What’s your earliest memory of a robot? Is it from a cartoon, live action movie or a book? Now that you have the picture of the first robot you can remember, is it in the shape of a human? More than likely you’re thinking of a humanoid robot, a machine that resembles a human and performs tasks that mimic human movement. The reason why robots are developed is to assist humans in completing complex or dangerous tasks but why do we insist they must look human? That reasoning is probably a much deeper conversation involving human psychology and behavior. Instead of us trying to recreate the human, why don’t we use animals and nature when designing robots to complete specialized tasks at hand?

What in the natural world can you think of that have qualities and characteristics to help it survive or complete tasks? Everything. From monkeys having long arms to swing from branch to branch to hummingbirds with tubular beaks to help it sip nectar from a variety of flower species. These traits have developed over millions of years through evolution in order to assist these organisms thrive in their surrounding environments.

If we were to borrow and apply design characteristics from nature’s evolution into our daily lives, where would we start? Let’s take the car for example. The wheel is the component that makes the automobile the one of the most efficient modes of transportation but what’s more efficient than driving on 4 wheels? Flying like a bird of course. We can effectively fly like birds right now but it requires large expensive airplanes and large swaths of land for airports. What does the future hold? More than likely we’ll be using transportation vehicles that will be utilizing more advanced versions of today’s quadcopter and drone technology or technology inspired by the way hummingbirds can hover with their wings.

We know where robotics technology is headed but do you know what the most sophisticated robots of today can accomplish? Here are 6 examples of robots that started in the biological world, inspired a design, were 3D modeled, prototyped, tested and built.

1) SandFlea by Boston Dynamics

At first, the SandFlea looks like an off-road RC car you could purchase from a local hobby shop but it’s advanced functionalities lie beyond its compact design. As its name states, the SandFlea was inspired by an insect admired for its ability to jump large distances relative to its small size. Armed with feet on both top and bottom of the vehicle, SandFlea plants itself firmly before using a piston with explosive force to propel the robot upwards of 30 feet into the air. There are some animals that can jump great heights but 30 feet is high enough to clear large fences, buildings and gaps. Of course, there’s probably no commercial use for the SandFlea in its current state but the jumping technology developed could be utilized in future applications like robotics designed to assist in law enforcement and military.

2) Swimming Snake Aqua-Robot by Eelume, Kongsberg Maritime and Statoil

This swimming robot almost looks a bit too realistic for comfort but the technology behind it is truly amazing. In the past, any type of machinery or robot used for underwater applications has always utilized propellers for thrust. Propellers work well in aquatic environments but the motions they perform are limited. By mimicking the smooth movements of a snake, the robot is able to quickly propel itself and perform maneuvers not possible with propeller and rudder. Not only are movements improved but the low profile of the robot allows it to reach tighter locations that usually would have to be tended by an underwater diver. Now, once extremely dangerous maintenance, inspection and construction projects performed by humans in the oil and gas industry, can be taken over by this hydro-robot reducing risk on employees well being.

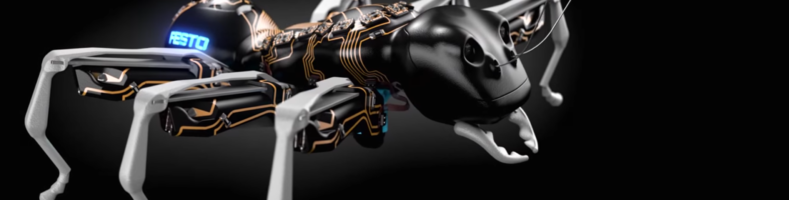

3) Bionic Ants by Festo

Festo, a German industrial control and automation company has developed a fleet of bionic ants that mirrors the insects exoskeleton design. Although the bionic ants are beautifully designed, it seems that the collaborative technologies implemented into their functionalities are what give these robots future value. The company used an ant colony as inspiration to paint a picture of what the factory of tomorrow will look like when all machines and devices can communicate with one another, working collaboratively to produce products safer and quicker.

4) CRAM Robotic Cockroach by Poly-PEDAL Lab UC Berkeley

What type of biological creature can withstand being squeezed 900 times their body weight without being harmed? The Cockroach. We’ve heard tales of cockroaches being able to withstand levels of radiation intolerable by humans and freezing temperatures but an amazing trait of the insect is being able to shape its exoskeleton to fit in crevices and cracks fractions the size of their normal shape. Not only can they fit their bodies through these tiny areas, but they are still able to move at alarmingly fast paces by reorienting their legs outwards.

Researches from UC Berkeley have used these discoveries to design a robot that utilizes a flexible top shell and articulated legs to squeeze into crevices half its normal operating height. This robot is only a prototype but it has allowed new technology to be developed in the “soft-robotics” subfield (Soft-Robotics is a type of Robot design aimed at making machines more life like to be safer when working alongside humans). Poly-Pedal Lab researches hope this new robotic compression technology can be applied to build robots to assist in disaster relief and the construction industry.

5) Cassie Bi-Pedal by OSU Robotics + Agility Robotics

In nature, most land mammals navigate their environments using four legs and paws. There are really only a few of mammals in nature that walk on two legs or move via bipedalism; kangaroos, monkey’s (limited), birds, and of course humans. Bipedalism has stumped engineers and designers in the past but there have recently been advancements in motor and balancing technology that have allowed for some of the first functional 2-legged robots.

One group that has developed this technology actually started as a lab research group at Oregon State University and has since evolved into viable business licensing the pedaling tech to other educational organizations and robotics companies. They believe, Cassie, their first legged locomotion robot, is a first step of many that could transform the future of logistics and shipping. They plan to adapt technology developed on the Cassie project to build more sophisticated machines. The technology will be used to navigate variable and unpredictable terrain like curbs, ramps, and stairs to deliver consumer packages to people homes. This delivery automation could reduce shipping costs to near nothing, opening new possibilities in global trade and logistics.

6) Sawyer, The Collaborative Robot by ReThink Robotics

So far, we’ve focused in on how robots have been inspired by nature in their physical design and actions but, what if we look beyond designing robots with only physical traits in mind and develop design based on behavior?

In order to protect people who work in close quarters with industrial robots, robots must be housed in a safety cage creating a physical barrier between human and machine. Robots are extremely efficient and productive but, since they are only metal, plastic and software, they cannot determine when a human may be in danger or not.

ReThink Robotics has taken this major flaw in robotics and has developed a new category of robots known as a “Collaborative Robot” with the development of Baxter and Sawyer. These new machines have been designed with the idea that the factory of the future will consist of humans and robots working as one to produce goods. In order to do this, robots must be equipped with sensors and safety mechanisms to protect humans who are in close contact with them. For example, if a robotic arm is assembling a computer component and a human walks by not anticipating it to spin backwards to pick up a new part, historically, the human would have paid the price with an injury while the robot continued to work as it was programmed to do so.

With collaborative robotics technology, the robot will be aware of human presence at all times and will be able to decide when it’s safe to move about. Not only can these robots always be aware of their surroundings but it’s been designed to utilize it’s interface screen as a humanoid head and eyes that look towards it’s next movement will be. These human characteristics keep employees safer in the workplace and create efficiencies once unthinkable.

Cad Crowd Gallery by Reda – Robot with Eyes

Robotics that were from sci-fi fiction have now reached reality and areas of robots once unimaginable are now being developed. These machines of the future have no limit on what they can achieve and every job out there can be improved with the help of a specialized robot to assist humans. These robots begin as ideas, transition to design, CAD modeling and result in finished products. If you’re in the process of developing a robot of the future, get a free quote quote on your project from skilled 3D modelers via Cad Crowd and bring your robotics initiative to life.