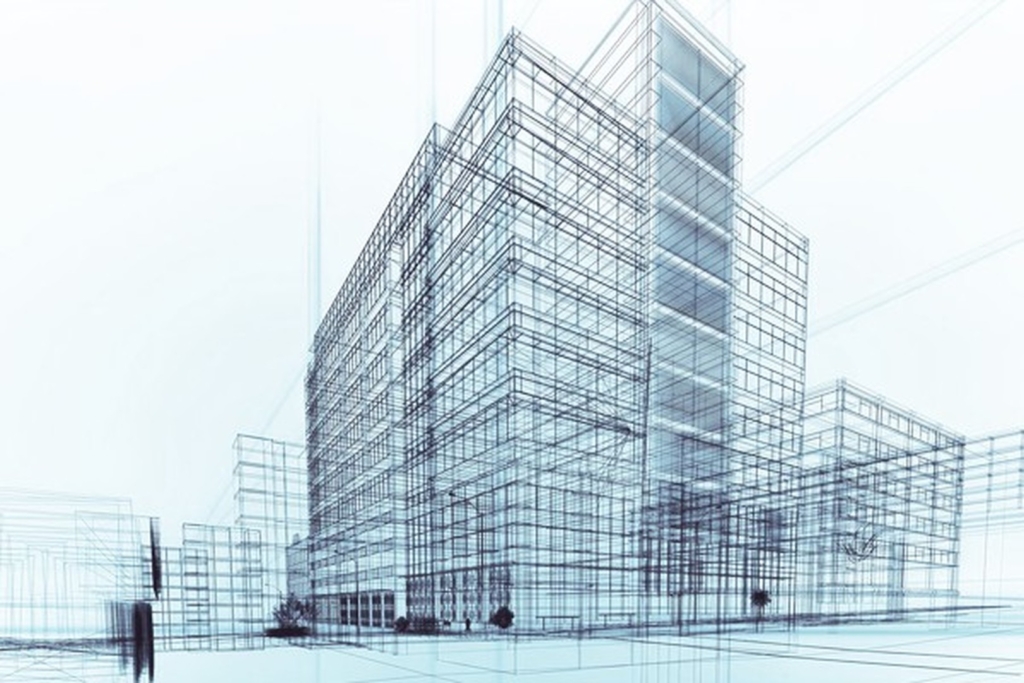

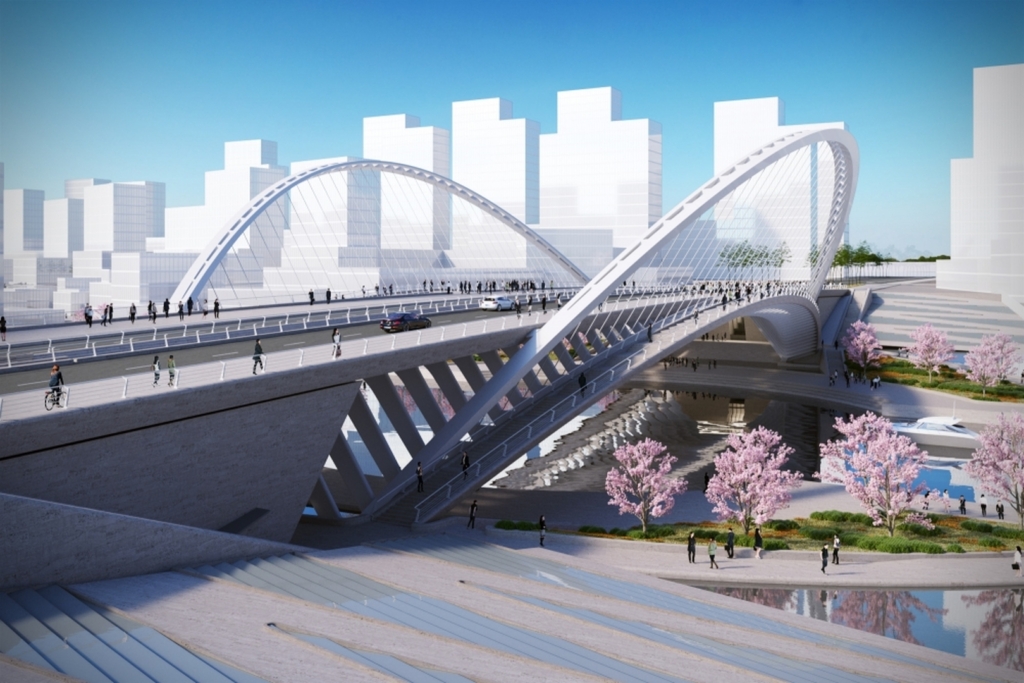

Steel detailing happens to be the most important process in the building industry, as it bridges the gap between the initial thoughts of designs and the final construction of the steel structures. It requires very accurate translation of architectural and engineering data into detailed plans for specific steel fabricators. Such plans are complete specifications along with expert technical drawings that provide clear instructions for all aspects of the steel components, from fabrication and assembly to the ultimate erection on site.

For this reason, during the detailing process, structural steel detailers interact closely with architects, engineers, and contractors. Nevertheless, the complexity of projects, coupled with the high demand for quick deliveries, leads many firms to outsource their services of detailing steel. This article delves into compelling and vital reasons why outsourcing is proceeding to streamline workflows, increase the efficiency of projects, and also provide cost-effective means of ensuring successful construction projects.

Cad Crowd has worked with many contractors, firms, and clients for over 15 years to find the best freelance service for steel detailing, and other architectural, structural, and interior designs. We’ve seen first-hand how steel detailing services (and similar ones) helped companies achieve success faster than they would have traditionally. Let’s take a look at some of the specific benefits you can take advantage of for yourself.

🚀 Table of contents

- What is steel detailing?

- Importance of steel detailing services

- Structural detailing problems

- Benefits of outsourcing structural steel detailing services

- Types of steel detailing drawings

- The steel detailing process

- Factors in choosing an outsourcing partner

- Possible risks and mitigation strategies

- Best practices when outsourcing structural detailing services

- Wrapping it up

- How Cad Crowd can help

What is steel detailing?

Structural steel detailing involves almost 99 percent accuracy since slight errors can cause huge time and cost losses. It is required in all manufacturing and construction works like residential or commercial buildings, factories, shipbuilding, etc.

This communication link should be inevitable between engineers, architects, contractors, and fabricators for accurate detail at any level of the process. This might mean outsourcing services to such professional companies with qualified engineers. Professional engineers have the technical know-how and experience in the preparation of designs, details, and drafts and will be able to handle complex design issues that are more suitable for the project outcome.

RELATED: Structural steel detailing services for companies: Steel detailer costs and rates complete breakdown

Importance of steel detailing services

Structural steel detailing services deliver detailed drawings, models, and documentation that can reproduce structural elements of a design for building or infrastructure projects. These services ensure that structures are safe, intact, and serve their purpose. Therefore, detailing comes in many forms- from steel and rebar to precast panels, among others and all require extreme accuracy and expertise in bringing the architectural design to reality.

Structural detailing problems

Structural detailing is a very involving process. However, complicated factors present problems for the success of a project. Complex designs, tight deadlines, and budgets often turn to pressurizing resources inside. Therefore, quality may deteriorate while project time schedules become susceptible to risk. Outsourcing structural steel detailing services can neutralize these problems and provide firms with a competitive advantage in the business environment.

Benefits of outsourcing structural steel detailing services

Structural steel detailing can be outsourced to provide various advantages. So let’s dive in and take a closer look at some of the key benefits:

1. Cost and time savings

Faster project turnaround: Generally, the outsourcing company has the manpower and experience to do the jobs efficiently, thus leading to a generally shorter period to complete the project.

Improved project predictability: Through outsourcing, firms can experience a probable detailing process leading to not-so-frequent delays and cost overruns often encountered with in-house efforts.

Reduced software and training costs: Outsourcing saves on the cost of purchasing expensive software licenses and training the employees about using the software. It not only reduces the cost but also frees time to bring the team up to speed.

2. Better communication and collaboration

Clear communication channels: Detailing companies have systems in place with robust communication protocols to keep clients informed during the entire project lifecycle. This close collaboration also helps ensure that specific needs are understood and addressed.

Responsive troubleshooting: Should questions or issues arise during the detailing process, dedicated teams in outsourcing partner companies can resolve them quickly, ensuring a smooth workflow.

3. Expertise and efficiency

Skilled experts: Designs of steel require strong structural engineering knowledge and industry practices. Outsourcing will connect you with outsourcing firms’ professional detailers who have special training. This ensures project completion is both efficient and fast.

Efficient process flow: Detailers employed by engineering outsourcing firms have already engineered processes to optimize for both speed and accuracy, which allows them to process projects within a short timeframe while freeing up internal capacity to use on the big things.

RELATED: A comprehensive guide on steel shop drawings for freelancers and construction companies

4. Flexibility and scalability

Outsourcing enables firms to gauge their structural detailing requirement related to the needs of the projects. This helps companies adjust resources up or down to meet either flexibilities or cost objectives.

5. Concentrated competency

Let other professionals handle the core competencies of management and engineering and structural detailing outsourced to a trusted partner. This would focus more on the project and make more efficient use of available time, increase productivity, and thus lead to more successful projects.

6. Quality assurance

Accuracy and detail: Great detailers are very painstaking; they come up with excellent drawings without errors that could be done when the fabrication and building take place.

Industry compliance: Professional detailing companies and firms are always compliant with all industry standards and codes so that errors related to such non-compliant detailing are lessened and delayed.

7. Minimum investment in technology

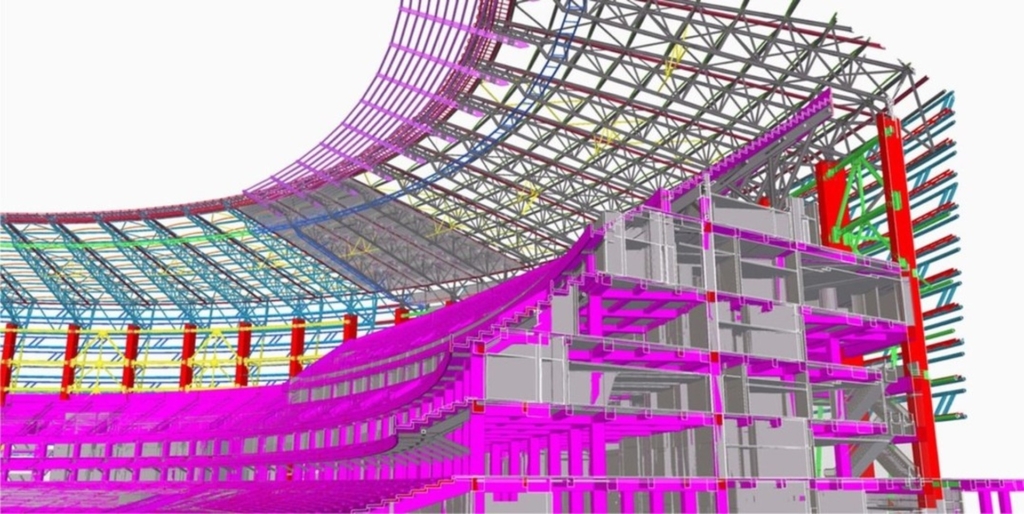

Access to latest software packages: Steel detailing requires advanced CAD software and BIM platforms, which are very expensive to maintain. Outsourcing allows companies to take advantage of the latest tools available through the detailing service provider.

Other specialized tools aside from CAD and BIM: Link designs, material analysis, etc. They can avail of all these comprehensive tools without committing much front-end investment by outsourcing.

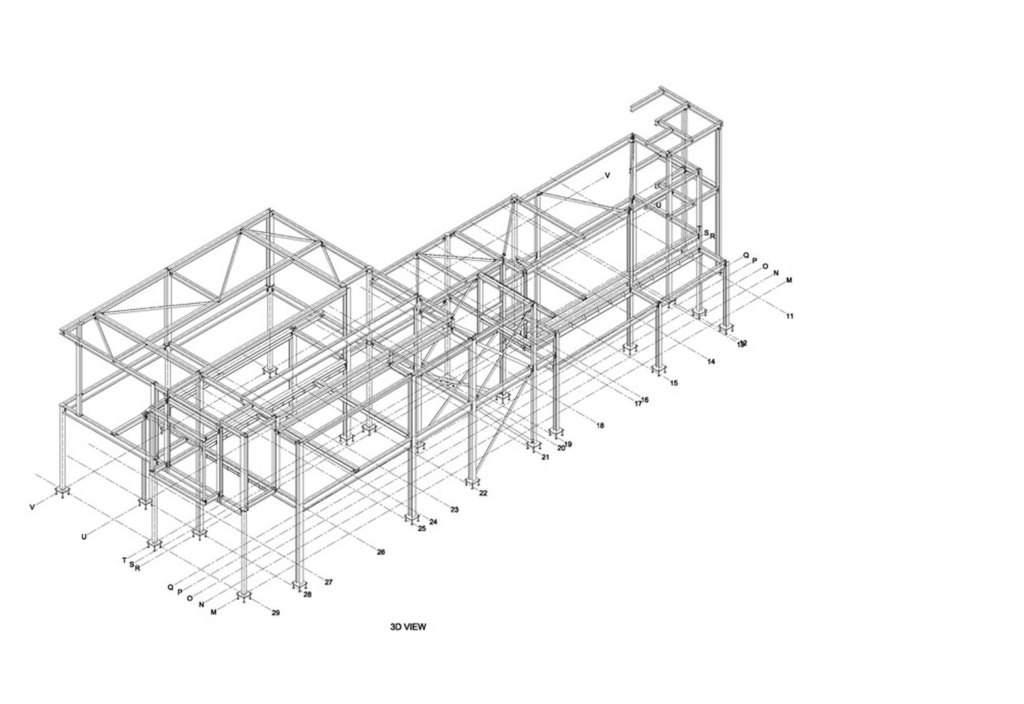

Types of steel detailing drawings

Steel detailing drawings are fundamental plans in construction. They avow the major specifications on how a given steel component should be manufactured and put together. There are two major types of detailing drawings

1. Erection drawings

The drawings serve as a guideline for ironworkers when fabricating the steel structure on the site. Some of the crucial information includes:

- Dimensions: Precise measurements of where to position each steel part relative to its location in the structure.

- Placement: Direct guidance on placing the steel elements.

- Connection types: Information on how to connect various steel pieces, including different types of connections (for instance, bolting and welding) as well as the welding requirement.

- Site work: The other work on site, whether bolting procedures or installing anchors.

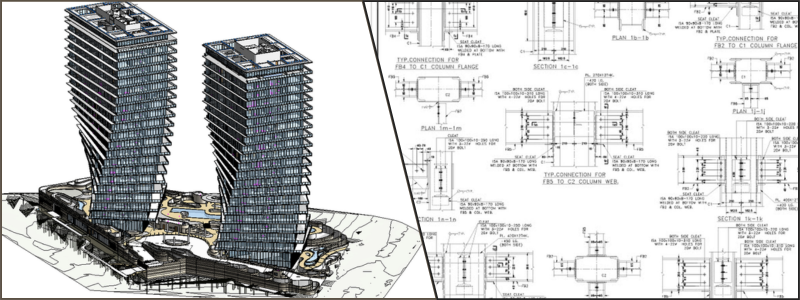

2. Shop drawings

Shop drawings are a manufacturing guide, preparing fabricators to manufacture components of steel off-site. They contain the most critical details of:

- Dimensions: All the accurate measurements for every piece of steel by length, width, and thickness.

- Material specifications: Details about the kind of steel to be used for every component.

- Cutting and bending details: Instructions on how to cut and bend the steel.

- Hole placement and sizes: Dimensions for holes within the connections, when required.

- Welding details: Descriptions of any welds necessary, which include sizes, types, and locations.

RELATED: 5 benefits of using sheet metal for your CAD design

The steel detailing process

Steel detailing services is a very critical process to ensure successful fabrication, assembly, and installation of a steel structure. Here’s a step-by-step look at each stage.

1. Creation of design drawings

- Software: Details utilize computerized software to produce both 2D and 3D drawings.

- Components: Drawings of individual parts of steel, which include columns, beams, and braces.

- Specifications: Engineers must provide all critical details, such as dimensions, orientation, and the connection method.

- Other details: The drawings also include floor-level details and alternate material considerations.

2. Materials and budget assessment

- Drawing review: Design drawings form the basis for the contractor, fabricator, or erector to review the project.

- Evaluation criteria: Assessments examine the possible utilization of steel, material inputs, estimated time to the point of completion, available resources, and other potential issues.

- Cost estimation: This evaluation, therefore, results in a precise cost estimate for the project.

3. Shop drawings

- Fabrication instructions: Shop drawings are the detailed outline of fabrication procedures interpreted from the design drawings by fabricators in the actual manufacturing of steel elements.

- Key information: Shop drawings shall include accurate measurements, material specifications, connection details, and welding processes.

- Erection marks: This is the outlining of the erection process.

4. General Arrangement Drawing (GAD)

- Software used: General Arrangement Drawing is generated by modeling software; it’s also referred to as a marking plan.

- Purpose: This drawing indicates the location of all shop-produced elements on site as well as their interfaces with other structural members.

5. Coordination and teamwork

- Team collaboration: During detailing, structural steel detailers consult with architects, engineers, and contractors

- Verification and checking: This coordination ensures no deviation from the intent of the design and that the structure meets structural intent

- Troubleshooting: The team solves all design problems that may crop up during construction for a smooth process.

Factors in choosing an outsourcing partner

The outsourcing partner in a given structural detailing service is very crucial. The following are some of the important factors for consideration:

1. Communication and project management capability

This is one of the crucial factors involved in any outsourcing partnership. Choose a partner who has good lines of communication and effective project management practices to streamline your relationship.

2. Data security and confidentiality measures

Data security is always something to be considered while outsourcing structural detailing. The outsourcing partner needs to have appropriate security systems in place to protect and maintain confidentiality with sensitive project data.

3. Experience and expertise

Evaluate the experience and reputation of the outsourcing partner, particularly in the industry. Try to look out for a team that has a proven track record of successful completion of structural detailing work.

4. Pricing models and contractual agreements

Evaluate the pricing models of the outsourcing partner to ensure they align with your budget and project requirements. Careful review of contractual agreements will clear all deliverables, timelines, and payment structures.

5. Quality assurance processes and certifications

Ensure the outsourcing partner ensures the strictest quality assurance processes are followed and is certified under any such recognized certifications, such as ISO. This would ensure that the deliverables would be maintained according to the industry standards.

RELATED: Structural engineering rates & costs for architectural design firms

Possible risks and mitigation strategies

While outsourcing structural design services has many benefits, there are risks, too. Consider the following and implement the mitigative measures appropriately.

1. Data protection and confidentiality

Mitigate security risks in data by taking protective measures, making NDAs with parties involved, and scheduling some audit compliance.

2. Language and cultural barriers

Implement the necessary effective communication channels and promote teamwork with cultural orientation to overcome possibly influential language and cultural differences.

3. Time zone differences

Working with an outsourcing partner in another time zone can present challenges. Overlap working hours, use project management tools, and establish clear communication protocols.

Best practices when outsourcing structural detailing services

You should consider some best practices while exploring how to optimize the benefits of outsourcing structural detailing services:

1. Define project requirements clearly

You ought to communicate project requirements and expectations clearly to the outsourcing partner. To the outsourcing partner, what will be communicated will ensure accuracy and quality with the deliverables.

2. Provide periodic progress reports

Conduct periodic monitoring of project progress and perform quality control checks for conformance to specifications. Do this in a manner that provides on-time feedback as a motivator for continuous improvement.

3. Continuously review the outsourcing partnering

Regularly review the outsourcing partnering process and identify possible areas for improvement. Gather comments from other stakeholders of the project, learn lessons from every collaboration, and bring these lessons learned into the next partnership.

4. Establish mechanisms for communication

Keep in touch through regular communication and transparent transmission of updates, and address concerns immediately. An effective collaboration approach with numerous communication tools will be utilized.

5. Collaborative relationship

Establish a strong collaboration on trust and transparency. Encourage an open exchange and proactive problem-solving approach for successful project outcomes.

Wrapping it up

Outsourcing structural steel detailing services will also provide a strategic advantage over most architectural design firms’ in-house detailing efforts. Some of the expected benefits that the company will gain after outsourcing are the lowering of costs, improvement of efficiencies, and getting hold of the latest technologies and expertise.

This way, internal teams can concentrate on core competencies while quality, error-free steel detailing guarantees successful outcomes for every project. Thus, with the construction industry evolving, embracing outsourcing as the best way to remain competitive while delivering projects on time and within budget will be important.

How Cad Crowd can help

Engineering firms and CAD design companies can always use some help with their projects. You might realize it even more so if you’re dealing with some steel detailing. Cad Crowd can connect you with the best and most trusted steel detailing services that will help you pull off quality results that will blow away your clients. Request a quote today.