3D printing services have changed the way we look at the production of products. Today, things are possible that were not even an option before. From the creation of sustainable housing to producing the engine that took a two-person crew to the international space station, 3D printing has added efficiency and higher accuracy to the manufacturing process.

Additive manufacturing, another term for 3D printing, is giving companies and designers more flexibility in how they design goods. And the use of this production method is growing, according to a survey by Jabil, six out of ten companies found that 3D printing has changed the way they operate. The usage of additive manufacturing is expanding, and as a result, like with traditional methods of manufacturing, designing for this production process is a critical component.

Today, companies need CAD designers who can design for additive manufacturing. The complexity of this emerging type of design process requires a unique skill set when compared to designing for other kinds of production. If your company is considering the use of additive manufacturing in your production processes, you must find an exceptional designer.

Fortunately, this is where the team at Cad Crowd can step in. For a decade, we have helped business owners, entrepreneurs, and others find expert design help. For a process like designing for additive manufacturing, you need to work with the best.

For a more in-depth look into the benefits of additive manufacturing and how the team at Cad Crowd can help, keep reading below.

Before we get into the benefits and principles of designing for additive manufacturing, it's worth it to discuss its meaning and purpose. In the past, when designing for the production of products, rapid prototyping services faced limitations regarding the tools, systems, and robotics related to the process. Designers have even had to develop parts to allow for ease of manufacturing.

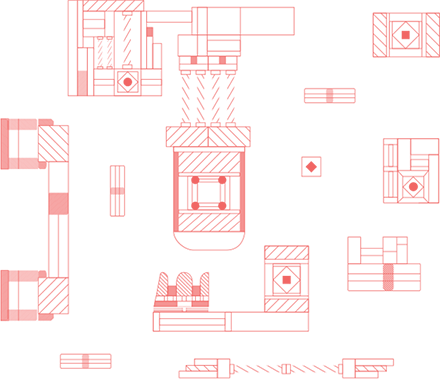

Today, additive manufacturing has changed this approach. Design for additive manufacturing is the science and skill to design a product for manufacturability with the 3D printing process in mind. Because 3D printing can more seamlessly copy and produce designs, mechanical engineers can develop more complex shapes and models for production.

Additive manufacturing allows you to accomplish more with your design ideas and strategies, and designers and companies have more freedom in how they want to develop designs. This approach can eventually lead to time and cost savings.

By itself, additive manufacturing brings many benefits to those who use the tactic. Again, design engineering services are not limited by the tool setups used in the manufacturing process, nor are they required to adhere to strict geometric principles.

However, if you’re wondering if there is an actual benefit to investing in designing for additive manufacturing, the simple answer is yes. Below are the reasons why you should make design for additive manufacturing a priority of your design process.

Sturdier and better-crafted part designs—When designing for additive manufacturing, designers have the flexibility to create more intricate designs that they once couldn't do when planning for traditional manufacturing. In the past, parts were dictated by the various tools and systems used in factories. A 3D printer can replace these tools so that designers can develop components that are more durable and result in a more high-quality product.

Eliminate the number of parts needed—Any sound design principle list includes a section that discusses how important it is for designers to eliminate unnecessary components. More parts lead to more material needed as well as more time to complete the design process. Design for additive manufacturing allows the 3D printing design service to decrease or combine the parts when necessary.

Greater accuracy—Since there are fewer steps in the design process, designers for additive manufacturing can better predict the final physical product of digital design. This step makes it much easier to see if all specs are accurate and if there is a need for modifications to a product's design before it is produced. Also, more precise design structures can be used—a great example of this would be lattice structures.

Greater efficiency through the use of digital files—The digital connection between designing for additive manufacturing and CAD is much greater than traditional manufacturing. Being able to use digital data to produce products more efficiently makes it easier to quickly modify these designs, share digital files, and efficiently manufacture products.

Greater customization—Again, since the industrial design service emphasis is no longer designing products to move through a specific system or process, designers can now focus more on personalizing designs for clients. This benefit is especially useful in the medical and automotive sectors.

The benefits of design for additive manufacturing are worth looking into. If you want to add more flexibility, efficiency, and cost savings to your production processes, design for additive manufacturing is the way to go. However, while additive manufacturing is rising in popularity, it is still an emerging process.

Many companies are still not familiar with what it is and how it works. This reason can make it challenging to find designers who specialize in this skill. Fortunately, our in-house team of engineering design services and designers have vetted and hand-picked a variety of designers, some from this field.

Additionally, our teams can help connect you with capable and talented design professionals who are capable of designing for additive manufacturing. For a closer look into how we do that, be sure to visit our How It Works page.

There are many reasons you should consider utilizing design for additive manufacturing over designing for traditional production, especially if your product design calls for it. Here are some ways these practices differ from one another:

The use of organic shapes—Unlike traditional manufacturing, design for additive manufacturing can better develop organic shapes. The geometric design needs associated with traditional manufacturing make it almost impossible to do this without having to use an injection molding service or machining, two costly processes.

Better opportunities for layering—Due to the way 3D printers are arranged, products can be designed so that they are printed in multiple layers. This tactic contrasts with single layer production from traditional manufacturing. Single layering can be less durable and more susceptible to damage, and multi-layering is a lot harder to do when planning or designing for a conventional manufacturing system.

Lighter and stronger parts—This is where the lattice structure comes into play. Regarding traditional manufacturing, injection molding would be required to produce products with the same strength, lightness, and nested cores as a 3D printed object. Again, this opportunity gives designers more freedom in how they strategically develop better designs.

No additional tooling costs—Let's say that a designer made a mistake in designing a product for additive manufacturing. Instead of having to retool and reset the design for a product, this is no longer an issue. Additive manufacturing doesn't require tooling or set-up processes like traditional manufacturing. This benefit gives the designer some leeway on developing products.

Both design for additive manufacturing and designing for manufacturing can get you to the finish line. It is important to remember that some products depending on their function and the quantity needed, may work better with traditional manufacturing. Nevertheless, additive manufacturing is worth looking into as it can leave you with more cost and time savings.

It can be hard to move into an emerging process, especially if you are not familiar with it. Fortunately, we do work with designers that are proficient in the skill of designing for additive manufacturing. They can help walk you through the process and realize the benefits of utilizing 3D printing in your production processes.

Again, our team is dedicated to helping you find the right professional for your designs. If you are interested in hearing more about how we have helped others find the designers they need, check out what our customers have had to say.

When it comes to additive manufacturing, the learning curve is steep. According to a survey by Jabil, 71 percent of companies are held back from pursuing 3D printing because of their lack of knowledge surrounding it.

Designing for additive manufacturing can benefit your company in a variety of ways, and our team wants to help you experience these advantages. This reason is why we are committed to helping you find an expert designer in this field. Whether you’re just hearing about additive manufacturing for the first time or have tried it in the past, we are confident that a designer can help guide you through this process.

Being an entrepreneur and business owner, especially today, isn't easy. You have a lot of moving parts to handle. We understand this, and we want to take the work of finding an exceptional designer who can handle designing for additive manufacturing off your plate.

Before you produce high-quality products, you need to work with a professional who knows what they are doing. So, if you are ready for our team to help you begin the first step of this process, we invite you to reach out for a free quote today.

At Cad Crowd, we have the privilege of working with some of the best manufacturing freelancers out there. Our team consists of qualified CAD designers, 3D modeling freelancers, and other professionals. If you'd like help with your project, get in touch today.