Electronics design and engineering companies are starting to realize the opportunities that outsourcing has to offer. Whether you need specific knowledge or lack resources, a small electronic design company can help bring your new products to life. However, not all electronic design companies are made equal. While some live up to their promises, others deliver mediocre or less than stellar results.

Table of contents

- What is an electronic design company?

- Why consider an electronic design company?

- Top considerations when looking for an electronic design company

- The bottom line

- How Cad Crowd can assist

This article aims to give you a quick overview of the top factors to consider when looking for the right electronic design company to help you develop your new product.

What is an electronic design company?

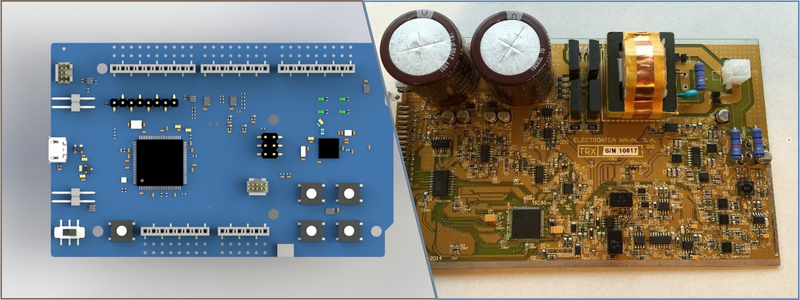

An electronic design company comprises a team of expert professionals who can help you create an electronic device at the different development stages. It doesn’t matter whether you are gearing up for mass production of your electronic products, building a prototype, or developing a printed circuit board (PCB); electronic design companies let you do everything under one roof.

RELATED: What are electronic manufacturing services (EMS) for new products & prototype design?

Services provided

Some of these companies provide services that include, but are not limited to:

- Design for assembly services and prototyping

- Certification

- PCB layout

- Mass production preparation

- Testing

- Schematic design.

RELATED: The best PCB design software for electrical engineering professionals in 2022

More specialized services

Some companies offer services beyond hardware design. Other companies also include high-level and low-level programming, for example:

- Developing board support packages, or BSPs

- Developing drivers or doing kernel-level programming

- Offering development of the real-time operating system, or RTOS

- Writing firmware for microcontrollers.

Companies that offer embedded software and electronic design services can conduct testing and development processes more quickly, thanks to the speed of communication possible within a single company. This gives them an advantage over companies specializing in developing electronics for devices. The market for outsourcing to engineering companies has become sizeable for a reason. They provide services to different domains such as consumer electronics, telecommunications, robotics, automotive, industrial, and medical systems. Providers of these electronic solutions also use various cooperation models and technology stacks that can cater to specific industry needs and project requirements.

RELATED: Hiring the best electrical engineers & freelance PCB designers

Why consider an electronic design company?

You might want to outsource to a new product design engineering service for several good reasons. But note that there are still instances when in-house development might be a better choice. Before going for a remote team, it is helpful to weigh the advantages and disadvantages to find the most appropriate solution. To determine whether you need to hire an electronic design company in the first place, here are some reasons to consider outsourcing the engineering of your new product:

- Lack of your resources

- Need for additional resources

- Lack of personal expertise

- Risk diversification

RELATED: How to reduce painful product development costs for your company

Top considerations when looking for an electronic design company

Now that you know what an electronic design company is, it is time to discover the essential factors you need to consider when looking for one. Here are some critical criteria to remember to help you make the right choice:

1. Service history and reputation

One of the best and easiest ways to learn more about a prospective electronic prototyping and design company is to read through reviews made by its current and previous clients. While these opinions may be subjective, they can still give you a good idea of what to expect from the company you will work with. The good news is that many platforms now share reviews and ratings of industry leaders, and referring to these sources can help you choose the right company.

Freelancing platforms allow remote collaboration where you can find rating systems for professionals in different development areas. These platforms also enable clients to give grades and leave feedback to their teams. You can also ask for references from your contractor, and it is always a positive sign if they are more than happy to share these references with you. An excellent level of customer satisfaction and service is the secret to long-term relationships.

RELATED: Business tips for new product design & development

A happy and satisfied client will surely come back to develop a new device or update and redesign their electronics. During the discussion of your project, you should pay close attention to the questions that the potential company asks you. Engineering experts from the best electronic design company will not only inquire about extensive technical details but also recommend solutions to problems. If you are unsure whether the company is the right choice, you can try giving them a test task or working on a smaller project first. Once the company completes the initial job, you can then proceed with developing a larger, more complex project.

2. Collaborative approach

An appropriate cooperative approach can ensure on-time delivery of your project that sticks to your budget. Learning more about their collaborative models is essential when looking for an electronic design company. “Waterfall” and “agile” are the two primary approaches to development. The waterfall approach is sequential and rigid, and you must complete and verify the first phase before proceeding to the next. This methodology is suitable for projects with definite specifications that don’t require any adjustment.

RELATED: Tips for PCB Design Services Creating New Products

The second methodology, the agile approach, provides incremental and flexible development. This model allows customers to correct the specifications as required, and the developer will alter the project accordingly. Your chosen electronic design company can use either of these approaches depending on your specific requirements. However, the agile development model is often preferred as this is a better way to meet clients’ expectations.

Remote product engineering services may also follow different collaboration models and frameworks. For example, you can work with a dedicated team if you require full-time project engagement and a chance to fully control the entire development process. You can begin with a research and development model if you have doubts about whether your project is feasible or not. You can also work with a reliable consulting service to review your current design.

RELATED: Product simulation and analysis: why it’s worthwhile

3. Communication and Project Management

Don’t be afraid to ask questions when interviewing a potential electronic design company. Who will be in charge of managing your project? Who will oversee the development process? How will communication be conducted? Who will be your main point of contact? Team members in well-structured design companies share different responsibilities. Core project teams in these companies often consist of the following members:

- A BDM or business development manager

- An account manager

- A PM or project manager

- A technical lead

- Engineers

- The CTO or chief technical officer

The BDM is the first point of contact: they supply you with all details regarding the company and guide you in understanding whether you and the company are suitable to work together. After signing the contract, the account manager will liaise between you and the internal team. The tech lead is responsible for the technical deliverables and management, and the project manager ensures that the team will deliver the project within the budget on time.

RELATED: 10 Tips for businesses on delegating to freelancers

When it comes to outsourcing your new product engineering to an electronic 3D modeling design company, it is a must for both the salespeople and the technical team to be fluent in English to enable in-depth discussion of the project, either in writing or verbally. The best electronic design companies have team members with an excellent command of English and work to enhance this knowledge regularly. When working with an outsourced team from a different region or country, you also need to consider any potential misunderstandings and cultural differences resulting from this diversity.

Before cooperating, ensure that you and the outsourced company are on the same page about the collaborative approach and business ethics. Make sure you also take note of the specific time zone of your chosen outsourcing company. It will be more convenient for you to choose a company that operates within working hours that suit your schedule. You might want to work with a company that works with clients from different parts of the world, such as the USA, Canada, Australia, Europe, or Asia.

RELATED: 5 Challenges of working with a distributed team (and how to solve them)

The best electronic design companies have project managers who work according to the schedule of their clients. They also refer to their client’s needs when choosing the time for online discussions. There are instances when the time difference can work in favor of clients. After the company’s working day, they can deliver the work, giving the client a day to review it and provide feedback.

An electronic design company is also expected to take advantage of online meetings and use the right project management tools to facilitate better cooperation during the outsourcing process. This will keep clients updated on the project and enable them to monitor it. Zoom, Google Hangouts, Skype, and Basecamp are some of the tools companies use to maintain open communication lines with clients through project development and even after handover.

RELATED: Accessible design: better products for everyone

4. Intellectual property rights

One of the most critical things you will need to consider when outsourcing new product engineering is the right to the IP or intellectual property created in the project development course. There are several measures you can take to keep your ownership rights well protected, including any of the following:

- Consult an intellectual property lawyer

- Assign tasks to several teams to prevent reverse engineering or copying of your entire product design

- Patenting services for your product and studying the patent law carefully in advance

- Sign a contract or master service agreement (MSA)

- Sign an NDA

- Specify the IP owner complete with the list of owned intellectual property and all the involved penalties in the contract

All the IP rights in the contract form are often transferred to the client once the completed works have been fully paid. From there onwards, the company will no longer be able to lay claim to the project deliverables and their ownership.

5. Payment

Payment terms vary according to the project requirements, type of cooperation, and business processes of the contractor and the client. Depending on the specific type of project, regular payments can be made per hour or in fixed installments for every milestone. A time-and-material or hourly-based model fits R&D or research and development projects that require investigating. This approach is suitable, for example, if you are unsure about the choice of component or technology for your electronics design and you want to check it first. It is also recommended when it is impossible to predict the exact deliverables or whether requirements may still change during the development process.

RELATED: Learn about electrical engineering consulting costs, services, and pricing in firms

The time-and-material pricing model allows a mechanical engineering service to work in repetitions and is suitable for projects connected with continuous testing and constant polishing. You can also opt for a fixed-price model when you have a definite scope of work with a stringent budget and deadline. For fixed-priced contracts, development companies also include all the potential risks in the project evaluation and take full responsibility for meeting the estimation. The model is a good choice for electronics design, particularly if the developer has similar case studies and experience in their portfolio.

There are also electronic design companies that follow an hourly-fixed pricing model. Here, the company estimates the project’s scope and specifies the fixed upper range they will not exceed. The client will pay for the specific number of hours, and the company will work these out until the next payment. The hourly-fixed pricing model lets you adjust your project as needed. Unlike fixed-priced contracts, the estimation doesn’t include the risks, and in real-case scenarios, product development takes less time, thus costing you less money.

RELATED: How much do mechanical engineer services typically charge for rates & firms?

Before you enter an agreement, it is essential to specify the payment method, order, and currency that suits both parties. Advance payment is possible, or you can pay after completing the job using an online payment system, credit card, or bank transfer. If you plan to cooperate using an intermediary platform, you might want to follow the payment methods and conditions they offer.

6. Regional rates

The hourly rate of electronic device design companies is among the primary concerns of most clients. These rates may vary according to the company’s location; national living standards and the economy will determine the salary scale. As expected, the hourly rates of engineers in the US, Western, and Northern Europe are higher than those of specialists in developing countries. For instance, Ukraine and Russia’s top hardware development companies have hourly rates ranging between $25 and $99, while their competitors from the UK and the USA have hourly rates of $50 to $300. This is why remote engineers from Eastern European nations are often in demand.

RELATED: What are industrial design rates & costs at product design services firms?

It is also important to remember that rates may also differ depending on the skill level and experience of the engineer working on your project. But note that high rates are not always guaranteed high-quality results. You may end up working with a well-versed engineer who charges a cheap hourly rate or a poorly qualified developer who is only out to overcharge you. Keeping an eye on rates and taking note of the rest of the criteria in this list will help you enjoy an excellent quality-to-price ratio. These points will help you choose the right electronic design company for your needs.

7. Similar portfolio projects

Relevant experience can help cut your budget and speed up the process of development, which guarantees the compliance of project deliverables with your expectations and requirements. When looking for an electronic design company, don’t forget to check their portfolio to see if they have similar case studies. Some projects may require the development of both software and hardware.

RELATED: How do engineers evaluate different design ideas?

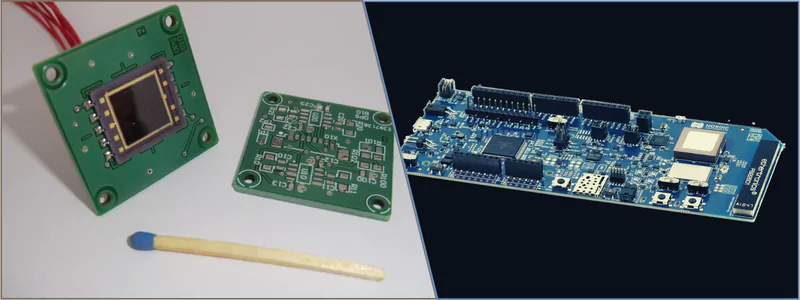

To develop a GPS tracking system, you will need PCB design services, schematics, frontend, and backend for a cloud platform, firmware, and a mobile app. It is most efficient and convenient to have the different project elements and parts developed by one team in one place. The best electronic design company can complete various tasks. For innovative home automation systems, for example, they can design electronics, write drivers, and create custom builds. For example, embedded engineers can build software and hardware for custom IP cameras for video streaming.

8. Workflow

Implementation of a project will be more efficient if there is an adequately organized workflow on both sides. Just be ready to designate someone who will coordinate actions and oversee the cooperation between the external and internal teams. An electronics design workflow, for instance, might include different phases, but a simplified electronic design workflow can ensure better results. After each subsequent stage, you can return to the earlier phases if problems arise. For instance, you might return to the component selection, PCB layout, or schematic design experts after the testing or review stages.

RELATED:10 Steps for product design services designing a prototype

There are also certain phases where your participation is needed. This is why it is vital to have clearly defined requirements right from the very first stage. A comprehensive specification will help you stick to your timeline and budget. The final document must include your electronic device’s primary functional requirements and core components. The engineering team will require the enclosure’s 3D model if you already have a clear vision of the mechanical design. You can at least provide the preferred PCB dimensions to make it fit the shape and size of the housing.

With the device’s functionality as the only exception, you must be familiar with your product idea and business requirements. Knowing these, the company can recommend the most appropriate approach and technology for the project design and implementation. Ensure you keep the electronic design company updated if any changes occur. Electronics design is a more complex process than software development, and any tweaks made take a more significant amount of time.

RELATED: Find the best prototype engineering firm services

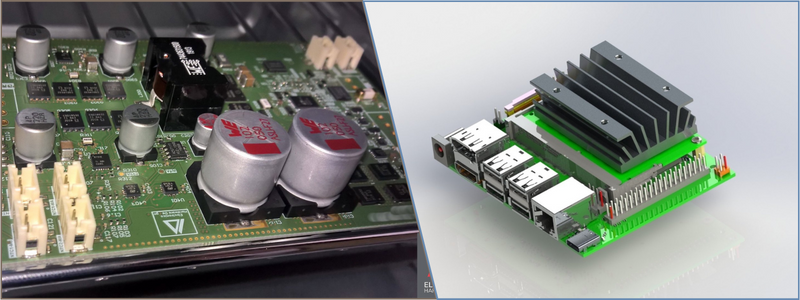

The design of complex electronic devices often involves multiple stages, including numerous iterations of PCB layout, prototype design engineering services, and routing. This may occur due to the difference between actual behavior and characteristics of the electronic parts and documentation. Following the initial PCB review, hardware engineers can decide if there is a need for a second iteration.

The engagement of your experts is essential in studying the intermediary results and testing the final deliverables. The company might require the connected equipment’s hardware for full-scale testing of electronic devices that are part of a more extensive system. For devices that require complex electronic enclosure design services, the company may also request that you send them the mechanical part. It is also a common practice to sign an NDA or non-disclosure agreement if you work with an outsourced electronic design company. It is the number one step in establishing trust between companies and clients.

RELATED: 3D models of electronic enclosures by freelancer designers on Cad Crowd

Aside from the NDA, clients are strongly recommended to sign a contract. Through this, you will be able to set out all the details of the cooperation, including the expected deliverables. The paperwork may take some time, but it can help specify the responsibilities of the parties and the collaboration framework. A reliable electronic design company will stipulate as much information as possible in the contract, which should include the following:

- Assumptions

- Confidentiality of the provided information

- Development environment and tools

- Cost Estimate with the structure of work breakdown

- Terms of payment

- Project deliverables

- Obligations and rights of the parties

- Project schedule and timeline

- Post-warranty and warranty support

9. Capabilities and expertise

After you have thoroughly studied all the details about the potential company on their official website, different business platforms, and professional network profiles, you can now schedule an introductory call and proceed with an interview with their engineering team. From the start, learning as much as possible about the electronic design company’s DFM design services, technical capabilities, and expertise is essential. You might ask them about the following while discussing your project:

RELATED: A product designer’s guide to design for manufacturability

* CAD or computer-aided software

The PCB layout and design tools may include P-CAD, KiCad, Cadence Allegro, EAGLE, or Altium Designer. Hardware developers might also use Quartus and Vivado for FPGA design. The best companies are well-versed with these tools. They will choose the one that offers an extensive range of possibilities and instruments for developing boards with different levels of complexity.

* Deliverables

After an electronics project is completed, your chosen company must give you all the necessary deliverables and output files, such as the schematic design and PCB files, 3D models, testing instructions, assembly design CAD drawings, Gerbers, and other files on PCB production.

RELATED: How to calculate total manufacturing costs for a new product

* Instruments and equipment

Your project development might also require different tools and devices, such as a signal generator, an oscilloscope, multimeters, a logic analyzer, and a laboratory power supply. It is essential to ensure that the company has all the necessary equipment.

* Technology platforms

The components of choice might vary depending on the project. Engineers may recommend different chips and modules, wireless and wired networks, or other options. It will help you understand the team’s level of awareness of the technology.

In addition, you can also get a preliminary bill of materials (BOM) before the start of the project. The company must be alert to the primary components’ lifecycles to ensure that these will not be discontinued and you will still get the necessary chips and other device components in the future.

RELATED: Top 9 design engineering tips for reducing manufacturing costs on new product designs & prototypes

* Validation and testing

They know how the company confirms its electronic design before and after production is essential. A good company must have a testing process with multiple stages, including internal reviews of the PCB layout and schematics. They should also use electrical rule checking (ERC), design rule checking (DRC), test points, and electronic circuit simulators in their validation process. They should also have quality assurance (QA) engineers to test the manufactured boards.

* PCB manufacturing

Don’t forget to ask a potential company where they develop PCBs and how they handle the process. The development team must also cooperate closely with a factory and provide them with necessary production files. The best electronic design company must have long-term relationships with different manufacturers and closely monitor the fabrication process. They will develop firmware for semi-automatic or automatic PCBA factory testing if necessary.

RELATED: How to price a new consumer electronic product for profit on hardware manufacturing cost

The bottom line

It is essential to consider several critical aspects when looking for the right company to help you make the most out of this cooperation.

The criteria for selection include but are not limited to the following:

- Service history and reputation

- Collaborative approach

- Communication and project management

- Intellectual property rights

- Payment

- Regional rates

- Similar portfolio projects

- Workflow

- Capabilities and expertise

Use this checklist to help you find the right electronic design company for your next outsourcing of new product engineering.

How Cad Crowd can assist

Not sure what you are looking for or how to begin? Check out some of our freelancers’ electrical engineering services, from PCB design, reverse engineering, electronic product design, product engineering, and many more. Contact us today and receive a quote from a friendly representative.

Thanks for the good blog