Any construction project begins first with ideation and design. Nothing can happen until the ideas are generated that will become the final building or structure. Prior to any foundation being laid or beams being lifted or drywall being installed, designers and builders work through a systematic process. The first phase, as with any creative project, is working toward a unified concept.

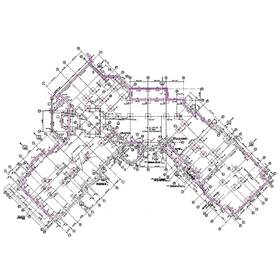

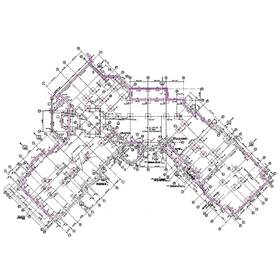

For construction projects of any size or scope, this stage entails a coterie of architects, interior designers, general contractors, engineers, and others. All members of the project team must work together. As a unit, they work to solve any creative and practical obstacles necessary for the project to be efficient and successful. During these early stages of the process, many drafts will be drawn and three-dimensional layouts rendered as needed for the specific nature of the project.

After this is finished, the next phase gets started. When constructing a large building, commercial space, warehouse, plant, factory, municipal building, or similar structure, concrete and steel are typically a significant part of the assembly’s structural integrity. A full set of rebar details must be crafted before construction can begin. Rebar literally means reinforcing bar. Rebar is used to strengthen the concrete in a structure.

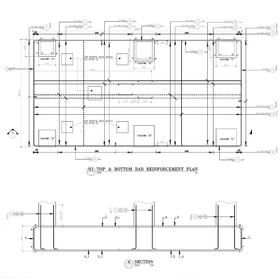

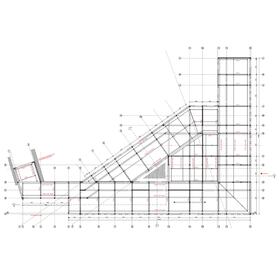

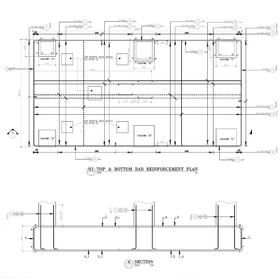

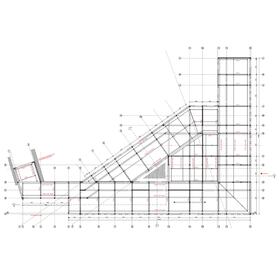

First, a structural design engineer will develop the specifications for the rebar to be used in the project. These rebar details are of most use to shop workers known as fabricators. Rebar detailing blueprints, also known as shop drawings, contain all the specifications of the precise requirements that rebar fabricators will use to shape and form the steel rods. The fabricator’s job is to cut the particular rebar that will be embedded in the cement used in the building. A full set of shop drawings lays out all details of every rebar piece, as well as how it should be fabricated and formed at the shop by a rebar fabricator. Rebar detailers must make sure all specifications are clearly indicated on the shop drawings. These will show the amount of rebar to be used, the dimensions of each piece, and any other important attributes.

Once the fabricators have the drawings they need, raw steel will be cut into the exact size and shape specified before being shipped to the construction site. Once on-site, construction workers fit the rebar according to details contained in separate drawings, known as rebar placement drawings.

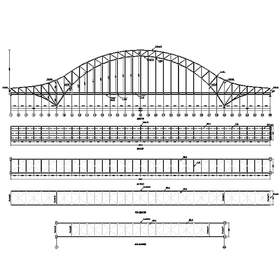

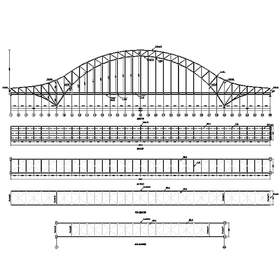

(A distinction is often made between rebar and other steel used on a construction site. While rebar workers are typically responsible for the placement of rebar, other workers, known as erectors, do the heavy lifting on a construction site. Erectors lift and install all structural steel components (like I-beams) into position to ensure the structural integrity of the building. Erectors reference a different set of drawings, known as erection drawings, that indicate exactly what the erectors are required to do and where to do it.)

Rebar detailers must fully comply with any industry standards that are in place as well as any other procedural formalities. Standards in rebar detailing are incredibly important and vital to a safe, secure construction project. For example, both the American Institute of Steel Construction and the American Welding Society have protocols that must be followed closely by detailers.

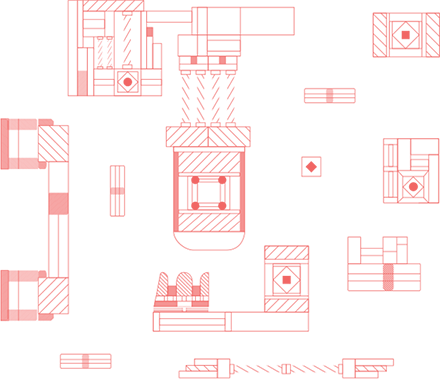

Rebar detailers employ several different methods to craft blueprints for rebar fabricators to use in the shop. In the past, shop drawings were made mostly using pencil and paper. The technicians would use T-squares, triangles, templates with various shapes, and drafting machines (this was not a computer, though it does sound like one) to produce detailed drawings. Technology, of course, has revolutionized the drafting world dramatically over the last few decades or so.

Today, drafting technicians and rebar detailers make use of advanced computing software and industry-standard applications to produce their drawings. This is usually known as computer-aided drafting (or CAD for short). Autodesk has been the leader in this field for many years now with its impressive software lineup. The company’s main drafting application is called AutoCAD. It’s utilized by literally countless designers, architects, engineers, and other drafting technicians around the world.

One of the more popular packages used by rebar detailers is Autodesk’s AutoRebar. (Structural steel detailers, on the other hand, often use Autodesk's Advance Steel program.) RebarCAD, SOLIDWORKS, and Tekla Structures are three others commonly utilized by detailers as well, for both rebar or structural steelwork.

Just as the building of a structure goes through multiple phases, rebar detailers work through a series of stages with their own detail drawings. As a general rule of thumb, rebar detailing drafts go through several stages of revisions as well. At first, rebar detailers visually describe as accurately as possible the work necessary for the material to be formed by shop fabricators. If more information is required before the work can be finished, then the fabricators must submit an RFI (or request for information).

These RFIs are typically sent to someone on the development team, usually an architect, a structural engineer, or even a general contractor. All necessary designers and contractors must approve a final version of the rebar drawings. All details must be proofed again by a different detailer (called a checker). Work can resume once the checker makes sure that the revised drawings are complete and accurate.

There are many industries that require the use of rebar details. Architects, designers, general contractors, and, of course, shop fabricators, all make use of these blueprints in their role as part of the building process. Any construction that requires steel-reinforced concrete in its structure will at some point along the way need rebar detailing.

Rebar detail drawings are used in the construction of high-rise apartment buildings, factories, warehouses, industrial plants, brewing facilities, automotive manufacturing plants, and many other structures. If reinforced concrete is going into the structure in some way, then rebar detailers are a pivotal part of the operation.

If your company deals with architecture, design, engineering, or construction with concrete and steel, it goes without saying that your team needs a rebar detailer. Ensuring that you bring on a high-quality detailer can be the difference between expensive revisions or completing a project on schedule and within the budget.

Allowing Cad Crowd to be an integral part of your team allows you to focus on your business as you ordinarily would, without any extra headaches. You also get the additional peace of mind that comes from knowing you have the highest quality rebar detailing experts around the world bringing your team’s vision to life.

Further, we make sure that only the absolute best rebar detailers have the chance to work on your project. Our tight-knit group of freelancers has years of experience and are highly qualified. They have worked hand-in-hand with companies and leaders in every field. Whatever your rebar detailing needs may be, rest assured that the detailers at Cad Crowd will create exactly what you need for a successful project. We can come up with a rebar-detailing solution for every client, no matter how big or small the project may be.

Cad Crowd will help you by utilizing our vast network of established rebar detailing freelancers. We only work with the best of the best. Each detailer and engineer uses the very latest technology, so submitted work will always be up-to-date and will abide by industry standards. If there’s a particular software program that you need us to use, just let us know, and we’ll locate the perfect detailer for your project.

Our rebar detailing firms are always available to assist any organization with getting started from scratch on a project, or they can build upon previous work. Wherever you are in the process of construction or planning, we can help you get exactly where you need to be. Our detailers work productively to save you money along the way.

No other site works with the same quality of detailers that we here at Cad Crowd do. There is absolutely no other place where you will find the same level of excellence, expertise, and efficiency. Get in touch with us to get started today.

At Cad Crowd, we have the pleasure of working with top-notch 2D drafting services, including rebar experts. Regardless of the type of drawings you're looking for, we can connect you with a rebar detailing and drawing firm that can help. Let us help you. Contact us today for a free quote, or to find out how it works.