Creating a product that will have its manufacturing outsourced comes with a range of challenges. Although the start of the process may look like any other, from coming up with an idea, creating a full concept, designing, and prototyping, there will be other considerations when sourcing a factory and dealing with aftercare procedures.

Whatever industry you’re in, from computer components to car parts, the basics of the process for an Original Equipment Manufacturer will be generally the same. Here, we’ll go through the eight stages you need to go through as an OEM, from design to end product, and cover some of the common issues that you might face at each stage.

8 Stages of an OEM’s Guide to Product Design and Manufacturing

1. Having an Idea

It’s such a simple concept – just think of something to make. However, it’s never that simple as anyone in the industry will tell you; you need to solve a problem and do it better than anyone else. You need to flesh out your idea to make sure that, at least in your mind, it is going to work and be useful to someone.

There are some basics that your idea or concept needs to cover before you proceed to product design services, namely:

- What is your idea?

- What real-world problem is it solving?

- How will it be used by people?

- How does it improve on what’s already out there?

- Is it more cost-effective, easier to manufacture, or better functioning?

- Where does it fit into the current market?

- Is it actually possible to produce it?

These are the absolute basics; you need to understand the form, function, and fit of what you want to create. It is going to need to be a product that is viable on the current market, so that people will actually want to buy it. You need to be able to make a profit with the product, and to be able to achieve either of these your idea must be useful to people.

Get It Designed

Once you’ve got your idea, it’s going to need to be designed. This is the point in the process that you’re going to need to commit your idea to paper, or at least pixels, so you can start to get a feel for what it is you want to manufacture.

During the design process, you can begin to refine what you are creating, how it’s going to work, and what it’s going to look like in the real world. Having a 3D model rendered by a designer will bring it to life somewhat and it’s a good early stage at which to spot any issues.

It’s possible to do some stress testing and make sure the basic functions that you’re aiming for are going to be possible. The best CAD systems can check basic load bearing of materials, for example.

Be Specific

When designing the product, it’s the right time to specify how it’s going to work in the market. You should understand and record what the user or product requirement specifications are. This is going to give you a solid outline of what you’re trying to achieve as you work through the design process and get the product made.

The key things that you need to think about are what the item is expected to do and what problem it is solving. Get this written down and shared with your team at the very beginning so everyone knows where they’re working towards. These specifications should form the basis that is going to lead the rest of the process and keep things on track.

2. Product Specification

Once you have the user or product requirement specifications pinned down, it’s time to get into the details. This stage is going to get the nitty-gritty hammered out and help you understand in a lot more detail what you actually need to do to get the product to the factory.

During this process, you need to be looking at the different elements that feed into your design, paying consideration to:

- The functional specifications of what your product is actually going to be able to do. You need to understand the outcomes you want to achieve in detail and consider any additional features. Think about how it’s going to be powered and how the user is going to interact with it – does it need Bluetooth, will you need to have an app designed?

- The design specifications will go into detail about how it’s going to look and be used. Does it need to be mobile and hand-held or a desktop item? You need to think about the size and weight requirements, as well as the colors you want to use and how it is going to feel to the user.

- Regulatory requirements need to be thought about, whether it’s a product that is being aimed at children which carry more stringent requirements, or is it going to hold data and security laws need to be understood. You’ll need to know the location of where your product will be sold so you can specify languages on the packaging and be aware of testing requirements.

- Environmental factors must also be taken into account by thinking about where and when your item is going to be used. Is it going to be used at temperature extremes, whether that’s the countries it’ll be sold in or the workplace it will be deployed in? Do you need to think about waterproofing? Are there power limitations to consider, for example, if it is going to be used in countries with unreliable electricity grids?

- Budgetary constraints also need to be kept in mind; bells and whistles and every-tech-ever-enabled all sound great, but will it make things too costly to appeal to the market? You are also going to have a limited amount to invest in production so you need to think about the number of units you will need to turn out to make enough for your subsequent production runs and eventually turn a profit.

By working through these points in meticulous detail, everyone within the design and manufacturing process will all be working from the same place and moving towards the same goal. Objective, thought through, and qualified standards will ensure there are no queries further down the line and no piece of work will be surplus to requirements.

3. Proof of Concept

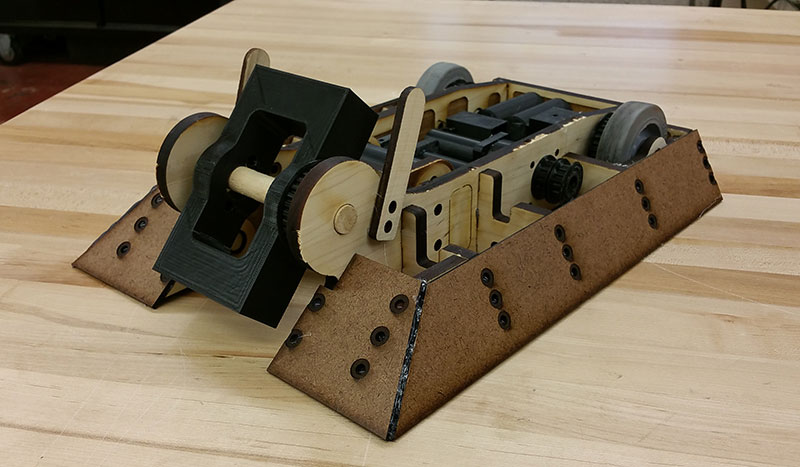

Once you’ve really got to grips with what your product is going to need to do, it’s time to see if it’s actually going to work when it gets made and used. To see if your concept is viable, you need to commission a prototype to be produced.

Traditionally, this would be done using off-the-shelf components so you could check the movements that you want to achieve work, for example. With the advent of 3D printing, it may be possible to have things made that look a lot more like what the end product will be so that you can check the functionality of your design. Either way, the way the product looks isn’t important at this stage, proof of concept is all about function.

By creating an object that a manufacturing service can test and manipulate, you can see if all of your stated aims are going to be possible. If there have been options about how you might achieve a certain function, these can be tested at the first prototype stage and you can choose the final functionality.

This stage will also allow you to engineer out any unforeseen flaws. Problems should be simple to spot when things have been put together and tested and you can play around with your prototype until you achieve the desired outcome.

Although your prototype design might not look like what your product will be, it should work in the right way after completing proof of concept. Design and function issues can be ironed out, and you’ll know that it is going to be possible to achieve the outcome you’re looking for.

4. Detailed Product Design

Once you’ve poured over your initial prototype to get the overall picture just right, it’s time to really bore into the details. Your prototype design service is going to look a lot more like the final product and the functions are going to be more fine-tuned.

This second prototype is going to:

- Present a complete user experience, allowing you to assess how easy it’s going to be to use, how it’s going to feel for the users, the form it’s going to take.

- Get much closer to the goals and specifications that you laid out in Stage 2 – it’s a good time to do a wholesale reassessment of these specs against this new prototype.

- Allow you to assess all of the components of the item; you might see opportunities to improve or integrate certain elements of the design

- Give you something that can be tested, whether you give it some staff that haven’t been involved in the design process, or even choose to give to external people to have a go. This is your chance to get initial feedback on what you’ve come up with.

By the end of this stage, you’ll have something that’s pretty close to what you’re going to be sending to the factory and getting on the shelves. All of your product or user requirements should be met with this prototype, and if you’ve decided to jettison any, there should be clear reasons to have made changes based on the product in hand.

5. Verify and Validate

In the previous stage, you might have entrusted your new invention to others for the first time to have a look over it and see what they think. When you move on to verification and validation, you start to test your product in earnest. Be ready to take feedback and possibly have to return to Stage 4 if major flaws come up.

Verification

First things first, does it do what you want it to do? Go through your initial specifications in fine detail to check you’ve hit your design targets. You need to think not only if it works, but if it works well and is it really doing things better than competitor products.

When you put it in the hands of new testers, can they make it work? You and your team know exactly what every knob and button does, but is it as intuitive as it needs to be for your target audience? Do your potential users think it fills the gap in the market that you’re aiming for? Plenty of questions to consider at this point, and there’s still a chance to make revisions if necessary.

Validation

As well as knowing it’s going to work as you’ve intended for the people you’re making it for, you need to make sure your item is safe. Any health and safety regulations that can be checked at this point should be looked at, bearing in mind that some product testing can only be done on something that has rolled off the production line.

Any material stresses can be tested now too. You can test durability of fabrics or plastics and see if temperature fluctuations aren’t going to affect your product. Be sure to really understand where your product might go. Think about how many cell phones and power banks have caused problems on planes, or the iPhone that bent when you put it in your pocket. Make sure to do some real-world validation to avoid major disasters in the hands of your users.

Bring in Marketing

Your marketing team should ideally be brought in at this stage so they can make sure that what looks like the final product is something that they can work with. Is it meeting a need within the target market and does it meet user expectations?

Since production is coming up, you need to know that there is indeed a demand in the market. Users are going to need to buy it with the mark-up you want to sell it after your costs.

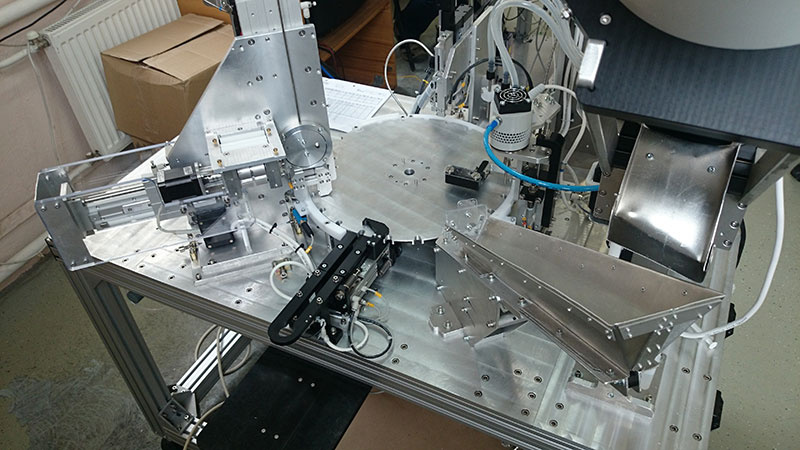

6. Designing the Manufacturing Process

Your product is ready to roll, but from where? There are plenty of factories and facilities out there that provide manufacturing services, with myriad countries you can send production too, all with their plusses and drawbacks.

The main things you should be looking for in a factory is one that is:

- Well-maintained

- Properly designed

- Flexible to your needs

- Has high standards

Along with the overall feel of the place, you need to assess whether your manufacturer is:

- Experienced in your market or industry

- Tooled up for your needs

- Able to meet production volumes

- Set up for necessary quality control

- Able to source and receive raw materials

- Equipped for a reasonable turnaround

- Ready for product testing and calibration

- Set up for sufficient, safe inventory storage

- Capable of handling your packing and shipping needs

- Going to deal with spares, repairs, and accessories

There’s a lot of things to consider in the process. Because you’re trusting your product to an external organization, you need to be crystal clear in what you’re going to get. Share with your production facility exactly what you’re expecting from them and what they can expect from your company in return.

7. Manufacturing

It’s now time to press the big green button and get the production line rolling. Or click on the screen to start the program that’ll get the robots in the factory moving. However the facility is set up, once your chosen supplier is good to go, your product can start being made.

Good planning up to this point should mitigate any issues that could arise. Giving a clear design and well-specified manufacturing plan to the factory you’re using should make it easy for them to create exactly what you want from them.

Going completely hands-off at this point isn’t a great idea, even if it feels like your job is done. There are things that you should still monitor to keep a tight rein on your product. Make sure that you’re monitoring:

- The supply and quality of raw materials

- General supplier management

- Overall assembly process

- Quality assurance and outside testing

- Packaging and shipping

It’s also important that you check the workstations that have been assigned to your product and make sure that the technicians have been well-trained too.

By staying involved in this part of the production process, you can be sure you have confidence in the end product as well as the processes that got you there. When your manufacturing partner knows that you care about how they do things, they will work to match your standards and meet your expectations.

8. Product Sustainability

Getting your product made may feel like the end of your journey. You’ve had the idea, refined it, dug into the details, and decided what it needs to do, how it was going to feel, what it was going to look like.

Prototypes have been made, tested, checked, remade, repurposed, and you’ve produced something that works how you wanted it to. After all of the testing and creating, a factory was chosen out of the hundreds of options available. Working with them, a production process has been created and finally, in your hands is the thing you wanted to make.

It’s not over at this juncture; far from it. If you want your product to be a continuing success there are still things you need to look after.

Fault Reporting

As much as it would be lovely for everything to work perfectly, there are going to be things that go wrong. There needs to be a process in place for your consumers to report faults, as well as recording and monitoring systems to collect the information and analyze it in case of inherent production or design issues.

Servicing and Repairs

Having your customers be able to get their item repaired is important, and you need to decide whose responsibility is this. Will the production facility take on repairs or do you need to contract service centers in the countries you’re retailing in? Can you do services and repairs in house?

Spares and Extras

Where are you going to hold your inventory of spare parts? It’s possible that your manufacturer has the capacity to keep spares and deal with the logistics of shipping them too. This could then introduce the need for communication channels or possibly quality control of their contact with your customers.

Being able to ship consumables that are part of your product is an important thing to look at. If your production facility is outside of your selling territory, make sure you’re aware of any potential delays in shipping such as customs and taxes – you might want to have things shipped to you direct so you can deal with postage for example.

Summing Up

It can be tricky to trust another company with making a product that you’ve designed. There are plenty of factories that specialize in this field and are well equipped to work with you, both from the perspective of hardware prototype tooling design, to being able to deal with the machinations of business.

A well-designed and detailed process that creates specifications is going to go a long way in making your journey easier. That’s shouldn’t be the end of your involvement in the process, even if your manufacturer agrees to take on all of the post-shipping aftercare.

Quality control is important, especially since it’s your company’s branding that is on the packaging. Monitoring the production process and being aware of pinch points such as the sourcing of raw materials and the training and well-being of the people working on your product can avert PR nightmares further down the line.

A great design, a careful prototyping process, and care and diligence during the selection of a producer are the key elements that go into a smooth outsourcing process.

Cad Crowd Has Freelance Product Design Professionals

Cad Crowd can help you connect with a product designer who can help you make your product idea a reality. From skilled and experienced CAD design freelancers to prototype developers, Cad Crowd has a vast database of nearly 25 thousand pre-vetted designers who can take care of any stage of your product design process.

If you are ready to get started, see how it works first.