In manufacturing, a company does not simply create and release products to the market and cease production once they become outdated. Careful planning is required even before the design process takes place. The company needs to have a clear picture of how every step in the products life will be carried out, beginning with product concepts to the eventual product retirement or disposal at a later date.

This kind of planning takes a systematic approach performed by people and computers working together. The goal is to reduce production cost and time while at the same time optimizing profits and marketing tactics. The plan must cover all aspects of product development from design and manufacturing methods to marketing tactics and profitability. This systematic approach is referred to as Product Lifecycle Management (PLM).

In the old days, PLM was all about particular business strategies that companies build and perform. Thanks to technological advancements, PLM is also associated with specific software. The term can now refer to both, and its actual meaning depends largely on context.

Things get even more confusing because those two different definitions can actually intertwine in real-life practices. For example, a clothing company may implement PLM as a business strategy to make sure its products stay competitive in the market and use specific PLM software to simplify data gathering and processing.

A Brief History of PLM

Product lifecycle management was used for the first time by the automobile industry in the United States. Interestingly, the company that started it was not one of the Big Three – Ford, General Motors, or Chrysler – but a smaller one known as AMC (American Motors Corporation).

An essential part of AMC’s PLM was the decision to use components supplied by outside vendors rather than manufacturing everything in-house. This allowed AMC to be sufficiently different from competitors without spending a significant amount of money all while delivering quality cars.

AMC was comparably small in relation to those three giants. It didn’t have a massive budget to build its own robust research and development department, but they were innovative. In order to keep on pushing new products onto the market, AMC turned to computer-aided design (CAD) practices with which the company was able to develop new variants of its main products quickly.

With CAD drafting services utilization, the engineers became much more productive. This strategy allowed AMC to simultaneously develop new cars while keeping the current model in production. Another big part of the strategy was to develop a proper communication system that stored all design documents and drawings in a central database. Engineers had access to that data and made changes considerably quicker than competitors.

While AMC turned out to be a formidable player in the industry, it only managed to gain intermittent success. After a rather unsuccessful partnership with Renault, AMC was eventually purchased by Chrysler in 1987. Not only did Chrysler inherit a proven-effective business approach from AMC, but it further expanded the system to connect everyone in the product development cycle.

Stages of PLM

In general, the main purpose of PLM is to bring about highly efficient product design and development services. Initially practiced in the automotive industry, other industries soon followed suit. Today, you will find it hard to come across companies without their own product lifecycle management strategies.

In times when consumers appreciate rapid innovation in the form of fresh designs, companies cannot afford to rely on brand-loyalty alone. They race to introduce new products faster than everybody else to stay ahead in the marketplace.

The entire process of crafting product ideas and releasing them is getting more and more complex. You cannot just copy other companies, offer the same-old features, or go completely devoid of innovations and expect to retain customers. All industries are becoming more innovative. For example:

- Smartphone makers are trying to introduce more user-friendly interfaces

- Clothing companies are always in search of new materials

- Consumer electronics crave better energy-efficient applications

- The automobile industry’s pursuit of eco-friendly operations

- Food and beverage manufacturers are struggling to fulfill the demand for healthier ingredients

Thanks to PLM, companies are able to collect various ideas, materialize only the best, and capitalize on innovations. The methods used to achieve goals and improve efficiency can be different, such as investing in new equipment, implementing more effective brainstorming processes, enforcing better company policies, and more.

PLM, as both business strategy and software, aims to simplify the product development process. Not only do the companies intensify workflow, but they also want to keep the cost manageable. Since it involves a lot of separate processes, PLM can be broken down into multiple stages.

Stage 1: Concept

This is the stage where a product’s lifecycle begins. Although the product only exists as an idea or concept, it requires a lot of research regarding designs and features as well as manufacturing viability. Simply because an idea of a product is great on paper doesn’t mean that the company has the resources to produce it. There can be various challenges, such as acquiring materials, investing in new machinery, hiring experts to oversee the designing and manufacturing processes, price points, production time frame, and so on.

All those problems typically arise when products are put within the context of real-world market conditions. For example, a company may be able to fund an expensive research and development department to build new equipment to manufacture a product with a great set of functionalities. However, the product may not gain financial success in the market because higher production costs also mean a higher price point.

PLM should be able to find solutions to the problems, either by purchasing materials in bulk or marketing the new product in a way that befits the price point. The company can also prevent losses by planning multiple versions of the product for future releases to offset the initial investment for equipment and labor. Assuming production is not possible, another method is to preserve the idea as a patented intellectual property.

Regardless of the solution, this “concept” stage is essentially a collection of ideas. PLM can come up with plenty of ideas and choose only one that is technically and financially viable depending on the company’s manufacturing capacity, market situations, and profitability. This is the part of the product development process where almost everything is outlined with great length of details about research methods, analysis of options, technical viability, design approach, and possibly target consumers.

Stage 2: Design

As soon as the initial planning has been documented and approved, the design can be further refined and materialized. It does not have to be a fully-functioning product from the get-go – prototyping comes first. Up until the second stage, PLM is much like any design process in which a product starts as an idea and then transforms into a working prototype. The notable difference is that PLM explicitly demands that all people involved in the process have easy access to a centralized databank.

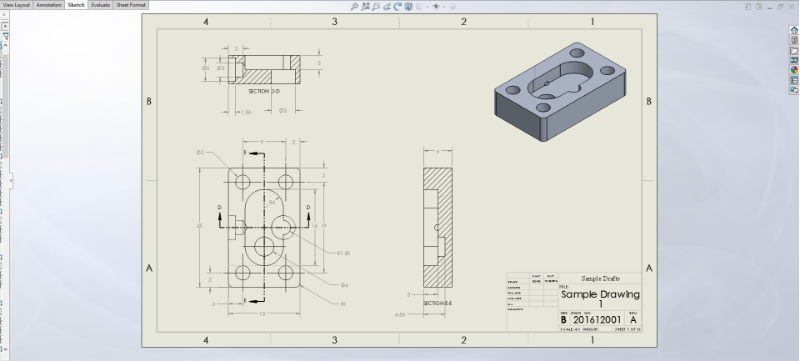

Just like when it was first implemented in the automobile industry by AMC, designers and mechanical engineers work on the same set of data including sketches and technical specifications. Because all data are saved in the same centralized system, everyone can access them and read the most updated version. This is where the definition between PLM as business strategy and software intertwines. The software makes use of proper data integration, while the people use the data to collaborate and execute every step of the process in accordance with the approved action plan during the previous concept stage.

Equipped with the same set of product parameters, designers can modify and test the changes made to the design more easily with CAD software. Product testing can be performed via virtual simulation, or real-world trial runs to figure out potential defects. Thanks to centralized data storage, designers and engineers can address the issues collectively at a much quicker pace. The use of CAD is indispensable in PLM.

Phase 3: Production

Following the design stage, a product enters the mass-manufacturing process. At this stage, the PLM system must analyze a wide range of variables that affect production cost. For example, materials (amount and origin), quotas per batch, completion time to meet the quota, labor requirements, potential manufacturing defects, equipment, energy or fuel for machinery, and more.

PLM is responsible for calculating every detail related to the production process. Otherwise, the company may face unexpected cost, release delays, and poor calculation of profitability. It is also in this stage that PLM can figure out the most cost-efficient manufacturing method without sacrificing quality.

Depending on the type of product and material, manufacturing methods may include CNC machining, molding, casting, manual assembly, or a combination of those. PLM can also decide to outsource a portion (or all) of the manufacturing process to other companies to reduce production cost. Such an approach can bring a promising ROI as long as the company practices proper outsourcing to make sure there is no degradation in the expected product quality.

One reason to outsource production is to save money – but if the result is below your standard of quality, then it is a bad decision on PLM’s part. In that case, you may have to deal with fixing defects or improving overall build quality, and you will end up spending a lot more money to repair the damage.

Similar to the previous two stages, documentation of the production process takes place even if the manufacturing work is done somewhere else by another company. There are plenty of data to be analyzed including but not limited to engineering information, parts list, workflow, and communication.

Stage 4: Distribution

The final stage in PLM is distribution, which includes warehousing the manufactured products, sending them to sales channels, service and maintenance, and finally, proper disposal methods. PLM plays its part in the data collection process where it analyzes product performance in the market.

No matter how good the product is, an entirely satisfactory market performance almost never happens. By tracking the information about complaints, purchase of replacement parts, and common issues reported by customer service, PLM should gather enough information to improve the product in the future.

All companies should understand that there is an end-of-life phase of every product. It simply has to make way for new innovations and keep up with changing market trends. Even big companies must retire their best product at some point and replace it with an updated alternative.

Take the iPhone, for example. The older models still work, but Apple decided to discontinue production and replace them with newer versions to keep up with competitors and fulfill market demands.

End-of-life is not merely about discontinuing production – it must be followed by the development of a new and improved design. This applies to consumer product design. When the same product is used for businesses or commercial application, the manufacturer may need to address proper disposal of the product along with the transition to a different product with as minimum a disturbance as possible.

Product Information Management

In practice, PLM is also about information-sharing. As previously discussed, product lifecycle contains several different elements, and every stage is related. Centralized data ensures that the information gathering process follows the same standard so that everybody can work together with easier coordination.

To facilitate data collection and sharing, companies can use PLM software with all the features necessary for synchronization, back-up, security and complex calculation of production cost. Basically, it automates various tasks involved in product creation.

Every stage is carried out in order; concept, design, production, and distribution. The data gathered in each stage is crucial to the next in line. For example, in the design process, there can be two separate teams to handle design and production. Having multiple teams working on the same product allows for quicker progression, but only when those teams work based on the same set of data.

The design team should determine product features, form factor, functionalities, and materials based on the company’s prototyping or manufacturing capability. Centralized data helps avoid mistakes and miscommunications during the production process. As long as the design team rules out anything beyond what the company can technically accomplish, product creation should run without issues.

PLM software can manage every single bit of information for everybody to access and use. Centralization prevents data loss, which can put the process into a long halt. Since data sharing is the most crucial part to carry out PLM strategies, it only makes sense that cloud-storage plays a major role in current and future landscapes of the industry.

PLM in Use by Companies of All Sizes

For the better part of the previous decades, PLM was mostly associated only with big companies mainly due to the cost of the technologies required. The good thing is that those technologies, both hardware and software, are getting more affordable even for startups. Although smaller companies may not have the financial resources to purchase their own hardware and software, they can always turn to cloud computing.

SaaS (software as a service) platforms allow consumers to take advantage of the system without the burdens of maintenance and updates. Rather than spending millions on an initial investment into new pieces of equipment to support PLM, small companies have the option to use a subscription-based service from a reputable provider. This does increase operational cost, but the results gained from a streamlined product creation process should offset the expense.

The future of product creation relies heavily on PLM. The system accelerates product lifecycle, which means companies will be able to release more products more frequently than ever before in a more manageable way. As the market becomes more competitive, prices will also go down for consumers’ benefits. From manufacturers’ perspectives, they don’t have to worry either because PLM allows them to run the business more efficiently and therefore keep up with competitors.

PLM a promising prospect indeed, but you need to remember that this software mostly functions as data sharing and analysis tool at best. Every company still needs professionals to craft the proper action plans in the product creation process. As great as PLM software can be, it cannot operate to its full potential without heavy involvement from humans. The system makes the job easier; it is never intended to come up with ideas because it is a job best left to creative people.