Mass-manufacturing is a common process in today’s modern world of business. This is the process of manufacturing products on a large scale in huge volumes. Immense factories may be equipped with automated production lines capable of producing thousands of units per day (or hour). Furthermore, advanced machinery and processes are used to meet the demands of mass-production. One particular process is the utilization of molds.

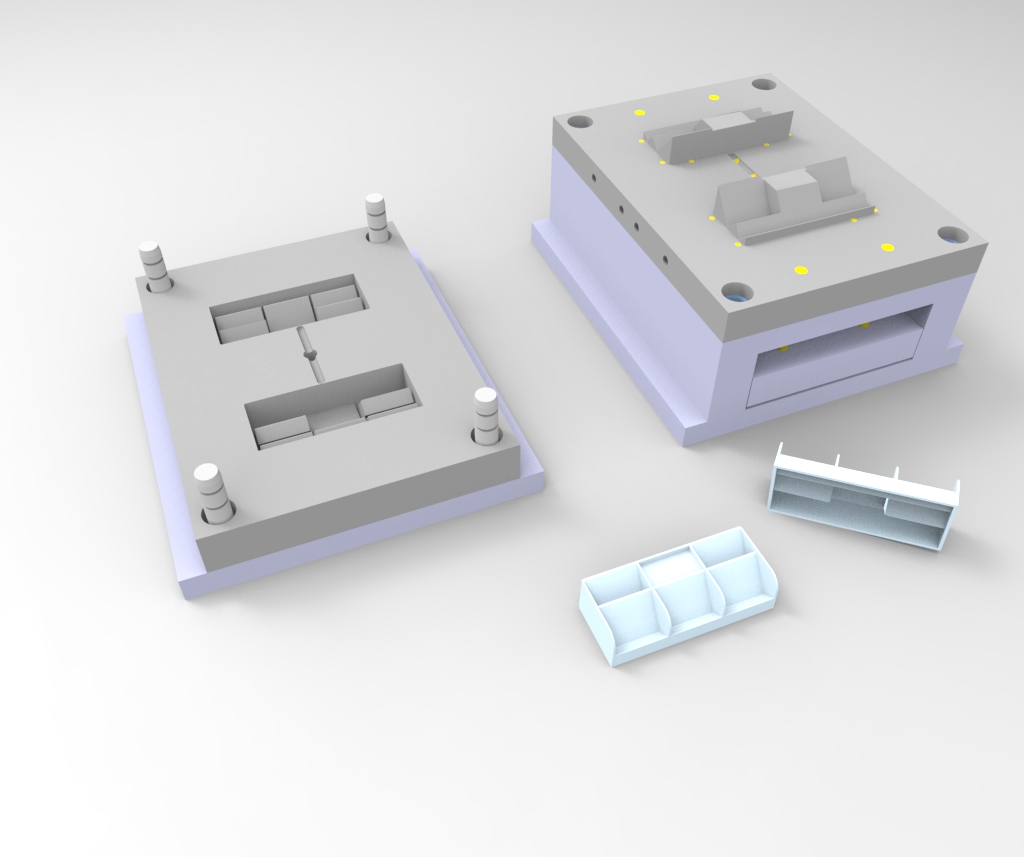

Processes such as injection molding are perfect for repetitive manufacturing on a large scale. Once a mold is designed, it can be used hundreds and thousands of times. This initial design process is highly important, however. If the mold used in production is poorly designed or has multiple flaws, the whole manufacturing process can fall apart.

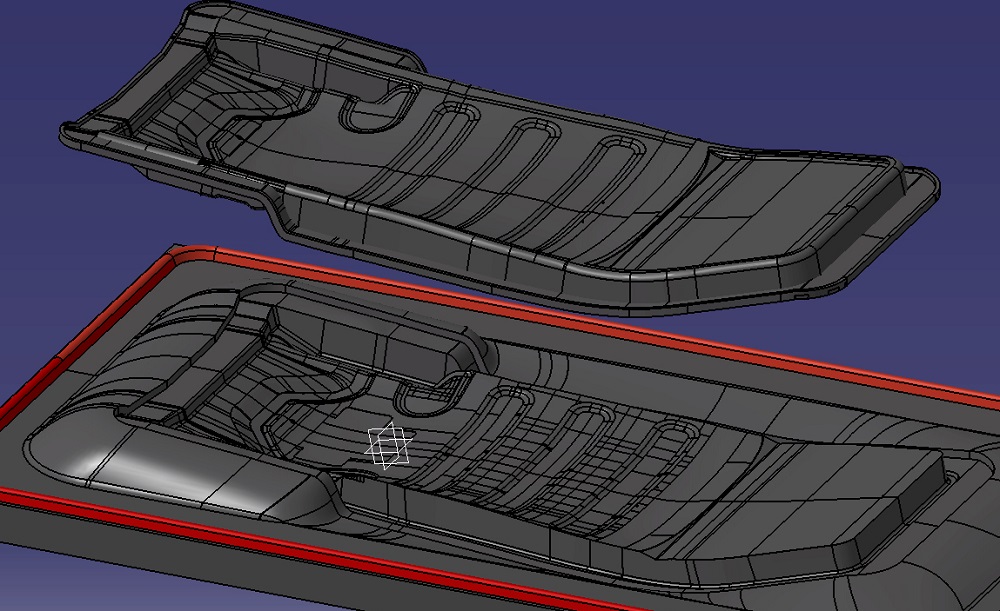

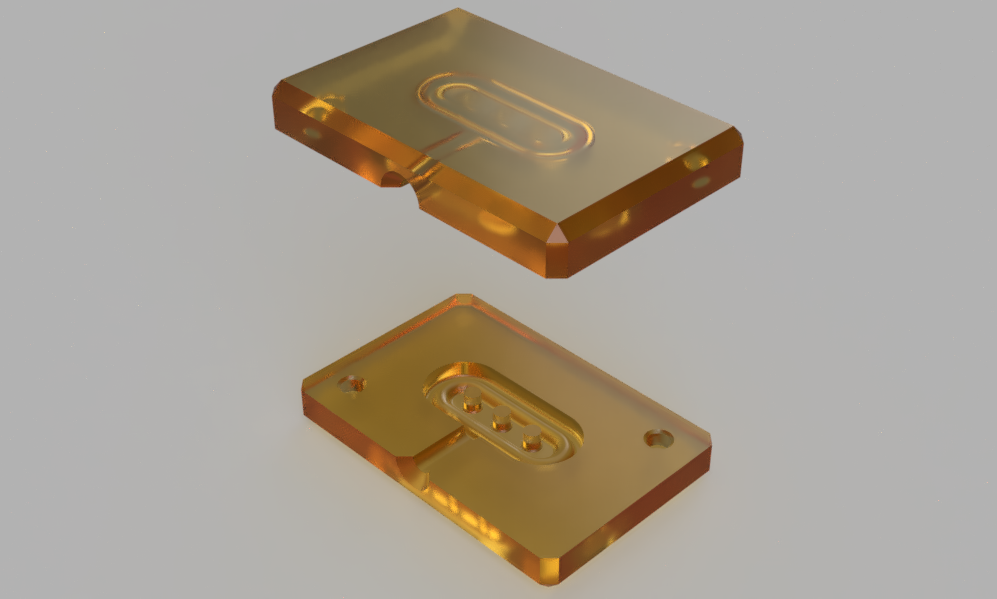

The mold has to be effectively designed using CAD and CAM processes. Furthermore, fine details have to be considered to ensure a cost-effective production operation that is beneficial for the business.

In this article, we look specifically at mold design tips for manufacturing. If you are considering utilizing mold production, or already have a system in place, these tips will prove invaluable. Furthermore, if you want to offer injection molding services, you must understand the basics and how to improve your offerings. These tips will ensure that your mold designs are efficient, practical, and easy to translate into a manufacturing environment.

What Is Injection Molding and How Can It Improve Manufacturing?

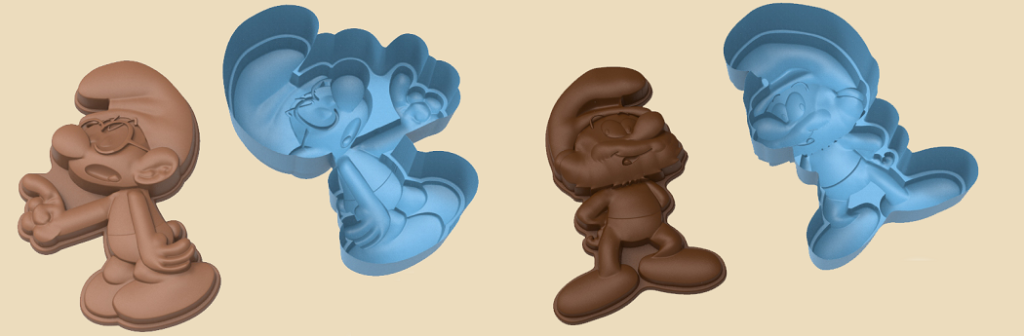

First, let’s look at injection molding and the benefits it provides. Molding is the process of creating products or parts by injecting molten materials into a pre-designed mold. The molten materials fill the available space and cool—thus creating the desired shape. The finished design is then ejected from the mold and further processed. The following are common injection molding processes:

- Die casting

- Metal injection molding

- Thin-wall injections

- Injection molding

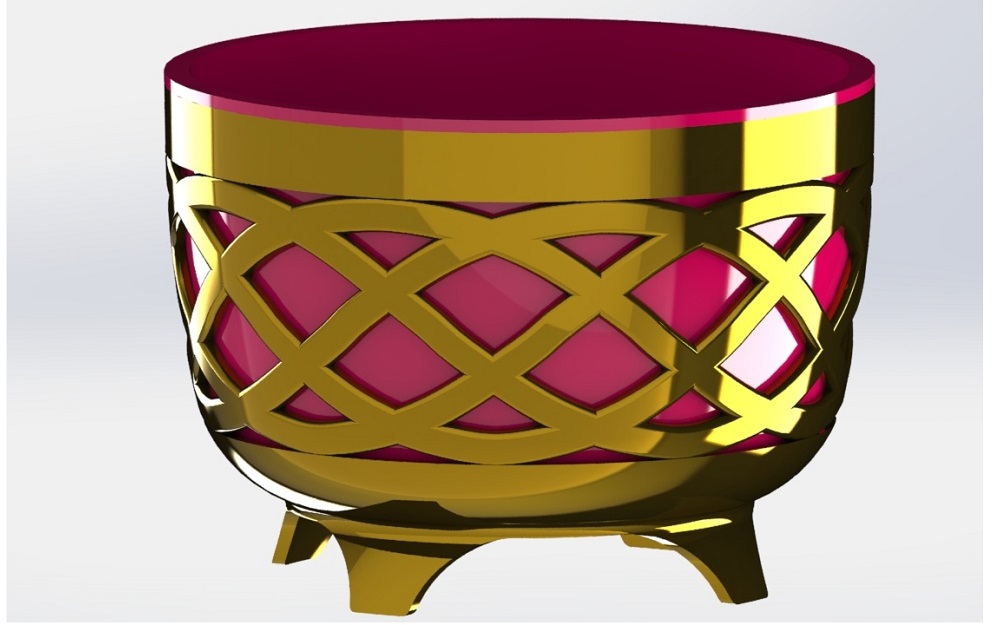

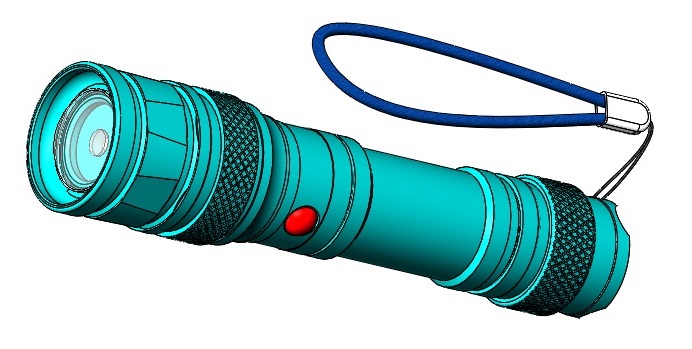

This is an extremely effective process that is widely used in mass manufacturing. Molding commonly uses materials that can be melted such as thermoplastic and thermosetting polymers. Furthermore, it is mainly used where product volume is important. It would not be used for single, bespoke items, as the cost of the mold and design process would be too great. The following are examples of products and parts that are made using injection molding:

- Packaging

- Automotive design services

- Toys

- Plastic components

- Furniture

- Mechanical parts

Essentially, any plastic product could be created using injection molding. It does have a wide reach and is used in hundreds of different businesses and industries. Molding is cost-effective and allows businesses to quickly mass-produce products and parts. Furthermore, the process is flexible and offers a great degree of control through the use of molds.

Improvements in manufacturing processes and available technologies have helped the evolution of injection molding, but one of the main parts of this process remains the mold design. Read on to find out useful mold design tips and why this process is so important.

Improve Your Manufacturing with These Mold Design Tips

So, what can you do to improve mold designs, and why is the design important? The initial mold design is vital for the whole manufacturing process. Imagine this—you have designed a product mold and manufacturing has begun. As the process starts, it transpires that the molten plastic is not filling the mold properly, and the finished item is difficult to remove from the mold.

This causes bottlenecks in production and wastage of material and time. These are just some examples of the negative impact a poorly designed mold can have. It can also cause the creation of poor-quality products that could lead to poor sales and reduced business reputation.

It is important to get the mold design right. Mold designing is the most important aspect of this type of manufacturing. It is the main thing that a business should concentrate on—this is why it’s important to understand the nuances of mold design, and how to get it right. These mold design tips for manufacturing should greatly help:

1. Look at Mold Wall Thickness

Wall thickness is one of the most important considerations for mold design. The thickness of the mold has many implications. Firstly, wall thickness impacts stress and pressure. For example, if one area of the design has thicker walls, this part of the mold could accommodate more pressure. In addition to this, the thicker walls in one area could divert pressure and cause areas with thinner walls to experience increased stress and potentially warping.

Variance in wall thickness reduces consistency. It can cause uneven mold surfaces and a poor-quality product. Wherever possible, it is important to maintain a consistent thickness—particularly of adjacent features. Many injection molding companies only produce mold parts that have a uniform thickness.

In addition to consistency, the different material thickness can affect the cooling process. Parts of the mold with thicker walls will take much longer to cool as there is more molten material involved. Ideally, the cooling process and consistency of the molding process should all be uniform.

2. Ensure Edges Have a Small Taper to Improve the Exit Process

A mold must allow for a quick and efficient exit process—this is when the finished product is physically removed from the mold casing. This process needs to be quick as time can be lost trying to force the material out of the mold casing.

A simple way to improve the exit process is to add tapers to the mold edges. This tapering is known as the draft. The draft is the motion of an item “popping” out of another. A prime example is an ice-cube tray—look at the ice cube tray design. The edges of each individual cube are not completely square, they are tapered. This is so the cubes can easily pop out of the tray. The exact same principle applies to injection molding.

By adding a draft to design edges, the product should easily be removed from the mold. The general rule of thumb is to apply 1 degree of the draft, per one inch of cavity depth.

3. Add Textures into the Basic Design

It is a common misconception that textures cannot be applied to injection molds and that they must be incorporated into future processes. For example, a second finishing process could be applied to the molded product once it has hardened. This is not true—it is possible to add a variety of textures to molds. Textures can be added using processes such as etching and milling.

A produce design service may have a flat surface on the mold, for example, and they want to add a textured surface to it, to provide extra grip. The mold surface could simply be etched to add this texture in. Adding textures into the mold itself offers a much greater degree of control over the whole process. Furthermore, it can save on costs and you are combining two processes.

4. Consider the Pros and Cons of Different Mold Materials

The material used to actually create the product is highly important. Questions must be asked. What is the melting point? What are the chemical properties of this material? What is its average cooling time in relation to the surface area? Does it react with other materials? How does this material typically harden? You must choose a suitable material that is easy to use in the molding process. At the same time, the material must be readily available and financially viable for the business.

5. Ensure Design Instructions are Clear and Concise

When creating a mold design, remember that someone else must then interpret your designs and create a working system. It is therefore important to be concise and clear. Omit nothing—any instruction, measurement, or footnote should be included. If you create an unclear mold design, the manufacturer or engineering service could waste time deciphering your work just to understand what you require. 3D drawings can have things included such as measurements and notes—be as detailed as possible and leave nothing to chance.

6. Ensure the Design is Practical

Practicality cannot be overlooked when designing manufacturing molds. This is one of the most important factors. If a mold isn’t practical to use, it can have severe ramifications and slow down the whole production process. This negates the point of using a mold in the first place to speed up production.

When creating a mold design, think carefully about its practical application. Ask yourself a variety of questions. Can you easily remove the product from the mold structure? Can the mold and product be used in large scale manufacturing? Is the mold material easily accessible? It is tempting to think purely about aesthetics and the design of the product itself. While this is important, the practicality must come first for injection molded items.

7. Design with the Mold Material In-Mind

While consideration must be given to the type of mold material used, you must also look at how the mold design could affect this material. Different materials have different mechanical and chemical properties. Furthermore, the materials used can react in different ways with the actual product material. Let’s not confuse the mold casing material and the product material—we mean the mold casing material that the molten material is poured into.

Metal is often used to create the actual mold structure as it has higher melting temperatures and can cope with increased pressures. Look at this material and consider how it could react with the molten material and the potential complications that could arise.

8. Consider Ejection Forces and Their Balance

When a unit is ejected from a mold, there is a motion called ejection force. This is the force of the hardened material being removed from the mold. Attention must be given to these forces and processes. Ideally, the ejection force should be evenly spread across the entire surface of the mold. Spreading the force in such a way reduces the chance of breakages or complications during the ejection.

If all the ejecting pressure is placed on a single area of the design, complications can arise. For example, the material could shatter once hardened—this would result in wasted material and increased production costs. Alternatively, a high level of ejection stress on a single point could result in warping and distortion. Parts of the product could be forced out of shape—this would result in faulty items out of specifications.

To create an even ejection process, consideration must be given to the thickness and mass of the material, and the design of the ejector system itself.

9. Avoid Sharp Corners

Sharp corners are not ideal for injection molding. Firstly, sharp corners have a much higher stress concentration than rounded corners. This means that the flow of molten material is restricted.

Think about this logically—when molten material flows into a 90-degree angled-corner, the flow is disrupted as it passes between the two contrasting edges. If that same 90-degree angled-corner was turned into a radius corner, the molten material would have a lower concentration of stress and could transition easier along the curved surface.

Think about the mold design, and if sharp edges are vital. If they are, consider using tapered edges, or slightly angled edges, so that the flow of material is less restricted. Multiple sharp edges and harsh angles can prohibit the flow of mold material and also result in areas of the mold not being filled. This could cause wastage and a failure to properly utilize mold space.

10. Ensure Communication with Other Business Departments

Communication is a vital part of any business. Without effective communication, business processes fall apart and become ineffective. Communication is extremely important during the mold design process.

Firstly, the mold designer must communicate with the 3D modeling service. Remember that the person is designing the mold—not the actual product itself. The designer must understand exactly what is required for the product. Furthermore, they must understand exactly what the product design team wants and how the product should look. This will ensure that a mold is created that allows for the production of an accurate product.

Secondly, communication with the manufacturing department and engineers is vital. The designer must ensure that their mold can be produced and that the manufacturing and/or engineering teams have the required materials and tools.

Utilize Low-Cost Manufacturing Processes and Improve Your Output

As you can see, there is a myriad of ways that you can create effective mold designs. It is important to undertake a thorough design process. The ramifications of a poorly designed mold could potentially be catastrophic for business. If this initial design process is given due consideration, you can save time, money, and effort, in the long-term. Furthermore, you can ensure that the injection molding process runs smoothly, and allows you to create high-quality products.

If you require assistance with mold designs, Cad Crowd can facilitate. We can find suitable CAD design services or other freelance designers who could help. Using a freelance designer to create a quality mold could allow you to concentrate on other business aspects such as product marketing, and manufacturing process.