This comprehensive guide will teach you everything you need to learn about new product design, CAD design services, engineering, and prototype design your new idea for mass manufacturing. Now more than ever, it’s not enough for your product to just stand out from the rest of the crowd. You also have to make sure that it attracts crowds.Your product idea may be an exceptional one that will be a big hit once it reaches the market. You are confident that it will help you earn profits as soon as you launch it.

But how can you be so sure that your amazing product idea will turn out as well as you envisioned it? Will it really work? Or might someone else get their hands on it and beat you to its production? Bringing product ideas to life isn’t as easy as it seems. A quick search online may not give you the answers to all those questions running through your head.

Table of contents

- Part 1: Getting started—the early stages

- Part 2: Look into your competitors

- Part 3: Pricing your product

- Part 4: Preparing your idea for the market

- Part 5: The product development process

- Part 6: CAD and its role in product design

- Benefits of using CAD in the product design stage

- Part 7: The prototyping phase

- What is a prototype?

- Importance of prototyping at different product design stages

- Human interaction is the heart of prototyping

- How prototyping has changed through the years

- Why do people skip prototyping during product development?

- Is a prototype necessary for your product idea before the manufacturing process?

- Benefits of developing a prototype

- How to develop a prototype

- What is the most time- and cost-effective way of developing a professional prototype?

- Part 8: From prototyping to mass production

- Part 9: Packaging

- Part 10: Marketing

- Wrapping it up

- Need product design help?

Part 1: Getting started—the early stages

One of the most common misconceptions as far as product design is concerned is that it is difficult to take your product idea and transform it into a real-life item. This might be the case if you try dealing with everything on your own. But what people don’t realize is that it can be surprisingly easy if you work with or outsource to companies skilled in product development and design, instead of trying to learn every in and out of the whole process yourself. By taking advantage of the expertise, skills, and knowledge of other people, you can easily and quickly turn your product idea into a 3D design, produce a prototype, and manufacture it, sometimes getting everything done by the same company from start to finish.

Know your target audience

Before you get too far ahead of yourself, it is important to gauge whether or not your product is poised for success. Identifying your target customers should be the very first step you take when it comes to developing any type of product. You also need to conduct in-depth research into your ideal customers. If you do this, you will have a more solid idea about whether your product is going to be a hit or a flop the moment you launch it on the market.

There are several important questions you should try to answer, such as:

- Do your target customers have a family?

- Do your target customers have a discretionary income?

- Do they have the buying power in the household, or do they need to use another person’s credit card?

- Are they homeowners?

- How much is their annual income?

- What is the age of your target customers?

- What do your target customers do during their free time?

- Where do they love hanging out online?

- What are the common things they spend their money on?

Create a picture of your target customer in your head. Do they have any difficulties or problems in their lives? How can your product remedy or fix these issues? What gap will the product fill that means they cannot help but purchase it? What are the possible effects of your product on their lives? Can it make them more prestigious or confident in the eyes of other people? Can it make their life easier or happier, or free up more of their time to do things they love?

It is important that, as much as possible, you are really here instead of being imaginative. Remember that this stage is not just meant to validate your product idea. At the same time, it lays the groundwork for your future marketing success.

When you have answered all of the questions above, you will be able to determine whether the market really needs the product that you are planning to make. If you don’t have the slightest idea where to begin, you can try using Google Trends or Google Keyword Planner to determine whether people are looking for products online that might be similar to your idea and in what specific quantities.

One important tip to remember is that market need is extremely critical if your goal is to earn profits from your product. If there is zero demand, you will only end up wasting a lot of money and time developing a product that no one is even interested in. It is also equally important that you listen to and look for potential ambassadors for your brand. This is something you can do in person, or you can try finding out where they often spend their time online, whether in forums or in other hangouts.

Make sure that you keep your ears open to their problems, their needs, and the things they say. If you are lucky, they might even give you some helpful tips on how to design your website to make it more enticing to the eyes of customers. You will only set up yourself for a painful failure if you don’t do this. It is all too easy to assume that people need your product, but you will never know unless you take this step.

RELATED: 10 Tips for Good Product Design

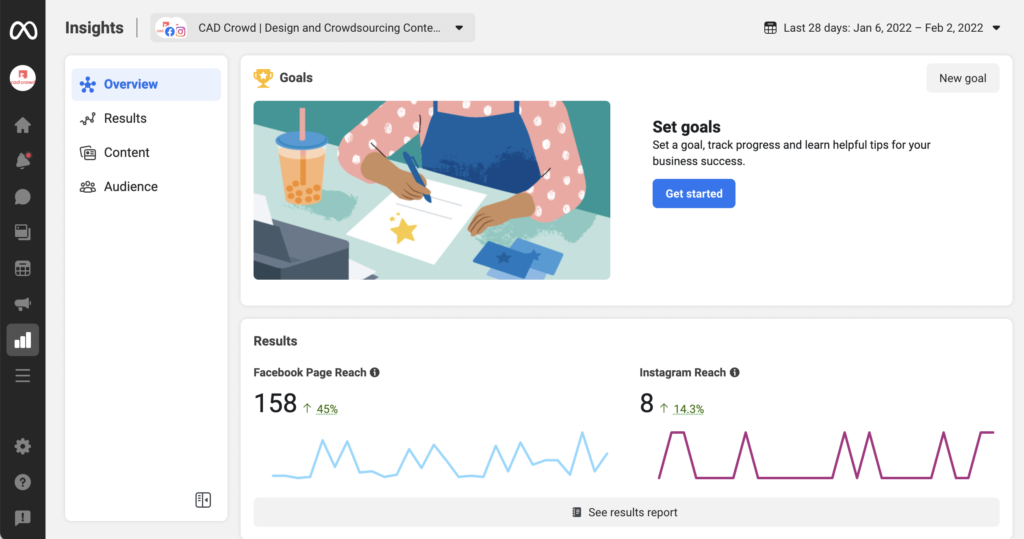

Use Facebook’s Audience Insights tool to conduct your research

If you are not sure about who the target demographic of your product should be, Facebook has a little-known tool that can come in handy. When you know your potential competitors, and their Facebook fan page is reasonably large, head over to Facebook’s Audience Insights tool. This can help you understand your potential customers through understanding your competitors’ audience. If you have no idea who your competitors are, or they don’t have a Facebook page in the Audience Insights tool, the next best thing you can do is to pick an area of interest.

Here are the steps you can follow to get the best results out of this exceptional tool:

- Select your audience. The most recommended here is “Everyone on Facebook.”

- In the left-hand column, pick the country you want to get results for. If you are not sure, you can just remove all the countries so that you can get the metrics for the whole world.

- You can also enter the gender and age range if you already have a general idea of your prospective customers.

- Prepare to get some helpful insights.

- You can now begin to add interests. However, remember that when you add more, your demographic data will also be more watered down. You can try adding them one by one to observe any changes in the demographics.

- You will see the following after you enter a certain interest on the Demographics tab:

- The number of active people around the topic every month

- The kind of life they have

- Their achieved level of education

- Their relationship status

- Whether your audience is mainly female or male and their age bracket

- Click on the Likes tab to see the following:

- The Facebook pages that they like as well as the number of people who frequent those pages

- Categories that your potential audience finds interesting.

Make sure you know your audience by researching where they often spend their time, what specific pages and categories they like, and other questions you may have. You can also go to these pages yourself to see how they are being monetized. This can help you with your research on the designs, colors, or relevant products that have already proven to be in demand among your potential audience. Make sure that you also search for the promotional status updates that have plenty of comments, likes, and shares. One more thing that makes Audience Insights such an amazing tool is that not only does it give you information about your audience demographics, it also gives you insights into what you have to know in order to develop and market your product.

In the left-hand column of the Advanced settings, you will find plenty of options to help you identify your ideal target customers. These include their purchasing behaviors on Facebook; their relationship status; their net worth or annual income; whether they have one child, are expecting, or have many children; whether they have recently been through some major event in their life; and the specific kinds of devices they own and use. The sky is pretty much the limit here because of all the information you can get. All it requires is for you to take time to try the different available options in the tool.

RELATED: How to Design a Product People Want: Designing for the Consumer

Part 2: Look into your competitors

After identifying your target audience, the next important thing to do is conduct market research to find out what your competitors are doing. Does the market already have similar products? How many pieces have already been sold so far? Is the demand high or are the numbers dwindling?

Once again, there are several questions you need to answer here:

- What makes your product a better option?

- What will entice your customers to pick your product instead of the existing product?

- What is the selling price of a similar product available on the market?

- What price should you set for your product to earn a reasonable profit?

- Will the price be less or more expensive than that of existing, similar products?

- What will convince a customer to spend more to buy your product?

- What are the possible additional benefits of your idea?

It will be of benefit to conduct thorough market research, as long as you do not allow it to prevent you from proceeding with your project. It will also be smart to know the sales forecast, as this will tell you what profit you can expect to make. For example, if you are anticipating selling 100,000 units during your first year, it is important that you know the cost of every part in order to know how much your expected profits are going to be.

After you are done with the research, the next step is to look for and work with a product development company. The experts can help you determine in advance the possible costs of rough design, prototyping, and manufacturing, well before you spend any cash on the project. With the information you acquire from your research, you will be able to judge whether the product and the project are worth investing in and whether they are going to be financially viable or not.

Working with a company that has long years of experience in product development under their belt also means that they can determine any hidden costs you might not know about. This is especially crucial if you are testing the waters of product development for the first time. Hidden costs can significantly increase the overall production budget, so it is better for you to know sooner rather than later how much it will cost you to complete the project, and an experienced company can help you with that.

Is your product design unique?

What will you do if there are no competitors in the market that have the same products like the one you are producing? While the absence of competition might seem like a good thing, the truth is that it is exactly the opposite. In fact, you might need to feel a bit worried at this point. Many product makers are interested in knowing if they have a unique product or if it bears any similarity to an already existing product. While it is not ethical to rip off other people’s ideas, if the market doesn’t have any precedent for what you plan to develop, you might be setting up yourself for a big failure.

If you have an idea that is too revolutionary and unique, how will consumers know that they need this kind of product? Who are you going to market your product to? How can you convince people that buying this product can make their lives better unless you have a large amount of startup capital?

There are some rare instances when a completely new and unique product idea turns out to be a huge hit. However, unless you are making something as groundbreaking as the iPod or iPhone, it might be next to impossible to develop a one-of-a-kind product that no one before you has ever conceptualized. Also, don’t forget that it will be so much easier and simpler to make a unique product, market, and successfully distribute it if you have the same fan loyalty and backing as big brands like Apple Inc., not to mention that they have larger-than-life capital to fund their advanced products.

Having said that, there is nothing wrong with your product idea being somewhat similar to existing products provided that it is still substantially different. For instance, your product idea may have some additional features that are not found in the current product. But there is a bit of a grey area as to how different the design of your product should be. This is why it is important for you to talk to a patent lawyer in order to double-check that you don’t cross any unwanted lines with an existing patent. However, it is also said that there are plenty of ideas that get patented only to be left to rot just because no one else has been able to make them.

Working with a patent lawyer will help you save a lot of money, time, and heartache, as it stops you in your tracks before you breach someone else’s intellectual property rights by accident by running with a product idea that has a significant similarity to an existing patent. The simple act of conducting a patent search online is usually not enough to give you the assurance that you are in the clear.

Will your product make you rich?

Aspiring product developers and entrepreneurs have an ideal lifestyle that they have always dreamed of—spending a relaxing time under the sun by the beach as your product sells like hotcakes, and you earn money even while you are sound asleep. Unfortunately, when you hear about people who live this kind of life, you mostly only see the results, but not all the hard work that has been done for the past few weeks, months, or even years just to reach that point.

There is lots of work that goes into product development and marketing until it becomes big enough to run on its own, or another company buys it out. Passive income is mostly a myth or requires plenty of work from the get-go. More often than not, it requires years for overnight successes to materialize in actuality. Having said that, it is important to proceed to the next stage so you can position yourself better for success.

RELATED: 10 Simple Products That Made Millions for Inventors

Part 3: Pricing your product

As long as you have done enough research in the previous step, you will be able to determine whether your product has a demand in the market and whether anyone is willing to spend money on what you plan to make. It is also important to know the price points of similar products. Although there are several methods to increase the price of your product and still attract people who will buy it, and going for the cheapest price is not a wise decision, you can use the price of similar products in the market to determine the price you will set. This will be a fairly good indicator of what buyers in your market are willing to pay for a similar product at the moment.

If there is no one who is willing to spend their money on your product, there is a big chance that you will find yourself broke sooner rather than later, that is, unless you are backed by a huge amount of capital. There are several exceptions in which profit is not always a big issue, such as in the case of charities and nonprofits.

There are some company owners who have developed products that they give out for free. There is no reason for them not to do so because they have the financial resources to do it. However, if you are just getting started, you might not have the kind of capital that you can just throw around. This gives you all the more reason to learn how to price your product properly. Aside from checking the offerings of your competitors, there are some other ways for you to determine the most suitable price for your product, and simple math is all you need to do it.

How to calculate the best price for your product

To determine the most suitable price for your product, you will have to consider the design costs, costs of prototyping, costs of manufacturing, shipping costs, costs of marketing, and distribution costs. You need to add these up then add approximately 25% to 50% as a safety net in the event that you meet with unexpected costs and a contingency plan is necessary. In some cases, consulting with a mechanical engineering firm is a worthwhile investment, since design optimization can often reduce manufacturing costs by 30% and 70%.

You then divide the total by the overall number of units that you plan to produce. The resulting total will be the price that it will cost you in order to develop one unit. The next step is to identify what you can realistically and comfortably sell a single unit for. Your profit will then be the difference between the cost of sale and the cost of production. If you are aware of how much you will need to live on comfortably every month, it will now be easy for you to determine the number of units that you will have to sell every month for you to meet or even exceed your costs of living and, at the same time, to set both your product and yourself for success in the near future.

Part 4: Preparing your idea for the market

So, you have finally finished doing your research, you have determined your target audience, you are familiar with your competitors, and you are confident that your product is going to be a hit and financially viable at the same time. At this point, hopefully, your product idea will be on much more solid ground and will be more definite in your mind. However, there is a chance that there are still several things you are not yet sure of as you plan the finishing touches of your idea.

These things can include the following:

- You are not an engineer or designer, so what is the best way of addressing design-related challenges?

- Who defines perfection? Is it you or your end user?

- There is a thing called MVP or minimum viable product. What does it mean, and do you even need one?

- Should function precede form? Is practicality or beauty better, or are these two both important?

- Do you need to add features that you think your product needs, or that your target audience thinks it needs?

- Should you choose a complex or simple design for your product?

To ensure that you will be better positioned for success, once again, pricing your product is the most important thing. There are three things you can use here:

- Rely on your intuition, which is free.

- Perform market surveys and research, including the costs involved, that is, either time or money, depending on whether you will be the one doing it.

- Work with a company who will do the research for you, which might be a bit expensive.

In the event that you have enough budget, you can even come up with several versions of the product for you to determine which one will sell best. Think of the different versions of the iPhone, for instance. It is also important for your product to be perfect for your ideal user as well as for yourself. It is essential that you use your market research to your advantage now that you have already done it. Referring to your research results will be a wiser decision than thinking that you know best, even if this might feel very tempting to do at times.

As expected, in a world of ideal products, some things are just impossible to design while others are beyond your ability or capacity to do. It is yet another area where it can come in very handy if you leverage the knowledge of a professional industrial design company. If there are any parts of the product that are not physically sound or are not possible to develop, the experts will explain to you the reason why. They will also present you with some alternative suggestions accordingly.

However, these days, there are many instances when almost anything and everything is possible to make, particularly because of the different advancements in the technology of 3D printing. As far as beauty and form are concerned, many people usually go for a product that looks nicer instead of a product that is more practically shaped or developed. This is why is best if you can strike that perfect balance between aesthetics and functionality. Just because the shape of the product is rectangular doesn’t necessarily mean that it will not look good if it is made with more rounded corners, for example.

There is also no need to worry if you are not an engineer or designer. You don’t have to be either of these two in order to develop an outstanding product. Should you encounter challenges in the design along the way, the main feature of your product will always be the first and most important thing you need to focus on. Always develop your design with this specific feature as your primary focus. In the event that something additional turns into a challenge or issue along the way, you can get rid of it to maintain the core focus of your product. It is also important to know that it is possible to have your product released in stages. This is where the concept of a minimum viable product can come in handy.

An MVP, or minimum viable product, includes only those features that the product must have for it to be launched on the market to determine the demand for it. For instance, the product might do well with just the off and on switch to start with. The producer can then later on add other features such as pause and timer to the same product for a much higher price. The additional features might not really be necessary for selling the product, but some consumers might still find them desirable or useful.

Developing a minimum viable product helps a lot in reducing overwhelm, since it eliminates the need for you to think of all the things that a user might demand in the first version of your product. An MVP is often faster and more affordable to design and manufacture because it has fewer features. It means that you can launch your product on the market much sooner and begin making sales right away.

An MVP will also let you test the waters of the process of selling and producing your product, instead of taking a dive right away into the deep end only to discover that it is too deep for you, and finding you have no idea how to swim in it in the first place.

Protecting your product idea

By this time, you are already on the right track to turning your product idea into reality. You are also envisioning it materializing right before your eyes. However, you are also worried that other people will try to steal your product idea. The good news is that there are lots of things you can do to make sure that this doesn’t happen, or at least reduce the risk. Unfortunately, it might not be possible to stop products from getting copied in some countries these days.

To get started, make sure that you choose to work with a design company that will be more than happy and willing to sign an NDA, or Non-Disclosure Agreement. At this point, the company will most probably have signed hundreds or even thousands of NDAs already. If you don’t have an NDA, the company will likely have a standard one that you can also use. This Non-Disclosure Agreement is basically a type of agreement that states that the design company is not going to steal or share your product idea anywhere or with anyone. The moment they do, they will put themselves at risk of getting sued and will have to pay some hefty fees for any damages incurred. It is best to look somewhere else if the freelancer or company you are planning to work with doesn’t want to sign an NDA.

Any product manufacturing or development company worth its salt will not even think of stealing your product idea at all. This is not just unprofessional and an instant killer of reputation and credibility. A reliable company that specializes in product development will have a genuine care for the process of product creation itself and would have a real passion for helping people introduce new products to the market.

One more way of keeping your product ideas protected is through the use of patents. A patent is a completely different topic on its own and going into it would require too much detail. However, there are several basic things for you to keep in mind. A patent is fundamentally a license that gives you the exclusive right, for a certain period of time, to sell, use, or make an invention. If ever someone has infringed on your patent, they will be obliged to pay a large sum of money for damages, not just to the owner of the patent but also to the legal system.

Although there are some people who file for a patent even before they make a prototype of the product idea, it is not always necessary. While a patent is not that expensive, it still costs money. It might also be necessary for you to work with a patent attorney, who can help you organize one. Whether you get a patent pre-prototype or not will really depend on what specific stage you are at or how far you plan to go with your product idea. It is possible that you simply want to develop a prototype to test things first and determine if your idea will work or not. If this is the case, there might be no need for you to have your idea protected just yet. What if the idea doesn’t work at all? If this happens, you will end up having spent your money and time for nothing.

To learn more about patents, it is best to go directly to the source and talk to a patent lawyer. The easiest and fastest way to find one near you is to conduct a Google search and use the keywords “patent lawyer” together with your state or city. You can then go and talk to them in person. You will be able to reduce a significant amount of the process of learning and research if you talk to someone who knows the ins and outs of the legalities and can offer you some guidance and assistance directly.

What happens if your product gets ripped off, though? One of the harsh realities in the market is that it is not easy to stop anything from getting ripped off overseas. In order to reduce this risk, it is best to work only with a trustworthy company, like the specific design company that prototyped your product idea in the first place. This is even more important if the company has contacts or manufacturing facilities based overseas.

There might also be some risks involved if you try to look for a manufacturer by yourself. However, if you invest in a decent and solid marketing strategy, this can also work in your favor. Even if the product gets ripped off, as long as you sell and market your product much better than the counterfeit ones, you might still be able to reduce the impact on your profits.

Getting your product idea out of your head

Believe it or not, it only takes five minutes to produce a simple sketch to give to your chosen 3D design company in order to get started with the process of turning your idea into reality. If you feel as though your idea for the product is not adequately formed, you might want to start talking to someone who knows and is familiar with every step necessary in the process of product development. A professional can also serve as your guide as you navigate the different stages of the process.

It is ideal if the person or company you work with not only has the knowledge and skills but can also work through the whole process and explain to you in detail all the things you need to know. You are surely familiar with the old adage that if you don’t understand something, you will never be able to explain it simply and quickly. The same rule is applicable here.

It is best to stay away from someone who has recently purchased a 3D printer or a member of the family who has only spent some time tinkering on their own inventions in the basement. Always remember that there is a big difference between career and hobby inventors, even though the two may overlap every now and then. You will also be able to avoid wasting your time if you go to someone who works in product development and design as a source of living.

Part 5: The product development process

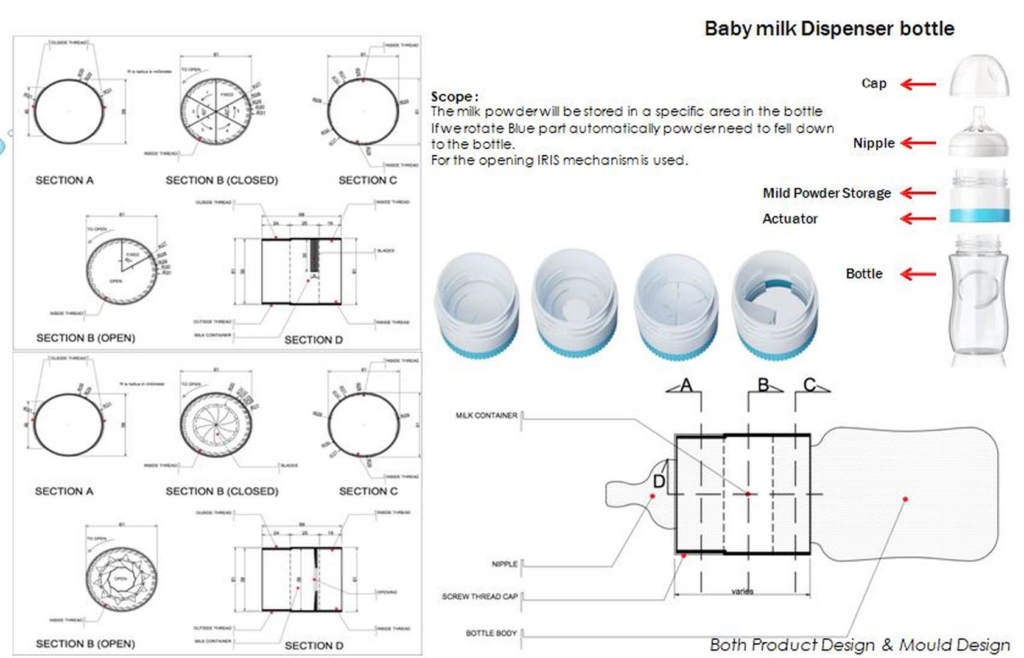

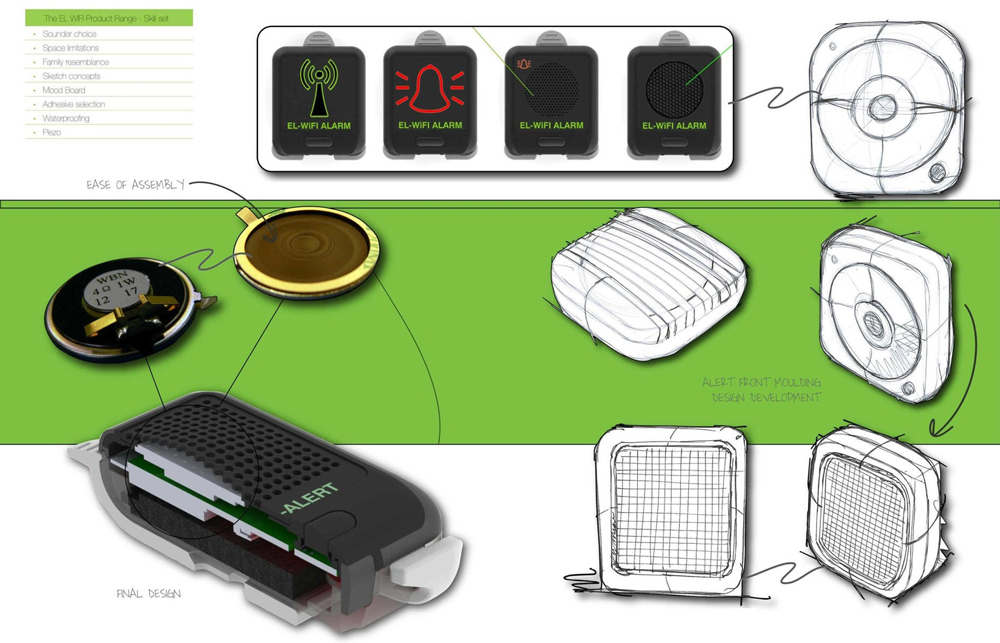

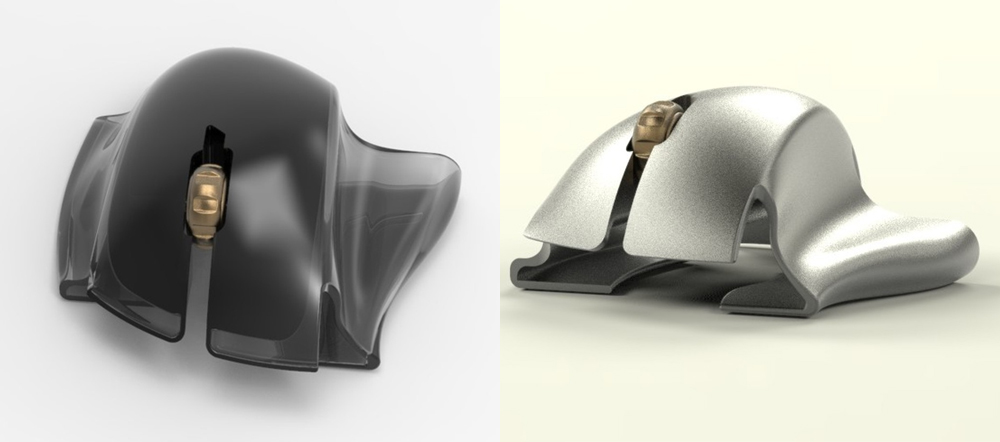

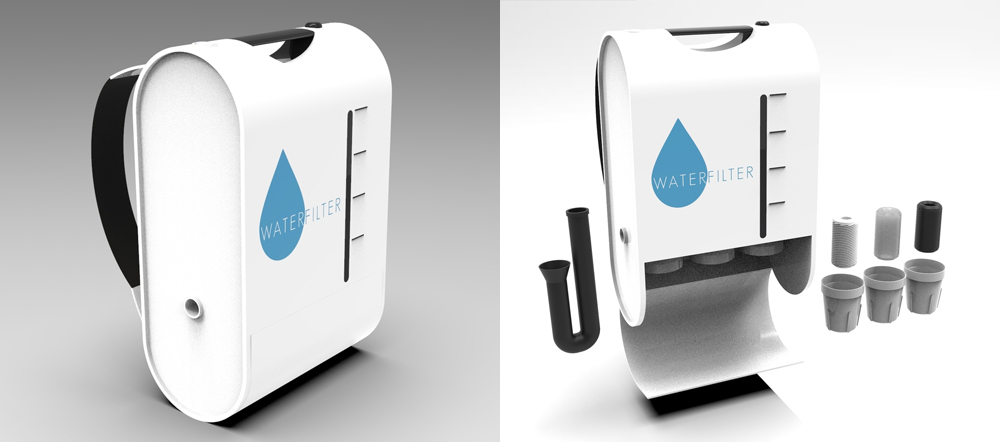

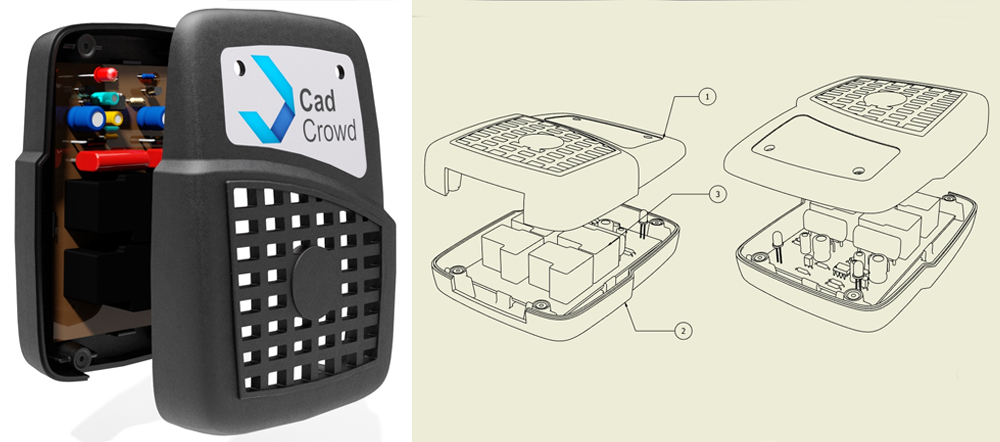

You are now finally ready to embark on the actual process of product development. The product begins with the design idea for your product and the 3D product renderings. Your chosen design company can come up with 3D visualizations of the product. These visualizations are photo-realistic enough to show what the product is going to look like in the environment where it is meant to be used. A good example is how a sink or faucet will look in the bathroom.

It is a must that you talk to the design company to confirm who will own the 3D files once they are done. There are some companies that don’t provide the CAD files without additional fees. However, a reliable design company knows and understands right from the get-go that you will be keen to own the design 100 percent. Once the CAD files are made, your idea will then go into the prototyping stage from there. Here, the renderings are going to be transformed into an initial version of the product that you can touch, hold, and test for potential issues.

Several revisions might be necessary before you get the final design of the product that will be ready to go to the manufacturing stage. A dependable manufacturing company will give you a walkthrough of all the steps involved. They can also handle every aspect of this process in-house. The costs involved in the different stages of the process may differ based on the brief. However, as a general rule of thumb, the design must never be too much. It can be just several hundred dollars, which depends on the simplicity of the part or parts.

The cost of developing a prototype from the design is often similar to or a bit more than the design stage, and the manufacturing phase is going to be the most expensive aspect of the process. For instance, if your product needs injection molding, just the molds themselves will often cost from $2,000 up to $5,000 for the majority of design partners. The price per part will also depend on the order quantity and the material required. It will be very expensive to produce 100 parts but, because of the economies of scale, 100,000 units of the same part will likely cost lower than $1 each.

Going about the initial stages with a professional design company

You can begin your search for a company to work with by reaching out to a design company whose specialty is product design. It is also ideal if the company has worked on projects in the past that bear some similarities to your idea. You will find it beneficial to hire a design company that will not just carry out the 3D CAD renderings and design, but also the 3D printing and prototyping. This will reduce the chance that your vision will get lost in translation by transferring the work to another company after the completion of the design phase.

The specific design company that you will work with will preferably design every part, one by one, to ensure proper printing, using their industrial-grade 3D printers. Unfortunately, what usually happens is that people spend long hours trying to learn and master 3D rendering. Some also hire freelancers, who will be mocking their designs, and may either try to produce the 3D printed prototypes at their own home or with a different company that only uses home-grade 3D printers.

In most cases, the outcome of this particular approach is that the parts will not come out properly. This is the reason why it is always best to ask about the type of 3D printers accessible to the design company and to hire their services for all stages of the process as long as they have the capacity or ability to do so. As a bonus, it is also best if the company you hire to handle the design and prototyping can also deal with the manufacturing process for you, or can give you a referral to a contact they trust to be able to do it well. For you to communicate the product idea you have in mind to the design company, most of the time, all you need to get a quote are photos of similar products or basic sketches. Pen and paper are usually more than enough if you are not well-versed in using basic CAD software.

As stated earlier, there is no need for you to be an artist just to design your product and develop it. There are a lot of people who are often worried that they don’t have the skills to draw well enough for them to express the idea they have. However, the truth is that it is never an issue at all. In fact, as long as you know how to draw circles and squares, you are already good to go. You can simply draw some rough shapes, probably some rough dimensions. These are sufficient in conveying your idea. Never underestimate or doubt your ability to sketch, because this is more than enough.

It is so much better to submit any drawing than not to have a drawing at all. Also, since these design companies have already worked on numerous projects, they will understand your product idea from your submitted rough drawing without any issue at all. The initial sketch you have is enough for them to determine the price. Nothing good will come out of spending long hours trying to put together all the information you can get, only to discover that designing your idea will cost more than your budget allows. You can just take five minutes to draw a quick rough sketch and get a photo of a similar product.

Once you are done with the rough sketch, use your phone to snap a photo of it and send it to the company to get a quote. You can receive this quote in just a matter of minutes if you are working with the right company. It is usually a red flag if it takes the design company days or even weeks to get back to you with a quote. Since the company designs hundreds of ideas and parts, it should be easy and simple enough for them to go through your photos and sketches and determine the cost of the design in a little less than an hour.

It is also perfectly fine if you don’t have a large budget to begin with. It should be free to get a quote for your design, so be sure to ask for it at the outset. This will let you how much money you have to set aside for making the design, engineering services, and the prototype. After you get your hands on the 3D design files and the prototype, it is now possible for you to use these to attract attention and capture the interest of investors who might be willing to pay for the costs of manufacturing. At this point, before you introduce your design to the public, you might want to look into getting a patent for it to keep your idea protected.

One important tip to remember is that when you are submitting the sketch to get a quote, it will be best if you can get a fixed price quote for designing your project. A design company that charges hourly rates might have no end or boundary to their fees, making your project blow your budget out of proportion before you even realize it. You will have the assurance that your budget will always remain the same if you can get a fixed price.

Validating the technicalities

There are times when some people hold back because they are unsure if they have a technically sound product. There are likely a lot of ideas that can be introduced in the market now, but they never see the light of day because people feel as if they don’t have the industrial, engineering, or technical background to determine whether or not their product is going to work in the real world.

Asking will always be the easiest and best thing you can do here. Discuss your idea with your chosen design company. More than anyone, the design company can guide you and let you know what will work and what won’t. They can also point out flaws with the design. During the process of developing the CAD files, the company should also look to get rid of any issues in the design that they think won’t work at all. If there are lots of moving parts in your product, you will have to explain to your design company what your product is going to do. The company will then design all the vital parts and pieces for it to function properly.

A professional designer, engineer, or machinist will also identify the design problems that might increase the costs further. Their job entails designing your product in the most cost-effective way. It is fundamental and is among the most critical areas of the method of design. If the design company is legitimate, you won’t have to worry about them telling you that your product is going to work even if it won’t.

It will be in their best interests to be honest with you, since doing otherwise will only result in wasted time, failed projects, and bad reputations. It is not economically sound for them to do so. If you are still not sure, you can take your design to the prototyping phase in the least expensive way possible. This gives you a chance to test your design after completion, through a functioning prototype, with no need to spend a lot of money and resources on manufacturing or making molds.

Who should you work with? A standalone professional or a company?

Before you proceed to prototyping, one more thing you have to think about is whether to bring in any outside freelancers to work on the project. Most of the time, it is better to hire a company than a freelancer. Established companies have long years of experience under their belt and can offer the following:

- Better hardware, or access to it if this is not on the site

- Better software

- Credit card processing

- More access to other useful resources

- More experience and knowledge

- More industry connections

- Refund policies

- And so much more.

However, as the world of freelancing gets better, and with more talented freelancers joining the crowd, working with one can assure you of quality results that can be on par with what reputed companies can offer. When you work with a trusted freelancer from the design stage to prototyping, and finally manufacturing, you will be able to build and develop on the relationship and trust that you have been forming with them at every phase of the project.

After the process is completed, you will not just get an amazing product. At the same time, you can also benefit from a solid working relationship, anchored on the trust you have built, and which you can take advantage of for future projects. Working with the right freelancer also means that the entire process of designing, prototyping, and finally manufacturing could be finished in-house. Also, if you choose to hire several freelancers, there will be more skilled people working on the same project. This can lead to more brains working together, which will ensure that the final product you get is exactly as you envisioned it to be.

When you work with several freelancers who oversee specific stages of the process of product development, they can also advise you better on the different areas of your project, instead of just a single specific field. Professional and skilled freelancers can give you helpful advice, not just on your CAD design but also on the materials suitable for your product. This will save you effort and time in having to research the different processes and materials.

One good example is if you want to use hard plastic for your product, but the freelancer has recommended that it would be better to use polycarbonate, ABS, or another material while listing out the advantages of each. It means that instead of trying to make every single decision all by yourself, the freelancer you hire will be able to identify the most suitable material or present several available options to help you pick the best one to suit your budget and design requirements.

Tips to find the best freelancer or company to hire

You can easily determine whether a prospective company will be great to work with if they ask you plenty of questions regarding your project and they show interest in the ideas you have. The company must also be responsive enough and must know what exactly you are searching for when it comes to the functionality of the specific parts you plan to make. For instance, if a certain part must be flexible, the company should ask you how flexible you want it to be for them to determine the best material to use to make it.

Meanwhile, if you plan to work with a freelancer instead, there are several important things you should do to ensure that you are protected from risk. During your search for a freelancer, make sure that you always check their credentials, and ask for sample work and photos of other products they have designed in the past. A short phone call will also give you a clear idea of whether or not they really know what they are talking about.

Think of it this way. Your car needs new brakes. When you call one mechanic, they just give you a rough estimate of the price but are unsure if they can get the parts. They then tell you that they still need to check whether it will be possible or not. Meanwhile, the second mechanic you call tells you that it will be an easy fix and that if you bring your car to their shop, they can change your brakes in an hour or so for a much cheaper price than the first mechanic told you.

You will most probably choose the second mechanic because it is obvious that they are knowledgeable about what they are doing, they sound more trustworthy and reputable and are also more professional. Consider it as a red flag if the freelancer you have hired doesn’t respond or takes a very long time to present you with something to check. Alarm bells should also start to ring if they send you work that looks amateurish. The designer must be able to send a professional design for you to review in a matter of days, no matter how rough the sketch is to begin with.

Part 6: CAD and its role in product design

The development of new products is among the primary drivers of today’s consumer society. The products are made through the product design process. Therefore, product design basically refers to everything done, from the initial idea to the time that the new product ends up in the hands or on the screen of the consumer.

For this reason, it is understandable that product design involves numerous, complex activities. This includes the identification of a problem that the consumer faces and developing a solution for it, as well as all aspects of developing the new product, from the processes used to develop it, to the materials used, the style, the mechanical architecture, and others. Simply put, this is all about developing a product that functions and works as it should.

Therefore, it is not a surprise that product design and CAD go hand in hand. CAD software provides solutions that simplify the entire design process. It streamlines workflows, reduces the need for physical prototypes, and allows designers to save revision histories on top of many other benefits. Read on below to learn how CAD has helped in changing the world of product design.

Benefits of using CAD in the product design stage

Even though CAD now plays a big role in various industries, this is notably revolutionary in the product design field. The shift from drafting using pencils and paper to developing the designs on the screen dramatically reduced waste and improved efficiency. However, this only marks the beginning. The use of CAD in product design offers many other benefits, most of which have had a substantial effect on the industry.

Accuracy

Increased accuracy is among the most obvious advantages of using CAD. After all, no matter how accurate a pencil and paper drawing or sketch might be, there will still be several small errors. On the other hand, CAD software is developed around working with the vector images. Mathematical coordinates define the vector images contrary to raster images and physical drawings. Vector images also contain objects and lines instead of pixels. All of these result in vector images that provide extremely accurate detail.

The mathematically defined nature of vector images is a specific benefit in the product design field as it eliminates the problem of drawing to scale. After creating your design to a certain scale in the CAD software, that scale can then be changed with no need to lose any accuracy and preserve the image’s definition at the same time.

Thanks to CAD software, designers find it easier to produce accurate drawings with the use of tools like grid snapping. This involves drawing objects and lines in a rectangular grid that allows the designer to designate the specific area, volume, and length of their design. It also means that designers can maintain the intended relation between various objects and lines.

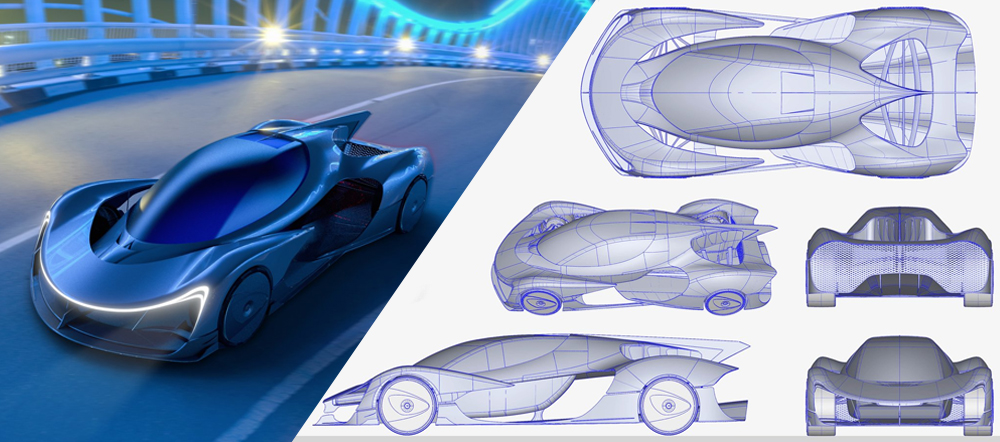

From 2D to 3D

Displaying 3D objects on 2D surfaces is never easy, and there are limitations on being able to do so with traditional paper sketches. Sadly, in the product design field, it is imperative to view objects in three dimensions as it guarantees that the design will meet the needs of the consumer as well as the specifications of their aesthetics. All of this has become easier with the introduction of CAD software. 3D modeling software enables designers to design using three dimensions right from the beginning and extend existing 2D objects to the Z-axis.

Designers can enjoy some major advantages when designing in 3D, including the ability to create a virtual object that looks like the finished product. 3D CAD software typically makes it possible to view a virtual model from several angles, with the ability to pan around the model. It is also possible to view a product’s internal workings by changing the opacity of the outer layers.

The ability to see the final product in virtual space not only gives the client a more immersive and realistic experience, but also allows the designer to identify and address any issues existing in the design. Prior to the birth of 3D CAD software, most faults were left unnoticed until the design got to the prototyping phase. Thanks to 3D CAD, product designers can easily fix design issues, save money, and work in a more efficient way.

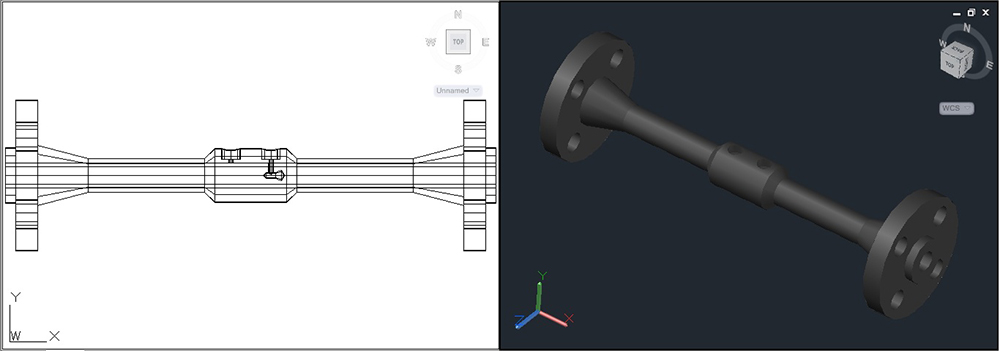

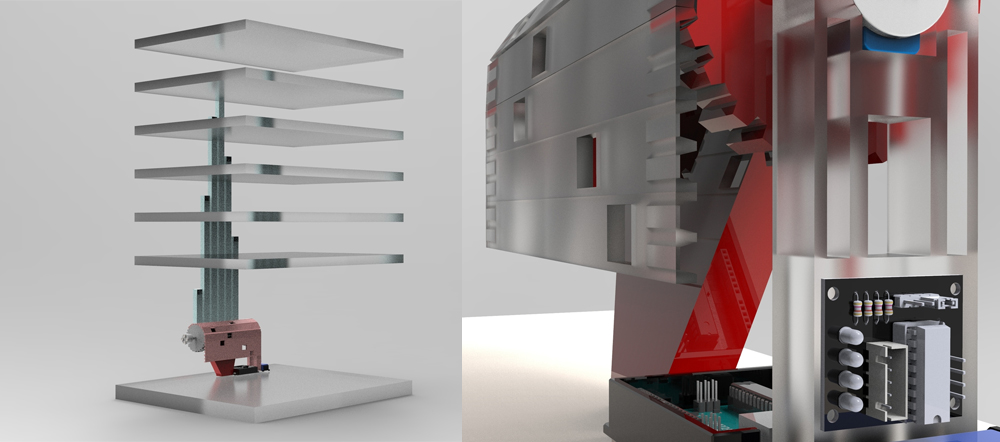

Designs are more ready for production

As stated above, using 3D CAD software helps designers create highly realistic and accurate virtual renderings of a design, reducing the need for several prototypes and speeding up the time between the initial concept and the end product. But the latest advancements in CAD software have reduced that time even further. One of the reasons for this is the fact that today’s CAD software offers comprehensive information on the way materials and parts will behave under specific conditions. For instance, product designers are now able to conduct tests like finite element analysis, computation fluid dynamics, and stress analysis.

These tests reveal the effects of various forces on the product, which effectively means that the CAD design can function as a virtual prototype. The designs made in CAD software also have another benefit because, as vector images, they can be directly converted into G-code, which can be used by different types of CNC machines. This has also paved the way for several new techniques of manufacturing, such as new CNC innovations, multicolor and multi-material 3D printing. These techniques mean that it is now possible to go directly from the virtual model to the finished product.

Revisions and remakes made possible

Back in the days before CAD was introduced, if you wanted to come up with another version of a product using an existing design, you had to manually trace over the current design, or come up with a new sketch while hoping that there weren’t a lot of differences with the original one. If the design had any errors while making it, it was a matter of using the eraser or even starting from scratch yet again. Obviously, this situation is not an ideal one.

The good news is that CAD was able to reduce if not erase these issues. When the product designer uses CAD and an error is made during the process of designing, all it often takes to remove it is to click Undo. It is also easier to make more substantive edits and, significantly, every object in the design can be individually edited with no need to change any of the lines or objects to which it is attached. Also, fixing even the most serious mistakes can be as easy as opening an earlier copy of your document, made possible because of the file’s revision history.

CAD has also made the process easier when it comes to developing another version of a design, for instance changing swatches or materials. And colors can usually be changed in a matter of clicks. It has also become simple to open an existing design, tweak a few features, and come up with something new, saving the designer from having to start from the beginning. This means that is it faster and easier than ever to develop customized designs that will meet the desires or needs of the customer or client.

Complete lifecycle of the product

Aside from the creation of extremely accurate product designs, the use of CAD software also aims to make up the different stages of the lifecycle of the product. It goes beyond the product design’s traditional goals, developing a product that meets the specifications and needs of the client. It also includes everything from manufacturing, to the usable life of the product, to its recycling and disposal.

Every aspect of the lifecycle of the product is considered. One piece of software, for instance, may allow designers to develop bespoke tools to create a certain product. Meanwhile, another program can allow them to select the most efficient factory layout for the product to be manufactured. The rest of the programs can then focus on what will happen once the usable life of the product comes to an end. This means that the product design field is becoming broader than it was before the era of CAD.

Part 7: The prototyping phase

If there is one thing that hasn’t changed in all these years, it’s how important it is to fabricate physical prototypes. During the late 90s, with the introduction of 3D CAD, some people were clamoring to put an end to the need for prototypes. This is because CAD allows users to see, review, and adjust every detail. The new software would help reduce risk, save time, and get rid of expensive and time-consuming prototypes.

However, this didn’t happen. In fact, 3D CAD didn’t eradicate the need to prototype. Instead, it allowed professionals to prototype sooner and maybe even more often. When 3D printing was introduced to the market, this further escalated prototyping. What is a prototype in the first place? What makes it valuable to design development as well as the business aspect of product design?

What is a prototype?

A prototype is defined as an example that will serve as the basis for future models. Through prototyping, designers are given the chance to research new alternatives as well as test the current design to check the functionality of the product before its production. Prototypes are developed to various levels for numerous reasons. This might be to verify, evaluate, demonstrate, or explore.

Importance of prototyping at different product design stages

There are different types of prototypes and there are also several good reasons why prototyping is important. During the early stages of product development, a prototype can be considered as a form of mock-up. It may be crude, and is usually made out of soft foam, foam core, cardboard, or any other material available. The purpose of this prototype is to uncover opportunities, explore ideas, and basically try a design out in physical form. It is common to see designers who go back and forth between mocking up and sketching an idea. After all, a prototype is fundamentally a 3D version of a sketch, making it a very effective tool for communicating and learning.

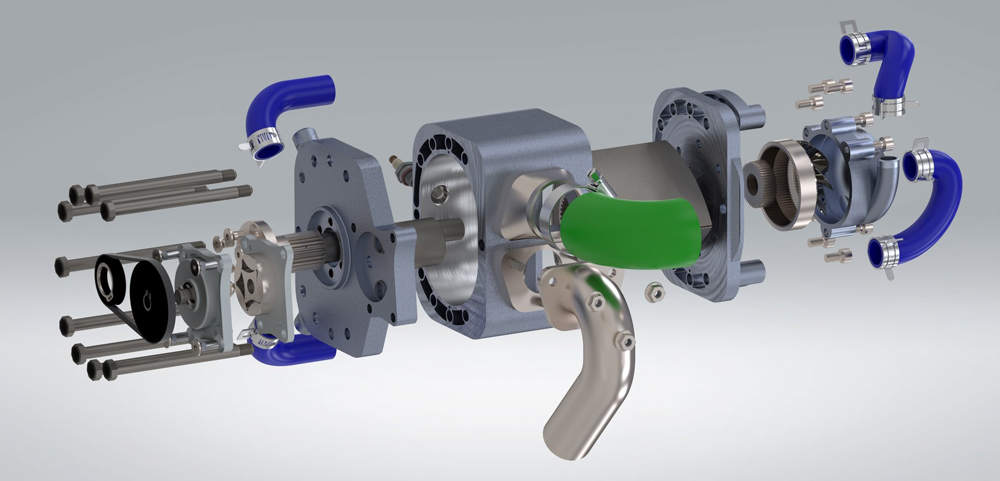

As the process of development continues and moves from the early stages of exploration to refinement, the concepts start getting developed in 3D CAD software. Prototypes used throughout this phase are called evaluation prototypes. Such prototypes might be made from different processes, such as sheet metal forming, resin casting, machining, or 3D printing. These are called learning prototypes, and facilitate the discovery of what will work and what won’t. You may be assessing the product’s assembly with sealing, wiring paths, or internal components. These can be used for gathering feedback from users on ergonomics, form, and other information on user interface. There are times when these might only be partially bult to analyze a certain product feature, like a hinge or other moving parts.

It is common for professionals to conduct extensive prototyping throughout refinement as a way to reduce risk, learn from, provide tools, and present solutions to the clients. These could be developed into various levels, starting from the unfinished parts printed in 3D to the final functional appearance prototypes representing the intent of production. Prototyping throughout development makes it possible to gather feedback, improve solutions, and save time. Some teams tend to print to see how things work. After all, there are things that you cannot efficiently review if you just stare at the 3D CAD model on a screen.

As you move to the project’s production design effort, prototypes will be continually used to check the final design solution. These are known as verification prototypes and can be unfinished, the parts usually 3D-printed in plastic in order to ensure component assembly and fit-checks, as well as to fulfil other requirements for production. For sheet metal products, products are prototyped in sheet metal to verify whether the solution will work as it is meant to do.

These verification prototypes are developed from the production design database to make sure that the files are accurate before release to the manufacturing stage. Any discovery made at this point will be easier to fix in CAD files than if the error is identified during the development phase. This can help save money and time and is a great insurance policy. Although humans continue to evolve, there will always be risk of error, although not everyone might admit it.

Human interaction is the heart of prototyping

Prototypes, or mock-ups, are made using simple materials as a representation of the final product to show what it will look like in real life, when everything is assembled and put together. Prototypes were used long before 3D CAD came to existence and served as a great way to communicate and present the design. But while there are lots of things that can be learned from prototyping, human interaction is what it really is all about.

You can attend a client meeting and place all those stunning renderings of the products on the table for everyone to see. But the moment you pull out the prototype and present it on the table, they wouldn’t even notice that the renderings were there in the first place. Most clients go straight into checking the prototypes. There are people who can see things much better in two-dimensional sketches. There are also those who would want to see a product’s three-dimensional form for them to get a good understanding of the concept. This is why prototypes are great tools for communication more than anything else.

How prototyping has changed through the years

Prototyping has enjoyed some significant advances with the recent rising popularity of 3D printing, which has been the hottest buzzword for the past few years. Through the help of 3D printing, it has become possible to carry out frequent prototyping almost in real-time, right within the office.This has substantially changed the cost and the speed of getting prototypes. It has become more affordable, and it has become possible to do so much more with it in a more accurate way. This is because the prototypes can be printed directly from 3D CAD files.

There are also new materials being introduced to the market, including plastics, ceramics, and metals, that enable designers to make the most out of 3D printing and its functionality. Traditional techniques for prototyping, such as metal forming, resin casting, and machining, continue to be used. The addition of 3D printing technology gives professionals more options to choose from for the particular needs they might have.

Why do people skip prototyping during product development?

The final verification prototype is the one step that is usually removed by clients, a decision that is often regretted by them afterward. Clients already have some sense of familiarity with the design solution, since they have seen how it appears in earlier stages. However, companies still try to convince their clients to do another prototype at this point.

While you will be able to get to the manufacturing stage sooner if you skip this step, it doesn’t mean that your product will be launched on the market sooner. The money and time you save will be lost right away if there is a need to make further changes to the product. It will end up being more time-consuming and expensive than making the changes to the 3D CAD model first. Thus, making the prototype makes more sense.

Is a prototype necessary for your product idea before the manufacturing process?

Although it is not really necessary to create a prototype for your product idea before you proceed to the manufacturing stage, you will be taking a serious risk if you don’t. Prototypes are tools that help you in expressing your idea and bringing it to life. At first, it can be easy and simple. However, its exact form will depend on your product idea. Handmade prototypes usually come in handy in the beginning but there are now different choices available for you. Today, prototype manufacturing has become more advanced than ever, making it possible to quickly develop sophisticated designs that can be tested before the start of production.

It is highly recommended that you create a prototype for your product before you move on to the manufacturing phase. With the help of a prototype, you will be able to touch your product and hold it in your own hands. You can also check whether the idea you have in mind matches the physical version that you see before you. This way, you can determine whether your product has any flaws that you need to fix before you move into the mass production stage.

Manufacturing and wasted products can easily cost you thousands of dollars if you don’t have a prototype. You can think of it like buying a house. Before making this kind of significant investment, many people schedule a building inspection to determine whether there are structural concerns that will cost more if fixed much later. Depending on the results of the building inspection, the homebuyer decides whether they will buy the house or not. Prototypes function the same way, as they enable you to address design issues early on in the process when you still have relatively fewer expenses.

As well as testing the product design, developing a prototype helps you attract potential investors who can provide you with the necessary funds for the manufacturing stage. When you can show them a physical product, or even just a part of it, it will be easier for investors to visualize and feel excited about your idea. Although you can choose to create a prototype for your product idea on your own using cardboard, paper, or anything similar, it is best to work with a professional prototyping company that can create the best prototype for you.

Benefits of developing a prototype

Before you create a prototype, it will help if you know the specific purpose that the finished product is going to serve. Creating an early version of your product can help you pinpoint any improvements that could be made as well as how you can move to the next stage of production.

Below are the benefits you can enjoy when you create a prototype for your product idea:

Compare different materials

One material probably performs much better over another. At this stage, the use of different materials will allow you to determine the one that will best suit your product.

Show off your product

When there is a prototype in hand, the manufacturer, attorney, licensing company, or other professionals involved in launching your product on the market can get a much better sense of how it works, what it does, and what benefits it can offer to users.

Test how the product works

Is the prototype functioning exactly as you have envisioned it to, or are there flaws that require fixing? If this is the case, you can continue to refine the invention until your expectations are met.

How to develop a prototype

While you may have the most vivid imagination, it is a long and tedious process to get from point A to point B. There are several important things to consider and steps you need to follow when developing your prototype.

Begin with a design and concept

You can start with a simple drawing followed by a three-dimensional representation. You can try using things like paper, cardboard, socks, milk containers, or glue to build an inexpensive representation, depending on your invention. This will give you a general idea of how the finished product is going to function. The next step is to develop a pre-production prototype. It will help if you own a 3D printer, but it might be better if you work with a production or manufacturing company.

Work with a manufacturer

At first, your product idea might not be as perfect as you want it to be. However, a professional manufacturer can work hand-in-hand with you to perfect and polish your design. If your budget is a bit tight, you can get the help of a handyman for the process, but it is more advantageous to hire an engineer, since several versions of the prototype might need to be made before all the flaws are fixed. The moment you get the actual product’s prototype, you can then look for a manufacturer who can develop it at a profitable cost.

Proceed with rapid prototyping

Different technologies, including additive layer manufacturing, CNC milling, and 3D printing, allow for improved accuracy and complexity. CAD data allows the development of functional prototypes in a short amount of time. The combination of different techniques cuts down the process of prototype manufacturing to several hours after the full development of the concept.

What is the most time- and cost-effective way of developing a professional prototype?

3D printing is one of the most cost-effective means to prototype your product idea, particularly if the product is going to be made using plastic. On the other hand, welding or machining is the best choice for products made from metal. The interesting thing here, albeit a bit counterintuitive, is that it is more efficient in terms of cost and time to hire a company that can print your prototype for you instead of doing it on your own. It is similar to the 3D design stage, where it is more cost- and time-efficient to work with a company that specializes in CAD design to carry out your designs instead of buying CAD software and trying to learn it yourself.

Prototyping was once prohibitively expensive prior to the introduction of 3D printing. It can easily cost several thousand dollars to develop test molds and conduct small production runs for testing the parts. You can substantially cut down this cost through 3D printing the parts, and the evolution of the technology makes it cheaper by the day. It often costs less than $1,000 to create a 3D print for a simple design, with a minimum turnaround of one week or so, and a maximum timeframe of less than a month.

Different factors that drive up prototyping costs

If your product design needs electronic components, this is where the costs of prototyping can get a bit expensive. Unfortunately, 3D printers cannot print working circuits yet. Instead, these should be made on a one-off basis for the prototype. Other factors that can drive up the cost of a prototype include the following:

- Whether manual labor is required to finish the part, such as polishing or painting

- Whether there is a need for machining instead of (or as well as) 3D printing

- The type and quantity of materials required for making the parts

- The complexity and size of the parts

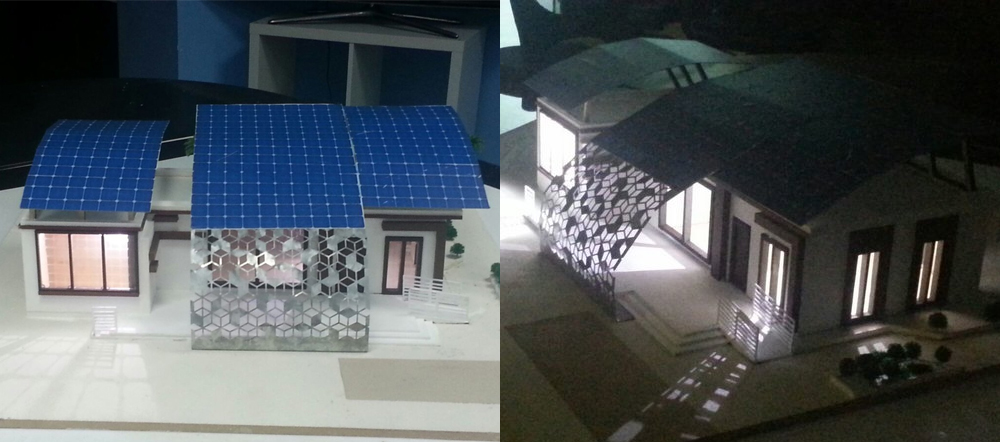

There are times when multiple iterations or phases of prototyping are required, when the design requires tweaking after making the first prototype. For example, after changing the design, the prototype might need to be printed again to confirm the final design that will be ready for manufacturing. If you have a particularly complex product, it might take ten or even more prototypes for your design to be ready for manufacturing. However, the number of prototypes is normally maintained at a bare minimum since developing a prototype several times will only add unnecessary cost to the product development.

If you have a large product, you can create a scaled-down, half-size prototype to save more money during the prototyping phase, which can also cut the cost by half. If a half-size prototype is enough, this is also a great option to help you save money. If you will be working with a prototyping company, your design company should also be able to refer you to a company they trust. However, it will work to your advantage if the design company can handle prototyping as well. Since they are the ones who are designing the parts, it puts them in the best place for producing the prototypes, as they also know the product’s design intent.

On the other hand, if you want to personally look for a prototyping company, talking directly to companies is the best and fastest way instead of getting information from non-interactive sources. To determine whether they really know their craft, you can ask them about the number of prototypes they have made in the past or the number of projects they worked on before. You should also inquire about the specific materials the company is able to work with and their turnaround time. After the design is approved, the prototype has been developed and tested, and you are satisfied that the product is fit for its intended purpose, you are now ready to proceed to mass production.

Part 8: From prototyping to mass production

One of the most common questions that people ask when it comes to the process of manufacturing, aside from the price itself, is whether there is a need to develop molds for the specific product in question. These molds tend to be very pricey, so the good news here is that these are only made for silicon or plastic products that require injection molding.

It often takes two to four weeks to produce a mold. However, after the mold has been developed, thousands of products can be developed in just one day. To assess the length of time required for mass production, the manufacturing company should be informed of your preferred number of parts. Then, from there, the company can identify the exact turnaround time. Another factor involved in meeting deadlines is shipping, although the time usually required for shipping doesn’t add that much of a delay to the order.

How to make the most out of your investment

To get the best return on your dollar, depending on how many products you plan to create, you can choose to work either with a large or a small manufacturer. This is another area where the design company you are working with can help. They can either look after the whole process in-house or they can refer you to trusted manufacturers they have a long-term relationship with. Through taking advantage of the relationships that companies have established through the years, you can usually get a lower price compared to what you could get if you tried forming a new relationship with the manufacturer by yourself.

Smaller manufacturers will obviously have an easier time manufacturing smaller quantities and for lower costs because of their lower overheads. However, large manufacturers are the exact opposite, although their pricing on materials might be better because they can purchase these in bulk. It means that, all-in-all, if you need to produce large quantities, the unit cost can be cut down significantly. You will also find that some manufacturers have a minimum order quantity. It is best to determine your order quantity and work with a company that offers the best pricing for that order size, as well as supplying good quality samples.

Similarly, to reduce your costs further, you must have a realistic forecast of how many products or parts you are likely to sell. Be sure to order only what you can confidently sell. While it will cost you less per part if you order 50,000 parts, the price per part can increase significantly if you can only sell 1,000 out of the 50,000 parts, not to mention that it will also fill up your storage facility or garage.

You will be able to save more money during the manufacturing stage if you stay on top of industry trends. For example, if a long time has passed between conducting your initial research and manufacturing the product, it is possible that technology has already changed to the extent that the product you are making has already become almost obsolete.

It is best to keep an eye on this during the weeks and months as you transition from the design stage to prototype to mass production. Stay on top of the market to ensure that you don’t waste money manufacturing something that is already obsolete. If you don’t, you might end up manufacturing thousands of parts that no one is interested in buying. Always do your research from the beginning. Test and offer free samples that allow users to provide their feedback. Gather all the information you need to confirm and reconfirm the market need before you proceed to mass production.

How to look for a manufacturer

The truth is that it can be very tricky to find a manufacturer if you don’t have any previous experience in the field. There is also the chance that you will get a product that doesn’t suit your standards if you try doing it on your own. You can find literally thousands of manufacturers across the world, which means that it is almost impossible to filter through each and every one of them. This is why it is best to get a referral to a manufacturer from a company that already works with them. It means that they have already spent time filtering through different facilities and have picked the best to work with.

If you try looking for a manufacturer on your own, you can do some due diligence to confirm if someone is reputable and legit. First, be sure to ask questions in the same way you do when dealing with other service providers or industries. This is even more crucial than usual since you are likely to spend a significant investment on them. Ask for samples. Do everything until you are confident enough with the idea of working with them. If something doesn’t sit right with you, follow your instinct and look for someone else.

During your search for a manufacturer, you have to decide whether you will be working with someone based in the US or outsourcing to companies overseas. Remember that the difference between these two is primarily cost-based. Working with a US-based company may cost you a bit more, but you can expect better quality and enhanced speed, efficiency, and price. It is not a good idea to go for the vendor with the lowest prices, since you might end up disappointed. Your decision should always be based on quality, turnaround time, and price. Deciding based on the price alone will never help you find the best manufacturer for your product.

Reputation and quality are both extremely important. Expect that the price will be higher if the manufacturer also has a higher reputation. Working with an unknown company with no references will often come with more risks. If you are willing to spend time doing your due diligence in the most intelligent way, even to the extent of personally visiting the facility if you expect to spend a large sum of money, you will be able to look for quality companies that offer quality prices.

Take note that all companies began at one point without any references. You can also inquire from other companies within the industry for advice. You may be surprised at the lengths they will go to and their willingness to help you out for free. However, if you are just getting started, you can save yourself plenty of headaches and even heartaches if you stick with the prototyping and design company, or have them refer you to a reliable manufacturer. You don’t have to worry about anything else if they have their own manufacturing facility.

They can handle everything on your behalf, making it the first choice for you to go for. Your second-best choice is to seek referrals. The moment you are referred to a certain manufacturer, the company is putting their reputation at stake by providing the referral, so you can be sure that they will only send you to someone they trust. You will be fine, unless the original supplier or designer is unscrupulous, and only works with you to make money without caring for the final product.

Looking for a manufacturer on your own should be your last resort since it is the most time-consuming and most uncertain. However, most of the time, it is just the same as searching for a local builder. You cannot simply walk into the builder’s showroom, choose a plan from the photos, and expect them to start building the next day. You have to ask for a referral from family and friends to learn as much about the builder as possible. it is even more important if you are working with a manufacturer that is not based locally. You have to make sure that your final product will look exactly how you want it to, without feeling worried that you will be ripped off or served poorly.

Part 9: Packaging

At this point, hopefully, you are already feeling the excitement and starting to imagine lining up the shelves of store chains across the world. However, you still need to wrap up several loose ends. Even if you have come up with the best product that the world has ever seen, it will never do well if you don’t have a good marketing strategy or campaign in place. Even if word of mouth can help it spread like wildfire, your initial buyers or the people who receive your samples for free to help you spread the word must still find their way to your product somehow.

An iconic logo, a strong brand, and memorable packaging are all parts of a strong and effective marketing campaign. The good news is that you don’t need to spend a lot on your packaging and logo. Your manufacturer can often arrange the packaging for you, or design it in-house for a minimal charge—or even for free, since you are already spending a significant amount of money on their services.

When to think about packaging

There is no need to worry about branding and packaging design until the product is ready. However, you need to factor it into the final price of every unit. The packaging cost will change according to the specific type of required packaging. It can be printed, plastic, shrink wrap, or cardboard.Packaging costs will also depend on the product’s size. But it doesn’t really cost that much since the packaging will only add a few dollars or cents per part.

If the company you are working with doesn’t want to do the design work or they charge a fee that is beyond your budget for packaging and logos, it is not too difficult to look for a reliable designer, especially in today’s world of freelancer marketplaces. There are several platforms you can use depending on your budget.

If you are looking for a freelancer, choose someone who has perfect reviews and has worked on numerous jobs in the past. You also need to check if their portfolio is consistent. People will usually show their best works in the front part of their portfolio. If the work’s quality gets worse further into the portfolio, it is best to look somewhere else. You also have to check for consistency in style. Inconsistent work styles can indicate that they are not the ones who worked on the projects in their portfolio.

Other options to look for a reasonably priced designer are to use crowdsourced design platforms or check the portfolios of some designers for hire. Specifically, you need to look for someone who has designed product packaging and logos in the style you are looking for. You can also post jobs on freelancing marketplaces if you want.

When using a freelancing website, it is likely that you will get plenty of spammy bids for your job from people who haven’t properly read your ad. To protect yourself in advance, your description should include a question that people should answer. The question should be a bit challenging without being cryptic. Ignore any response that doesn’t answer the question. One dead giveaway that you are getting a generic job bid is that it is also addressed generically instead of addressing you by your own name.

There are some platforms that allow you to restrict the countries people can respond to the job posting from. Unless you truly know what to avoid and what to look for, you will experience less frustration and get better results if you hire from the US, although expect that you will have to pay more.

Part 10: Marketing

As far as marketing is concerned, this is now the best time for you to look back to that market research you conducted during the early stages of planning the development of your product. There are several ways for you to market a product. However, the specific type of product that you are making and the place where your target audience spends most of their time will be your primary indicators when coming up with your marketing strategy.

Pay-per-click advertising