Product development is a strategic process for the innovation, expansion, or survival of a business in the marketplace. It is an elaborate journey from concept to reality, with careful planning and thorough research coupled with rigorous analysis to ensure that a product meets its target audience’s needs and yet can be sold at a competitive price.

However, one burning question is left unanswered in most entrepreneurs’ minds: What is the development cost of a new product?

It is essential to get a better understanding of the costs of different product development services to avoid unpleasant surprises in your finances. This guide will explore the various aspects of product development, including industrial design and engineering services, prototyping, and testing.

🚀 Table of contents

What is product development?

When a brilliant idea for a product comes along, it is very easy to lose track of things in the excitement of seeing it come to life. Even before rushing into its development, one needs to look back a bit and figure out the financial implications involved.

If the costs of product development are not gauged correctly, they can shoot into the skies in no time. Product design firms can soon find that even simple design changes or changes in materials or methods of building a prototype can soon amount to huge amounts.

This will allow you to make the right design decisions that will not eat into your bottom line. Keeping product development overheads low without compromising on quality will ensure that your product is something of which you are proud-and it’s the kind of product that could rake in substantial profits.

RELATED: Understanding the cost of prototyping for product design services and budgeting for your company

The average product development cost

The cost of product development is tough to estimate since such costs vary greatly based on a number of unique factors, including the complexity of the product design, available resources, choice of raw materials, design and prototyping methodologies, manufacturing techniques, timelines for development, and desired production quantities, among others, plus the level of professional product developers versus self-made approaches.

For a rough estimate, the cost to develop an average product that is modest will be around $30,000. This would mean designing, prototype, test phase, and launching the product. However, costs go upwards as the complexity of the product being developed goes up. In a few cases, development costs go into hundreds of thousands.

All this being factored in, it’s very important to break down the cost item by item or request a breakdown in detail from product developers. Responsible product development professionals would be more than happy to walk you through the costs involved in each step and may even help guide you on how to cut costs where possible. If you know what to expect ahead of time, it will help you plan properly and avoid unexpected cost dodges.

What are some of the crucial elements of new product development costs?

New product development services, particularly with technology-based products, are often a survival tool for your business. However, most entrepreneurs misunderstand the various costs involved in new product development. Below are the ten common costs of NPD, broken down into three main areas: process costs of new product development, design for manufacturing, and regulatory compliance costs.

1. Ideation process

Estimated cost: $0-$10,000

Ideation is the stage that lays the appropriate foundation for the development of the product. That stage is when the brainstorming continues, even with some market research, and your initial concept gets validated or invalidated. Without a proper plan, projects can easily end up running over budget because of design change orders and uncertainty.

2. Industrial design

Estimated cost: $5,000 – $15,000

Industrial design focuses on the aesthetic and interactive aspects of the product. This phase is critical since it is what gives the overall look and feel of things, which consequently impacts market success. This stage should then apply a problem-solving methodology, like one based on design thinking, for the product to fit the needs of the target consumer.

3. Prototyping

Estimated cost: $200 – $10,000 per prototype

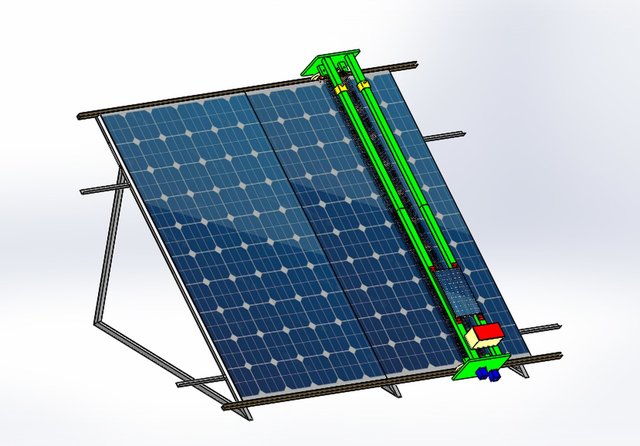

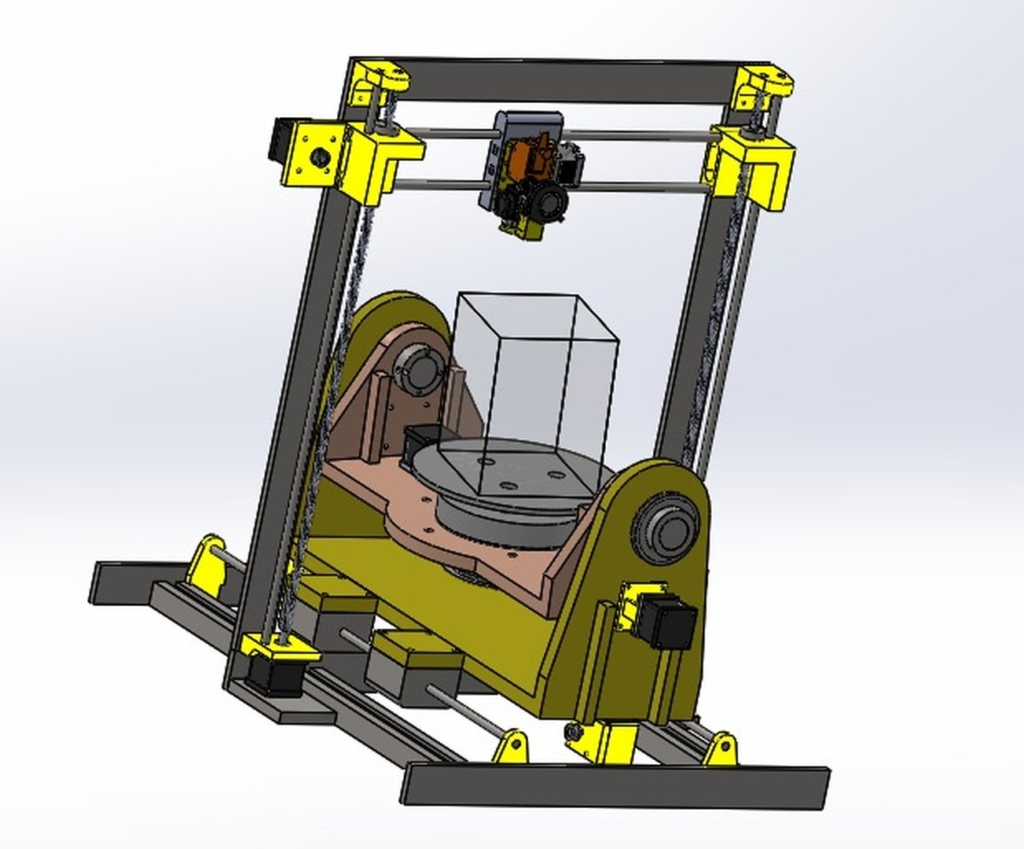

Prototyping is the making of a physical representation of the product with respect to its functionality and design. During this phase, the electronics and the enclosure of the product are typically developed using rapid prototyping technologies like 3D printing design services. Successive testing with early adopters is important before moving on to detailed development.

RELATED: Designing prototypes: 3D design services for inventors and companies

4. Electronic engineering

Estimated cost: $4,000 – $40,000

This stage would require the right electronics for the product as well as printing a circuit board that would house all these components. The product will also interface with a mobile app; therefore, firmware development should be undertaken. Tests at this stage are meant to ensure that all the electronic parts meet the quality and regulatory requirements.

5. Mechanical engineering

Estimated cost: $4,000 – $40,000

This stage is where the 3D CAD engineer creates the product’s plastic case and interior parts. The design must be optimized for injection molding to be free from distortion issues. Proper mechanical engineering ensures quality but may also save a lot of cost by reducing assembly time and labor.

6. Certifications & testing

Estimated cost: $5,000 – $50,000

Testing and Certification: The product should be put under intense testing and certified to meet the requirements of the industry, mainly when there is mass production. This will take three months but may be worth the investment as it saves the returns and legal battles in the future. Certifications would include FCC, UL, CE, and RoHS, depending on the market.

7. Packaging design

Estimated cost: $2,500 – $5,000

Packaging design services is an important driver of product sales and revenue. An attractive and functional packaging of the product will be designed by the graphic designer and be made to prototype at a packing factory. Skipping this step may jeopardize the product’s marketability and, finally, success.

8. Mold tooling and manufacturing setup

Estimated cost: $10,000 – $100,000

Tooling for volume production is typically a cost-intensive part of engineering a new tech product. This would also encompass the injection mold tooling of plastic parts and the setup of the supply chain. Once in place, the unit cost drops precipitously, along with higher profitability.

9. Manufacturing batch size & minimum order quantity (MOQ)

Estimated cost: $25,000+ (order size dependent)

The minimum order quantity often carries a substantial upfront cost. This will typically be measured in the thousands and is sometimes necessary to keep quality and priority from suppliers.

10. Shipping and import costs

Estimated cost: $5,000+ (depending on order size)

Shipping and importing products also depend on the size and weight of the respective items. Generally, importing cargo is the cheapest way to import goods; however, such imports require careful planning in order to avoid overspending.

Overall, the investment in new product development can be really heavy. It goes by the rule of thumb that pre-manufacturing is above $75,000 for a custom consumer product expert, while production and logistics start at $30,000. However, it may change with the project’s specific needs and characteristics.

Low-cost development strategies

Regardless of the business’s nature and size – small startup or big corporation, low product development costs are vital to maximum profitability. Here are some of them:

Lean product development practices

Lean product development is a product development philosophy used that seeks to remove waste, improve design quality, and speed up the development process. Key principles include:

- Reduction of waste: Streamlining of processes and materials leads to reduced costs and improved efficiency.

- Customer needs identification: Avoiding unnecessary features begins with knowing what the target market needs.

- Superior quality of products: Higher product quality ordinarily leads to higher sales and, consequently, improved customer satisfaction, meaning returns.

- Compress development cycle time-to-market: Going early to market with your product puts cost earnings for its development sooner.

Strong knowledge base end

Record all previous designs and concepts to have them available readily without having to rehash mistakes of the past, thus smoothing the design process.

Invest in your team’s education on lean product development concepts. This will help minimize mistakes and reduce the probability of miscommunication, hence curtailing inefficiencies that might bring extra costs.

Implement concurrent engineering

The sequences of some development phases can overlap with each other, saving time and money. Doing market research together with open innovation services can help make real-time adjustments in light of emerging data.

Tap engineering expertise

Enabling experienced engineers to lead the design process can result in a better-streamlined product. This approach results in quality and lower production costs most of the time.

RELATED: Key differences between prototyping and prototype engineering for companies & firms

Use rapid prototyping

Rapid prototyping enables the creation of many prototypes in a short time, and therefore quite quickly spot defects and improvements.

Choosing the best product developer

You could try to apply lean practices in-house; however, sometimes, the best product development typically deals with too much expertise. The following is how you can find the best product developer:

- Reproducible Quotes: A good developer should quote you costs based on your product’s specific requirements, and there should not be any surprise costs when the project is finished.

- Flexibility: A good developer will always allow you to make changes during the development phase, and updated quotes will reflect all these changes.

- Experience and tools: The developer should have the right set of tools and an experience in the effective implementation of the lean principles.

Why you should work with new product development services

The world of business is shifting at an ever-faster pace. Every single day, the competition in the marketplace advances, as does the capability of improving products. NPD Services are believed to be a necessary good for business improvement. With the help of New Product Development Services, many organizations simplify the process of product development, develop creativity, and therefore present better products to the market much earlier.

- Knowledge and expertise

It is surely through NPD services that collaboration creates opportunities to tap into specialized expertise. Product design, market research, prototyping, and testing are a few stages that NPD companies’ professionals are very aware of. They can thus identify potential pitfalls early in the development process so that companies avoid errors that prove costly later on. That kind of expertise is of great value to the business venturing into new markets or industries where it does not have that knowledge.

- Streamlining development process

NPD services may greatly facilitate the management of the product development process. Building on established methods and best practices helps an organization develop a structured approach to development, including stages such as idea generation, feasibility study, design, testing, and launch. Defined processes limit delays and foster better teamwork among employees with the purpose of reducing time-to-market. This has become the need of the day in this fast-paced world where being the first to market may provide better competitive leverage.

- Cost-effectiveness

The opposite for most firms is that using NPD engineering services is a cost complement rather than a cost burden. In the long term, companies can save enormous sums of money by outsourcing product development to professionals. The overheads of in-house design teams are saved, and also an opportunity to find cost-effective solutions and optimize the resources while remaining within budgets. This efficiency is particularly beneficial to new entrants and smaller firms constrained in resources.

RELATED: How to reduce painful product development costs for your company

- Enhancing creativity

Successful product development essentially boils down to innovation and NPD services are thought to activate a climate of creative thinking. Companies have the liberty to adapt ideas and concepts they may not have seen otherwise by engaging with experts who have exposure to different types of ideas. To come up with novel ideas, NPD teams use various brainstorming techniques and design thinking methodologies and the ability to bring forth products that stand out differently in the market.

- Risk mitigation

A new product carries a load of risk in any case, whether it is acceptance in the market or actual production problems. NPD services usually ascertain the risks taken by ensuring studies on the target markets and also by user testing. These practices validate the ideas with early target audiences, who often provide insights into how the final product can be designed and placed in the marketplace more efficiently. This way, one can minimize the odds of product failure and maximize the likelihood of success when it comes out in the market.

Working with new invention development services is a company’s way toward survival in a competitive environment. Many people and companies feel it necessary to work with experienced people who can advise and guide them through the entire development process. The service actually complements the technique with expert competence to reduce the long period that would have been taken without them; hence, cost benefits arise. Risks are mitigated, and products get to the market much earlier, allowing organizations to bring successful products to life.

As an ever-changing marketplace continues to evolve for businesses, they will have to tap the NPD services’ skills if sustained growth and prosperity are to be achieved. Teamwork with these experts is not only savvy but necessary for those who want innovation and success in the present economy.

Conclusion

The path of translating a concept into a market-ready product has its problems and costs. However, it is successful because there is an understanding of what constitutes product development and that production strategies can be adjusted for low costs.

Investment in quality developmental processes and teamwork with experts will ensure you produce products that meet the market needs and, therefore, yield appropriate returns on investment. This is across multifaceted planning, out-of-cost management, and strict quality focus in the development process.

How Cad Crowd Can Help You

CAD companies should understand the real cost of new product development services. Properly finding the right company that can complete your projects within your budget will help the CAD work succeed. Cad Crowd is an industry leader in providing vetted professionals to CAD companies that you can rely on who will deliver without breaking the bank. Request a quote today.