Discussion of assembly drawings can get a little heated from time to time. The driving concept behind what makes assembly drawings effective or not remains the same. It’s mostly a matter of perspective as to whether they are prioritized enough by decision-makers or not. This type of drawing has been overlooked by decision-makers on enough occasions that there are some apparent stereotypes about their opinion on them.

In any case, we’ll take an in-depth look at this subject by beginning with what assembly drawings are. We’ll also take some time to look at the various types of assembly drawings and their uses. There are more types of assembly drawings than most are aware of. In addition to these points, we’ll also discuss why assembly drawings are so critical for consumer product designers. Now, let’s get started.

What Is an Assembly Drawing?

Since there are various types of specialized assembly drawings and many of the professionals who work with them refer to all of them as assembly drawings without differentiation, let’s start with a broad definition.

An assembly drawing can be broadly defined as any drawing which shows more than one part and the way those parts fit together. Some terms vary based on the industry, but for the most part, each specific type of assembly drawing has a slightly different use.

For example, even instructions that are included by furniture design services can fall under the category of an assembly drawing. Assembly instructions tend to be painful for many consumers to follow, but there are several reasons for this, which will be mentioned later.

When looking at the term assembly drawing from a more traditional perspective, we can piece together a more specific definition. From this perspective, an assembly drawing shows multiple parts of a product and the way that they fit together.

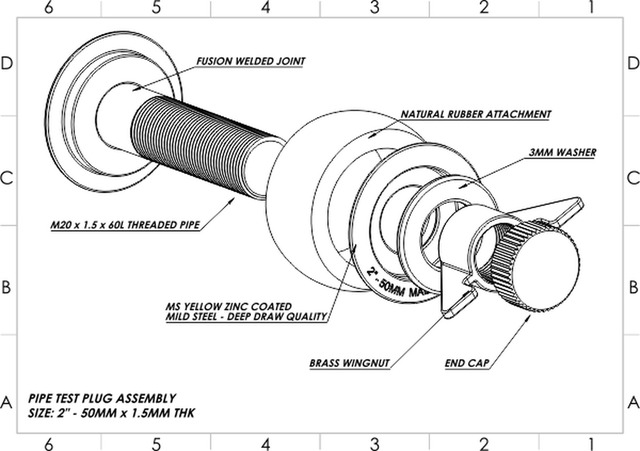

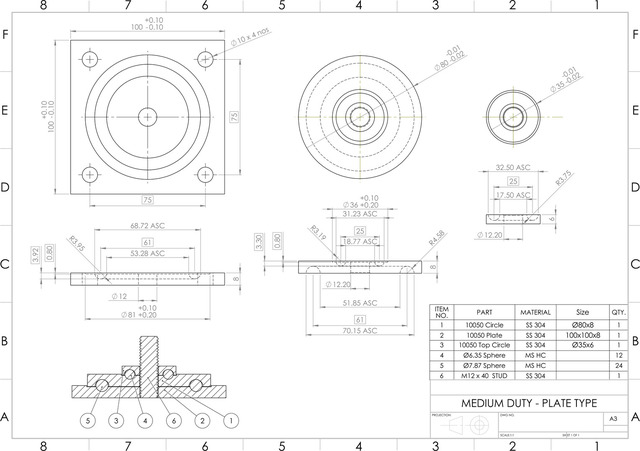

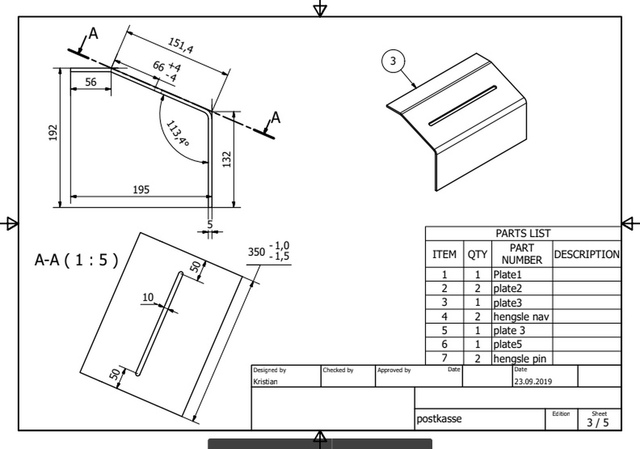

A textbook definition traditional assembly drawing will also include a part list. This list is typically numbered and calls out each component individually, including parts that are not unique to the product, such as screws, bolts, and other hardware. A list like this should also include the quantity of each part. This specific type may also be referred to as a general assembly drawing by assembly drawing services.

Various types of assembly drawings can be used during different stages of the product lifecycle. Instructions that are included with the product for the customer’s use are just one type. Other types of assembly drawings may be used during manufacturing for specific assemblies within the product. They may also be used for the whole product, and that’s just within the context of a manufactured product. These drawings are also used in other fields.

How Assembly Drawings Work

When everything goes according to plan and each area of an assembly drawing is adequately detailed, the drawing will allow anyone with even minimal technical skills to assemble the product quickly and without much frustration.

Since instructions and assembly drawings don’t always seem to facilitate this, what is it that separates a high-quality assembly drawing from a low-quality one? Some assembly drawings can create an unnecessary hassle for experienced professionals, while others allow practically anyone to complete the task efficiently.

Let’s use a general assembly drawing as an example. For this example, the general assembly drawing is included as part of the instructions that come with the product. The product is a trendy new piece of home exercise equipment. It provides resistance through an elaborate setup of weights, pulleys, and cables. If a cable or pulley in this product is not assembled correctly, it could be very frustrating to fix and potentially hazardous if it were to go unnoticed.

In this type of scenario, it’s even more critical to work with a CAD drawing service that clearly illustrates the way everything fits together. This is exactly the kind of situation where a top-notch assembly drawing protects and benefits everyone involved in the product lifecycle.

Let’s say that the assembly drawing was included in the instructions as a bit of an afterthought. The drawing itself leaves a bit to be desired, doesn’t show the product from enough angles, and creates a few blind spots. An assembly drawing like this is likely to leave customers frustrated. This could potentially manifest as low sales, reduced market share, and may damage relationships with existing customers.

On the other hand, let’s say that in a parallel universe, the same product was released with a very comprehensive assembly drawing that forms a rock-solid base for the instructions. The clarity provided by the patent drawing makes assembly a breeze for customers. It may not appear to make an immediate difference in the reception of the product at first glance, but it will likely lead to better sales and improved customer relationships. It may even give your product an edge over some competing products that it would not have had.

As you can see, assembly drawings have the potential to make a significant impact on the way a manufactured product is received by customers. However, the quality of the assembly drawing dictates some other factors earlier in the product lifecycle as well. We’ll take a look at this aspect later.

Types of Assembly Drawings

We’ve already touched on the fact that there are several varieties of assembly drawings. The most basic and widely recognized of these is the general assembly drawing. We’ll give these a closer look as we examine all the types of assembly drawings.

Depending on the industry and what kind of professional you’re dealing with, these terms may not be so clearly separated. Just because a shop floor worker may refer to a specific drawing as a blueprint, a technical drawing, or a fabrication drawing doesn’t necessarily mean that drawing is not something that may fit the definition of an assembly drawing. So, on to the types.

General Assembly Drawings

When it comes to manufactured products, general assembly drawings often make their way into the instructions that are included with the product. Some of these will include a grid in the picture that can be used to convey the scale of parts and components of the product. However, a grid like this is not something that will be found in every general assembly drawing.

That being said, there are several things that you can expect to find in any assembly drawing that falls into this category. A general assembly drawing should include a part list with quantities, one or more views of the product and its components, and necessary dimensions.

General assembly drawings will often be referred to by many involved in various stages of the manufacturing process. These drawings will often be seen and used by decision-makers, shop floor workers, and sometimes even the customer depending on the type of product.

Assembly Instructions

Assembly instructions are crucial for virtually any manufactured product. They typically have several differences that separate them from something like a general assembly drawing. For instance, a general assembly drawing will list the components, but assembly instructions will also often list any tools or other products that the customer may need for the process.

RELATED: Injection Molding Tips for Cost-Effective Prototypes and Mass-Manufacturing by a Mold Design Firm

Perhaps the most apparent difference between assembly instructions and a general assembly drawing is the fact that the instructions are laid out in a step by step sequence. A certain level of technical proficiency may be assumed when creating a general assembly drawing, but such assumptions can be problematic in the case of assembly instructions. General assembly drawings can be instrumental as a component of assembly instructions, but they should not be seen as a full guide in most cases.

Assembly instructions will also usually provide a greater number of views and images. Where a general assembly drawing may simply show the complete product from several views, it’s a wise choice to include exploded views and pictures of specific sub-assemblies, components, and spatial relationships.

Providing a greater number of views is often necessary to provide the customer or end-user with a sufficient perspective of the product and its various components. Failure to include such a variety of views and images can create questions that would otherwise have self-evident answers.

It is sometimes possible to create assembly instructions that can fit on a single page. However, this is only truly appropriate for the simplest of products with minimal assembly required. In other cases, it tends to be more advantageous for both companies and consumers to have highly detailed and in-depth assembly instructions.

Fabrication Drawings

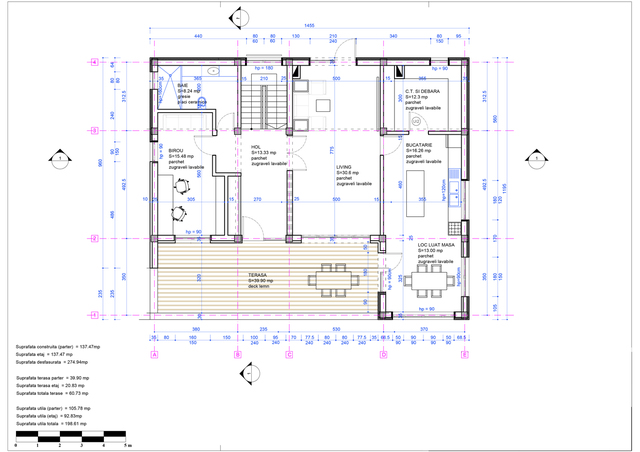

Yet another type of assembly drawing is sometimes known as a fabrication drawing. This term is more commonly found outside of the manufacturing industry, in fields such as construction and architecture. That being said, some assembly drawings are passed along under this name in manufacturing.

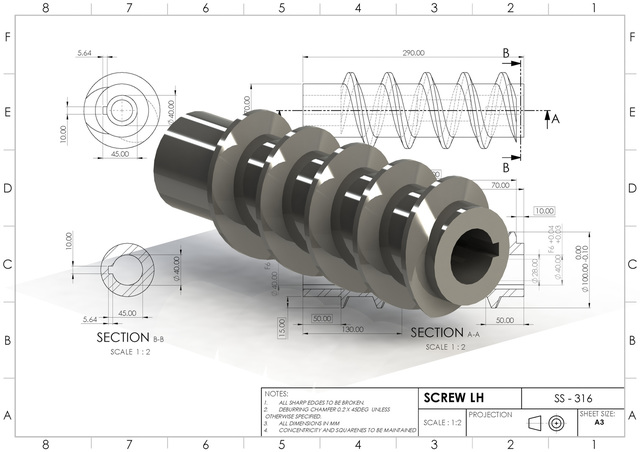

Typically, if something is being called a fabrication drawing for a manufactured product, then it is a little different than a general assembly drawing and it is quite different from assembly instructions. Fabrication drawings are more technical and have more emphasis on things like dimensions, clearance, and exact spatial relationships. This type of drawing may even go into a little more detail about tolerances, finishes, and coatings, or other secondary processes.

Fabrication drawings are not made for customers or end-users. This type of assembly drawing is specifically for shop floor employees and other skilled workers that are involved in the manufacturing process. Passing this kind of information along to the customer is of no particular benefit to them.

Assembly Drawings vs. Assembly Models

In addition to the various types of assembly drawings, there are also assembly models and 3D product modeling services. Assembly drawings and assembly models can overlap in some situations, but for the most part, they serve different purposes.

First, let’s start by clearly drawing a line between the two. We’ve already spent some time discussing what an assembly drawing is and some of the most common varieties. For clarity, let’s just stick with a general assembly drawing as our working definition of the term assembly drawing. It shows the product, typically has more than one view and lists the individual components. It provides the basic information necessary for assembling the product in a two-dimensional format.

On the other hand, an assembly model is something that is created and exists within a CAD program. Among the most obvious differences between an assembly drawing and an assembly model is the fact that an assembly model is in 3D. An assembly drawing may contain one or more views of a 3D model, but an assembly model is the actual 3D object as it exists within a CAD system.

Unlike an assembly drawing, an assembly model can be manipulated just like the real product. Many of today’s CAD programs have this capability. With the widespread use of advanced 3D CAD systems, 3D assembly models often form the base of assembly drawings that are used during production.

3D Modeling and 3D Assemblies

You’re likely already familiar with the fact that a vast majority of today’s freelance engineering design services work almost exclusively with 3D CAD systems, or 3D modeling software, to create their drawings. There are several reasons for this, including the high level of precision these drawings can display as well as the ease with which they can be shared.

When it comes to 3D modeling and 3D assemblies, these tools stand out compared to the methods that were used in the past. Let’s illustrate this with an example.

Say you have a new product that has a variety of moving parts that must fit together with a reasonable level of precision. Let’s also go ahead and say that the project began with the idea of the desired function, and then the product was designed from there.

A mechanical product like this could be difficult to imagine if you were only working from flat 2D drawings. You could make 2D drawings of the finished product and its internal assemblies. Still, this perspective by nature leaves room for interpretation, and problems with the design may go unnoticed until a physical prototype is made. This kind of problem can be avoided with 3D assemblies and 3D models.

3D assemblies allow engineers and injection molding freelancers to test the fit and relationship of components before physical prototypes are made. Some 3D modeling software can simulate basic forces so that you can watch the components of the assembly move, provided that the proper spatial relationships are present. This is a tremendous advantage that can save significant amounts of time and money during the development process.

Benefits and Importance of Assembly Drawings

By now, given the specific details and uses of various types of assembly drawings discussed previously, it’s easy to see that assembly drawings are integral to manufacturing in several ways. Here, we’ll examine the benefits that high-quality assembly drawings offer to companies and consumers separately.

Assembly Drawings in Manufacturing

The ways that an individual with little to no manufacturing experience can bring a new product idea to the market with the technology that’s in use today are stunning. It’s never been easier to take a product idea from concept to production. However, all of this hinges on a few factors. One of those factors is the presence and quality of CAD drawing services and 3D models.

It is very common to utilize a variety of service providers and contractors throughout the process of manufacturing a single product. In cases like this, it’s imperative communication between all parties is clear. Depending on the specifics, there may be a language barrier. This makes drawings and 3D models even more critical, including assembly drawings.

As for the benefits that high-quality assembly drawings can offer companies and entrepreneurs, they are numerous. Perhaps the most significant advantage is that high-quality assembly drawings help to keep production efficient by minimizing downtime and the number of products that are assembled improperly. This does not pertain to all products, but it is a factor for anything that has some portion of the product already assembled when it leaves the warehouse.

In addition to reducing production costs and minimizing downtime, assembly drawings can benefit companies and entrepreneurs after the sale as well. Customers always appreciate assembly instructions that are clear and easy to follow. Top-notch assembly instructions are easy to create when there is already an existing high-quality assembly drawing. Including great assembly instructions keeps customers satisfied and goes a long way towards receiving favor from them when it’s time to buy again.

Assembly Drawings for Customers

In most instances, the assembly drawings that customers see will be limited to assembly instructions. Customers benefit from high-quality assembly drawings almost as much as companies do. Clear and accurate assembly drawings and assembly instructions can save customers a lot of trouble after they’ve made their purchase.

However, the benefits to customers extend beyond simply avoiding frustration during assembly. It goes without saying that when products are assembled well, they function well, but it’s worth pointing out here. This is one of the ways that excellent assembly drawings and assembly instructions contribute to customer satisfaction.

Assembly drawings and instructions can also help to keep customers safe. This is true both during the assembly process and when using the product afterward. If everything is assembled as it should be, then there is far less room for accidents and mechanical failures.

Tips and Advice for Creating Assembly Drawings

There are several specific technical qualities of assembly drawings that should be considered in every situation. Before we get to those qualities, here are some tips for your perspective and approach during the process that will help to keep things smooth.

Communicate Clearly

If you’re going to be working with another professional to have your assembly drawings created, such as an engineer or product design service, then unambiguous communication is vital. If they’re going to deliver precisely what you want, then you need to be able to tell them what that is.

Be as concise as possible when it comes to what the assembly drawing will be used for. Tell the mechanical engineer service or designer about your needs and any specific factors that should be taken into consideration for the drawing.

Maintain Professionalism

While they aren’t as prevalent as they once were, there are still some stereotypes about freelancers in any field. What many who put weight in these stereotypes fail to realize is that freelancers must be both dedicated and highly skilled; otherwise, they would stop getting new projects.

When working with a freelance engineer or designer to get your assembly drawing, remember to stay professional. If you have time constraints or other project-specific factors, just let them know. They’ll be more than happy to accommodate you so long as they have the means to. Remember, when you’re their customer, they want you to be fully satisfied with the outcome of the project.

Technical Tips

Tip 1. – Be Thorough

Regardless of what the product is, its assembly drawing needs to be complete. A single missing detail can hold up production or worse. It’s far better to have too much information present on the assembly drawing than to have too little.

Tip 2. – Be Precise

Precision is very significant with any kind of CAD drawing or 3D model. The fact that modern CAD software allows such a high degree of accuracy during the design process is one of its most valuable features. This tip goes along with being thorough. Remember to be specific with dimensions and tolerances where necessary.

Tip 3. – Include Unique Tips and Insight

If something about the assembly of the product is unique and may not be evident to others from viewing the drawing, it’s best to include a note about it. It may be something small like the order that some components are added when the order doesn’t appear to matter, or something more significant. If something like this has been discovered during the prototyping phase, be sure to include that information so it can be used during production.

Tip 4. – Take Advantage of Multiple Views

Even if the assembly drawing needs to be printed on more than a single page because of all the views that are included, it’s better than leaving out something important. Perhaps a left side view and a right side view are both necessary due to an asymmetrical design.

Maybe it’s just a matter of perspective and a cross-section or a close-up view is required to see the exact relationship between components. At any rate, don’t be shy about including additional views and perspectives if they’re going to be useful.

Tip 5. – Consider Separating Sub-Assemblies

If there are multiple sub-assemblies within the product, you may want to consider giving them their own sections or even their own drawings. While assembly drawings must be complete and comprehensive, it is possible to make a space so crowded that the drawing is hard to use.

Q&A

My product only has a few components. Should I still have an assembly drawing made?

Yes! Assembly drawings are useful in many situations and can answer a lot of questions as they come up in the manufacturing process. Many skilled workers involved in the process prefer to see an assembly drawing if it’s available. These drawings help them to gain a better understanding of the product and any of its specific components that they’re working on.

Is there a type of product that doesn’t need an assembly drawing?

Assembly drawings are great to have in a variety of circumstances, but they are not always necessary. They are very often necessary, but not always. Products that genuinely don’t require an assembly drawing are usually a single solid piece.

I’ll be taking care of production and assembly myself on a small scale. I don’t need an assembly drawing, do I?

An assembly drawing is not absolutely necessary just yet in this situation. However, it would still be useful to have, especially if there are design changes as production continues. If you plan to scale up and outsource production eventually, then you’ll definitely want to have an assembly drawing made before that point.

Does Your Project Need an Assembly Drawing?

If you’re going to need a high-quality assembly drawing for your project, but you don’t know where to turn, don’t worry. There are plenty of vetted freelance engineers and designers to choose from here at Cad Crowd.

Finding the right designer or mechanical drawing service for your project can be a challenging task, but we’ve made the process quick and easy for you. The freelance professionals in the Cad Crowd talent pool are already experienced and proven. Additionally, it’s standard procedure here to use non-disclosure agreements. You’ll be able to use their services confidentially and you’ll keep all of the intellectual property rights.

Our pool of vetted freelance designers and engineers is here for you. If you want to get the help of a vetted professional for your project, you can start the process today by getting a quote.