What’s your first reaction when a vital part suddenly breaks or you realize you’re already running low on your inventory? For most people, sheer panic washes over them when they face such problems. Things can quickly go out of hand once you call the manufacturer and learn about the high cost, long lead time, the part is already obsolete, or worse, the manufacturer itself has already gone out of business. What should you do in this case, then? This is when 3D printing services for replacement parts can come to your rescue. This article discusses how you can leverage such services to enhance the overall operations of your company.

Table of contents

Table of contents

How to create replacement parts through 3D printing

3D printing for replacement and spare parts is becoming a more and more powerful and effective solution to address concerns about the availability of spare parts and disruptions in the supply chain. It is now possible to use 3D printers to create and develop almost anything, from stopgap replacement parts to DIY spare parts customers. 3D printers are also ideal for enduring replacement parts, which can replace parts created with traditional tools to empower manufacturing design companies to switch from massive inventories to on-demand production of spare parts. Here are the steps that 3D printing services use to develop replacement parts:

RELATED: What is 3D printing? A beginner’s guide

1. Determine if it’s feasible or not

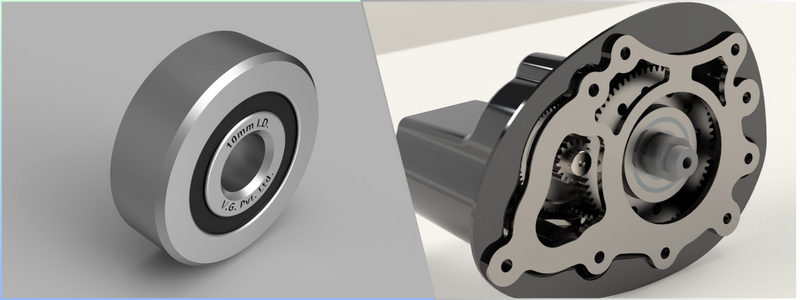

Replacement parts function in a system. To guarantee the proper operation and workings of the 3D-printed replacement parts, it’s essential to consider the part’s technical requirements first. These include mechanical stressors, intended use, material, and geometry.

Geometry

3D printing services offer almost infinite freedom in terms of design. It increases the likelihood that you can also 3D print almost anything made using conventional tools. There might also be some advice to adjust the design to optimize for better strength, improved speed, and reduced costs.

Material

It’s also possible for 3D printers to replace some metal parts and most plastic parts. Look for a material that mostly resembles the properties of the specific material used to manufacture the original parts.

RELATED: 6 Ways 3D printing will change the world

Size

The part must also fit into the 3D printer’s build volume, typically about 15 to 30 centimeters in any dimension for benchtop and desktop machines. On the other hand, it’s also possible for product concept design services to design the replacement part as an assembly of several smaller components.

Stresses

It’s essential to consider all the impacts and stresses the replacement will face. Opt for more advanced engineering materials and 3D printing technologies for longer-lasting parts. Even though the 3D-printed replacement parts might not tick all the boxes, most of the time, they can still be used as a stopgap replacement to reduce machine downtime. This is one of those cases of using a spare 3D printed part that offers proper functionality but has limited long-term durability only until a more durable substitute becomes available.

2. Develop the 3D model

After you have confirmed that it’s possible to 3D print the part, it’s time for you to get the replacement part’s 3D models. The digital file must be easily accessible if the replacement part is for your company’s product and the 3D product modeling artist can use CAD software to design it. Some manufacturers can also provide the replacement parts’ original CAD models if you’re using third-party tools.

RELATED: 3D Printed threads and screws: innovative product design options for companies

If no design is available, you can always use CAD software to create the layout on your own or get it from a design service. Parts with a simple design can be made according to manual measurements. However, if the designs are more complex, reverse engineering combined with 3D scanning is a powerful workflow for designing and producing the replicated parts. A 3D scanner is used in reverse engineering to capture the required mesh to develop the 3D models.

3. Proceed with 3D printing

Use print preparation software to get the CAD model ready for 3D printing and send it to the 3D printer. Remember that, at this point, choosing and using suitable materials and technology is critical. 3D printed parts need some form of post-processing, including depowering, washing, sanding, post-curing, or removing support structures. You can then directly use the details or post-process them further for specific applications by coating, painting, smoothing, and more.

RELATED: A Brief history of 3D printing

4. Test and iterate

After the replacement part is made, the next step is to perform tests to confirm that the 3D-printed replacement part functions and works as intended. When deficiencies are highlighted in the trials, 3D printing firms will make it easier to iterate the design to enhance the performance of the replacement parts. The testing’s depth must be dependent on the use case. S topgap replacement parts can work as planned within a limited time.

However, manufacturers who wish to use the 3D printed stand-in parts as an alternative to traditional components must have the newly-made parts undergo the same testing cycles as their predecessors. At the same time, the 3D printing process’s specific characteristics should also be considered, such as the difference in strength according to orientation.

RELATED: 3D Printing with metals: making fully metal parts and products with additive manufacturing

How to choose the suitable material and technology for 3D printing replacement parts

Through the years, 3D printing has been a staple in product development and prototyping design services. This maturing and continuously improving technology is now enjoying widespread use in manufacturing. As far as the process of product development is concerned, manufacturers are starting to leverage 3D printing’s flexibility for the production of internal tools, including fixtures jigs, as well as other aids in manufacturing or even rapid tooling like thermoforming or molds for injection molding.

The latest developments in software, machinery, and materials open opportunities for producing high-precision 3D prints that are fully functional and can substitute for end-use parts, such as long-lasting replacement parts and spare parts. It’s common to use 3D printers to produce plastic parts, although there are also available metal 3D printers but at a significantly higher cost. 3D printers are available in many different forms and types.

RELATED: 3D printing technologies for modeling and prototyping

Selective laser sintering or SLS, stereolithography or SLA, and fused deposition modeling or FDM are the most popular processes for producing plastic parts. Although many traditional processes of manufacturing call for skilled operators, dedicated facilities, and pricey industrial machinery, 3D printing allows in-house production with reduced infrastructure and low overhead. Compact benchtop or desktop 3D printing systems to develop plastic parts are cheaper and need minimal space without any special skills.

If your replacement parts are not time-sensitive, you can consider outsourcing. However, note that this typically comes with similar challenges and difficulties as stocking your inventory of physical spare parts. Timelines for delivery can be several weeks instead of less than 24 hours for most 3D printed, factors which can increase the risks of lost productivity and more extended machine downtime.

RELATED: Selecting materials for 3D printing your new product or prototype

Replacement parts for digital fabrication

CAD digitalization services for the production of replacement parts and management of spare parts inventory offers manufacturers the chance to eliminate several traditional challenges, such as minimum quantities of orders, waste because of obsolete parts, and issues with the supply chain. One of the most cost-effective methods to lower inventory management costs is to set up a digital warehouse.

Combining the system with in-house digital fabrication tools such as 3D printing can support on-demand strategies and allow manufacturers to reduce lead times and costs, mitigate downtime, and enhance resiliency. The spare parts or digital warehouse inventory is utilized for storing the designs of spare parts, managing inventory, optimizing bills of materials, and systematically categorizing components. 3D printers and other digital fabrication tools can be used to produce spare parts to replace parts or stock a physical inventory as necessary.

RELATED: Guide to surface finishing for 3D printed parts

Is it legal to 3D print replacement parts?

Generally, 3D printing of replacement parts is legal, although it still depends on the precise case. Utilizing reverse engineering design professionals is ordinarily legal, with manufacturers opting to 3D print replacement parts with their in-house designs without breaching trade secret law. Manufacturers wishing to 3D print replacement parts for commercial use might become liable under the relevant law. They might be obliged to supply goods or designs that meet some quality and safety requirements as indicated in their contracts.

How Cad Crowd can help

3D printing replacement parts is one of the fastest, most efficient, and most affordable ways to eliminate lost productivity and extended downtime. 3D printing your replacement parts can also save you time, money, and headaches in the future.

Cad Crowd is a platform where you can find trusted experts who can help you 3D print your replacement parts so you can reach your goals and meet your objectives in no time. With the help of 3D printing professionals, it will be easier for your company to enhance its everyday operations, boosting your bottom line in the long run.