Bringing an invention to market isn’t easy. You need to model, produce and sell your idea before you’ve got any revenue coming in. That being said, if you save money where possible, get the right investors at the right times, and go in with an accurate idea of what your costs will be, your invention will be on the shelves (and flying off them!) in no time.

Stage 1a: Developing your concept

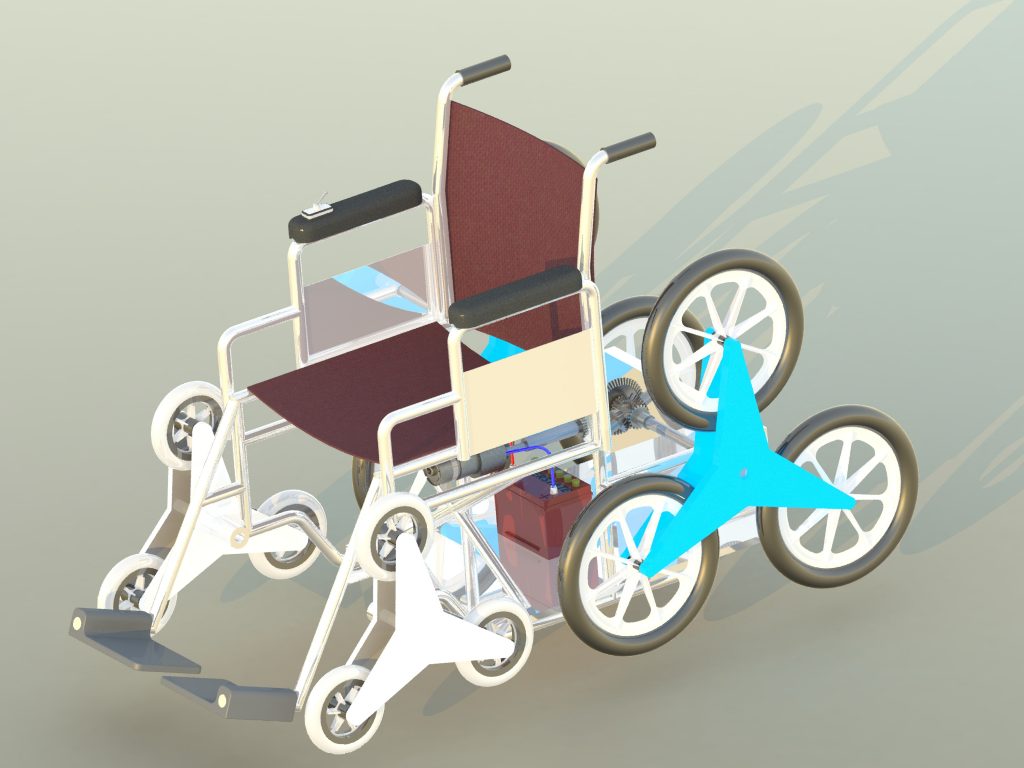

The first step in turning your idea into a reality is fleshing out your concept. To help make your vision more concrete you’ll want to produce either a graphical mockup, 3D model, or video rendering. This will help you to develop and improve your concept and to share your idea with potential investors, partners, and licensors. Here at Cad Crowd, we can connect you with the top freelance CAD designers on the web to help you develop a top-quality graphical representation of your invention at an affordable price. This could help in getting investors interested, thereby offsetting future costs. Producing a written description of your product can also help you to work through your concept and iron out the kinks. Whatever routes you choose, it’s always a good idea to model your invention in more ways than one.

This is also the phase where you’ll want to research what similar products might exist, patent your product, and find earlier investors. Patenting always carries a cost, which varies depending on your location and the nature of your invention. That being said, the other tasks in this stage can either be carried out by you personally with little overhead or subcontracted to a professional.

Stage 1b: Developing a business plan

This should happen concurrently with stage 1. Your business plan will allow you to estimate your projected profits and plan your manufacturing costs accordingly. A good rule of thumb is to “estimate conservatively” – also known as planning for the worst – which means projecting your costs as lower than what you actually expect them to be, and your expenses as higher. This can help you weather the storm when the inevitable “hidden costs” and setbacks crop up. Consider all factors in your budget: market penetration rates, cost of loans, cost of insurance, marketing costs, packaging costs, shipping costs, staffing, warehouse costs, and your own salary (which can be surprisingly easy to overlook). Any planning you do now will save you a lot of money later.

At some point, you should browse stores where you expect your product to be sold and check out the competition. What are competing products going for? Is there a reason they might be sold for more or less than yours? Is your product “fair-trade” or ethically made in some way that might justify a higher cost? Or is there a way you might offer it for cheaper?

While you’re in the store, try to find about five products that are physically similar to yours. They don’t have to be for the same purpose, or even in the same industry. Try to find items that don’t have any particular reason for being unusually priced. Average the cost of these five items and divide by ten to get a rough estimate of your manufacturing costs. That’s right, most companies sell items at about ten times the cost it takes to produce them!

The phone can be your best friend in fleshing out your business plan. Never underestimate the utility of calling up insurance companies, government agencies, or shipping companies to get a “back of the envelope” quote. Better to have an accurate idea of cost now rather than be surprised later!

You can use the internet to further this kind of research. Try to balance cost and quality: your product will only succeed if it’s well-made, but if all your costs are being sunk into manufacturing, your business may not succeed. By the end, you should have a clear idea of what your product will cost to produce, what other costs will come up in getting it to market, and what you’ll be charging.

Stage 2: Building a working prototype

This is where your invention goes from being a concept to a reality. Here you’re building a prototype, a working example of your invention that you can test, show to investors, market research and refine. Your prototype will also be useful in finding a manufacturer. Generally, you’ll want to subcontract manufacturing unless you’ve already got the in-house facilities set up; it’s generally cheaper, and less of an investment for what’s still, at this stage, a risky venture.

So how do you create your prototype? One possibility is through 3D printing, a powerful technology that allows you to custom design all parts of your invention to your exact specifications. Here at Cad Crowd, we can connect you with the best 3D printing freelancers on the web, to help you come up with the prototype of your dreams. The alternative is getting a manufacturer to design a prototype for you, but manufacturing an individual prototype tends to be expensive; as a general rule, 3D printing is cheaper for prototypes and manufacturing for mass production.

Stage 3: Launching a pilot production

This stage tends to be the most expensive. Now it’s time to find a manufacturer, set up a marketing campaign, and start touring trade shows. This is your first chance to reveal your product to the public, and you’re going to make it count!

Hire a marketing team. This may require hiring a web designer, logo designer, and salesperson. You’ll also need to update the graphical representations you produced in stage one, as your product and your intended audience will have changed. For all graphical work, Cad Crowd can help connect you with designers to produce materials that will blow your competitors away.

At this stage, you’ll also want to file a non-provisional utility patent in the US and file with the PCT (the international patent system). Keep in mind, if you plan on marketing your product internationally, you may need to patent separately with your target country’s patent offices.

Stage 4: Taking the plunge!

With the success of the pilot stage, it’s time to do a full-out launch! By now you’ll have a realistic idea of what it costs to run your business, and with a few tweaks of your pilot stage, you should be ready to go.

Whether you’re modeling a new idea, designing a prototype, building your web graphics or running a business, a skilled CAD designer could be that asset that sets you above the rest. At Cad Crowd, we’ll connect you with the very best in the field, helping you make your invention stand out and succeed. Contact us for your free quote today!