How do companies benefit from 3D modeling services for engineering designs? Accurate documentation and design are some of the most critical considerations in engineering, where projects are often complex and large-scale. Advanced engineering designs play a pivotal role in shaping project outcomes, whether they involve aspects as straightforward as piping design or delve into more intricate and detailed engineering services.

The engineering industry is becoming more digital by the day, and the importance of 3D modeling services becomes more evident and can’t be stressed enough. Faster turnaround times and improved profitability of leaner projects are now the ultimate goals of businesses amidst stiff global competition, fluctuating energy prices, and ever-increasing costs. Here are some of the top benefits of 3D modeling services for engineering designs:

Table of contents

Table of contents

- Benefits of using 3D modeling services for engineering designs

- Cheaper and faster time to market

- Better design representation than 2D

- Improved future forecasting ability

- Identify errors early on

- Higher quality deliverables and more accurate designs

- Perfect for 3D visualization

- Enhanced designer output

- Better documentation

- Simplified integration

- Compatibility with international standards and codes

- More effective and manufacturable designs

- Improved and simplified piping design

- More cost savings

- Hire the best 3D modeling services at Cad Crowd

RELATED: How computer-aided design (CAD) services are used by engineering firms

Benefits of using 3D modeling services for engineering designs

Cheaper and faster time to market

Companies and owner-operators are pressured to cater to international demands in a competitive and challenging environment. Modern plant design software has evolved regarding sophistication, power, and scope, allowing these companies to provide higher-quality deliverables on a tight budget and deadline. Freelance engineering design experts can spend their time developing 3D models and manually making detailed drawings one line after another. Once the design is completed, they will review it while considering the quality processes.

3D modeling services can reduce the need to remodel between detailed and conceptual design as they bring forward the initial layouts of the concept and take them into more complex engineering. It can take four to six months for engineers to develop simple designs using the traditional method. When the designs are more complex, they require more time.

Automating designs through 3D modeling services has been proven to reduce time significantly. From a simple 3D model, accurate equipment data, material quantities, and design drawings can be extracted quickly. 3D models are then presented to contractors to help reduce engineering process time. The planning and efficiency benefits and the expedited process of getting the essential permits are also critical.

RELATED: 20+ Free 3D models and downloadable CAD files of mechanical and engineering designs

Better design representation than 2D

If you look at a simple 2D drawing, you may need help envisioning the completed design. You might even encounter difficulties picturing the final design. Professional CAD drawing professionals can help engineering design firms to present more accurate depictions of the project and allow clients to view a built-to-scale representation. Thanks to 3D modeling services, it becomes possible to highlight certain structural features, choices, and exterior paint colors, to mention a few. Through this, it becomes possible to imagine how the project will look upon its completion in real life.

Improved future forecasting ability

3D product modeling services can also help in terms of productivity savings in terms of fundamental design disciplines. Through these services, companies, and owner-operators can visualize the final project better while allowing them to develop data-driven and intelligent forecasts and decisions. Clients can also see multiple what-if scenarios throughout the entire design process. The development of virtual 3D models allows non-design and non-CAD stakeholders to join and provide input.

RELATED: 7 Steps of the engineering design process used by freelance engineers & companies

Identify errors early on

Although it may seem implausible, 3D modeling services can catch errors in their models, which helps save project funds. There are instances when engineers may commit glaring mistakes that can result in heavy losses when the errors are overlooked during the initial design stages. However, with the help of the combined capacity of simulation software and 3D models, it is possible to speed up the process and identify shortcomings before the production and manufacturing procedure starts. Through this, we check, test, and revise the project before production is possible, ensuring that no 2D design or drawing can ever be allowed.

Higher quality deliverables and more accurate designs

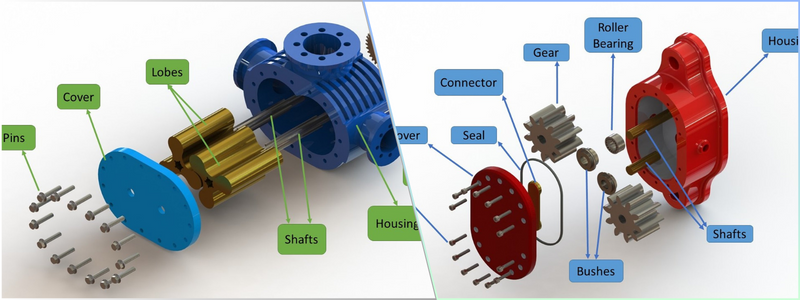

Engineering designs made in 3D can limit the risk of errors in the design and design process. 3D design engineering companies enable automatic validations and calculations for quantities of materials, clearances of equipment, and the modification of the equipment arrangements. Equipment modification allows adaptation of the design requirements to the particular site while optimizing the design. Additional modifications like the replacement of specific types of equipment can also be more easily and quickly achieved when the additional risk of errors is prevented.

3D modeling services also allow engineering design firms to ensure the spatial correctness of their models. It involves connectivity between the components, including the physical details, engineering properties, and materials. All this data is connected to functional design documents and a database like one-line diagrams. It gives engineers the information they need to automate the extraction of cost estimates, schedules, and drawings, with little room for errors.

RELATED: How freelance mechanical engineers use 3D modeling for design

Perfect for 3D visualization

With the help of 3D visualization experts, the presentation of projects has become more straightforward with walkthroughs for design, maintenance, operations, commissioning, and construction. With 3D models, clients will find 3D visualization of dimensions, sizes, clearances, access, movement, and space a whole lot less complicated. 3D designs are incredibly realistic, offering details regarding every element. It eliminates fewer unexpected and unwanted surprises down the road.

3D models also facilitate interdisciplinary coordination throughout the design process, as they allow every stakeholder to visualize the dimensions and inferences of the design. Also, the fact that it is possible to plug different design options into the model to test possible scenarios has helped confirm decisions and spot problems sooner. It is also easier to alter or modify the project during the early stages of the design process instead of after the start of the construction itself. Well-designed 3D models can guide the design process, making them crucial marketing pieces for engineering firms, allowing their clients to view the project throughout.

RELATED: Why freelance Engineers and architectural design firms need to use 3D building models

Enhanced designer output

3D modeling services also exploit the available designer resources by eliminating design’s tedious and manual aspects. This also helps the designer envision every component in 3D during the early stages of the design and edit or modify them immediately if needed. It helps improve the designer’s productivity while reducing the number of iterations required.

Better documentation

With the help of new concept design and product development companies, 3D models for engineering designs can also enhance data management to manage and organize design documents and assets. It lets you regulate the drafting and detailing process, automate the process, and increase the accuracy and speed of output. This can also help estimate the consumption of materials while allowing more efficient time for fabrication and procurement.

RELATED: Top 9 design engineering tips for reducing manufacturing costs on new product designs & prototypes

Simplified integration

Advanced 3D modeling services can give you a single file for more accurate extraction of all necessary drawings, including architectural and steel drawings, BOM, cable routing, GA, isometric drawings, layouts, and other documents. It provides tighter control and a more comprehensive overview of the quality and design across various disciplines.

Compatibility with international standards and codes

Compliance with international standards and codes for different designs and processes becomes more accessible and straightforward with 3D modeling services since every standard’s specifications are already included.

More effective and manufacturable designs

Undoubtedly, 3D models developed by DFM professionals are more efficient than their 2D counterparts when representing designs for manufacturability. 3D models have the potential to get your design’s quality across much more effectively, eliminating any inconsistencies in the supposed implementation and imagination as compared to 2D drawings. Thus, engineering design forms can use 3D models to examine geometric and linear tolerances together with the effects of these values on the process of manufacturing.

RELATED: Why prototype DFM services are useful for product design at companies and firms

Improved and simplified piping design

3D solid modeling services can also help streamline the iterations with a more user-friendly pipe routine. 3D CAD software’s sophisticated capabilities, combined with design and engineering input, can create 3D pipelines with suitable fittings from the sketched paths and set up the necessary connections and other components.

The software these service providers use is also enabled to validate the conformity of different components to specific characteristics such as pressure and diameter, thus resulting in a highly accurate pipeline process and design reliability. Depending on the process in question, 3D models can also enable the creation of instruments and piping diagrams.

RELATED: Design and engineering techniques: how to create a viable product with design firms

More cost savings

The reduced schedule ultimately impacts the total cost. 3D models that generate the bill of materials and get rid of discrepancies between deliverables can result in a significant reduction in project costs. The feasibility and quick cost estimates of projects at their early stages or during construction have proven beneficial and accurate.

Hire the best 3D modeling services at Cad Crowd

Cad Crowd is the best platform for searching for the most reliable providers of professional 3D modeling services for engineering designs that can help ensure the success of engineering design projects.