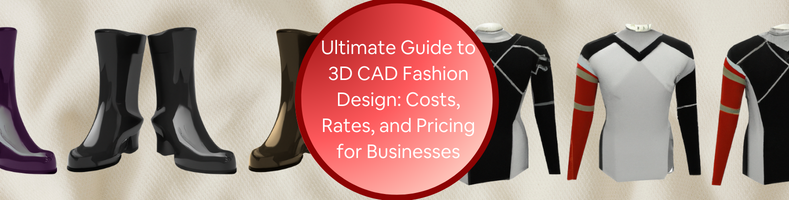

CAD Fashion Design Services, as the name says, is used to create and design such fashion items as clothing, footwear, and accessories. Not only do they make sketches and illustrations, but they also provide instructions on making the designs. In a typical design project, they are responsible for the following tasks:

- Research fashion trends and build new ideas based on the findings

- Determine the theme for any particular fashion collection

- Draw manual sketches and utilize CAD software to draw digital designs

- Acquire sample fabrics, patterns, or materials from manufacturers or suppliers

- Work together with a tailor or seamster to produce prototypes

- Choose the overall style, patterns, and colors for fashion items

- Present technical documents of a design to the client

- Work together with factory partners to oversee production

An apparel company usually hires an in-house team of fashion designers with different product specializations. According to BLS data (May 2021 – latest data available), the average annual wage for fashion designers in the United States is around $63,320, which equals an hourly rate of $30.44.

RELATED: Clothing 3D rendering cost, 3D modeling rates & design prices

Workflow and cost

Every fashion designer may have a specific approach to a project, and the workflow may vary from one professional to the next. The same thing applies to cost because the rates are affected by various factors, from educational background and specialization to experience and reputation. The most common workflow and pricing for each project phase are listed below.

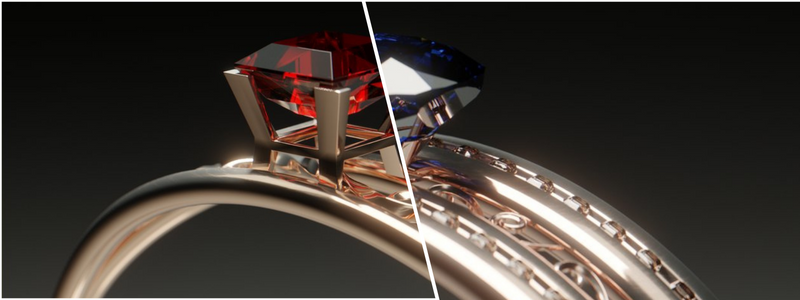

Research

A professional CAD fashion designer doesn’t immediately take the pencils out and draw some sketches at the beginning of the project. Unless the brief mentions clear references and provides clear samples, most designers will have to research the market first. They may have to study the price points, trend reports, competitors, and target demographics. On-the-field data are essential when creating a new design to penetrate the market, especially in specialized areas like jewelry CAD design services. Some designers resort to arts, entertainment media, pop culture, and the environment as inspirations to create a unique design. Depending on the amount of data gathered and the time spent to collect them, the research phase costs between $35 – $100 per style. Incorporating essential trends and market insights is crucial in ensuring the final design is innovative and commercially viable.

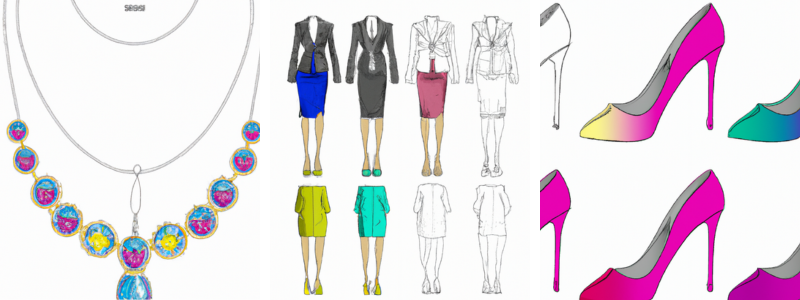

Sketches

Every fashion design sketch is drawn naturally and quickly by hand. However, some designers may also employ CAD drawing services to refine and digitize their sketches for enhanced precision and detail. Based on the information gathered from the research, an experienced designer can probably create dozens of sketches in a day. All sketches are numbered, dated, and sent to the clients. Some designers attach a fabric swatch to the drawings only to give a glance into the material used. They may experiment with affordable materials to see how the designs look and adjust the details as needed. Sketches are not final, and integrating CAD drawing services can facilitate necessary modifications and improvements in the subsequent design stages.

Sketches are not usually done in colors for speedy completion; drawing a colorful and realistic illustration is time-consuming. Designers prefer giving more ideas and rough sketches to spending hours on one detailed illustration. All the sketches will eventually be refined in the following phases anyway, so it makes little sense to work extensively on them now. Only the approved sketch will go forward into the next phase. The cost for sketches mainly depends on the designer’s qualifications. A seasoned, internationally recognized fashion designer can charge up to $800 per style, but many other qualified freelance CAD designers are happy to provide their service for $50 – $100 per style.

RELATED: What are AutoCAD designer rates, drafting costs & services company pricing?

CAD flats

In the initial stages of product design development, designers predominantly use pencils and paper for sketching their ideas. However, as the design progresses, they shift towards using CAD software for refining their sketches. This transition is a pivotal part of the product design services, as it enables designers to quickly and accurately make alterations, test their designs on virtual models, and easily customize various aspects of the design. The software’s user-friendly interface allows for rapid changes in colors, shapes, and details, providing designers with the flexibility to experiment and iterate on their designs until they achieve the desired outcome. CAD sketches, which usually offer both front and back views of the design, are an integral component of this process, aiding designers in visualizing and refining their concepts.

Mind you, CAD Flats are not technical drawings but merely detailed illustrations. Fashion sketches must be done by a technical designer – specializing in the fashion industry – rather than an artistic illustrator. A technical designer knows the product well and will produce an illustration that the pattern maker and factory can understand. It is about creating a detailed drawing and an industry-compliant one. All design changes from the sketches are done in this phase before the file is sent to a pattern maker. The cost for CAD Flats ranges from $30 – $70 per style.

RELATED: How much does 3D CAD modeling design cost & what are prices for freelance design service firms?

Pattern making

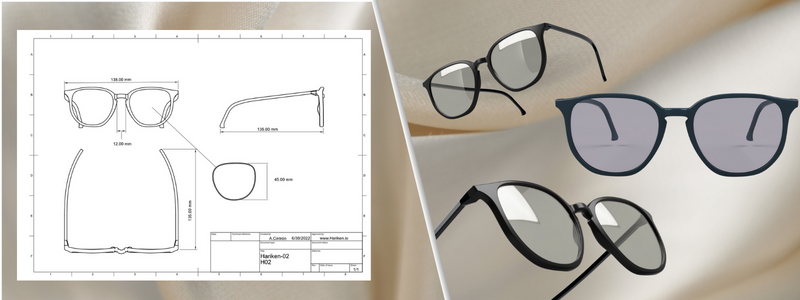

In the CAD fashion design workflow, pattern-making is a vital component, particularly essential for providing 3D footwear design services that demand high levels of design intricacy and accuracy. This stage ensures that the design meticulously translates from concept to physical form. The complexity of the design, influenced by various elements such as seams and materials, directly impacts the cost. A well-executed pattern is crucial as it directly contributes to the prototype’s accuracy, allowing for tangible testing and refinement of fit, comfort, and style.

Pattern-making is one of the most expensive parts of CAD fashion design. Design complexity plays the utmost important role in determining the cost. The number and variety of seams, collars, pockets, sleeves, layers, color combinations, and types of materials will affect the price. More details cost more money. A single pattern may cost around $750 at the most complex level. The good thing is that the pattern-making service for most fashion items only costs half that amount, perhaps even less, between $80 – $300.

Patterns initially crafted on paper are seamlessly transformed into digital formats through CAD digitalization services, enhancing the grading and modification process. While manual pattern-making is still prevalent, adopting CAD technology streamlines the workflow, ensuring efficiency and precision in design visualization and adjustments.

Prototype sewing

Like pattern making, sewing is not digital work. During the production run, an operator may control the operation via computers, but manual sewing is the best way to approach fashion prototyping. Designers produce and deliver design samples to the client. The cost for the sewing process ranges from $75 – $550. The price you pay covers the cost of materials such as fabrics, linings, label trims, buttons, and zippers, among others.

- Note: Prototype sewing might not be a standard inclusion in CAD fashion design services. However, you can explore options such as hiring a tailor separately or negotiating with the designer to integrate prototype design services into the package. If you only need the digital design work, skip the sewing part and jump to the next phase.

RELATED: How does product prototyping with 3D modeling help grow sales and save R&D money?

Tech pack

Technical drawing in fashion design is known simply as “tech pack,” which functions like specification sheets. The designer creates a tech pack to specify the fashion details so that manufacturers can transform the information into finished products. Think of a tech pack as a fashion blueprint. The document has some images (sketches) and descriptions such as materials, measurements, sizes or grading, and colorways.

A Bill of Materials (BOM) is mandatory in a tech pack. BOM contains a list of raw materials required to produce the design. The document acts like a guidebook on where to source the materials, how to ship them to manufacturing facilities, and how much you should pay for everything. The list of materials may include main fabric, secondary fabric (or lining, if needs be), trims, labels, buttons, thread, and packaging, to name a few. Garment, clothing, or any fashion item is a physical product; the materials you choose significantly affect the product quality and sale price.

In some cases, a technical designer collaborates with product developers to produce a single BOM. They use the CAD flats to specify all the raw materials and additional items required for manufacturing. Also described in BOM are the following:

- Sewing instructions, including but not limited to stitching styles, hemline finishes, and overlock.

- Hardware or trims, such as zippers, buttons, snaps, thread type, and colors.

- Company label details, size, and placement.

Technical designers and product developers are likely in direct contact with the factory partner to remove discrepancies between the tech pack and the manufacturing process.

Most factories and contractors will not take an order without a tech pack. The primary purpose of a tech pack is to minimize the need for prototypes before production. It also eliminates the risk of production mistakes—and, by extension, financial loss—on the client’s part. A tech pack may be used as a master document to track design changes until the manufacturing phase. A tech pack costs anywhere between $75 – $550 per style.

Taking the lowest number from the approximation for each fashion design phase (including the pattern-making and prototype sewing services), you should get an overall cost of $345 per style. On the other hand, using the higher price in the range results in $1,670. Old wisdom suggests you should neither go for the cheapest nor the most expensive but look for something in between, preferably closer to the higher range, to balance quality and price.

RELATED: Elevating Your Company Using CAD Product Design Services During Product Development

Fashion Design Visualization

If 3D visualization is necessary, you will need to pay an additional cost between $50 to $600 per design. Your contractors and factory partners do not usually require 3D visualization for manufacturing specifications, but it does not hurt to have a realistic depiction of the design as an additional resource.

Many fashion designers in the United States work full-time for manufacturers or wholesalers. They might not be willing to take custom orders. Your best bet is to hire self-employed or freelance designers who typically offer custom services to individual clients.

How Cad Crowd can help

If you have sketches that you’d like to turn into 3D models, Cad Crowd can connect you with CAD freelancers who are experts in the field. Our top-of-the-line designers can make you a model ready for manufacturing, whether using 3D printing or traditional manufacturing. Whether you’re designing clothing, accessories, or jewelry, our 3D modelers will help you bring your vision to life. Get a quote now.