Product design does not merely refer to a product’s shape or form factor. It has everything to do with functionality, safety, ease of use, durability, sustainability, and price point. From a manufacturer’s point of view, a product needs to deliver all the goods while remaining technically viable without sacrificing profitability.

One of the most effective ways to accomplish those goals is to computerize the design process using industrial design services. Hundreds of CAD (computer-aided design) software are on the market today. Some are simple or intended for personal use. In contrast, others come as software suites filled with multiple applications in one package to help companies cope with product design on an industrial scale.

Here are the top 10 industrial design software applications in order of user popularity.

Autodesk AutoCAD

Regarding CAD software, Autodesk AutoCAD is arguably the most popular. The software has been around for over 35 years and is also compatible with Windows, Mac, iOS, and Android. It’s one of the few CAD programs that work well on Mac computers. AutoCAD is widely used by both professionals and beginners, not only because of its time-tested capabilities in the world of product design but also the software’s intuitive user interface. A lot of high schools and colleges use AutoCAD to introduce 3D design to students, making it a common choice among young professionals.

AutoCAD design services work with the program because it has a wide range of features to draft and edit both 2D and 3D models using mesh objects, surfaces, and solids. You can also annotate the drawings with texts, tables, dimensions, and other related information. While it may not be the best for more complex design projects, all the available tools allow for seamless introductions to CAD programs.

Users are also provided with access to documentation, handbooks, and guides to continuously hone their skills, even if they start as complete beginners. The software includes a library of materials, including wood, brick, and a multitude of colors. It lets you adjust lighting and apply photorealistic renderings of drawn models.

Dassault Systèmes

The main focus of Dassault Systèmes is on being a PLM (product lifecycle management) solution and 3D digital mock-up tool. The company claims to have 100 million users based in 140 countries and 210,000 enterprise customers. A PLM solution allows you to manage data across the entire lifecycle of a product more easily because the information is stored in a central repository. This way, you can connect people (engineers, designers, and everybody involved in the design process) in an efficient and accountable way.

RELATED: Dassault Software: Comparison List for Freelance CAD Designers & Engineers

It is a well-known application in multiple industries, such as computer software, automotive, aviation, aerospace, construction, and machinery. Some major companies that use Dassault Systèmes include Lockheed Martin and Aurora Flight Sciences, Honda Power Products, Safran Electronics & Defense, and SkyWay Technologies Co., to name a few. While it’s primarily based in France, most companies that use the software are in the United States. In North America, the company is based in Waltham, Massachusetts.

SolidWorks

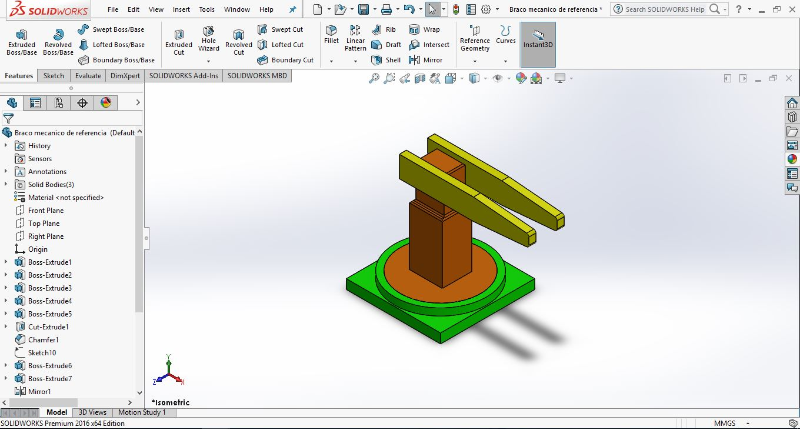

Also developed by Dassault Systèmes, SolidWorks may be the most widely used CAD solution mainly due to its powerful rendering capabilities, user-friendly interface, and relatively affordable cost. Many users are in the engineering and design industries, but it is less prevalent among those in the architectural business. Many academic institutions also use SolidWorks as a 3D design learning tool.

SolidWorks is often classified for intermediate users compared to other complex industrial design software. The only reason for the classification is that many users can get familiar with the features and navigate the layout relatively quickly. It is one of the easier CAD software to use without being overly simplistic, which is why freelance SolidWorks designers are aplenty.

SolidWorks helps you create 2D objects and fully detailed 3D models. You can access a library of materials – for example, glass, brick, and wood- or create a custom material. Virtual prototyping is also available, allowing you to improve quality even when the product is still in virtual form. Its rendering capabilities are not the most advanced but are impressive enough when working with smaller objects.

LabVIEW

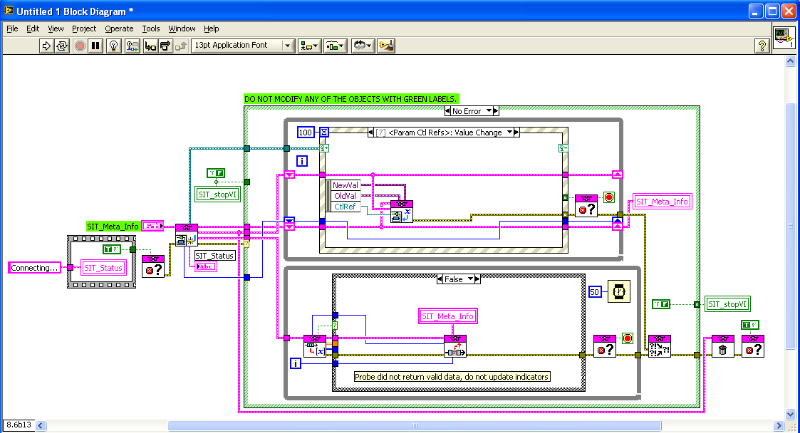

Laboratory Virtual Instrument Engineering Workbench, commonly called LabVIEW, is a design platform mainly used for creating industrial automation, data automation programs, and instrument control. It’s compatible with Windows, Mac OS, various versions of UNIX, and Linux. Unlike all the aforementioned design software applications, LabVIEW is not for creating 2D and 3D models on computers. Companies use the software to configure how their hardware or equipment interacts with each other and utilize available data.

Any engineering application that requires tests, measurement, and control can take advantage of LabVIEW’s extensive hardware integration and graphical approach to programming for easy visualization. It allows engineers to design a program and detect any coding mistake as soon as it happens. Engineers are not designing the actual end products, but the equipment used in the manufacturing process.

Initially released in 1986 for Apple Macintosh, LabVIEW has become much more advanced. It is now able to visualize data from just about any I/O device. The user interface is relatively easy to handle even non-programmers can learn and create small applications thanks to the included documentation and examples. Some big companies that use LabVIEW include TESLA, Northrop Grumman, and KLA-Tencor.

CATIA

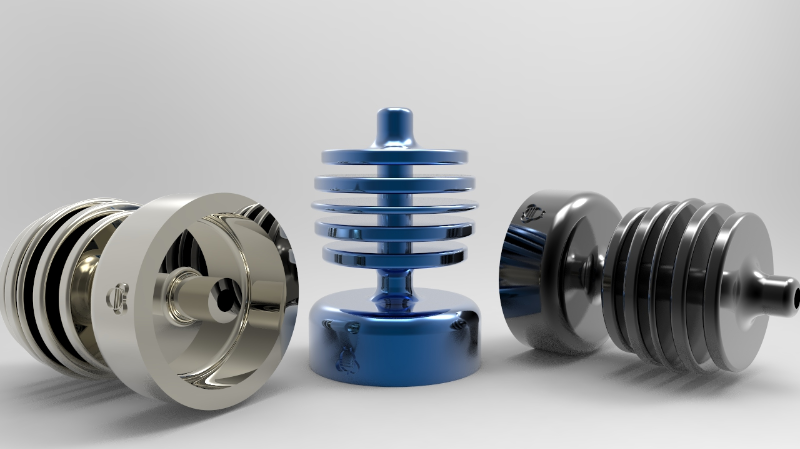

Computer Aided Three-Dimensional Interactive Application – better known as CATIA – is another design software suite from Dassault Systèmes. Written in C++, CATIA design services are more powerful rendering functions than SolidWorks. Due to the way, CATIA is written. However, the software may look a little bit outdated in a market flooded with heavy-graphical user interfaces.

Fortunately, the shortcoming stops at that. Regarding functionality for 3D modeling, it’s one of the best on the market. CATIA is more than just computer-aided design software. The scope of the application covers manufacturing, engineering, and product lifecycle management functions.

The tools in CATIA are meant for advanced engineering – aerospace, electrical parts, engine components, and power generator systems. It’s a complex software built for expert users. The user interface is not its best strength, but it has plenty of commands to give users total control over the models. Thankfully, you can create macros to make the workflow easier by consolidating frequently used functions into a single command line.

Beginners will need to spend a lot of time figuring out how the software works but experienced CATIA design services would be able to create some of the best-looking objects. Goken America, Cyient, and Triumph Group are big companies that use CATIA.

Autodesk Inventor

Despite its limited compatibility, Autodesk Inventor is one of the most recognizable names in the industry and is used by major companies such as Aerotek, Flowverse, and ABEC. Some key features include free-form and parametric modeling, stress analysis, dynamic simulation, and part design automation. Versatility is Inventor’s most significant selling point. The software is prevalent across various industries, including but not limited to graphic design, architecture, engineering, machinery, automotive, and manufacturing.

The above-average simulation feature allows you to create a virtual product design and test it for strength and function using multiple data points like friction loads, stress, or weight. Simulation makes it easier to refine and improve many product characteristics well ahead of the production phase when used for testing product ideas.

Integration of 2D and 3D data in a single environment is equally useful. Designers can validate every little detail of the product in its digital form, increasing productivity. You can think of it as an all-in-one 3D CAD software application that significantly assists in materializing ideas and minimizing errors in the process.

PTC (Parametric Technology Corporation)

The primary offering from PTC is the Creo Suite, which is a 3D CAD design software compatible with the Windows operating system. Creo comes with parametric solid and direct modeling and all sorts of visualization functions, including technical illustrations, schematic design, orthographic views (2D), simulation, and element analysis. The suite consists of multiple apps, each offering different capabilities to intensify or improve users’ roles and performance in product development.

The software company itself has a lot more to offer. Since 1985 when the company was founded, it has acquired dozens of companies, mainly in the software technology industry. In addition to the Creo Suite, PTC provides product lifecycle management, augmented reality, and the Internet of Things.

There is also Mathcad built to solve and analyze complex engineering calculations. It is a leading industrial innovation platform with more than 800 partners worldwide. BorgWarner and Woodward are two industrial giants that use PTC solutions.

ANSYS

If the simulation is needed, ANSYS is the right name for it. The finite element analysis software creates a digitally simulated environment for models such as products, structures, machinery, or electronic parts. Users can use various attributes or data points to see how the models behave under certain real-life usage conditions.

For example, it helps an automobile designer conduct a crash test in the virtual world when the product (a car or any other vehicle) is still in the development phase. Although an actual crash test is still necessary, at least engineers and designers can address any possible issue beforehand.

ANSYS engineering simulation software is used in various industries, including automotive, aerospace, defense, healthcare, energy, electronics, and consumer products. The company also claims that 96 companies in the FORTUNE 500 list use ANSYS.

Simulation is not limited to manufactured products only, but also natural elements such as fluid, light, and electromagnetic. In the manufacturing industry, accurate simulation is likely the most cost-effective way to figure out how any product functions and performs. It can be done before production begins, or even before the prototyping phase. A few big names that utilize ANSYS are Blue Origin and Aerojet Rocketdyne.

CNC Software

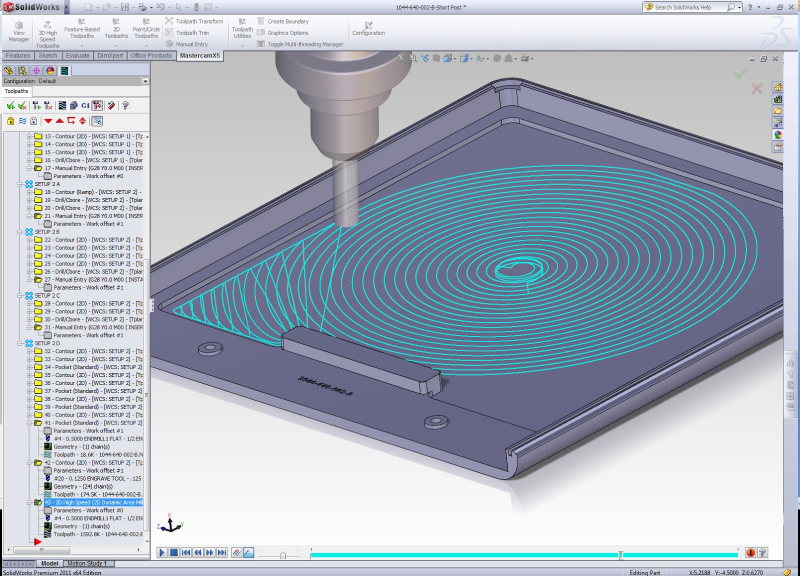

Mastercam is the main CAD application offered by CNC Software. The company is one of the first to provide a PC-based computer-aided design/manufacturing solution designed specifically for engineers and designers.

The software suite combines a 2D/3D modeling platform and configuration tools for computer numerically controlled machine tools. The newer version of Mastercam brings 3D wireframe modeling (as opposed to 2D modeling only in the original version) functionality and broad compatibility with common CAD files.

CNC software also provides a multitude of manufacturing equipment that works with Mastercam, so it does give a complete set of solutions to be used during design and production stages. Users will be able to create the virtual form of an object and then machine that object or parts of it into solid models. CNC Software also makes Mastercam for SolidWorks so that you can design pieces directly on the SolidWorks interface.

AutoCAD Civil 3D

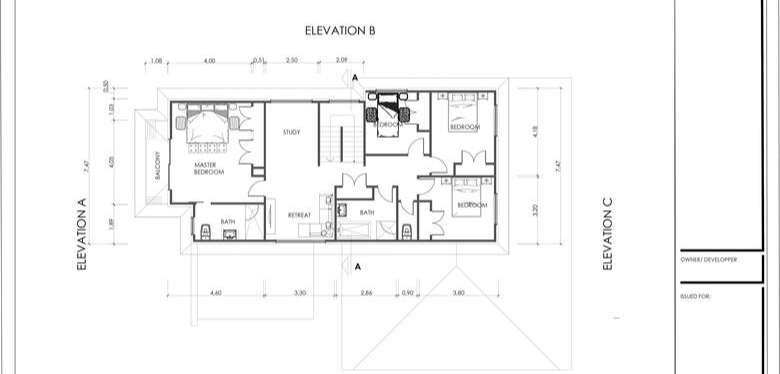

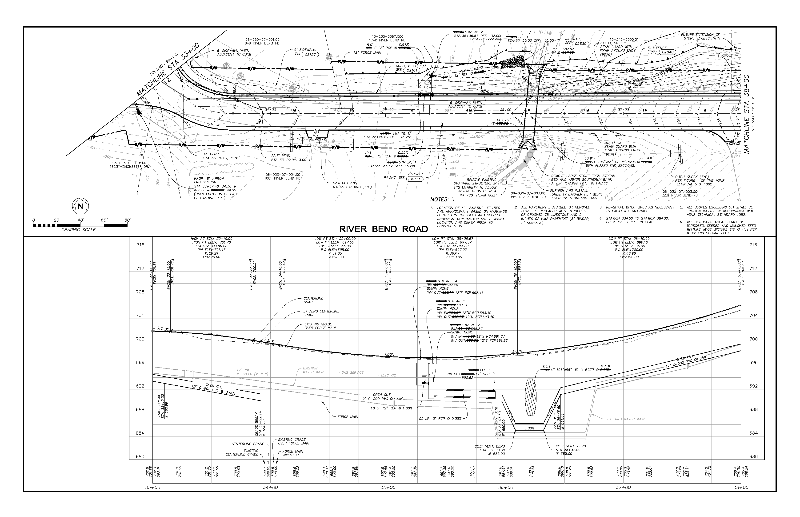

As the name suggests, Civil 3D (part of the AutoCAD series by Autodesk) is designed mostly for civil engineering projects which fall into three big categories, including land development, transportation, and water. Used widely by professionals for various types of infrastructure projects, the software allows for 3D modeling of objects without neglecting the dynamic relationships with multiple related data points, for examples contours or grading.

Civil engineers (or other professionals who design civil infrastructure) can benefit from the software’s ability to support BIM (Building Information Modeling) to document everything well. It gives them the opportunity to conduct a more thorough analysis of data and ensure productive collaboration between multiple teams or individuals thanks to a more manageable workflow. Visualization, simulation, and water tools are all integrated with the design process.

All those design applications and software suites make a strong case that today’s design and engineering industries have been heavily digitized. Nearly everything you see and use today started as digital files drawn on computer screens. Some applications mentioned above are pretty pricey and best used for commercial undertakings rather than personal purposes.

Companies need to implement effective product lifecycle management and thorough testing with simulation before they can confidently release any product to the market. The manufacturing process itself must be cost-efficient to ensure reasonable profitability.

Cad Crowd Is Home to Freelance Drafting Services Who Have Mastered These CAD Design Programs

At Cad Crowd, we work with hundreds of the best freelancer CAD designers worldwide. They’re pre-vetted, confidential, and have worked with some of the best designers in the world. Regardless of the type of project you need to be completed, let us help. Find out how it works.

Try this list for more industrial design options:

Shoutout for putting KeyShot, the software is a godsend.