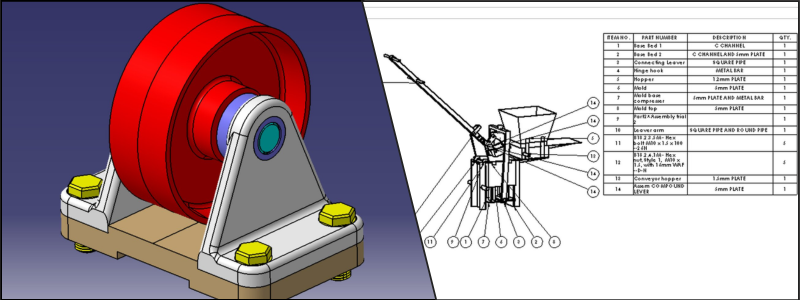

Assembly drawings are visual tools that are used to present an entire system or machine in order to identify all of the parts and components precisely. Its primary purpose is to specify items, label these parts for a correct and seamless assembly, and indicate the standard requirements.

These drawings can also give a view of the overall Bill of Materials or BOM, weight, mass, sections, orthogonal plans, elevations, and more. Assembly drawing services serve as a medium or middle ground where conversations and streams of ideas between two technical people can take place. It is where exchanges of various ideas of different multitudes can take place.

Assembly drawings are designed for products, units, devices, and types of machinery. These services assist in assembling the intricate parts of a mechanism, just like furniture guides for building up those new pieces for your room. However, some requirements should be met, such as manufacturing, operational, and maintenance requirements.

🚀 Table of contents

Why companies and firms need assembly drawing services to succeed

Your company or firm can look forward to more success if you take advantage of professional assembly drawing services.

More apparent plans for complex items

Just imagine what it would be like to try to figure out how an excellent car or super complex machine should be put together without guides to help out. It would be like demanding a final product, expecting all the features and functionalities without knowing how each part works, even more so all the parts involved.

An assembly drawing can give you and your company this much-needed visual, both a bird’s eye view and a zoomed look into the smallest and most intricate parts of your mechanisms. It can break down the design into different simple parts to show how every piece fits together. You can think of it as a roadmap, with all the crucial checkpoints, that helps solve a puzzle and guides you with the correct steps to finish the journey with a perfectly assembled project. Assembly drawings let you know where every piece of the puzzle should go to form the whole picture.

Avoid mistakes and save money

An assembly drawing is also similar to a safety net that catches mistakes and errors even before they pop up. CAD design experts can avoid costly mistakes and mix-ups since the assembly drawing gives precise details about measurements, sizes, and how everything must be put together. Once again, this helps ensure that the pieces all fit right before the actual building begins to ensure that nothing will go wrong or amiss.

RELATED: Benefits of outsourcing steel detailing services for engineering firms and CAD design companies

Better communication with suppliers

Assembly drawings are like the universal language of designers who work with others who produce the parts. These drawings help explain the requirements and how something should be made. Suppliers can refer to the assembly drawings to ensure the perfect fit of their pieces, whether it is a custom part or a special one. It simplifies the process of getting parts, not to mention that it also helps forge excellent and robust relationships.

Effective blueprint for teamwork

Assembly drawing is just like that particular dedicated language understood by all members of the production and design teams. These drawings show a product’s whole picture to help all the parties involved in its creation work hand in hand. This is also similar to a team of musicians that follows a meticulously written musical sheet. An assembly drawing helps play their parts to come up with something unique.

How to create assembly drawings

A technical person prepares an assembly drawing that is clear without any room for misinterpretation. Accurate, correct, and precise drawings make it possible to produce automobiles and machines on a mass scale that require numerous assemblies and sub-assemblies.

The person who drafts assembly drawings must have extensive technical knowledge of the traditional drafting practice and principles alike. The absence of this may result in misinterpretation and even litigation.

Aside from this, the person who interprets assembly drawings should also have a proficient understanding of the graphical language they use. If not, it would be challenging to come up with the machine in the proposed manner for engineering firms.

If no assembly drawings were made, the technical ideas would then have to be conveyed either by writing or speech rather than graphical language. It makes it harder to understand the shop floor level, not to mention that it will also be labor-consuming and prone to errors.

The effective use and application of assembly drawings is the very reason why many objects like locomotives, automobiles, aircraft, and others have been crafted and produced.

RELATED: What are costs for floor plan design blueprints, CAD designer rates and company services pricing?

Different types of assembly drawings

Assembly drawings have one primary purpose. That is to identify the different components and parts and show their specific working relationship with each other. The drawings contain a detailed and comprehensive drawing of all the elements, the subassembly, and how the final assembly should be made.

The following are the main categories of assembly drawings, some of which have their sub-categories.

General assembly drawings

| Assembly drawings for catalogs | Assembly drawings for catalogs are particular types of assembly drawings, which, as their name implies, are prepared for company catalogs. This kind of drawing depicts only the relevant dimensions and details that a potential buyer will find interesting. |

| Assembly drawings for instruction manuals | This type of general assembly drawing is used if a machine that is already assembled should be knocked down to check the different parts. It is shipped away to be assembled again and installed somewhere else. Every component in these drawings is numbered to help in the process of reassembly. Assembly modeling services can be helpful in the process. |

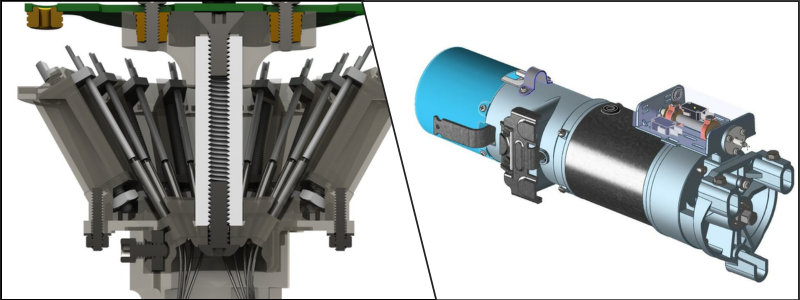

| Design assembly drawings | Design drawings are drawings made during the design phase. These represent the different angles of the machine that will be assembled. The drawings or layouts help visualize a machine’s performance. The clearances and shapes of the other parts that make up the machine are visible. |

| Detailed assembly drawings | Detailed assembly drawings show the assembly process of every machine component and offer specifics such as the dimensions, the materials used, the joining methods, and more. Ideally, these drawings are used to assemble smaller machines made up of smaller parts. Aside from regular assembly drawings, these drawings can also show enlarged views of certain parts, as well as how everything fits together which is especially useful for manufacturing design companiwes. In assemblies like lathes and automobiles made up of both individual parts and pre-assembled components, the distinct groups of parts can be assembled and typically tested as a unit before being put into the final arrangement. The pre-assembled units are called sub-assemblies. Sub-assembly drawings are assembly drawings of a group of related components that make up a part of a more complex machine. |

| Exploded assembly drawings | Exploded assembly drawings are technical drawings of objects that show their different parts. 3D exploded diagrams produced by assembly drawing services depict the components slightly suspended or separated in the surrounding space in an assembly sequence. These drawings give an idea of how the finished product is going to fit together. An exploded assembly drawing can be easily understood even by a layperson, which makes it handy to be used in catalogs for parts, instruction materials, or assembly manuals. |

| Installation drawings | Installation drawings are drawings made for the assembly or erection of a product. These drawings offer details about the position of a component concerning the adjacent or supporting components. They also provide information regarding general configuration, hardware description, and dimensional data. These drawings offer valuable data for assembling a machine because they show all the components of a machine in their proper working position. |

| Machine shop drawings | A machine shop drawing is intended for the end-user or the person in charge of the machine’s operation. Since the machinist isn’t concerned with the information and dimensions relevant to the earlier stages, machine shop drawing services only provide information regarding the machine’s function. Based on this similar principle, it’s also essential to create sheet metal drawings, pattern shop drawings, forge shop drawings, and the like. |

| Schematic assembly drawings | Schematics are defined as pictures that simply depict something with the help of symbols. Schematic assembly drawings represent the parts of a device or process with the help of standardized lines and symbols. The simplified illustration of a system or a machine replaces every element through their respective traditional representations. Schematic assembly drawings are helpful because it is not easy to understand the different operating principles of complex machinery just from the assembly drawings alone. The schematic representation of a unit allows easy understanding of the operating principle. |

RELATED: How 3D real estate rendering services boosts traffic and visibility for realtors

Wrapping it up

Assembly drawing services are essential for companies and firms as they show how different components and parts fit together visually. It will be easier and more effective for professionals to explain product assemblies and their complexities to assembly workers, manufacturers, and engineers with the use of an assembly file and drawing sheet. This provides a smooth and seamless transfer starting from the design stage up to the manufacturing stage.

The different parties involved in the assembly process will get a more precise grasp of the process with a carefully crafted assembly drawing that includes annotations and dimensions indicated in the design sheet. This inclusion of tolerances, sizes, and other essential details not only cuts down the risks of errors taking place during the process of assembly but also enhances the overall success and effectiveness of a project.

How Cad Crowd can help

It takes expertise and skills to create assembly drawings. Cad Crowd is an industry-leading platform that can assist you in finding the best assembly drawing services to eliminate errors and ensure a successful production. We