PCB design is a pretty lengthy process and a team effort that involves multiple engineering professionals from different disciplines, including mechanical, software/firmware, and, of course, electrical.

The schematics are created by an electronics engineer, whereas a mechanical engineer designs the board packaging or envelope; every step has its own constraints based on the project requirements. An electrical engineer builds the layout, and a programmer writes the firmware code for it. Finally, a custom prototyping firm puts all the components together and fabricates the finished product. You might even need independent engineers to review the features and functionality.

It’s quite a lengthy process that involves a lot of people, but you can simplify everything by outsourcing/hiring a PCB design firm to do the job. That way, you communicate with only one contact person or a project manager if you like and let the firm handle all the tasks for you.

Cad Crowd is the industry leader in helping companies find the best professionals for engineering, design, and manufacturing projects. We’ve learned a lot about PCB design over the years – especially about the costs of finding the right talent for your projects and its associated costs. Let’s take a look at the specifics below.

🚀 Table of contents

RELATED: What are the costs for new hardware product design, PCB prototyping rates, and services pricing?

How much you can expect to pay

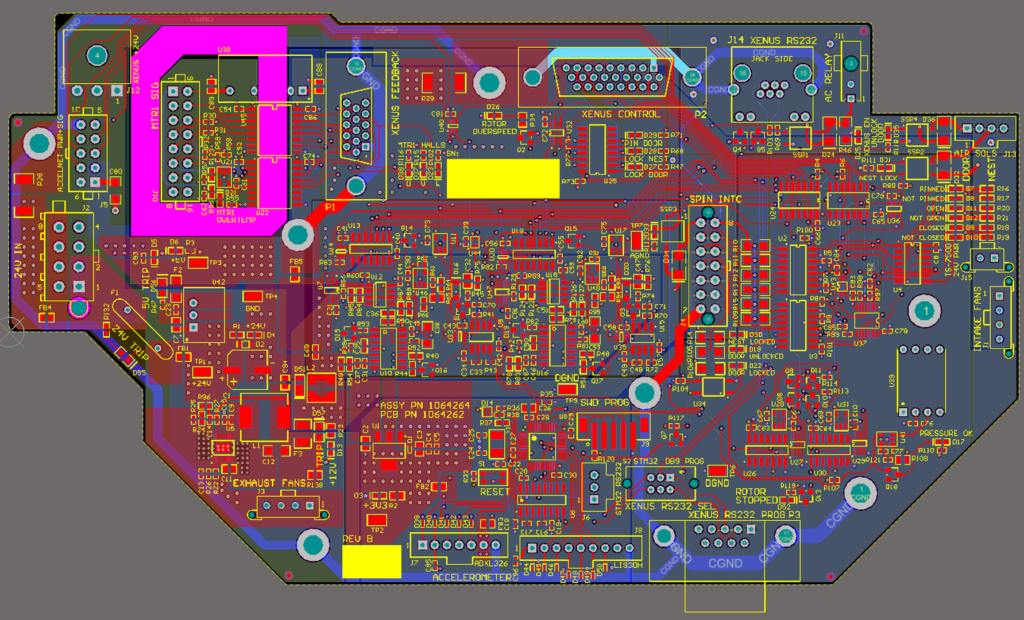

PCB design process goes through two major steps: the shape of the envelope or blank board and components assembly/soldering. You can break down the process further to create a typical workflow, as outlined below.

| Design phase | Completion time (Hours) | Rate per hour (USD) | Service cost (USD) |

| Schematic | 40 | $100 | $4000 |

| Library creation | 20 | $2000 | |

| PCB layout | 60 | $6000 | |

| Routing | 120 | $12000 | |

| DFM analysis | 12 | $1200 | |

| Total | 252 Hours | $25,200 | |

The total cost doesn’t actually include prototype fabrication, which may set you back up to $2,000 per iteration. And in many cases, you need “at least” two prototypes before finalizing the design.

PCB routing is the most time-consuming part of the design process. A professional can create a layout in a week or less, but it could take a few months to route the PCB without any automation tool. Even with advanced software, it’ll still take at least two weeks.

If you’re going the freelancer route, the hourly rate ranges from $30 to $100; a design engineering firm (with all the overhead and range of services) may charge anywhere from $90 to $145 per hour. The freelancer’s experience and educational background affect the hourly rate to an extent, but you can generally expect to get the best bang for your buck at around $100 per hour, where you’re in a good balance between cost and quality.

What affects the cost

Like all other custom products and services, there’s no universal pricing for PCB design. The actual dollar amount depends on many different factors, including:

- Circuit complexity: as the circuitry gets more complex, the board requires more components. Therefore, you have to spend more money to source those components and for the assembly process as well. For example, a PCB that’s designed for a smartwatch with wireless connectivity features and waterproofing protection requires far more complex circuitry (and therefore more expensive) than a simple board for, let’s say, a generic flashlight.

- Layer count: a PCB with more than six layers is pretty complex. Not to mention that every additional layer requires more material and processing steps during fabrication. Depending on features and functionality, some PCBs need to have eight or more layers with a single connection point. A multilayered PCB is significantly more expensive than a single or double-layer type at every step of the design process.

- Shape and size: you want a custom-designed PCB because you can’t source pre-made ones with the right dimensions. Not every PCB is square, rectangular, or circular – it doesn’t really matter what shape you end up with as long as it has all the right connections, routing, components, and pins. However, a PCB with an unusual shape may require special tooling to prototype, which may increase the design cost. Given the same number of components, a larger PCB should be easier to design than a smaller one, but it also means you need more materials to build it.

- Selection of components: in general, higher-end components cost more money, but you’ll end up with better performance overall. You might be able to save more money by sourcing all the components from only one supplier to save money on shipping and handling.

- Material: now that we’re talking about PCB materials, the basic parts of a PCB include a substrate for the structural support, copper for fool-proof electrical conductivity, overlay or solder mask for insulation purposes, and silkscreen for legends. As far as design for manufacturing (DFM) services are concerned, you also have to take into account fabrication materials such as FR-4 for flame-resistant lamination and Teflon for fast signal speed applications. Copper also comes in many different grades, so a highly conductive type is preferable for PCB fabrication. In short, better-quality materials cost more money.

RELATED: PCB design engineering rates, costs & freelance service prices for new company products

| Note | Cost per square feet (USD) |

| A high-performance substrate with the ability to handle high-power and high-temperature applications without breaking a sweat. Again, the ceramic material is covered with a thin film of copper. It’s also the most expensive of the bunch. | $1 – $10 |

| The aluminum material in PCB actually comes with a copper layer and another thin layer of dielectric material. Thanks to its top-notch thermal conductivity, the material is typically used in applications where high power is necessary to ensure functionality. The price range is right in the middle between FR-4 and Rogers. | $20 – $50 |

| The aluminum material in PCB actually comes with a copper layer and another thin layer of dielectric material. Thanks to its top-notch thermal conductivity, the material is typically used in applications where high power is necessary to ensure functionality. The price range is right in the middle between FR-4 and Rogers. | $10 – $20 |

| It’s a flexible material, so you can use it in a device where the PCB has to be shaped in certain ways or bent to a degree. It still has a copper layer for conductivity, but the material is mostly made of thin polyimide film. | A high-performance substrate with the ability to handle high power and high-temperature applications without breaking a sweat. Again, the ceramic material is covered with a thin film of copper. It’s also the most expensive of the bunch. |

| A high-performance substrate with the ability to handle high-power and high-temperature applications without breaking a sweat. Again, the ceramic material is covered with a thin film of copper. It’s also the most expensive of the bunch. | $50 – 200 |

Note: in every PCB design process, you’ll need to build two or more physical prototypes for testing and validation purposes. No design work is complete until the end result is verified as being capable of doing what it’s supposed to do. No matter how experienced the design team is, you can’t realistically expect them to build the perfect design in the first attempt. Each prototype iteration needs all the right materials according to the design specification. Of course, it all depends on the PCB shape and size, but a square foot of anything isn’t really that large of an area. Material cost doesn’t include the components.

This goes without saying, but PCB specifications and requirements definitely affect the design cost. For instance, the design work can be either easier or more difficult if you need the PCB to have specific tolerances, meet certain standards, and pass multiple certification procedures. It’s easier because the engineering team knows exactly what to aim for, and at the same time, it’s more difficult as some of the requirements might impact reliability/performance.

Additional costs

In addition to the designing and specialized prototyping costs, certain PCBs (depending on the type of device and where you plan to sell them) require testing and certifications for electrical safety and environmental impacts. For example, an electronic device that comes with Bluetooth and emits radio waves (electromagnetic radiation) will have to undergo testing by the FCC in the United States. For electronics products sold in Europe, having a CE marking means the product – including the PCB, of course – conforms with European standards for health, safety, and environmental protection. Some certifications are voluntary in nature, but they may help with the marketing.

Design for manufacturing

Prototyping is a pretty big deal here. You’re not designing a PCB for the sake of designing – you want to design a PCB because you need a custom one to be manufactured and used for a specific electronic application or device. If the design is for a DIY project of some sort, you wouldn’t probably need to hire a design firm in the first place; instead, you’ll likely purchase a pre-made blank PCB.

RELATED: DFM for new product design excellence: Complete guide for company success

Making the prototype

A prototype is meant to answer specific questions and address glaring issues. For instance, the first-ever PCB prototype is an answer to the question, “Will it actually work?” If the answer is no, then you go back to the drawing board. If it’s a “yes,” you begin to test the PCB and see whether it has any issues with the features and functionality. This is where your engineering team discovers problems and solves them. It might involve some rework on PCB routing and design simulation software. Once everything looks good, it’s time to make another prototype, which is meant to be an improvement over the previous design. And repeat.

Prototyping has always been an iterative process where you try to improve a product through a cycle of repetitive work. At the end of the design process, you’ll end up with a working production prototype.

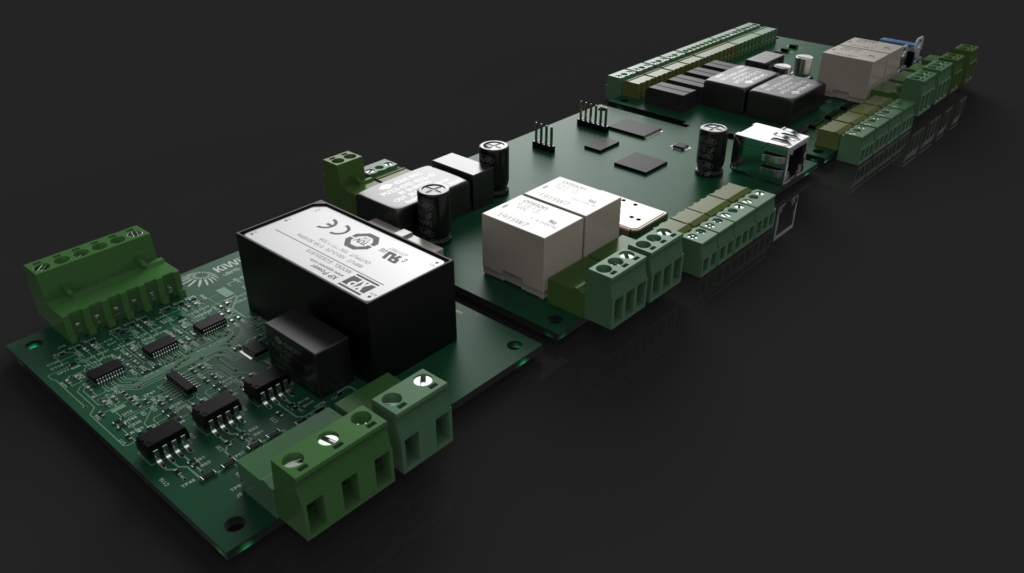

While it’s possible to build your own PCB at home by purchasing ready-made blank boards and components, you’re likely limited to simple designs only. Assuming you need a board with custom dimensions, multilayered configuration, complex routing, and proper DFM analysis, outsourcing the tasks to PCB design professionals is a no-brainer. With the DFM approach, the engineering team makes sure that the final prototype is basically ready for mass production, requiring only minor adjustments, if at all.

The fabrication process of a prototype is just about the same as mass manufacturing; the biggest difference lies in the scale, with the latter being in a large-volume production of thousands of units or more. In simple words, here is the general step-by-step process:

- You start with a laminate core (the base material, whether FR-4 or any other, as previously mentioned), which provides the structural strength for the board and serves as the insulator between the conducting layers.

- For a single-sided PCB, you only need one laminate core covered with copper film on one side. The double-sided board also has one laminate core, but you need two copper layers, one for each side. A multilayered PCB, as you’ve probably guessed, needs multiple laminate cores with alternating thin copper films between them. The copper is the conductive material on the board. The vast majority of PCBs use even numbers of layers (except the single layer, of course), like two, four, six, or perhaps eight layers.

- Each copper layer has a laser-plotted layout design. Next, you apply a light-sensitive material called “photoresist” to create a patterned coating on the copper pads and traces. The copper layers are then exposed to UV light to harden the photoresist coating.

- The copper layers must be processed through a chemical solution to remove any remaining photoresist material that isn’t hardened during the UV treatment. You then run the board through a different chemical solution to remove the copper not covered by the photoresists. Once everything is done, you must remove the already hardened photoresists you created in Step 3. The point is to have only the desired copper to form the intended pads and traces.

- A lamination process bonds all the layers. If you’re building a multilayered PCB, the lamination makes sure that your stacked board remains secured together.

- To connect signals on different layers on the board, you need to drill some holes (technically known as vias) through the stack. If you must use through-hole components, you need to do some more drilling to mount them properly. It’s generally recommended to use only SMT (surface-mount technology), if possible, to save soldering and fabrication costs.

- All the exposed metal surfaces (including those in the inner walls) must be covered with copper for better conductivity. Even copper surfaces also need another layer of electroplated copper. At this point, you’ve successfully made a blank PCB.

- Now, it’s time to solder all the electronic components on the board. In a modern fabrication process, you don’t have to do everything by hand. Instead, you can use robotic equipment called a “pick-and-place” machine to select the right components for the right spot. A solder paste, which essentially is a mixture of solder and flux, is applied to hold the components temporarily.

- The board is now run through a reflow oven to melt the solder paste and secure the components permanently.

Implementing a DFM service from early on in the design process helps simplify the manufacturing process at a later date. In the old days, engineers created a design and handed it to a manufacturer, who then had to figure out how to actually build it; interaction between the engineers and the manufacturers was practically non-existent. The DFM approach requires the engineers to develop a PCB design with manufacturing in mind. This means the engineers will avoid building a design that would be too complex to fabricate.

Where Cad Crowd comes in

Designing a PCB is a complex undertaking, especially if you have no professionals to help with the process. Here at Cad Crowd, we can connect you with the country’s most experienced PCB designers and engineering team to tackle even the most complex project at an affordable rate.