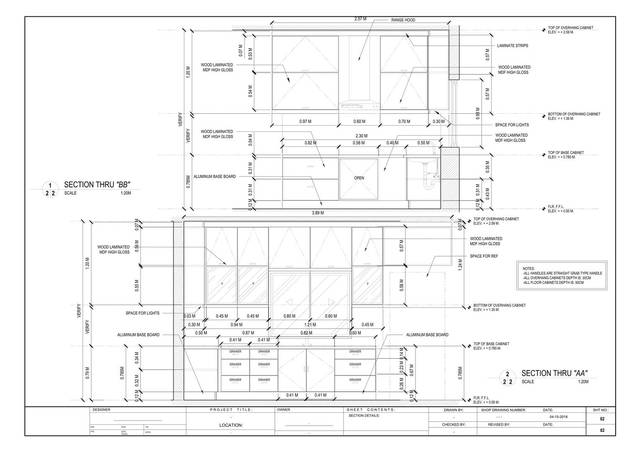

In the field of product design services, especially that of house interiors and carpentry, the term “casework shop drawing” refers to a detailed sketch that represents the assembly of casework and contains specification information, including but not limited to material, dimension, and installation instruction. Now, let us break it down further into:

- Casework: An aggregate or assortment of assembled parts that make up an entire cabinet (or any furniture piece for that matter) or the techniques implemented to keep those parts securely assembled. Although “casework” is most often used to describe commercial-grade cabinetry, it can be used as an umbrella term for all cabinets that require different material specifications to build.

- Shop drawing: A set of drawings produced by a material fabricator, supplier, manufacturing design service, and contractor (or subcontractor) to be used as a detailed visual representation of prefabricated components, showing how they should be installed or manufactured.

A shop drawing is the drawn version of a construction document produced by a contractor or manufacturer. Construction documents do contain a myriad of information, but a shop drawing shows more detail. Not only does a shop drawing explain all the materials required to fabricate components to be assembled, but they also inform the proper assembly or installation methods.

Shop drawing has a different style from a freelance architectural drawing service as the former emphasizes on the specific product or installation yet excludes notations concerning other products unless integration is required: this is a stand-alone drawing.

Table of Contents

Table of Contents

Casework vs. Millwork

Both casework and millwork are common terms in construction and building architecture, but contrary to popular belief, they are not interchangeable. Both also fall under the same category of carpentry, albeit with different manufacturing perspectives.

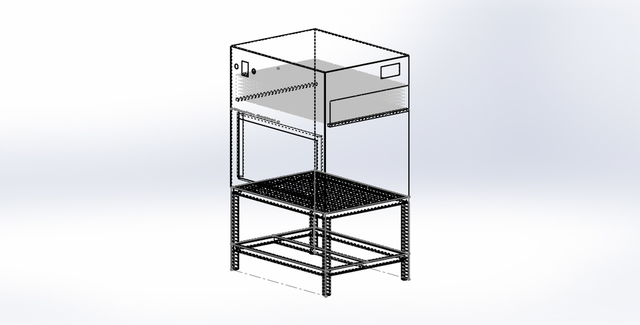

Casework

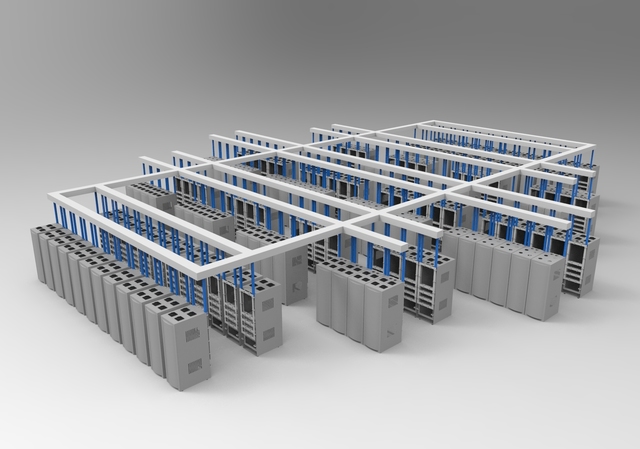

As the name suggests, it involves making boxed furniture pieces such as storage spaces, bookcases, cabinets (display and storage), drawers, racks, etc. It is defined as the assembly of box-shaped furniture. The most important characteristic of casework is modularity; in other words, the components—and by extension the final products—are generally used for modular purposes.

The central idea of CAD drawing services is to give a visual hint of the boxed-furniture’s components to be delivered. In this case, the components are prefabricated and they must be assembled on-site to build the final product.

Millwork

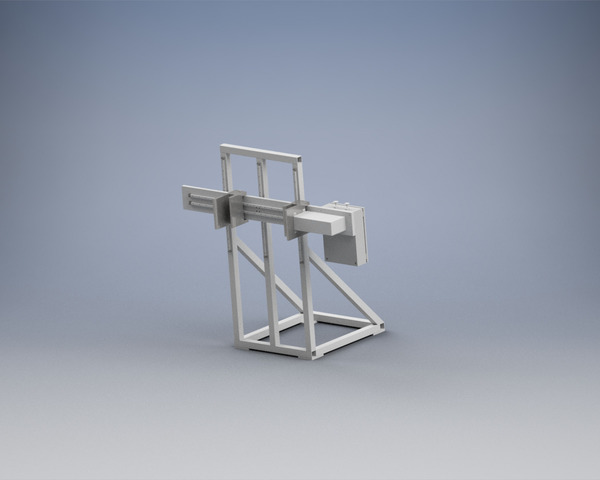

On the other hand, millwork refers to woodwork products that are custom-manufactured in a mill. As far as millwork shop drawing is concerned, it most likely (although not always) encompasses decorative or ornamental products. The drawing as well as the components are fabricated based on the customer’s specifications; components are engineered-to-order.

A cabinet can be categorized as either millwork or casework depending on how the components are made. Casework includes stock goods and ready-to-purchase cabinetry, for example, IKEA products. Millwork includes custom-made products built to buyers’ specifications.

RELATED: Why IKEA uses 3D renders vs. photography for their furniture catalog

Since casework is mass-produced, it tends to be more affordable than millwork. And just like everything mass-produced, casework comes with pre-defined specifications. Although the cabinetry may not be the best to represent personal preferences, there are many different varieties and finishes to fit every budget. Another thing to consider is the dimension. Casework pieces are not bespoke, so they are not exactly made to fit the dimension of any particular space in any particular building.

Despite the clear distinction, there is also such thing as a custom casework shop drawing. Casework always follows pre-defined specifications, but most manufacturers have multiple sizes and materials available in their warehouses. This means customers can order custom casework with specific dimensions, colors, finishes, and materials. However, all the components are pre-fabricated. And then, there is the decorative detail and structural engineering service.

No matter how ornate the carving is, the component also is stock good. Customers can purchase custom casework, but they have to choose from the available mass-produced parts, so the level of customization is limited. Millwork has no such limitation because every single component can be custom-made.

Information to include

One of the main purposes of a casework shop drawing is to provide engineers, architects, interior design services, and general contractors the opportunity to review the manufacturer’s version of the casework before placing an order. Even with the limited customizability, casework is not a one-size-fits-all product.

This means there is room for error, so it is good to have the product information reviewed first before taking a delivery. For the CAD drafting and design freelancers making the casework shop drawing, they must include at least the following information.

Comparison information

Customers place orders for casework with a set of specifications. The shop drawing must include information for the customers to compare to the orders. In addition to prescriptive descriptions, it should also address appearance and performance (or features).

Freelance AutoCAD drafting services must understand that casework shop drawing is possibly used to facilitate the approval of all parties involved in a construction project. A casework shop drawing has to be as detailed and clear as possible for everybody to understand.

Modification information

When the first casework shop drawing turns out to be incorrect or does not satisfy the customers, revisions are necessary. Drafters need to make some changes to the original documents and submit new drawings. To make it easier for customers to review changes, the new drawing must include modification information that explains the differences from the original document.

Customers ask for the changes, so it only makes sense to provide an easy way for them to analyze the changes. The successful installation of new casework is the result of good communication practices between fabricators, architectural design services, and customers.

Fabrication information

Assuming there is a special fabrication technique to be implemented, such information must be included in the casework shop drawing as well. Fabrication drawing services rely heavily on a casework shop drawing, instead of construction documents, to get informed on what will be manufactured and delivered.

Fabrication information many also include dimensions and manufacturing methods. That being said, casework does not necessitate custom milling because all components are pre-fabricated.

Job site dimension information

Depending on job site conditions, the dimension shown on construction documents and the actual dimensions may vary. Some manufacturers even go the extra mile by sending their personnel to verify dimension rather than relying on information provided by contractors.

While the dimension shown on the document for new constructions is usually sufficient, in other projects, it may not be. A freelance construction design and drawing service can get your job site designed.

Installation information

When someone receives a casework shop drawing, they can expect to see installation information. Fabricators or DFM experts usually provide symbols (along with the explanations) to be used in instruction information. There can be a list of materials too; some of the materials are appropriate but they are not always included in the final product, such as adhesives and fasteners.

In case the casework is integrated with (or required) electrical system or other components to work properly, the shop drawing may need to provide suggestions concerning the possibility of hiring a third-party professional to install the product.

A consensus for casework shop drawings

In a large residential project, there can be multiple decision-makers within a team. Unfortunately, there isn’t a consensus on the format or level of details and clarity required in a casework shop drawing.

Things can get more complicated when there is more than one casework contractor involved in the project. Discrepancies in detail are not uncommon as long as the information included is clear enough to review and understand.

CAD drafters may use more annotations as requested by an architect. That being said, each freelance architectural drafting service has personal preferences, so differences in the level of details should not be considered mistakes on the drafters’ part because they merely follow the directions provided by superiors.

Although such differences are not particularly troublesome, a bigger project usually brings greater challenges as well. Ideally, all architects and engineers working in the same project can agree on a single format to avoid confusion.

Standard practice

Despite the lack of consensus, there are some standardized practices that architects can adopt for a large project. Casework shop drawings and furniture design services may adhere to recognizable standards. By establishing one standard to follow, the drafting teams should be able to create shop drawings in a uniform format.

Why casework shop drawings are important

The act of agreeing on a single standard for the sake of uniformity is just the first step to creating a practical casework shop drawing. All parties involved in the project, including CAD drafters, furniture designers, architects, casework makers, and customers must continue working together to turn shop drawings into something functional and beneficial for the project. When developing casework shop drawings, the intentions to keep in mind are as follows.

Avoid Potential Conflicts

As mentioned earlier, CAD drafters who create casework shop drawings always follow the guidelines or directions given by architects. The drafters interpret architectural plans and use their expertise to best create a comprehensive shop drawing.

In a bigger project where multiple architects are involved, the architectural plans may differ in terms of the level of details and annotation. The good thing is that an easy-to-understand shop drawing can help clarify the discrepancies.

RELATED: CAD conversion: Do your drawing conversions in-house or outsource?

Even during the design stage, shop drawings are vital to resolve design conflicts. Detailed shop drawings with just the right information and annotations may help architects align their architectural plans.

Budget consideration

Experienced drafters equipped with the advanced technology of parametric CAD can calculate details in the shop drawing with almost unmistakable accuracy. Design communication between architects, freelance civil engineers, and contractors becomes more efficient as well.

Part of that communication is the discussion about budget. Properly created casework shop drawings allow drafters to mark any last-minute changes in materials, dimensions, or designs without repeating an entire process of making a new drawing.

Annotation about the changes is easily visible for a quicker approval process. Detecting errors during the design stage eliminates the possibility of undoing progress. Ultimately, this affects the project completion time-frame; the sooner it gets done, the less expensive it is.

Accurate details

For a lot of 2D CAD drafting services, it’s easy to fall into the trap of adding all possible details into a shop drawing in the hope that the information makes it more clear. Drafters have the tendency to depict the artifact in the best possible representation down to the joinery and dowels. But extra details can hurt at times because an overload of information can introduce confusion, and worse, misinterpretations.

Repetitive information should be excluded to the point where the shop drawing remains usable and understandable by everybody involved in the project. The exclusion, however, must be based on a consensus. Once again, deciding on an agreeable format before developing a shop drawing is crucial.

Mistakes you can easily avoid

It is one thing to forget to use the right measurement system as requested by a client because simple conversion can solve the issue, but coming up with casework shop drawings that turn out to be inaccurate is an entirely different level of mistake.

If you’re a drafter of casework shop drawings (especially beginners), there are some common mistakes that you can easily avoid.

Getting to work with minimum information

Many budding drafters and architectural site plan rendering services will want to impress their clients by getting the job done in the shortest possible time. It shows professionalism and expertise above all else. But not having enough details regarding the project is a recipe for disaster.

At the very least, you should know who will use the shop drawing and have people to contact anytime you need a verification of the architectural plan. It can be a verification of dimension, material, colors, finish, and so on.

Measure “Once” cut once

The correct rule is: measure twice, cut once. This may apply more appropriately to a tailor, but it works just fine for every other application that requires accurate measurement—drafting a casework shop drawing included.

Most houses and buildings have multiple different rooms and spaces. Based on the architectural plans, you are informed about the dimension of each room and how it is going to be used.

Casework for a bedroom should be different from that of a bathroom. And then you should also consider whether the bedrooms are for kids or adults. A garage or basement may require casework with a lot of storage options; the same thing applies to kids’ bedrooms.

The differences are the types of materials and colors. While kids’ rooms need storage options that can withstand abuse, the cabinets in the garage and basement should be even sturdier because they contain heavier items.

You must also consider leaving out extra room for future installations. Modular casework can withstand moving and reconfiguration, but it is only possible if the original furniture pieces do not take up too much space.

Purposeless design

Types of materials and designs must be dictated by the intended functionality. For example, casework done in a garage may work better without doors. In an office, on the other hand, wooden doors are ideal for the level of privacy they provide. Some storage shelves function better with glass panels, especially when they are used to store small items such as medicines or fashion accessories.

Going with the standard configuration is acceptable in most cases, but there is always room for creativity.

Overlooking integrated components

Cabinets are not going to be the only items in any given room. Sometimes cabinets and storage shelves are placed together with other appliances, so there needs to be extra space for HVAC work, electrical wiring, and plumbing. There are some important considerations:

- Most states require the top of furniture to be at least 18-inch away from ceiling sprinklers

- Wall cabinet and base cabinet with the same width are best for design consistency

- Casework depth must be exactly the same as the depth of alcove

A lot of details seem minor and are easily overlooked, but leaving them out of the consideration can result in a poor casework shop drawing nobody can use.

RELATED: Hire freelance contractors on demand for affordable shop drawings

For the sake of accuracy and quality, casework shop drawings must be the result of a collaboration among drafters, developers, architects, engineers, and contractors. Even if architects hire a team of drafters as an external entity, good communication practices help bridge differences in approach to design.

A fully-functional casework shop drawing doesn’t have to include all possible details, but just enough information to help resolve potential discrepancies and make it easy-to-understand without sacrificing accuracy.

Cad Crowd’s Drafting Services are at Your Disposal

At Cad Crowd, we have the privilege of working with some of the best CAD drafters on the market. If you’d like to work with us, contact us today for a free quote.