Today, we share CFD engineering rates, consulting service costs, and company pricing. As the name suggests, CFD (Computational Fluid Dynamics) is a computerized simulation of the flow of fluids in an engineered system. The simulation displays how fluids (liquids and gases) behave in an enclosed system and how they affect the hydrodynamics, aerodynamics, and heat transfer within the boundary conditions (known constraints and differential equations).

A CFD analysis expert offers a service that helps engineers understand the fluid flow and all the related issues that may arise from the interactions between liquids, gases, and solids. CFD predicts the flow and behavior of fluids, mass transfer, heat transfer, chemical reactions, and the rate of change in each phenomenon within a system.

Table of Contents

Table of Contents

RELATED: Product simulation and analysis: why it’s worthwhile

CFD Engineering Rates, Consulting Services Costs & Company Pricing

The Cost

The price of a CFD simulation service is typical $2,000 for a simple 2D analysis and around $20,000 for a time-dependent, complex analysis, such as in the automotive industry. However, a single simulation is usually not enough because the analyst needs to ensure the validity of the result. Follow-up analysis is, therefore, necessary to test alternative boundary conditions and design variants. Although the cost for every follow-up simulation is cheaper than the initial procedure, it is not optional.

Your money covers the computational cost and the hourly rate of the analyst. A typical CAD project requires multi-step work, including CAD 3D modeling design service provider projects, mesh creation, simulation setup, and the analysis of the results. Each must be accurately designed to improve the chances of a reliable interpretation. Depending on its complexity, the entire process takes two to five weeks, while follow-up simulations require a few days.

RELATED: How much do mechanical engineer services typically charge for rates & firms?

The timeframe above assumes that you have prepared a complete set of CAD files (in a format the analyst can use) and clearly defined operating conditions to simulate. The simulation also requires a powerful computer, or a cluster of powerful computers, to meet the timeframe. Computational cost is not the dominant pricing factor, but it can be the case if the project is highly complex and you need to simulate multiple design variations. Some United States companies are willing to do computational fluid dynamic services on a per-project basis at around $1,500 to $4,500 per analysis or $80 to $120 per hour.

5 Types of FDA engineering services

Thanks to CFD analysis, it is possible to figure out the mathematical equations that govern the motion of fluids in an extensive range of complex engineering situations. The equations allow engineers to generate insights into fluid flow and make quantitative predictions. Common types of fluid dynamics analysis are:

- Incompressible: a type of CFD simulation in which the fluid density variations are considered negligible. The assumption is valid when temperature and velocity gradients are minimum, depending on the situation.

- Compressible: a CFD simulation is employed when the fluid density variations affect the system to a noticeable level. Variations in fluid density occur at a flow velocity of 30 percent of the speed of sound.

- Convective Heat Transfer: a CFD analysis used when changes in fluid temperature trigger variations of fluid density and movement due to gravity. The transfer of heat through fluids by molecular motion occurs naturally, but the analysis is also helpful for forced-convection situations.

- Conjugate Heat Transfer: an analysis to simulate heat transfer between (and within) fluids and solids. The simulation displays thermal energy exchange at the materials’ domains. Typical applications for CHT simulation include heat exchangers and electronic enclosures, and this is where an electronic enclosures design professional’s services prove invaluable.

- Multiphase: a CFD analysis to determine time-dependent behaviors of a mixture containing two different materials, such as water and air.

RELATED: How freelance mechanical engineers use 3D modeling for design

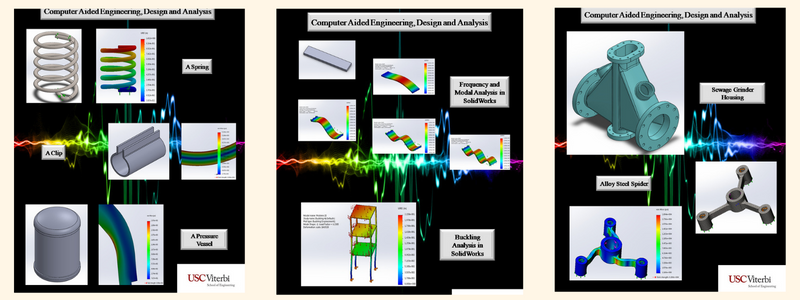

Other CFD analysis types can simulate the behaviors of liquids, wind, and solid bodies. For example, the Pedestrian Wind Comfort analysis simulates wind directions and safety for pedestrians; Heat Transfer simulates temperature distribution in a solid body; Frequency Analysis generates insights into the deformation behavior of free parts and assemblies.

Typical Applications for CFD engineering

CFD simulation has various applications in various industries, from aviation to battery, from HVAC to rotating machinery. Common applications include:

HVAC. The physics of fluid dynamics plays a crucial role in how HVAC operates. An HVAC system must maintain and condition the air in any given space efficiently while keeping a comfortable airflow. An insight into air behaviors under different pressures and temperatures helps engineers design a system that will run efficiently for decades with low maintenance. CFD simulation predicts the potential performance of a specific technique, leading to constant improvement in the design of components such as diffusers, coils, and thermal units.

RELATED: What are MEP design costs, drafting fees & engineering service rates for companies?

Aerodynamics. Finite element analysis experts provide essential stress testing analysis to ensure the product is working at its total capacity. The most well-known application of CFD is in the world of automobiles or aviation, especially in aerodynamics. The flow of air around the body of a car and airplane (or any other device designed to travel at high speed) affects how fast the vehicle can go. CFD simulation tells engineers how to build an aerodynamic design, which forces air to behave and flow to the vehicle’s benefit. Instead of generating drag and friction, the air can aid traction and braking without getting in the way of optimum performance.

Battery Usage. Although a battery doesn’t seem to depend on airflow and fluid dynamics properties to operate, this seemingly simple power generator for devices like radios and flashlights depends on effective heat distribution to maintain proper functioning and ensure safety. Ambient temperature (among other factors) affects battery life and performance. CFD airflow simulation helps battery manufacturers maximize air circulation around the battery to increase efficiency.

RELATED: How industrial designers and engineering services have influenced the product design world

Rotating machinery. Some examples of rotating machinery are steam pumps, compressors, and gas turbines. All work in different mechanisms, but they have one thing in common: the structure must be able to withstand intensive cycling load actions. Each machine relies on labyrinth seals to prevent the escape of lubrication liquid (oil). With each rotation, the gas passing through the seal can generate a strong enough force to trigger unstable vibration. CFD simulation provides insight into how a design (of parts or assemblies) can minimize the adverse effects of air.

When looking for a CFD analyst to do a simulation project, remember that CFD is an interdisciplinary practice using the principles of applied mathematics, physics, and computer science. The simulation results provide a hypothesis based on predetermined conditions.

How Cad Crowd can assist

Cad Crowd connects you with pre-qualified, vetted, talented engineers who can work with molded and formed plastics, machined components, sheet metal, castings, and weldments. Hire a skilled freelance engineer to help you design your product. Take advantage of digital prototyping tools to analyze how that product will respond to vibrations, heat, fluid flows, fatigue, and other real-world stresses. Cad Crowd stands apart from conventional engineering companies by offering a complete range of design, freelance 3D modeling, drafting, and engineering CAD services. Contact us for a free quote today.