3D printing and CAD services are changing new product development across industries. From quick prototyping to low-cost manufacturing, businesses adopting these technologies are experiencing faster time-to-market, better design accuracy, and more innovation possibilities.

As a certified professional industry expert, Cad Crowd is well aware of the requirement for good quality 3D printing and CAD services, particularly for businesses whose products are being manufactured. These businesses are brought into contact with the finest talent on the platform that can bring back results and give more than expected.

Whether you have just started a business or are an established company, the collaboration of CAD services and 3D printing can enhance product development efficiency greatly, lower the cost of production, and provide customized solutions with ease.

Here, we will see how 3D printing and CAD services are revolutionizing product development, what the main advantages of their implementation are, and how they will mold the future of manufacturing and innovation.

🚀 Table of contents

The role of CAD in product development

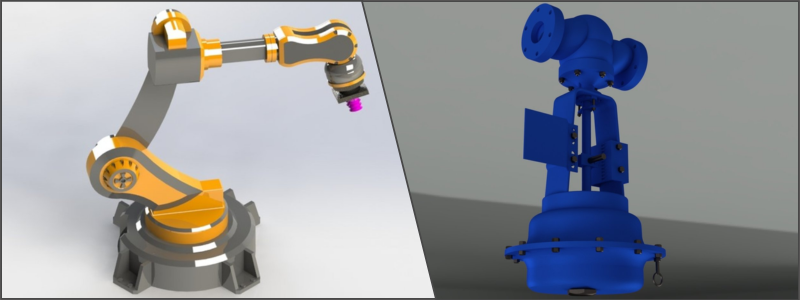

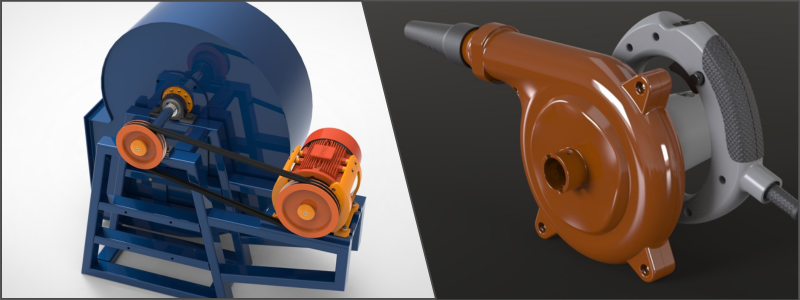

CAD software is no longer a tool but an integral component of the entire design and manufacturing process in the current product development age. CAD is at the forefront of producing new products that are efficient, precise, and viable from idea creation to production finish. Designers and engineers use CAD to envision, design, and finalize their concepts before they are ever real prototypes. Its influence is felt across industries as diverse as automotive and aerospace, consumer electronics, and furniture design.

RELATED: Benefits of AutoCAD for electrical drawings with freelance engineering services & companies

Improved design capabilities

One of the greatest advantages of CAD is that it can produce intricate and detailed designs that would be practically impossible—or at least highly impractical—to do manually. Traditional drafting methods, while helpful, cannot compete with the flexibility and precision provided by CAD software. Designers can easily change dimensions, modify ratios, and make design changes with parametric modeling without having to redo from scratch.

Furthermore, CAD technology has high-end simulation capabilities that enable designers to see the finished product in a virtual environment prior to actual production. This capability eliminates guesswork and enhances creativity through rapid checks on various design parameters. From an ergonomic tweak in a chair to a structural reinforcement in an aircraft part, CAD experts enable every single design change with precise digital models.

Better collaboration

Product development is seldom a solo effort. There are numerous stakeholders, including engineers, industrial designers, marketers, and manufacturers, who need to collaborate to take a product from idea to reality. CAD tools, particularly cloud-based tools, have revolutionized collaboration between teams.

With access to design files in real-time, remote teams are able to see, modify, and improve models without the lag normally seen through email conversations or paper reports. Changes are immediately apparent, cutting down on miscommunication and version control problems. This integration allows for a more streamlined workflow, enabling companies to cut development times and respond faster to design feedback.

RELATED: Essential product design checklist when working with freelance experts & services companies

Design validation and optimization

After a product is already being tested during production, however, it would have already been subjected to durability, performance, and accuracy tests of how it would fare in actual conditions. CAD software can include simulation tools and analysis programs that would enable its users to conduct virtual stress tests, thermal analyses, and movement simulations. These tests enable these companies to detect and correct faulty designs before manufacturing results in heavy financial losses through errors or defects.

This design validation ahead of time conserves material, reduces the cost of production, and leads to a better-quality end product. Whether it’s evaluating the aerodynamics of a new car design or the ability of a bridge component to handle loads, CAD-based analysis markedly enhances design trustworthiness.

Seamless interfacing with 3D printing

3D printing design services have changed the game when it comes to product prototyping, and CAD is its foundation. The CAD models can be easily converted into 3D-printable files, enabling us to obtain rapid prototyping with a precision hitherto unmatched. It enables the designers to convert their digital models into physical prototypes within hours instead of weeks.

By marrying CAD with 3D printing, businesses have the ability to prototype form, fit, and function early on in the design process and fix prior to scale manufacturing. Virtual design coupled with physical prototyping speeds up innovation and shortens the time to market.

CAD has revolutionized product development at its core by offering increased design accuracy, encouraging collaboration, allowing proper verification, and seamlessly integrating with newer manufacturing technologies such as 3D printing. As the world of industries continues to explore newer horizons in innovation, CAD will be at the forefront, charting the path for the future of product conception, making, and realization.

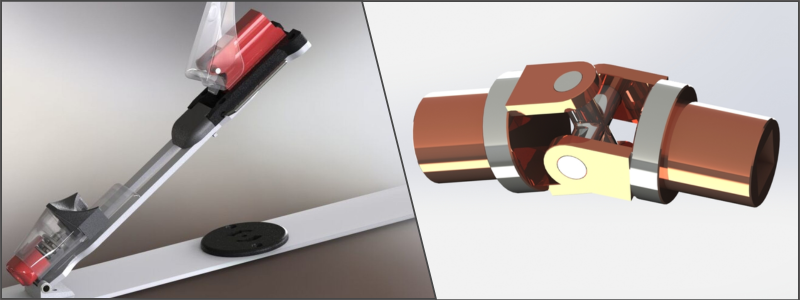

How 3D printing aids product development

3D printing or additive manufacturing has transformed the environment of product development experts. The technology has opened the door for companies to prototype, test, and produce products faster and more flexibly than ever before.

A product that takes weeks or months to develop now can be achieved in days or hours. Aside from speed, 3D printing is also cost-effective, supply chain resilient, and can produce geometries that are difficult or even impossible to produce using conventional manufacturing techniques. Let us explore further how 3D printing affects product development in concrete, industry-changing ways.

Related: How much does PCB assembly cost? 5 expert tips to reduce rates and pricing for design companies

Rapid prototyping: speeding up innovation

Prototyping is a critical phase of product development, where concepts are brought into physical existence to test and audit. In conventional manufacturing, making a prototype entails sophisticated tooling, machining, and molding, an expensive and time-consuming affair. With 3D printing, businesses are able to circumvent all these limitations by making a functional prototype in weeks, not months.

For instance, imagine a startup firm creating a new shape for a smartwatch. With 3D printing design experts, the design team can print out a functional prototype overnight, try it on, check its ergonomics the following day, and make design adjustments a little while after that. This quick iterative process reduces development cycles by a great deal, allowing firms to get products to market sooner and keep their competitive advantage.

Second, 3D printing allows it to produce many iterations without necessarily spending too much. If there is a prototype that requires minimal adjustments, then the computer file can be edited and then reprinted afterward, avoiding retooling time and costs in conventional processes. This is highly beneficial in industries that require design accuracy to be at the top, including medical devices, car parts, and wearable technology.

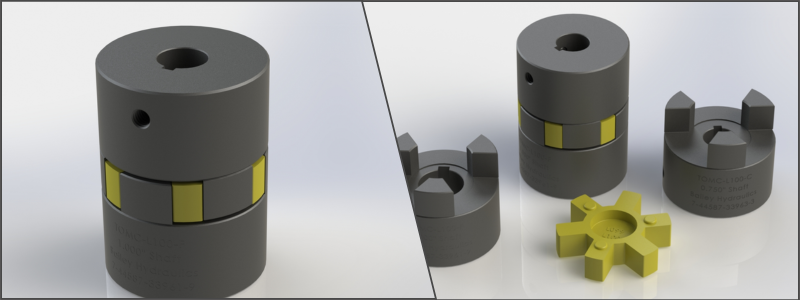

Economical production: minimizing overheads and waste

Production costs can be the killer of a product’s profitability. Conventional technologies have the propensity to involve expensive molds, tooling, and high-volume runs to make an effort to amortize expenses. 3D printing reduces most of the drivers of cost by enabling businesses to create parts from computer models without requiring specialty molds or sophisticated assembly lines.

One of the largest benefits of 3D printing is that it minimizes material waste. Conventional subtractive manufacturing technologies, such as CNC machining, remove a shape from a material block, resulting in great volumes of scrap material. Additive manufacturing, by contrast, layers up products in layers, only consuming the material that is needed. This saves waste, minimizing both environmental impact and material expense.

Moreover, low-run productions become more economical. Small firms and start-ups, not being able to place minimum order quantities in conventional manufacturing design services, are able to produce small batches of customized or niche products at affordable costs without shelling out the big bucks.

Customization & personalization: meeting individual needs with ease

One of the most important characteristics of 3D printing is that it has the ability to create fully personalized products with no extra expense. Conventional manufacturing is a principle of mass production in which prices are established on economies of scale. If an individual needs a personalized modification, this typically implies expensive retooling or independent lines of manufacture. In 3D printing, customization is only a matter of changing a digital file prior to printing.

Consider the healthcare sector. Patients requiring prosthetics, orthotics, or implants in the teeth usually need customized-fit solutions to their physiology. With 3D printing, doctors can now create custom-fit dental crowns or prosthetic limbs that fit absolutely a patient’s specific requirements to enhance comfort and functionality at pennies rather than conventional costs.

In the same way, 3D printing is also useful in the automotive design industry. From personalized dashboard components to bespoke tools for mechanics, automobile manufacturers can create individual designs or batches at reasonable prices. Even domestic items and the fashion industry have started using 3D printing to design unique footwear, frames, and other accessories according to an individual’s personal style and size.

RELATED: The role of human factors engineering in product design for CAD companies and freelance services

Simplification of supply chains: increasing efficiency and agility

The COVID-19 pandemic exposed the vulnerabilities of global supply chains, with manufacturers struggling to secure essential components due to shipping delays and supplier disruptions. 3D printing presents a solution by enabling localized production and reducing reliance on complex supply networks.

Rather than waiting weeks for a part that is imported from overseas, a business can print the component on-demand at a local factory or even in-house. This reduces lead times and provides a more resilient supply chain. Furthermore, businesses don’t have to keep huge inventories of spare parts, as they can just have digital files on hand and print as required.

For organizations such as defense and aerospace, where supply chain integrity is most critical, 3D printing is a strategic strength. Aerospace engineers and defense organizations can manufacture replacement parts in-house with no loss of production time, enhancing their readiness for operations. Likewise, industrial machinery makers can offer on-site replacement parts for obsolete components, extending the lifespan of machines and lowering maintenance.

Complex geometry and lightweight structures: reducing new design freedom

The most thrilling feature of 3D printing is the capacity to create complex, organic shapes that are not possible or hard to produce using conventional manufacturing methods. In contrast to conventional methods involving cutting, molding, or casting, 3D printing has the capacity to create complex internal structures, lattice structures, and hollowed-out parts without loss of strength or durability.

This is especially useful in the automotive and aerospace industries, where weight needs to be kept to a bare minimum. The lighter the component, the greater the fuel economy, reduced emissions, and improved power. For instance, airplane manufacturers can fabricate 3D-printed engine parts and brackets with lattice structures inside them that have equivalent strength but substantially reduced weight.

With 3D printing in consumer electronics design services, it is possible to build thin, high-performance devices with material positioning for the best performance. Laptop housings, heat sinks, and cooling systems may be designed with fine details that enhance efficiency without an increase in size. Even sporting equipment is made possible by designing lightweight but extremely resilient bicycle frames, golf clubs, and protective equipment.

3D printing is no longer the domain of hobbyists and engineers; it has become a must-have innovation enabler across multiple industries. Through rapid prototyping, low-cost manufacturing, easy customization, lean supply chains, and unfettered complex design ability, 3D printing is transforming product ideation, product development, and product launch.

As technology advances, we will only see more efficiencies, better materials, and further applications from industry to industry, from medicine to construction. Having the capacity to print as one needs, create complex and thin structures, and tailor products on a mass level will continue to increase, solidifying 3D printing as a cornerstone in contemporary product manufacturing.

To businesses that need to remain on top of their game, investment in 3D printing technology is not only an option—it’s a strategic imperative.

RELATED: Why additive manufacturing is the future of CAD and 3D modeling services for engineering firms

Industries that profit from CAD and 3D printing

Aerospace & defense

The aerospace and defense industries make widespread use of CAD (Computer-Aided Design) and 3D printing for innovation and efficiency. The technologies allow manufacturers to produce light yet durable components, reducing airplane weight and fuel usage. Aerospace engineers create intricate geometries that are impossible with traditional manufacturing. In addition, 3D printing enables quick prototyping and the creation of customized parts for aircraft, spacecraft, and military applications. It also reduces assembly time and the risk of mechanical failure since intricate parts can be produced in a single print.

Automotive

Automotive firms and suppliers incorporate CAD design experts and 3D printing in the manufacturing and design process to make it more efficient. CAD computer applications allow designers to visualize new models of cars with stunning precision, and 3D printing streamlines the process of making test prototypes for assessing aerodynamics, safety, and performance. It saves a great deal of time and money when it comes to verifying designs. 3D printing also facilitates the economic creation of customized auto parts, especially for sports and high-end cars where one-off parts are required.

Healthcare & medical devices

The medical field has embraced 3D printing since it is capable of creating patient-specific treatments. Prosthetics and implants can be tailored to the individual anatomy of a patient, which makes them more functional and comfortable. Surgeons also use CAD-based 3D models to plan complex surgeries, reducing risks in surgery and improving patient success. Aside from implants and prosthetics, bioprinting is revolutionizing medicine, allowing researchers to create artificial tissues that could one day lead to functional organ transplants.

Consumer goods & electronics

Consumer electronics and home appliances firms use CAD and 3D printing to minimize product development time. Rapid prototyping design services enable designers to experiment with different shapes of a product before mass production, ensuring high quality and functionality. 3D printing also facilitates the easy production of small batches or bespoke products, like personalized phone accessories, wearables, and even apparel. This provides companies with the option to cater to niche markets without having to commit to mass production.

Architecture & construction

CAD and 3D printing are employed by architects and construction companies to transform building design and manufacturing. Scaled models of buildings enable stakeholders to visualize projects prior to the start of construction. 3D printing facilitates the production of prefabricated building parts, minimizing waste and accelerating construction timelines. Companies are even testing the production of entirely 3D-printed buildings, which offer affordable and sustainable options for housing and infrastructure construction.

Ultimately, CAD and 3D printing are changing businesses across numerous markets with increased precision, reduced manufacturing costs, and degrees of customizability unseen before.

RELATED: Enhancing parts design and engineering with 3D scanning: A guide for company services & freelancers

Difficulties and considerations

Although CAD and 3D printing bring much to the business, organizations do have some issues to get around when utilizing them:

- Initial investment expenses: Industrial-level 3D printers and software of the highest quality come with some initial investment costs. Still, long-term returns on the savings and efficiency can usually absorb the initial outlay.

- Technical expertise requirement: Experts are needed to operate CAD and 3D printing technology. Businesses might be forced to train staff or employ experts in a bid to maximize the application of such technology.

- Material limitation: While 3D printing material has improved, certain applications still call for conventional production because of requirements for the strength or durability of materials.

- Intellectual property concerns: Due to the ease of dissemination of digital files, the secrecy of proprietary designs and intellectual property is still a worry for firms that embrace 3D printing and CAD services.

Emerging CAD and 3D printing trends in product development

- AI-based design optimization: Artificial intelligence is utilized in CAD tools to optimize designs automatically for performance, material use, and design for manufacturability services.

- Multi-material & advanced 3D printing: Future 3D printing technologies will provide the ability to print in multiple materials, producing very functional and integrated components.

- Eco-friendly materials & sustainability: In the future, more recycled and biodegradable materials will be utilized for 3D printing to minimize environmental problems.

- On-demand & distributed manufacturing: Localized production is facilitated by 3D printing, minimizing supply chain dependency and providing opportunities for decentralized models of production.

RELATED: Using 3D printed injection molds and prototyping for high quality company product design ideas

The bottom line

The combination of CAD services and 3D printing is revolutionizing new product development through the improvement of the functionality of the design, cost reduction, and faster time-to-market. Organizations that adopt such technologies can gain a competitive advantage, improve innovation, and shorten their manufacturing cycle. By leading through barriers and being on the cutting edge of the next trends, organizations can leverage the full benefit of 3D printing and CAD to transform their product development approaches.

Cad Crowd is here to help

Companies now need to invest in these emerging technologies and leverage their potential to shape the future of manufacturing and innovation. Cad Crowd is an industry leader that can get you the talent you need to foster better products. Reach out to Cad Crowd today to discover more about our 3D printing and CAD solutions.