A product begins with an idea, but that is only the beginning. Bringing that idea to life means turning an idea into an actual tangible thing — hopefully, one that people will want to buy. An important step in that process is prototyping. There are different kinds of prototypes for different purposes, though, so it’s handy to have an idea of the strategy that will work for you and your product.

While software simulation tools are great and help to reduce the role of physical prototyping during the development of a product, creating prototypes is still necessary for certain projects. Simulations are great for narrowing down the focus of your prototyping, but you’re still going to want to build some mock ups!

In this blog, we’ll tell you a bit about the different kinds of prototypes, as well as when and where they are useful.

The Concept Model Prototype

This kind of prototype gives a general idea of the look and feel of your product. It won’t necessarily look exactly like your product will when it’s manufactured, but this is a close representation. A concept model is usually used early in the development cycle and does not represent the full functionality of the item, but rather focuses on communicating the idea and demonstrating the feasibility of the thing.This can also be referred to as a proof-of-concept prototype.

The purpose of a concept model is to provide a general outlook of what the product would be like when it finally comes out of production. The actual object may not exactly look the same but this model provides makers with a tangible object they can work with while developing the product.

This model also serves as a test to see whether or not the ideas for the product are feasible. In this sense, having a concept model can help you identify problems your product may have. From there, you can address the design issues to ensure they don’t come up in the actual output.

Having a concept model is ideal when you’re shopping around your idea for potential investors. It is also a very useful tool for refining your design. This is a very common type of prototype that is beneficial for almost all design projects.

Presentation Model Prototype

This is, as its name suggests, a model use for presentation purposes. In short, this model has no functionality at all. What makes it different from the Concept Model Prototype is that it closely resembles the eventual product. It may not use the materials the actual product will be built with but it gives a good idea of how it would look like. The focus here is generally not at all on function, but rather on the visual aesthetic of the design. This is your showpiece. It might not actually do anything other than look and feel awesome.

Another way to describe this model is as a sensory model. This model represents what the experiential aspects of the product in terms of how it looks and feels. The primary purpose of this kind of prototype is to impress investors and wow consumers. Whether or not you choose to develop a presentation model will depend upon your marketing strategy.

Scale Model

This is also called a miniature model and like its name suggests, it represents a smaller version of an actual product. This kind of prototype is ideal for showcasing how a building, vehicle or infrastructure might look like in real life. Since it’s rather inconvenient to be dragging around life-sized models of really big things. Obviously, this is only really appropriate when you’re talking about large-scale projects. There’s no need to make a scale model of a cell phone or a toothbrush.

Suppose you’re seeking potential investors for a high-rise condominium to be built on the beach. It’s not enough to just say that it will be 50 stories high with 360-degree views of the area it will be constructed in. You also have to give them an idea of how this structure would look like. This is where a scale model comes in to help.

Just like a Presentation Model, it gives potential clients and investors a look into how a product will look like. While it’s best used to showcase homes, apartments, and buildings, it can also be used for other kinds of projects. For instance, it can be used to demonstrate the different rides in a planned theme park. It can also be used as educational materials to be displayed in classrooms or museums.

Functional Prototypes

This is best described as a prototype that looks like and feels like the actual product. Unless you’ve designed a paperweight, you’re probably going to want to test out the actual performance of your invention with more than just a presentation model.

The best way to figure out if something works is to try it. Functional prototypes are the workhorses of the prototyping world. This is where iteration comes into play. You will often want to go through several different trials of prototypes before you settle on the precise configuration that you can take to the manufacturers.

This process is necessary to ensure that you not only put out the best product possible but also one that is safe. In order to produce such a product, you need to have it go through various scenarios a user might subject it to.

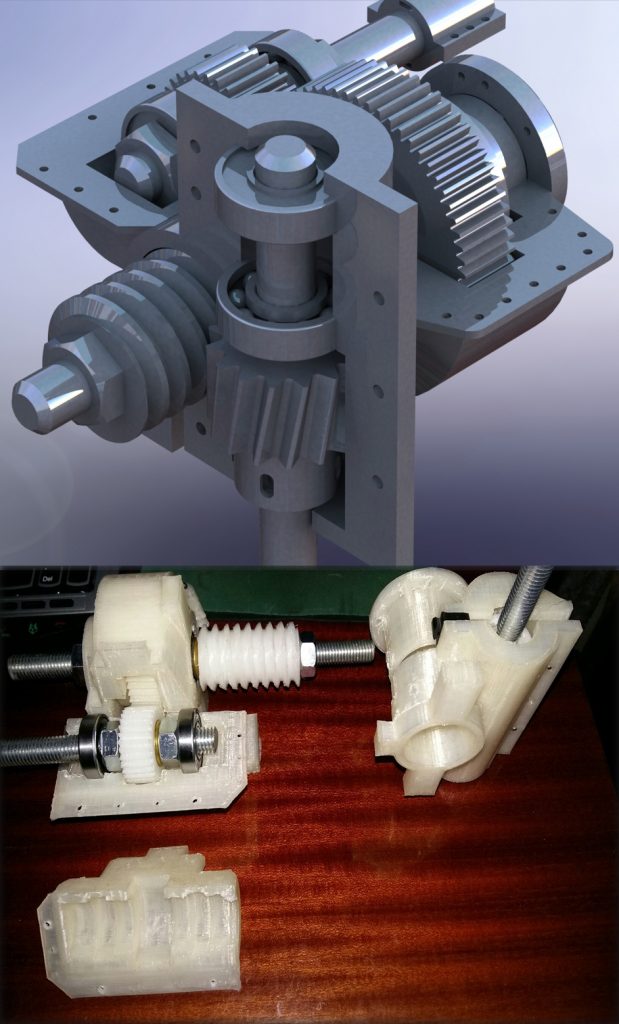

Although simulation tools exist, having an actual physical model that is ready for production validates the result of tests done through simulation. Creating this model also helps in figuring out problems that the product might encounter and fix them before the start of production.

With the ever increasing variety of materials available or 3D printing and rapid prototyping, designers can now quickly do small-volume production runs to create functional prototypes from materials that are identical or nearly identical to what will be used during full production. This gives you the opportunity to make functional prototypes that also look and feel like the real thing.

A functional prototype is an important design tool for most product design projects.

Factory Sample

If the Concept Model Prototype is the first one you’ll make, this is the final one. What makes it different from the Functional Prototype is that it is made using the same process as the actual product. Like the Functional Prototype, this too uses material that will be used on the eventual product. This is like your test sample from the factory before full blown production kicks in.

A number of factory samples can be produced until a customer is satisfied with the output. This is one of the reasons that make producing this prototype a costly part of the product development process. It can take several weeks, and you might have to go through several iterations. The designer will have to pay a deposit upfront to finance the production of these samples.

It might sound like a big pain, but it’s worth it. You need to get it right now, before you order several thousand items made. Early samples will be kinda ugly, but it is your first real opportunity to evaluate the product as it will be on store shelves (just uglier). Check the form and fit, look for any sink marks or any problems with the molding. The factory will send another round of samples, and you do it all again until the result is perfect.

The Uses of Prototypes

Prototypes are essential in the product development process. These are objects that represent the closest thing to the actual item that will come out of production. While there are different kinds of prototypes, each has their own significant use.

There are prototypes that are used for demonstration purposes, be it at an exhibition or during meetings. These models will serve as a gateway to gain prospective customers as well as potential investors. Funding is very important for the continuation of a project and presenting a well-made model that captures the attention is a good way to boost your chances of getting funded.

Some prototypes are also used for educational or informational purposes. For instance, a scale of a planned apartment complex can be displayed to give potential residents an idea of what living there would be like. A scale model of different kinds of houses can also be used to give students a three-dimensional object to observe.

These are just a few of the ways prototypes can be used to create physical simulations of actual products.

When you’re ready to start prototyping, let us know! With our wide range of contract manufacturing services, it’s easy to connect with manufacturers for both quick-turnaround 3D printed prototypes, as well as full-scale production facilities. Contact us for a free quote today and let us know about your design project!