Millwork traditionally refers to any woodworking element produced in a sawmill from hardwood or softwood. In modern professional woodworking, however, millwork might be fabricated using not only lumber but also composite materials, particle boards, and even plastics, such as fiberglass. Although millwork is commonly associated with furniture designs and cabinetry, you might also see them on doors, sashes, fireplace mantels, and ornate moldings.

Unless an architectural project requires nothing but ready-made wood products, it needs millwork shop drawings services as a part of the construction documents to serve as the blueprints for the custom wooden components. And like every blueprint, they contain detailed visual representation of the woodwork, including materials, measurements, finishes, installation instructions, and any other design elements as specified by the client.

Table of contents

Table of contents

Millwork shop drawing cost

As a rule of thumb, the cost for millwork shop drawings should not exceed roughly 5% of the woodwork itself. For example, if an interior renovation project involves $20,000 worth of millwork products, the shop drawings fee alone is likely in the $1,000 range. Keep in mind that it’s only an approximation, as the actual cost is affected by several factors, such as complexity, timeframe, and pricing structure. The most common pricing structures are as follows.

Rate per sheet

A single piece of furniture may require multiple pages of shop drawings; each page represents a specific viewing angle. In a typical custom woodworking project, you will need the following viewing angles:

| Page | Notes |

| Plan view | Millwork design observed from a bird’s eye perspective. |

| Elevation | A relatively simple two-dimensional millwork drawing seen from the front. If the back and sides have noticeably different designs from the front, they also need their own elevation view pages. |

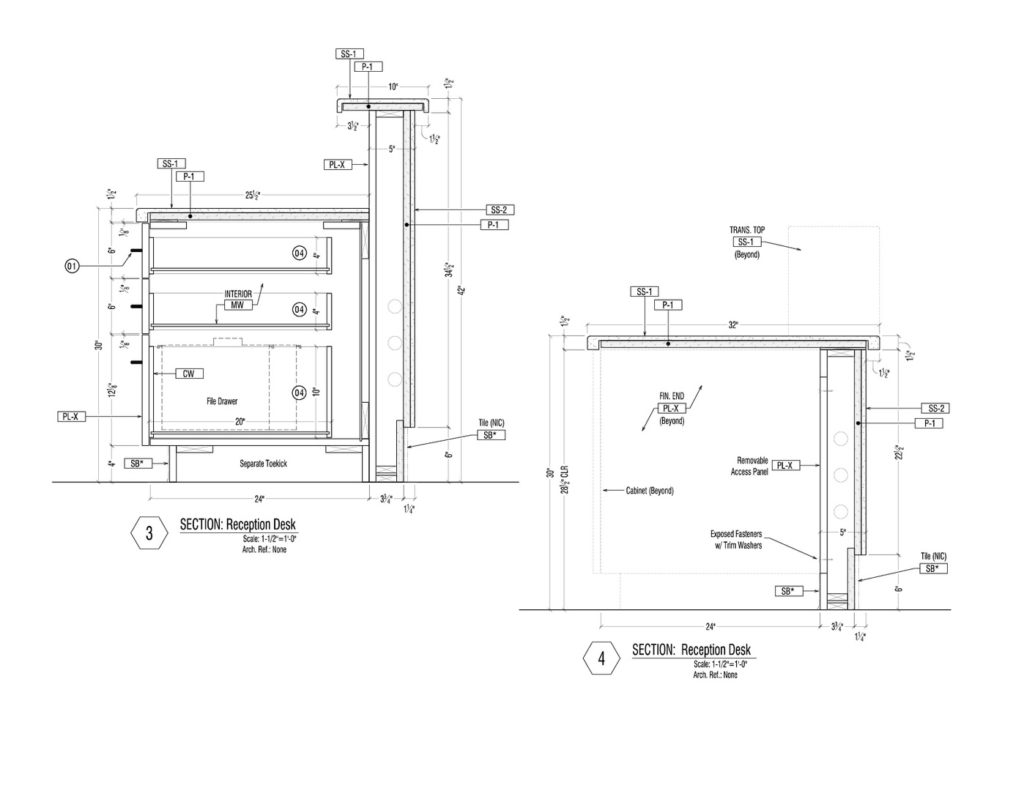

| Cross-section | A view of the object as if it has been cut in half vertically or horizontally. A cross-section view is important if the object has inner components, such as compartments or drawers. |

| Detail | An additional page that highlights certain small components like hinges, locking mechanisms, hidden storage, lighting, etc. |

| Isometric | Visual representation of the design as a three-dimensional object. |

RELATED: What are redline drawing costs & CAD drafting rates for construction companies?

A non-intricate product like a rustic patio bench or a plain waterfall coffee table might not need “detail” and “cross-section” views, but a complex nightstand with multiple drawers or an L-shaped office desk can certainly use such elaborate perspectives.

The cost per millwork drawing sheet ranges from $30 to $250, depending on the company providing the quote. At the lower-end of the spectrum, chances are you’re dealing with a one-person business operating as a freelancer; if the cost per drawing is upwards of a hundred dollars, make sure the work is handled by an accredited designer or a reputable company. Of course, you can always opt for something in the middle to get a good balance between cost and quality.

Why choose cost per drawing structure?

Practicality is the main reason. Rate per sheet simplifies the pricing because the costs are fixed for every deliverable. With simplified pricing, the budget for the project becomes more predictable. Suppose you need three millwork drawing pages for each of five furniture pieces; if the rate is fixed at $50 per sheet, you can expect to pay exactly $750 for all the sheets. The pricing structure might also help encourage efficiency as the drafting expert may strive to get the job done faster without cutting corners in terms of quality. One possible drawback is that it usually comes with less flexible negotiation for revisions.

RELATED: Fabrication shop drawing services: all you need to know

Rate per hour

If the rate per sheet focuses on page count and deliverables, the hourly rate is entirely based on time. No matter how many sheets you need, the final cost calculation is estimated by the number of hours the drafter needs to complete the work. As with rate per sheet, however, the hourly rate varies greatly among drafters.

Someone with a full-time profession as a draftsperson might be willing to produce the drawings for around $20 per hour as a side job. On the other hand, a drafting service company with a reasonably large overhead could charge $100 or more per hour for the same amount of work. Even if the drawing quality from both of them is comparable at the end of the day, the company is likely able to send all deliverables quicker because it has multiple drafters working on the project.

Is the rate-per-hour pricing structure best?

One of the biggest advantages of an hourly rate pricing structure is flexibility. Cost directly correlates with the time spent on the tasks, so it’s ideal for projects with varying levels of complexity because the amount of work put into different drawings can fluctuate a great deal. An hourly rate is probably best in situations where the sense of urgency matters.

The decision to the pricing structure ultimately falls to the client, and there are various situations where one is better than another depending on the project specifics.

Who produces the drawings?

If you’re a client, you probably won’t lose sleep over who produces the drawings, but this is actually an important thing to know to avoid confusion in case problems arise with the design at a later date. Millwork shop drawings are officially created by the person in charge of the project, like an interior designer (but it can also be an architect or a general contractor, depending on how the project is handled). That being said, for practical reasons, they’re allowed to delegate the task to a professional draftsperson or a millworker.

There’s no set of strict rules when it comes to custom woodwork products, so the design can be as creative as possible in accordance with the client’s preference. A millwork shop drawing usually is based on ideas proposed by the interior designer, who provides general outline and specification, before it goes to millwork for further development. Next, the document goes back to the design firm for approval, so it’s collaborative work.

Back and forth process

In most millwork projects, the designer only needs to produce the basic layout, geometry, and dimensions before the millworker takes the document and interprets it into a technical drawing. But just because the initial document contains only “basic” information, it doesn’t mean the designer can produce an overly rudimentary sketch, either. For instance, it needs to contain specifications for decorative hardware, types of joinery, specific hinges, certain opening and closing mechanisms, under-mount glides, side glides, whether or not the product should come with hidden compartments, etc. The designer should also mention the materials, finishes, and colors. All information must be clearly visualized in annotated drawings.

The initial drawings are fairly technical, especially when the products themselves are pretty intricate, but still not detailed enough for the designer to make all the decisions on how to approach the fabrication process. And that’s why the final millwork shop drawings should be in the domain of the millworker – and sometimes the willworker also hires a draftsperson to do the job, too. However, before the millworker can start the production, the drawings must be sent back to the designer for review and approval. The point is to make sure that the original ideas (from the designer) remain in place and that the millworker does indeed have the right tooling for the job.

It can be quite a lengthy process and will be even more so if the designer discovers a lot of things that need to be corrected. Every single change to the design intent suggested by the millworker must be first authorized by the designer. To avoid having too many discrepancies and therefore revisions, the designer or general contractor gets to choose which millworker to partner with. If you’re a client and unless there are uncommon considerations involved, the cost for millwork shop drawing is already covered in the designer’s fee.

Contents of millwork shop drawing

The purpose of millwork shop drawings goes beyond outlining the specifications of the woodwork. Every sheet in the document also serves as a communication tool between shareholders to share details about materials processing, fabrication methods, and installation. To fulfill all its purposes, millwork shop drawings should at least include the following information:

- Dimensions: measurements of the final product and all its components

- Materials: specifications, including types and dimensions, of all materials required to build the product

- Assembly: detailed instructions on how to bring the processed materials into the desired design

- Finishes: the expected final outcome of the project

Shop drawings must also contain notes of comparison to the original construction documentation because even a single modification may alter the production timeline, tooling, and budget.

You cannot stress it enough: millwork shop drawings play an important role in a custom woodworking project. They contribute a great deal to project planning and minimizing errors, as they improve communication between designers, millworkers, and clients. The drawings cover everything, from material procurement to assembly/installation, and help identify mistakes even before the actual production begins to make sure that the result meets the desired specifications and expectations.

RELATED: How do companies use millwork shop drawings for 3D furniture modeling and design?

Cad Crowd and millwork shop drawings

Whether you’re an architect, a general contractor, an interior designer, a millworker, or perhaps a client planning for your next custom woodworking project, Cad Crowd connects you with experienced draftspersons to help you produce professional quality millwork shop drawings at an affordable rate. Reach out to Cad Crowd to understand how we handle the procedures for you and get your free quote at your earliest convenience.