States. Federal regulations of toys for children aren’t likely to have come up at the dinner table.

All the challenges you face along the way will hopefully pay off and you will be rewarded with a great toy at the end of it. Along with the toy, you will have built great relationships with your freelance team, ready to go through the process again with the next great idea for a toy that you come up with.