When someone mentions 3D CAD conversion services, the topic of discussion usually revolves around construction documents or, more specifically, translating two-dimensional, hand-drawn sketches or blueprints into 3D CAD models to get a better visualization of the project. Once the file has been converted, you can rotate and zoom the model on a computer screen for a better spatial understanding of the construction process and make changes to the plan using CAD software without having to redo the entire blueprint. Since 3D models are easier to understand, architects can use the models to communicate the design to clients and general contractors. If necessary, CGI professionals can generate photorealistic visualizations of the project based on those 3D models as well.

Cad Crowd is an industry leader in providing architectural, design, and engineering firms with the best outsourced 3D CAD design and conversion services. Here’s what we know about how you can use 3D CAD conversion for efficient manufacturing.

🚀 Table of contents

CAD to shorten the product development cycle

The same principles also apply to product design in the manufacturing industry. It’s been said time and again that shortening the design cycle through workflow optimization and lean processes is an effective method to stay ahead in the increasingly competitive market. In every product design cycle, starting from concept generation all the way to manufacturing and market launch, ideation and prototyping are among the most time-consuming steps. The good thing is that you can shorten the time spent in those crucial development phases using a modern 3D CAD approach. This means you need to convert from the old process of using two-dimensional design sketches and iterative physical prototyping into state-of-the-art 3D modeling and visualization.

Where do CAD conversion services come in?

Not every design firm has an in-house 3D CAD team, and perhaps by choice. The problem is that the cost of hiring, training, and keeping full-time staff can be too much of a financial burden, and even more so for a small product design firm. Let’s not forget about all the overhead associated with the infrastructure itself, such as office space and electricity. Some CAD software options are indeed open-source and free (such as FreeCAD and Blender), but chances are a design firm will also need premium ones (like SolidWorks and Autodesk Inventor) to be able to operate as a professional business. In short, the combined cost of software and workforce management is often budget-demanding for a small firm. But there is a workaround. Every product design firm can always partner with 3D CAD freelancers, meaning the firm outsources the CAD conversion task to an external company.

Just like the firm that specializes in product design, freelance CAD companies offer all sorts of services related to the creation of CAD files, including but not limited to blueprints, shop drawings, 3D models, as-builts drawings, renders, and paper-to-digital conversion. And because they specialize in every single one of those trades, they have all the powerful hardware systems, advanced software, quality control measures, technical expertise, and skilled professionals to get the job done.

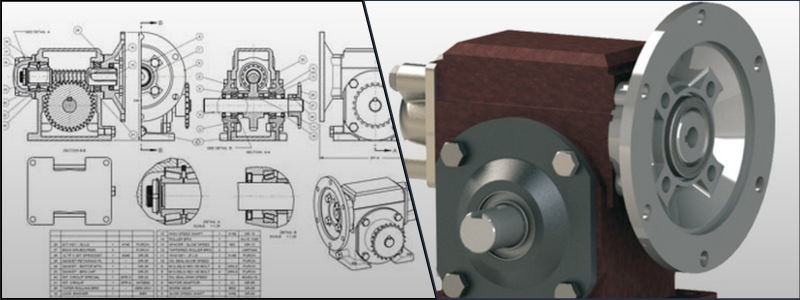

As for file conversion, the job primarily involves transforming two-dimensional drawings, such as hand-drawn sketches or even finished technical drafts, into 3D CAD formats. The resulting documents are more than just mere copies but brand-new digital drawings that offer interoperability while maintaining data preservation. Interoperability ensures that the new files are compatible with various CAD software programs, which means the file is saved in neutral formats, such as IGES, STL, STEP, QIF, and 3D PDF, to name a few. The purpose is to allow the files to be usable (opened, edited, imported, and exported) by different CAD applications. At the same time, the conversion also needs to adhere to data preservation purposes so that the new drawings keep all the important design information contained in the original file.

How it works

CAD file conversion isn’t just scanning but also preserving the geometric data, material specifications, mechanical properties, annotations, and every bit of information associated with the product design. Product development professionals use conversion that aims to bridge the gap between the printed and the digital versions of the same file accurately by preserving, if not improving, the fidelity of the original. To achieve this purpose, the file conversion has to go through several steps:

- Get a good grasp of the requirements: Of course, the first step is to try and understand the client’s requirements. This step involves taking a close look at the source file (including the format and the information contained), the software or tools used to create the original file, the target format, the CAD software to use for the conversion, and the level of details required in the outcome. If the target format needs to adhere to specific standards or guidelines, the conversion must conform to those as well.

- Collect the data to be included in the converted file: There might be additional data missing from the original file due to torn pages or unreadable annotations. In case the converted file must also restore those missing information, the client has to provide them prior to the conversion. The client can send the additional data in separate files like scanned images, notes, or physical drawings. In other words, you can’t expect to get a proper conversion unless the person doing the task has all the data.

- File pre-processing: If the original file is in poor condition due to improper storage practices, water damage, or stains of any shape or form, some pre-processing tasks are in order. Pre-processing might involve removing noises and unnecessary artifacts, as well as cleaning to make sure the file is ready for digital conversion. In some cases, the CAD conversion firm actually has to re-draw the file completely or risk getting poor-quality results.

- Converting the file: the actual conversion is done on a computer using specialized CAD software. While the software features quite a lot of automation, such as vectorization and format compatibility configurations, there are also plenty of manual adjustments involved in the process.

Once the conversion is done, the firm runs the file through quality assurance checks to make sure it meets the pre-defined specifications and standards. The file is sent back to the clients for review and approval. If revisions are necessary, it goes back to the CAD design firm for refinements; otherwise, the final documents are ready to use.

Where you get the competitive edge

3D design technology is no longer an optional tool in your arsenal; it’s mandatory and perhaps the single most important tool you need to help the business stay relevant in the increasingly competitive market. The automotive and aerospace industries have dominated the adoption and implementation of 3D CAD in the decades that have passed, but now, the same technology is also becoming more prevalent among mainstream manufacturers. If your company hasn’t had the chance to make the full transition to a 3D-based design process, the time is right for you to begin to move things along. All indications suggest that 3D CAD reinvigorates productivity and sharpens your competitive advantage in the constantly changing market.

Businesses in the manufacturing industry find that migrating from conventional 2D drafting to 3D CAD drawing does increase work efficiency and design accuracy, which leads to an overall better-quality product. Exploring new ideas and experimenting with unique design elements become more practical when designers and engineers don’t have to spend a lot of time making two-dimensional drawings on paper. Instead, they can visualize the concept and see how the design performs in a virtual environment (on screen) with 3D CAD software. The result is a massive boost in productivity regardless of the product being designed.

Converting two-dimensional technical drawings to 3D CAD models means you can see the object in its entirety from every angle. The software allows you to rotate and zoom to inspect every little detail and make changes to the design right on the screen. Most modern 3D modeling experts have no problems visualizing even complex objects and assemblies, such as intricate casings that feature textured surfaces, large components built from dozens of parts, and mechanical parts with fasteners, among others.

Virtual prototype

The biggest competitive edge manufacturers have with 3D CAD is that now they have access to virtual prototyping. All modifications made to the original design – after the drawings have been converted to 3D format – happen in the virtual environment. The entire design process doesn’t require the manufacturer to build any physical prototype at all. Advanced 3D CAD software professionals can also perform complex calculations to detect possible design flaws by taking into account the material characteristics, heat dissipation, weight, and mass.

The automated functions help streamline mechanical design verifications and, of course, shorten the development cycle to a large extent. All of those features give manufacturers the power to design a completely new product in a quicker and more practical manner than ever before. 3D CAD, thanks to both the modeling and visualization capabilities, is, at the moment, the fastest way to plan and develop a product.

It’s true that every new product design still needs a physical prototype for evaluation, but you won’t need it until the pre-production step because the iterative design process is done virtually with great accuracy. As a matter of fact, 3D tools can even generate photorealistic visualization (whether still images or animated) of the product based on the finished models before it even gets to the production line.

Cad Crowd is here to help

Migrating from a 2D-based design process to a 3D CAD approach doesn’t have to be a difficult or expensive transition. As long as you already have the two-dimensional technical drawings ready and all the related design information available at hand, it only takes about a week or even less to transform the images into 3D CAD format.

To improve your chances of getting good quality results, remember that 2D-to-3D conversion is a job best left to the professionals. You might come across a lot of sales pitches taunting “automated conversion with just a few clicks away” every now and then online, but a proper conversion cannot be all-automated. It has to go through several complex manual processes for cleaning and data validation works before the conversion, as well as quality assurance afterward. Whether you are trying to convert only a few pages or a whole bunch of legacy drawings to 3D assets, Cad Crowd can help connect you with some of the best CAD professionals in the country to get the job done flawlessly. Contact Cad Crowd today to get your free quote.