Precision is paramount in construction. Steel shop drawings play the most important role in having every steel component produced with detailed requirements of a building project. The subsequent guide will discuss the need for steel shop drawings, purposes, components, and other tips on how to make a quality shop drawing as a freelancer or part of a construction company.

Table of contents

Table of contents

- Understanding the purpose of steel shop drawings

- Major characteristics of steel shop drawings

- Why steel shop drawings are important

- Steel shop drawing best practices for freelancers and construction companies

- Outsourcing steel shop drawings – why construction companies do it

- Prices for freelance steel shop drawings services

- Steel shop drawings hurdles and moving past them

- Wrapping it up

- How Cad Crowd can help

Understanding the purpose of steel shop drawings

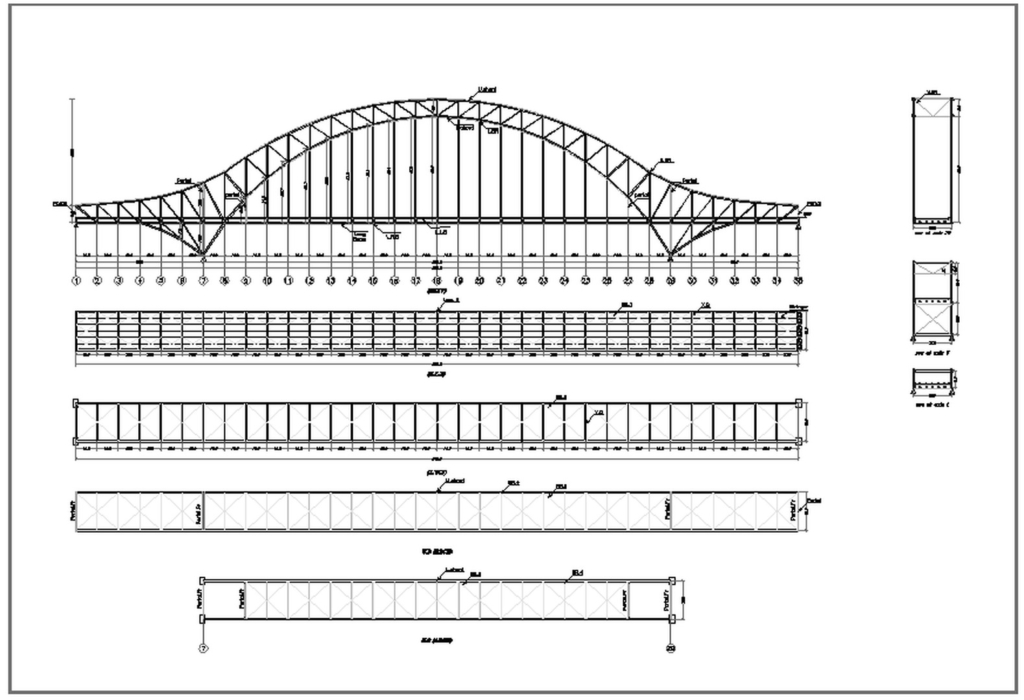

Steel shop drawings bridge design and construction. Preliminary design plans provide a general overview of the structure of a building, but shop drawings go further and delve into specifics, thus providing fabrication and installation teams with detailed instructions on the crafting of steel components. There is a higher risk of miscommunication, potential delays, cost overruns, or structural issues if shop drawings are not accurate.

From skyscrapers to bridges, all the material requirements, measurements, and arrangement must be strictly held to the correct specification design. These are essentially a “playbook” that metal fabricators and construction teams refer to in order to manufacture architectural visions.

RELATED: Structural steel detailing services for companies: steel detailer costs and rates complete breakdown

Major characteristics of steel shop drawings

Most probably, the standard sheet steel shop detail would have several of them for the purpose of precision and clarity, with the most obvious ones:

- General Arrangement (GA) drawings

GA drawings are a view that shows where steel members go in the structure. They are top-down and side-view placements of the steel layout with possible unique identifiers marked on the members. This makes it quite easy to see how all of the pieces fit together into the overall structural plan since each piece of steel is shown in its place.

- Assembly and erection drawings

These drawings give step-by-step instructions on how to assemble and erect the steel components in position. Assembly drawings usually detail the relationship, sequence of erection, and welding or bolting information that enables safe and correct assembly. Erection drawings serve as the basis of work done by contractors and installation crews to ensure all parts go in as contemplated.

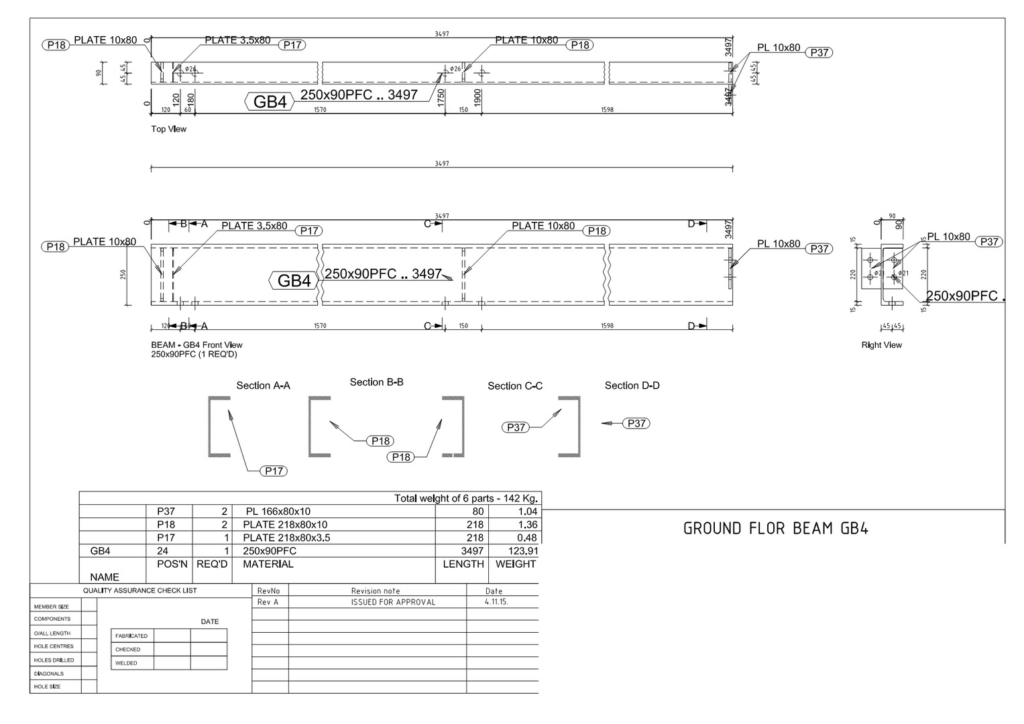

- Fabrication drawings

The bread and butter of steel shop drawings are fabrication drawings. The drawings break down dimensions, cutting patterns, hole location, and any welding mark for each piece of steel. These are the actual drawings fabricators use to make individual components.

- Connection information

Steel connections are very important for structural stability. The connection details describe how a steel member should be connected to another, through welding or bolting, and give details of whether the weld will be of the fillet or groove type, if the bolts are shear or tension-type, and specific material standards with spacing and size.

- Material specifications

Material specifications include the grade, type, and finish of the steel. Much of this information is given in accordance with industry standards such as ASTM or EN for quality and structural integrity. Coatings or treatments are further provided for resistance to corrosion in many specifications, which apply to outdoor or exposed structures.

RELATED: Fabrication shop drawing services: all you need to know

Why steel shop drawings are important

There simply cannot be guesswork in steel fabrication. Steel shop drawings:

- Increased accuracy: With precise details, the steel shop drawings eliminate all possible confusion and ensure that the finished product will be as planned.

- Improve communication: In that sense, shop drawings also become the lingua franca for freelance CAD designers and construction companies, as well.

- Support quality control: Every steel bar is made focusing on shop drawings to ensure that it meets standard quality.

- Prevent cost overruns: Mistakes are expensive; shop drawings help minimize the chance of rework as detailed, correct plans are implemented from the very start.

Steel shop drawing best practices for freelancers and construction companies

Whether the CAD freelancer is an independent contractor or part of the construction company, accurate steel shop drawings are required. To achieve the industry standard, here’s how:

Through extensive coordination

Coordinate with engineers, architects, and other stakeholders before drawing. The intent behind the design will make it easier to identify the critical aspects in the shop drawings, whether load-bearing components or aesthetic design elements.

Obey the norms and conventions

Make sure your drawings are to industry standards, such as the AISC standard in the United States or Eurocode in Europe. Labeling, dimensioning, and notations according to these standards help the fabrication and construction teams better understand the drawings.

Use CAD software proficiently

A good freelancer should be able to perform well in applications such as AutoCAD, Tekla Structures, or Revit. All these applications vary with templates and features in making shop drawings, from automatic detailing to error checking. For construction companies, standard CAD workflow is convenient to simplify the drawing when the situation calls for drafters.

Note all comments

The notes and all relevant comments have to be done on the drawings. Areas that wouldn’t easily be interpreted also demand notes. The type of weld and the quality of the weld should be required on the weld symbols. The more specified annotations, the less likely of an error from the fabricators.

Confirmation and verification

Once a shop drawing is finalized, verification is the issue. Freelancers should cross-check the drawings with the originals for differences. Construction companies may have an in-house quality control team to deal with this step. All measurements, angles, and specifications should be in line with the intention of the original design and avoid expensive mistakes.

Effectively control changes

Changes are something that will be present in the construction project. Freelancers and companies should have clear procedures of revisions. Each version of the shop drawing must be dated and uniquely numbered. It will be easy to spot changes having change notes and “clouds” around the area of the change as compared to stale information.

Outsourcing steel shop drawings – why construction companies do it

Some construction companies prefer to hire freelance CAD designers or specialized drafting companies to prepare their shop drawings. Outsourcing might be the solution for all the following reasons:

Cost-effectiveness: The cost of hiring in-house CAD experts can be quite high. With outsourcing, one can get good-quality shop drawings without a full-time in-house team.

Access to expertise: The experience of most freelancers also involves steel detailing and shop drawing software, which will ensure quality work up to specifications.

Capacity management: Outsourcing brings comfort in fluctuation such that the construction firms may increase or decrease the workforce size according to the need of the project, and they do not need permanent employees.

Prices for freelance steel shop drawings services

As a freelancer, understanding how much to charge for your services when creating steel shop drawings may depend on such aspects as timeframes of job completion, the difficulties of the project, and the experience you possess. Factors include:

Hourly rates vs. project fee: Most freelancers opt for an hourly rate for cheaper projects, while more expensive projects may attract a flat rate, especially in cases where several deadlines are agreed on beforehand. It may be wise to assess the prevailing rates around your country for such projects.

The challenge and the degree of detail needed: most of the time complex projects that involve designing complicated connections, many changes, or 3D images will cost even more than simple drawings.

Understanding what the client wants: It is important to set the expectations with the clients at the very beginning on how much is the retainer. Will corrections be charged separately? What about a specific client-requested software for the work? Clarifying these matters from the beginning will help to avoid frustrations later on.

Steel shop drawings hurdles and moving past them

The process of producing steel shop drawings though fulfilling has its own set of difficulties. Here’s how to tackle some common issues:

Handling tighter work schedules

Most of the projects are time-bound and allow minimal delays if any. As such, freelancers must ensure that there is open communication with the clients while managing their workloads with more realistic ones. To ensure proper management of the shop drawing processes, construction industries can adopt the use of the project management drawings software.

Adhering to standards

Adhering to specifications has its challenges. For instance, it is advantageous for independent providers to undergo training periodically on new tariffs and detailing codes of steel. Such quality measures can incorporate quality assurance stages, where each drawing will be reviewed and marked for compliance.

Making use of resources effectively and efficiently

While steel fabrication shop drawings ought to be precise to the last detail, excessive rendering of the drawings will lead to delays in the project. Employing CADwares skillfully and the availability of predesigned forms can shorten the cycle of producing the drawing if not compromise on the accuracy.

Wrapping it up

The elaboration of steel shop drawings is the primary component for the productive construction of structures made of steel. By ordering precise shop drawings of the steel fabrication, structural steel erectors and designers can be sure that every individual steel member will be designed, made, and erected correctly.

Knowing all the components of a shop drawing, knowing the requirements, and doing the work in an organized manner, steel shop drawings can provide the spine for construction, mainly without hitches. Whether you are a CAD specialist or a contractor, acquiring steel detailing skills can help you gain new projects, enhance processes, and impress your clients.

RELATED: Redline & as-built drawings explained for construction companies and architects

How Cad Crowd can help

Today’s freelancers and construction companies are expected to master steel shop drawings and all their intricacies. Here at Cad Crowd, we will be more than happy to connect you with the right people who can provide quality steel shop drawings according to your needs and budget. Request a quote today.