The fact that you’re reading this article means that you’re interested in millwork or involved in it in one form or another. You may be a cabinet manufacturer who needs someone to draw your upcoming project plans. Whatever your background, it’s essential to know the history and evolution of millwork shop drawings used for design and drafting services.

Millwork drafting and drawing services are critical in every architectural project to help achieve efficiency, accuracy, and overall success. The thorough millwork shop drawings indicate exact specifications and measurements for millwork production to guarantee personalized and specialized solutions that can meet the project’s requirements. Millwork shop drawings also allow effective collaboration and communication between millwork fabricators and architects to lower the risk of rework and errors.

Reducing the need for on-site alterations and speeding up the entire construction process can also aid in time and cost efficiency. Shop drawing firms like Cad Crowd know the actual value of these millwork shop drawings is essential for any architect who wants to produce exceptional results that meet or exceed the client’s expectations.

Millwork history at a glance

Humanity has been using wood for centuries, and wood carvers and carpenters are among the ancient professions dating back 6,000 years or so. However, commercially produced and mechanized millwork is still needed. Millwork, as its name suggests, is woodwork produced in the mill. In the late 1800s, also dubbed millworking’s Golden Age, almost everything found inside houses, buildings, and interiors (including furniture) was made from wood.

Along with the advancement of technology, other furniture and interior architecture materials have developed, including synthetic veneers that look like wood. Combinations of synthetic elements and wood are also regarded as part of the millworking process. Different types of softwood and hardwood are often used. Specifically, eight types of softwood and 13 kinds of hardwood were used during the golden age of millwork. Most of these woods continue to be used in the 21st century in one way or another.

The beginning of change

Most buildings in the 21st century, particularly skyscrapers, are made of steel while incorporating other materials like cement, stucco, and brick. This occurred because fire and building codes were introduced during the latter part of the 19th and early 20th centuries. Wood is less commonly used as a building material.

Millwork in the modern-day

Even to this very day, millwork designs from professional architectural detailing professionals continue to enjoy immense popularity. You can find something that could be a millworking product almost anywhere, and everywhere you go. The door you use to enter the office and the stairs leading to your home may result in millwork. Millwork goes beyond practicality purposes. A carefully made millwork piece and its aesthetics can be a true wonder everyone can enjoy.

RELATED: Millwork Drafting and Design Drawings: Rates and Costs for Companies and Firms

Difference between casework and millwork

A lot of people think that casework and millwork are synonymous. While both are associated with carpentry and architecture, these two entities are entirely different. Custom-made is probably the most direct definition of millwork. This is used for both decorative and practical purposes. You can see more examples of these millwork designs inside residential houses (i.e., stairways, crown molding, or a simple drying rack).

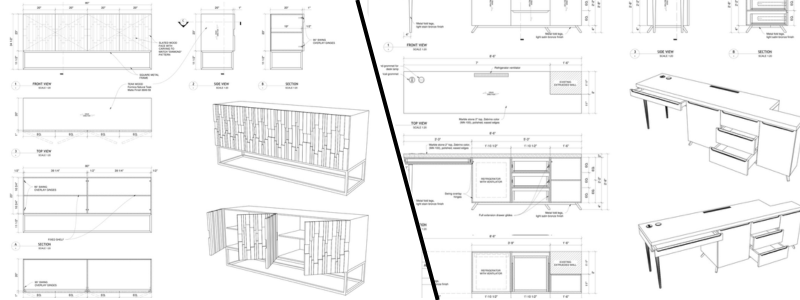

However, casework might be more cost-effective than millwork. It is more time-consuming to complete a project with custom work. However, the final product is more than just any original and unique piece; it is high-quality. Alternatively, casework is also custom, but the difference is that the architectural drawing designer uses standard dimensions and measurements. The easiest way to describe casework is to imagine the mass-produced cabinet you can see in almost all stores, banks, or hospitals you walk into. Anyone needing excellent millwork shop drawings for a casework project must send the drawing to the cabinet maker who will make the built-to-order product.

Millwork and its undeniable beauty

Designing millwork requires a lot of expertise and knowledge. From a chair rail with a simple design to a staircase with intricate weavings, any millworker, architect, or drafter can see and appreciate the hard work and effort that went into the drawing of the millwork piece. New Mexico’s Loretto Chapel Staircase, crafted between 1877 and 1881, is one of the most notable pieces that continue to be an enigmatic mystery in the world of millwork. The millwork piece is mysterious because the carpenter behind the staircase is unknown.

Two other mysteries surround the staircase. For one, the person who built the stairs at 20 feet could do so without a central pole’s support. Secondly, the stairs don’t have a single nail, no matter how much you look. Since no nail was driven into the wood, the stair’s mystery carpenter possibly used glue and wood pages to put the entire piece together.

RELATED: What Casework Shop Drawings Are and Why Architectural Design Services Use Them

Main types of millwork manufacturers

Millwork manufacturers are mainly categorized into custom and commodity or mass-produced millwork manufacturers. Both have their pros and cons. Of course, your final choice will ultimately depend on the specific type of project you will be working on. Mass-produced millwork products have two subcategories: those tested to AWI standards and those not. Those that need to meet the AWI standards are often found in most big box stores, while others are designed for residential applications.

These come with lower price tags since these are produced in bulk, typically using more affordable materials in limited sizes and species. It also means that the overall quality may not be as excellent as expected. The design might also not suit your client’s specifications and tastes. On the other hand, pieces made and tested to the AWI Standards might still have limited sizes. However, these are often available in higher-quality materials to give your client more options while still being in complete control of the costs.

Custom-designed architectural millwork usually has an excellent craft that provides many higher-quality materials. Your clients will be able to specify exactly what they need or want and are often willing to spend more than usual. Now that you know more about millwork shop design drawings, here’s how they can help with millwork design and drafting services.

Safety assurance and compliance

Using millwork shop drawings in architectural design and drafting services is critical to meet code compliance and safety standards. Essential details such as accessibility rules, fire ratings, structural specifications, and other crucial criteria are included in these services. Millwork fabricators can guarantee that all the millwork elements fulfill suitable structural integrity and safety standards. Contractors and architects can lower liability and risk by prioritizing safety and compliance thanks to millwork shop drawings.

Time and cost efficiency

Architectural projects can also become more timely and affordable with the help of millwork shop drawings. These drawings help prevent costly on-site adjustments and modifications by providing thorough measurements and precise specifications. Accurately customizing millwork shop drawings also lowers rework and material waste to help save money. These drawings are essential to achieve time and cost efficiency in an architecture project by cutting down errors, maximizing the use of resources, and taking efficiency to a whole new level.

RELATED: Millwork Drawings Outsourcing by Freelance Contractors on Cad Crowd

Better collaboration and communication

Millwork shop drawings can also significantly improve the communication and collaboration between millwork fabricators and architects involved in architectural projects—the drawings function as both an in-depth and visual illustration of the purpose and requirements of the design. They help minimize disparities and misconceptions by conveying the details more effectively and openly. Millwork shop drawings are also a common element of decision-making and discussion that promotes teamwork. Fabricators and architects may resolve any changes or problems early if they work closely together.

Ensure precision and accuracy

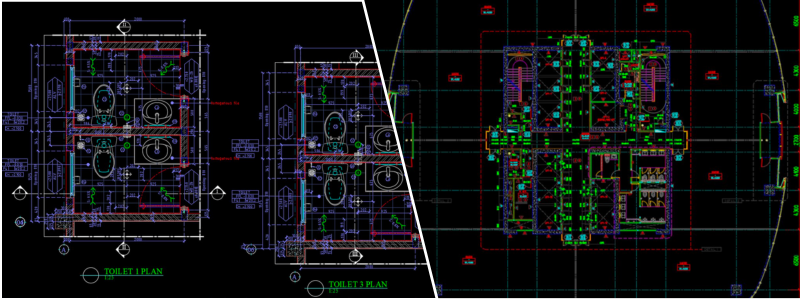

Millwork shop drawings are essential for architectural projects to be precise and accurate. These drawings help millwork fabricators make one-of-a-kind components that follow the project’s specifications by offering thorough measurements and specifications. The drawings also help guarantee fine customization and ensure the exact representation of the finishes, materials, joinery, and measurements. This high level of care lowers the risk of discrepancies and mistakes during installation and fabrication to develop a final product that follows the original design.

How Cad Crowd can help

Architectural projects can get better with the help of millwork shop drawings. Cad Crowd can connect you with experts in the field to ensure that your upcoming project will be much better than you have ever imagined. Contact us today for a free quote.