Prosthetic design has a very long history, and few advanced technologies have changed as much as 3D printing does. It brings access, affordability, and personalization on a global scale for revolutionizing prosthetics. Companies who service the healthcare sector or serve consumers who are vulnerable to accessibility are embracing 3D prosthetic design services as key factors that positively impact the lives of limb-different individuals.

The article breaks down the innovative aspects of 3D prosthetic design services and why companies should consider these services within their operations and how they impact accessibility for millions around the world.

🚀 Table of contents

The emergence of 3D printing in prosthetics

Traditionally, prosthetics manufacture is a long and expensive process. It involves custom molds, huge amounts of manual labor, and expensive materials. Thus, prosthetic devices were highly expensive for a large part of the population, especially in developing countries. Here again, 3D printing technology services has totally shaken the model by permitting the rapid and affordable manufacture of prosthetics, which are functional and tailored to specific needs.

3D printing, or additive manufacturing, is a use of CAD software that creates highly detailed, three-dimensional objects layer by layer. This enables the production of custom-made limbs that fit precisely to measurement and mobility requirements in prosthetics, resulting in a more comfortable, functional, and far more affordable prosthetic than traditional ones.

This is where 3D prosthetic design comes into play. These services are leveraging the possibilities of 3D printing to create, develop, and manufacture on-demand customized prosthetic limbs, unlocking a life-changing opportunity for users in this field. For business innovators looking to disrupt the industry in the health sector, 3D prosthetic design services open opportunities to participate in a revolution changing accessibility.

RELATED: Designing prototypes: 3D design services for inventors and companies

Key benefits of 3D prosthetic design services

Customization and personalization

One of the most important advantages 3D-printed prosthetics can offer is extreme customization. No two limb differences are alike, and no two individuals are alike for mobility, comfort, or a little bit of both. Traditionally made prosthetics could only have a few “standard” configurations with very little room for personalization, but 3D designers make prosthetic limbs tailored precisely for the body dimensions of the user, thus enabling a more comfortable fit and better functionality.

3D prosthetic design services includes detailed consultations in which scans of the residual limb or affected area are taken. Digital models can then be imported into CAD software to allow the designer to alter the prosthetic to the user’s exact requirements. The result is a prosthetic that feels much more natural and is greatly more user-friendly than those off the shelf.

Decreased costs and increased affordability

Traditional prosthetics can be very expensive, reaching in some cases as high as tens of thousands of dollars. Such costs are often simply unaffordable to the populations in many lower-income regions; hence this meant that many people remained without access to prosthetic devices needed for everyday living.

These costs are drastically cut through 3D printing since the production of such prosthetics saves on material and labour costs. In fact, material cost has been largely brought down through the use of light weight yet strong material such as polylactic acid, a biodegradable plastic, and other plastics, while their production process has saved on so many labor hours.

The cost of high-quality prosthetics continues to fall as more people are utilising 3D printers, which are becoming easier to access. Having adopted 3D prosthetic design services, companies can make a meaningful contribution to accessibility while providing a more accessible and affordable solution for those who really need it, so it opens up the market and expands their social responsibilities to larger scales.

Faster turnaround time

The turnaround time for a custom limb can be weeks to months in traditional prosthetic-making processes. Such a long period of waiting may become very exasperating for users who rely on prosthetics in everyday life for mobility and dependence.

A clear benefit of using 3D prosthetic design services is the drop in waiting time. From the point of having a digital model, a prosthetic can be printed in hours or days, depending on the detail of the design. It makes the prosthetics delivery much faster because a person can get back to their feet and start life as soon as possible.

Companies that offer swift, 3D prosthetic service can look forward to this speed as an advantage of differentiating them from their competitors who are still dependent on the most traditional and slow ways. This is one such scenario where a limb needs to be readjusted or should be changed periodically, like in case of medical emergencies or for children who grow faster.

RELATED: What are the main prototypes used by companies in industrial design prototyping?

Lightweight but rugged materials

Many traditional prosthetics, particularly those made from metal or heavy polymers, are notorious to be extremely heavy and clumsy. This can be inconvenient for a long time wear and thus give the user limited mobility and even strain other parts of the body.

3D design for prosthetic lightweight is very durable. Advanced composites such as carbon fiber or flexible polymers are frequently used to make prosthetics offering comfort and durability against the common wear and tear of everyday life. Their application also allows for more ergonomic designs, decreasing wear and tear fatigue, and thus raising the overall satisfaction level of users.

The state-of-the-art functionality and aesthetics

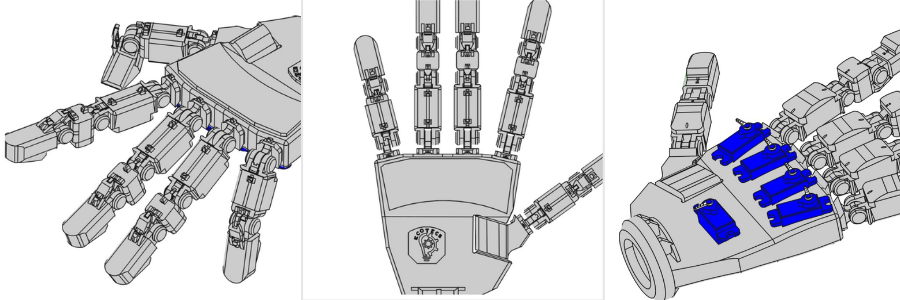

Besides limb replacement, 3D prosthetics are now opening up entirely new and different capabilities both in functionality and aesthetics. With 3D design, even the complex, multi-jointed designs that closely mirror natural movement can be included. For example, very newly prosthetic hands made via 3D printing can now add independently moving fingers for giving the user higher dexterity as well as control.

Aesthetically, 3D rendering design services enable users to personalize prosthetics in ways unimaginable before. Users can customize according to color, texture, and design elements that they can turn a prosthetic into an extension of their personality. In fact, some companies have prosthetics resembling superhero or futuristic motifs, designed to be fun and empowering for the users, particularly the children.

Industry adoption of 3D prosthetic design solutions

Most companies with diversified business lines have recognized their prospects in 3D prosthetic design solutions and are now embracing the solutions into their business lives. Not even governmental agencies, health care organizations, and other charities can resist the advancement as it will enhance accessibility of health care facilities and improve the quality of life among people with disabilities.

Healthcare organizations

Hospitals and healthcare organizations are the biggest users of 3D prosthetic design services. It enables healthcare organizations to quickly make suitable prosthetic devices for patients within a short and much cheaper time frame. Medical practitioners have also been shocked to discover that a more comfortable, functional design leads to better patient outcomes, including greater patient satisfaction and fewer long-term complications.

Non-profit organizations

Non-profit organizations, which are generally non-profit organizations with the mission to deliver medical relief in poor nations, would employ 3D printing technology in order to provide prosthetics to the less privileged. In liaising with 3D prosthetic design services, these organizations can deploy low cost yet very high quality prosthetic limbs to people who are otherwise unable to get them.

Government and public policy

Governments worldwide are gradually becoming aware of the extra benefits that 3D prosthetic design services have with regard to accessibility and public health. Some governments initiate policies that promote the use of 3D-printed prosthetic aids in public healthcare services, providing financial incentives to organizations and businesses in the form of subsidies or grants to adopt this technology in their provision.

Needs of companies entering the market

For businesses that want to offer 3D prosthetic design services, here are a few considerations that should be taken into account before doing so. First of these would include investment cost, the potential need for technical and/or specialized skills and software, and working closely with healthcare professionals to deliver the best possible outcomes for patients.

Investment in equipment and expertise

Although 3D printing has minimized prosthetics costs, its startup cost for equipment and expertise is high. First of all, the companies will have to invest in high-quality 3D printers that can print medical-grade devices. They will also have to educate their employees on how to use CAD software in making custom prosthetic

Collaboration with healthcare professionals

Organizations offering 3D prosthetic design must have a close association with health care providers who may include doctors, physical therapists, and prosthetists. The last will be responsible for assessing the patient’s needs and ensure that the prosthetic is fit appropriately and thus serves its purpose correctly. In addition, they offer support after the rehabilitation process.

Compliance with standards requirements

As prosthetics fall under the umbrella of medical devices, it requires that companies do not heed lax regulations but rather meet the very stringent regulatory requirements enforced to ensure these products’ safety and efficacy. This may involve certification, for instance, ISO standards governing medical devices, and others such as laws governing healthcare at the local level.

The future of accessibility with 3D prosthetics

The 3D prosthetic design service is changing the face of prosthetics, making them more accessible and affordable and personalized than ever. Companies looking to innovate in the healthcare and accessibility markets will find an opportunity to touch lives, at the same time tapping into the growing market, by embracing the services. The benefits of 3D printing technology can really help fill in the gaps between accessibility and affordability through custom, high-quality prosthetics, hence improving mobility, comfort, and independence for millions.

How Cad Crowd can help

Accessibility is now a must-have for companies, and if you want to stay ahead of the game, taking advantage of revolutionary and breakthrough 3D prosthetic design services can help you achieve just that. Cad Crowd will help you find the most suitable services for your budget and requirements. Request a free quote today.