Today’s post focuses on tips for companies and firms hiring freelancers to design electronics enclosures. Enclosure design and development are very crucial in the industrial equipment and electronics world. This is because electronic components have to work efficiently with protection from external factors. 3D design technologies have changed the approach engineers use to electronics enclosure design to get more efficient, cost-effective, and robust enclosures for industrial applications. The next section delves into eight essentials of designing electronic enclosures suitable for modern industrial engineering requirements.

1. Environmental conditions

It is important for electronic enclosures to withstand external conditions, which are mainly temperature, humidity, dust, mud, and corrosive substances. Identifying the environmental conditions in which your enclosure will operate is as important as designing your enclosure. Although they are mainly used to protect the electronics inside, given that they are the primary layer of protection, they should still be durable enough for any environmental condition.

Tip: Identify the environmental conditions you want your enclosure to operate. Is it for Indoor use? For outdoor use? Will you be exposing it to extreme temperatures? Do you live in a moist country?

In harsh conditions, corrosion-resistant, waterproof gaskets and heat management materials may be more suitable for your enclosure. In order to accurately identify which material is suitable for your enclosure, the use of 3D design services can simulate such environments to check the enclosure’s performance and help you decide which is better.

RELATED: 3D Models of Electronic Enclosures by Freelance Designers on Cad Crowd

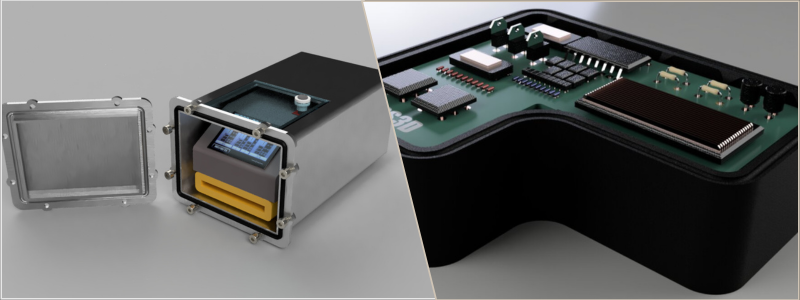

2. Material selection

Metals such as aluminum and steel and plastics such as ABS, polycarbonate, and fiberglass are more commonly used for enclosure design. When the freelance mechanical engineer the appropriate material for your enclosure design is one of the important factors that affect its performance, durability, and cost. As each material has its own advantages, the suitability will still depend on the weight, cost, and environmental conditions you want to subject it.

Tip: For better visualization, apply 3D design software to compare different materials and their effects on the prior design.

For example, if you want a lightweight enclosure that will be used in rugged conditions, aluminum, and a few polymers can be used. For rugged environments, metal enclosures reinforced with plastics could be more suitable. The selected material should be compatible with electrical, electrical, thermal, and mechanical needs.

RELATED: Top 10 Thermal Management Designers for Hire in January 2025

3. Thermal management design

High-power system electronics generate heat and must be released to the surroundings to avoid overheating. Proper thermal management is needed to avoid component failure, reduced performance, and fire hazards. This involves integrating heat sinks, ventilation, and cooling fans into the design of the enclosure.

Tip: Electrical engineering companies use modeling software for the simulation of the thermal behavior within the enclosure. Engineers can use these simulations to optimize the design by finding hotspots. Adding heat sinks or fins to enhance the surface area exposed to natural heat dissipation might be provided. High-performance electronics could also be coupled with external cooling systems such as fans or liquid cooling systems.

4. Proper cable management

Effective and proper cable management must be taken into consideration to maintain an organized system and, most importantly, avoid damage. Poorly secured cables inside the enclosure can cause an electrical short circuit, overheating, and plenty of safety hazards.

Tip: Plan for cable management from the outset of the design process. Utilize 3D design to envision cable routing in the enclosure such that there are enough spaces allocated for connectors, strain reliefs, and cable ties. Proper fixing of cables in the enclosure not only saves one from safety-related hazards but will also make later maintenance and upgradation easier. In case removable parts like doors and panels are designed into the enclosures, route cables in a way that interferes with fewer parts.

5. Design for accessibility and maintenance

Electronics enclosures, especially those in industrial equipment, are often subjected to periodic maintenance tasks like component replacement or updates. When a new product design company has a design that makes it difficult to access internal components may increase downtime, reduce productivity, and increase maintenance costs.

Tip: Include easy-access features in your design, like hinged doors, removable panels, or slide-out trays. You can then use 3D design to really see how all these things are going to interact. As you design to be easy to access, you guarantee that maintenance is fast and, again, doesn’t require special tools or excessive teardown. You could even include labels or other markers inside the enclosure to label important components inside, making those maintenance procedures as simple as they can be.

6. Standard dimension and mounting requirement

While designing the electronic enclosures, always follow industry standards and mounting features. Without standards, an inappropriate dimension might end up as an un-integrateable enclosure or possibly cause integration conflict with systems that are presently deployed. Adequately sized enclosures would reduce tremendous costs in terms of manufacturing and assembly.

Take an existing standard for enclosure size, DIN rail mount system, and pre-existing standardized sizes such as rack mounting. In such designs, appropriate mounting provisions shall be available on enclosures to install the inner contents, which will include PCB standoff, mounting bracket, or simply DIN rail clip. Determining the dimension check of inner components and corresponding mounting holes with the help of 3D CAD confirms compatibility with common equipment and accelerates design cycle time.

7. Add EMI shielding

EMI is one of the most common issues in electronics design, especially in an industrial environment where strong electromagnetic fields may be generated by machinery and power equipment. These fields can cause interference in the operation of sensitive electronic components, resulting in malfunction or degraded performance. Hence, shielding should be incorporated into the enclosure design.

Tip: Use 3D design software to evaluate the ability of the enclosure to block or absorb electromagnetic radiation. Add shielding materials, such as conductive metals or special EMI gaskets, to protect sensitive internal electronics. Consider grounding and bonding the enclosure to prevent the accumulation of static electricity. It can also direct unwanted electromagnetic energy away from sensitive components. This will further guarantee the proper shielding for the device, ensuring it adheres to acceptable standards, such as meeting FCC and CE certifications.

RELATED: What Certifications are Used for New Electronic Hardware Products & PCB Design Services?

8. Safety and compliance

Safety standards compliance in electronics enclosure design is an inherent aspect. Due to the locality and application purpose of the electronic equipment, there will be several different standards that may need to be adhered to in the design, such as UL (Underwriters Laboratories), CE (Conformité Européenne), or IEC (International Electrotechnical Commission) standards. These requirements guarantee that protection from electrical danger, fire threats, and other types of mechanical damage is present in the enclosure.

Tip: Be familiar with the applicable safety and certification standards for your region or industry. The 3D design software can be used to check if your design meets the standards through simulation of testing conditions such as impact resistance, flammability, and electrical safety. Make sure that the enclosure offers electrical insulation, is made of fire-retardant materials when required, and is equipped with circuit breakers or pressure relief valves.

Importance of good electronics enclosure design

The design of an electronic enclosure is of extreme importance because it goes a long way in determining the performance, lifespan, and safety of the devices. A well-designed electronics enclosure protects internal components besides improving functionality and user experience. Here are some key reasons why a good electronics enclosure design is essential.

1. Protection from environmental factors

Electronics are exposed to various environmental hazards such as dust, moisture, and temperature changes. An excellent enclosure protects the internal circuits and components from these elements so that they keep working. This is especially critical for devices used outdoors or in an industrial environment where exposure to harsh conditions is commonplace.

2. Thermal management

Heat dissipation is an essential consideration in electronic design. A good enclosure prevents the overheating of internal parts through proper ventilation; otherwise, overheating might lead to failure or malfunction of the device. An effective design has ventilation holes or heat sinks for the handling of thermal buildup, which prolongs the service life of a device.

3. Mechanical protection

Enclosures also provide mechanical protection of the internal parts sensitive to impacts or vibrations. For instance, in automotive or aerospace industries, where devices are constantly moving, having a good enclosure design will ensure that they are not damaged while operating or transporting them.

4. Aesthetics and user interaction

Except for the technical issues, an enclosure design gives the general aesthetics of a product. For consumer electronics, smooth ergonomic design freelancers is aesthetically more pleasing to the eye and to the customer. The placement of buttons, screens, and connectors has further helped to improve usability. A good electronics enclosure design is not just about the appearance but ensures that the protection of the device will be guaranteed and allows proper performance. The effective enclosure design balances form, function, and safety for the creation of durable, high-performance electronics.

Conclusion

In order to have a practical design of an electronics enclosure, a holistic approach is required in that it protects and supports the inner components yet remains functional and industry standard-compliant. Now, with the 3D design tools, engineers can conceptualize, prototype, and even finalize their designs before producing them for mass consumption so as to guarantee efficiency, safety, and economy for the final product.

How Cad Crowd can help

All these eight key tips will help the engineers in making high-quality enclosures for modern industrial applications with an understanding of environmental conditions, selection of material, thermal management planning, and cable management for easy access, standard dimensioning, EMI protection issues, and safety and compliance. Cad Crowd is here to connect you with top engineering services from across the globe. Request a quote today.